Partition type waterproof structure of subsurface structure baseplate and construction method

A technology of waterproof structure and underground structure, which is applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve the problems of increasing the difficulty of leakage maintenance, construction difficulty, leakage, etc., and save labor and materials. Cost input, significant economic and social benefits, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

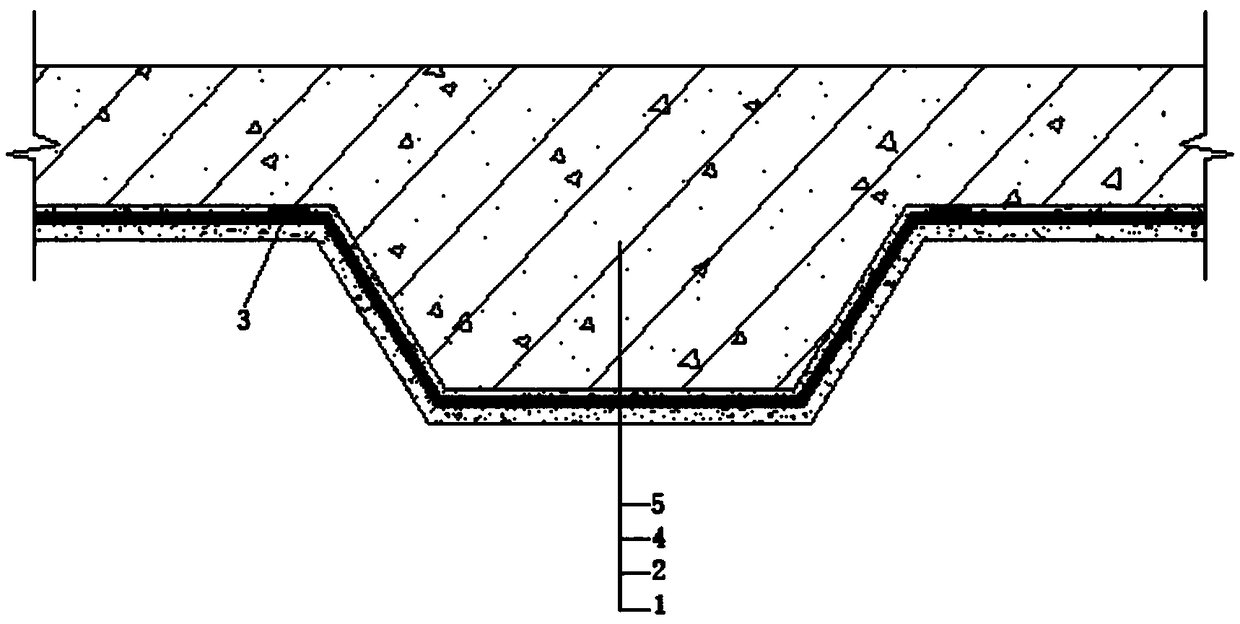

[0020] A sub-compartment type waterproof structure for underground structure floor, including concrete cushion layer 1, modified asphalt waterproof membrane layer 2, non-cured rubber asphalt sub-compartment grid layer 3, waterproof mortar protection layer 4 and concrete structure bottom plate from bottom to top Layer 5.

[0021] The modified asphalt waterproof membrane layer is laid on the concrete cushion by the point-bonding method or the strip-bonding method. The membrane should be spread as flat as possible, and the thickness of the modified asphalt membrane is 4mm.

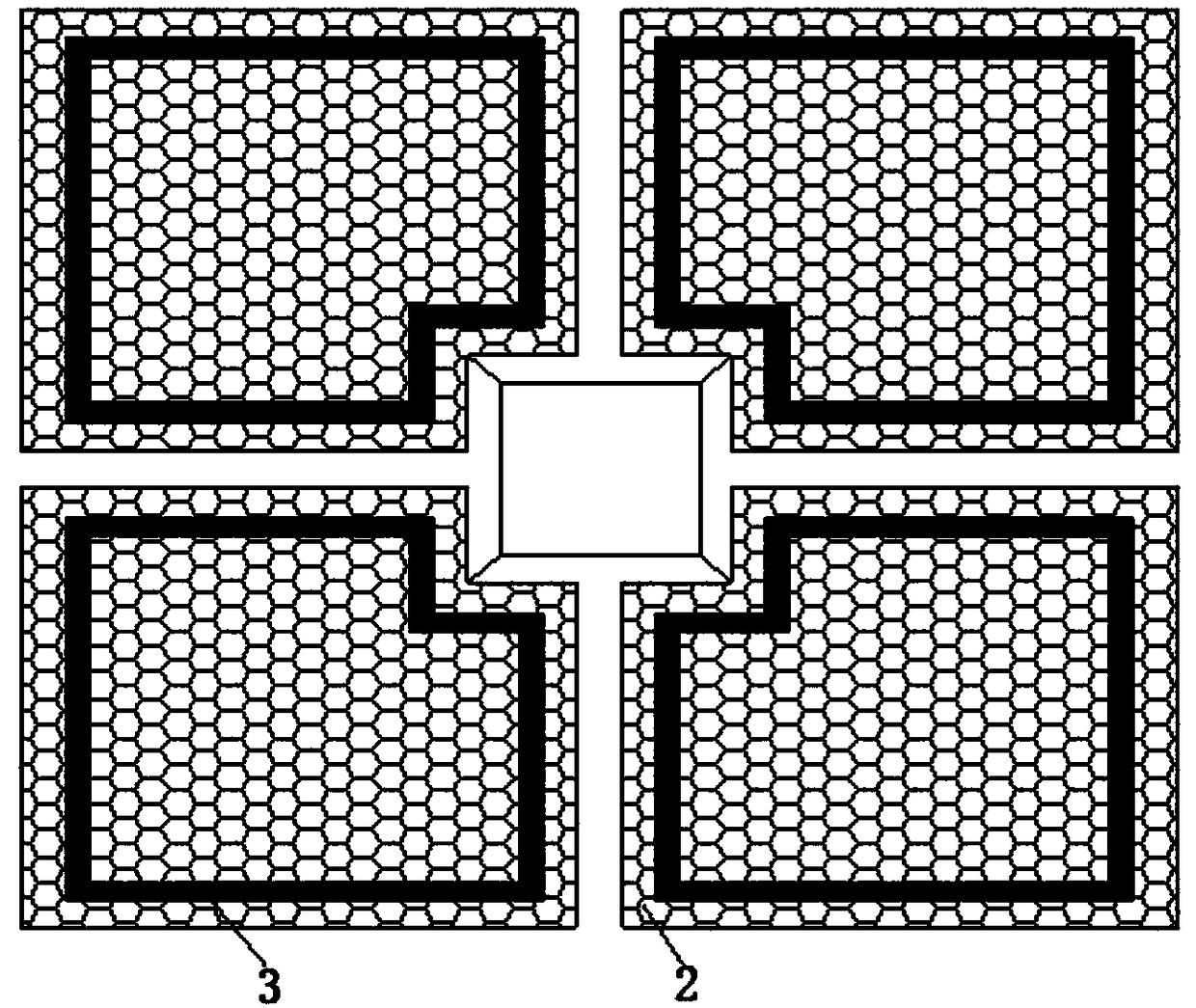

[0022] The grid layer of non-cured rubber asphalt sub-warehouses should be arranged on the waterproof membrane layer according to the requirements. The layout of the grids should be reasonably arranged according to the shape and size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com