Automatic welding machine device and welding method of 360-degree pipeline

An automatic welding machine and driving device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of laborious installation, heavy iron crawler, insufficient magnetic force, etc., and achieve the effect of simple track installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

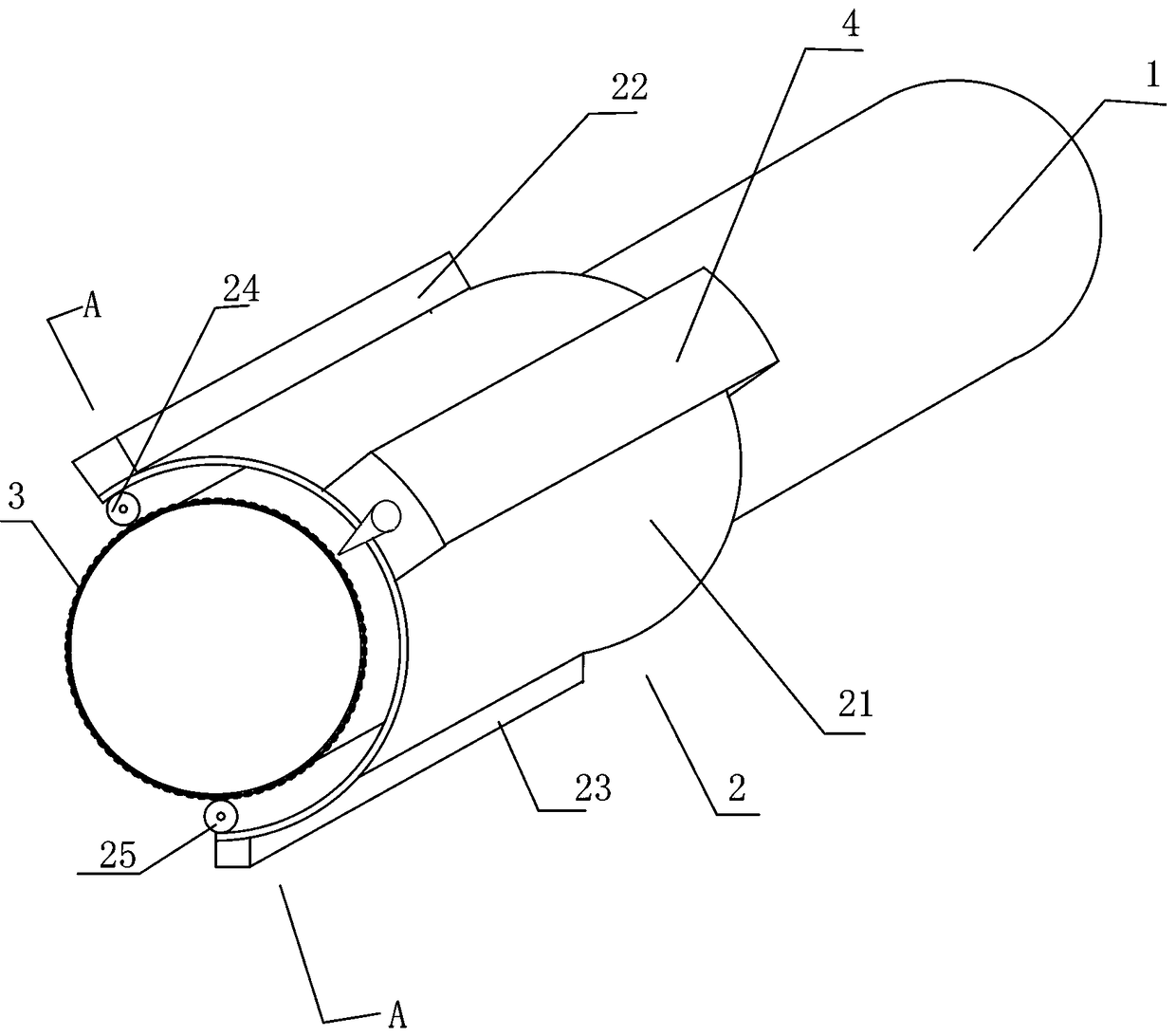

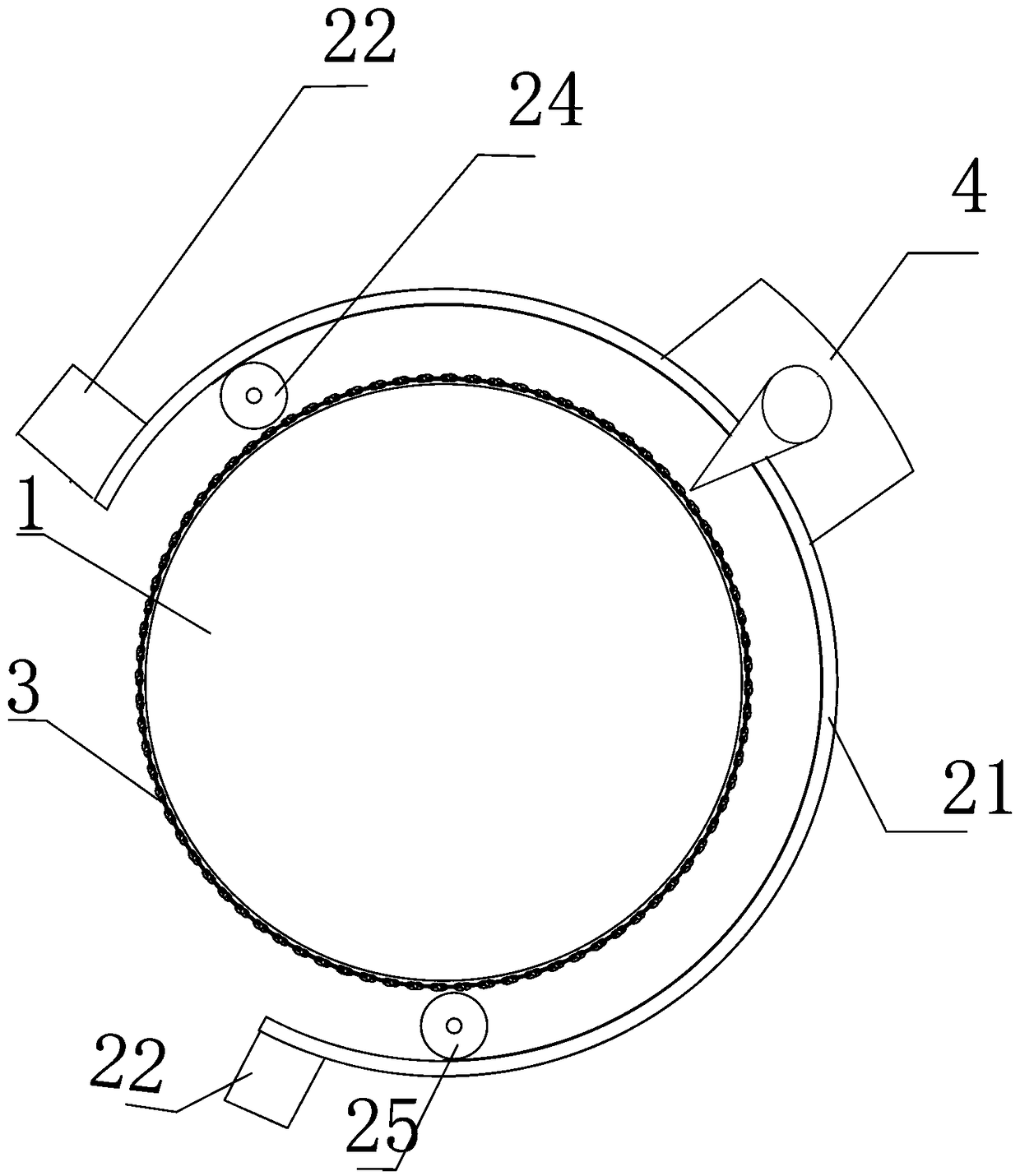

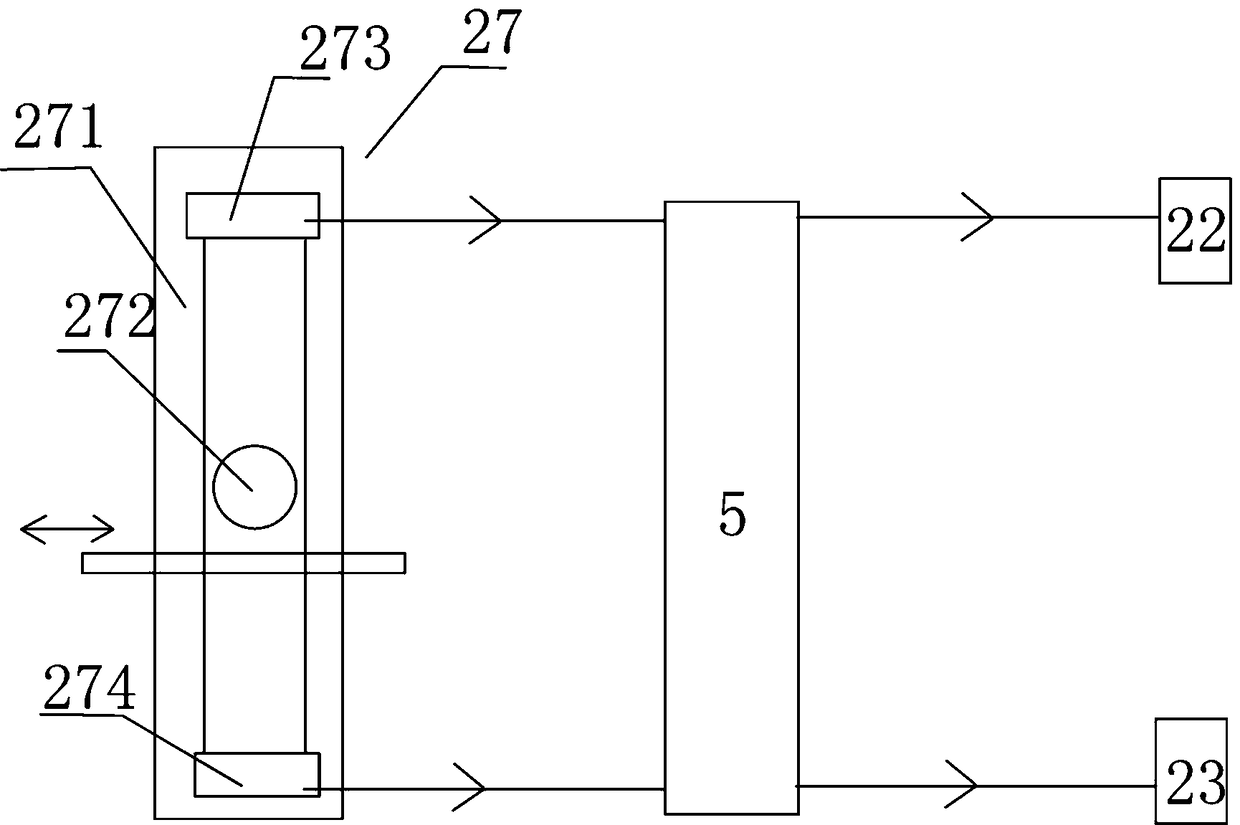

[0023] like figure 1 , 2 Among them, the 360-degree pipeline automatic welding machine device includes two parallel chains 3 fixed on the pipeline 1 (the two parallel chains 3 form a track) and a movable frame 2 that can move along the three chains. 2 is provided with a welding head 4, the welding head 4 is connected with the welding machine through a connecting line or a connecting pipe, the welding machine can be placed on the movable frame 2, and can also be arranged at other positions. When in use, the welding head of the welding head 4 and the pipeline 1. The positions that need to be welded in the form of rings or partial arcs are in contact with each other;

[0024] The movable frame 2 includes an arc-shaped frame 21 (the arc-shaped line type of the arc-shaped frame 21 is the same as that of the pipeline 1, and different arc-shaped frames 21 need to be selected for different diameters of the pipeline 1 to ensure the quality of welding. The device is aimed at steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com