Reel facilitating line clamping for textile machine

A textile machinery and reel technology, applied in the field of textile machinery reels, can solve the problems that the strips are not easy to wind, pull, and double-layer rolls with small reels, so as to improve the adhesiveness, increase the reliability and avoid the speeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

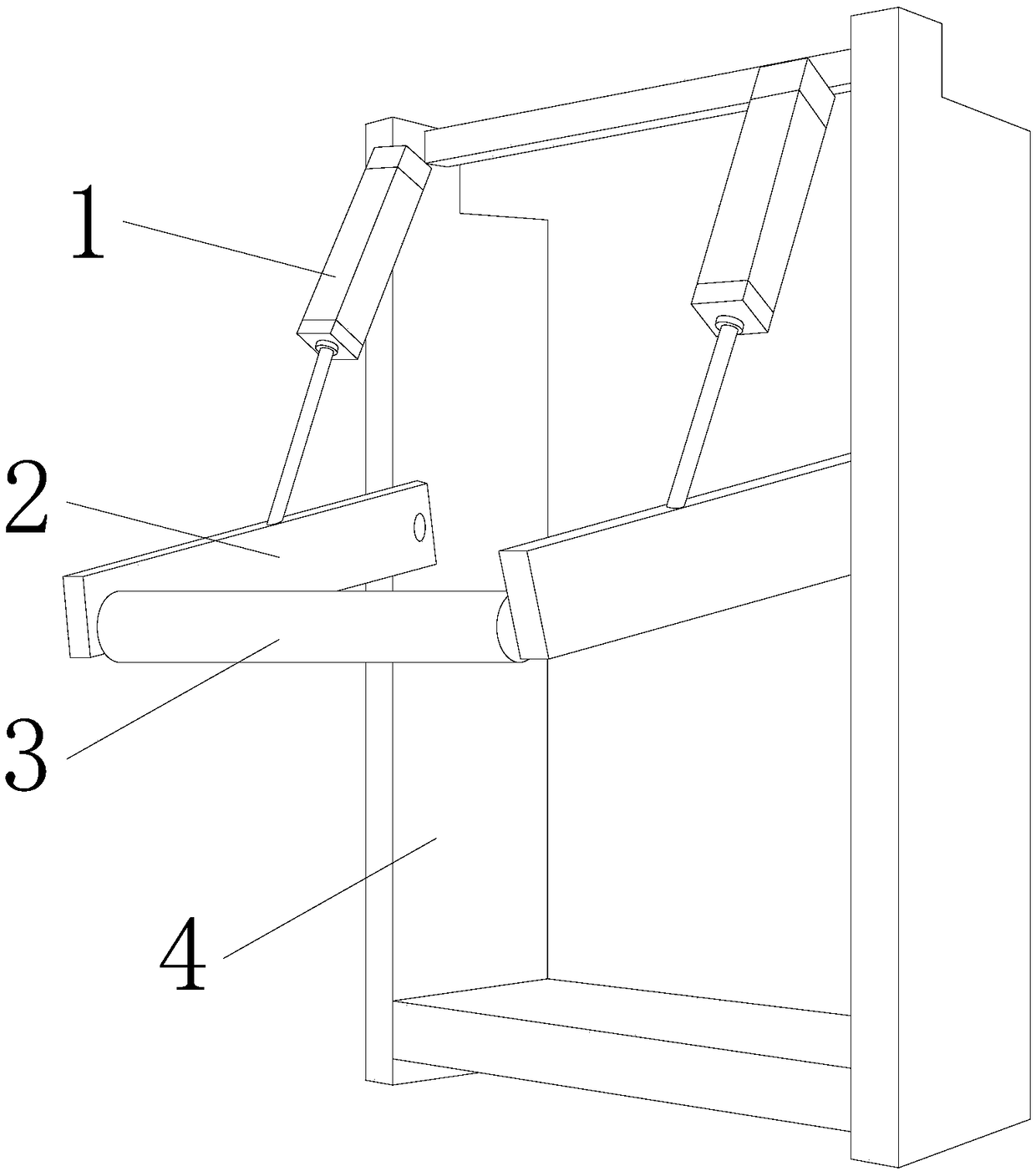

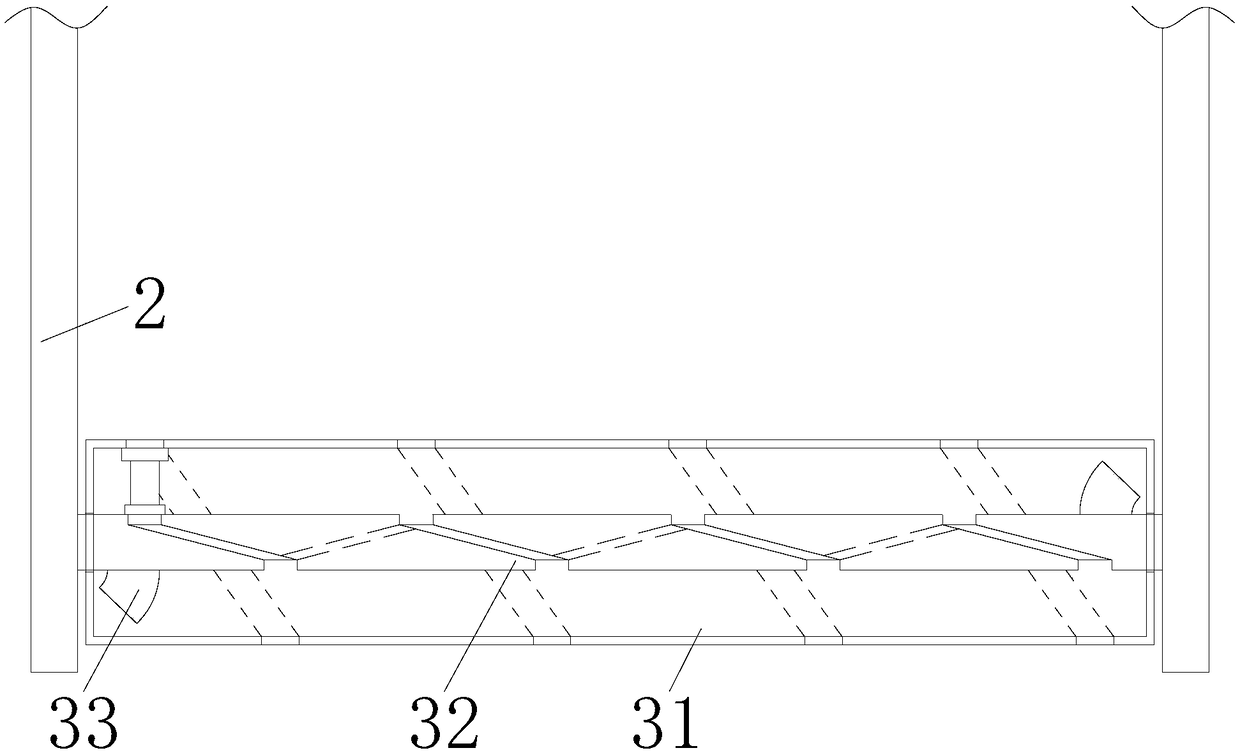

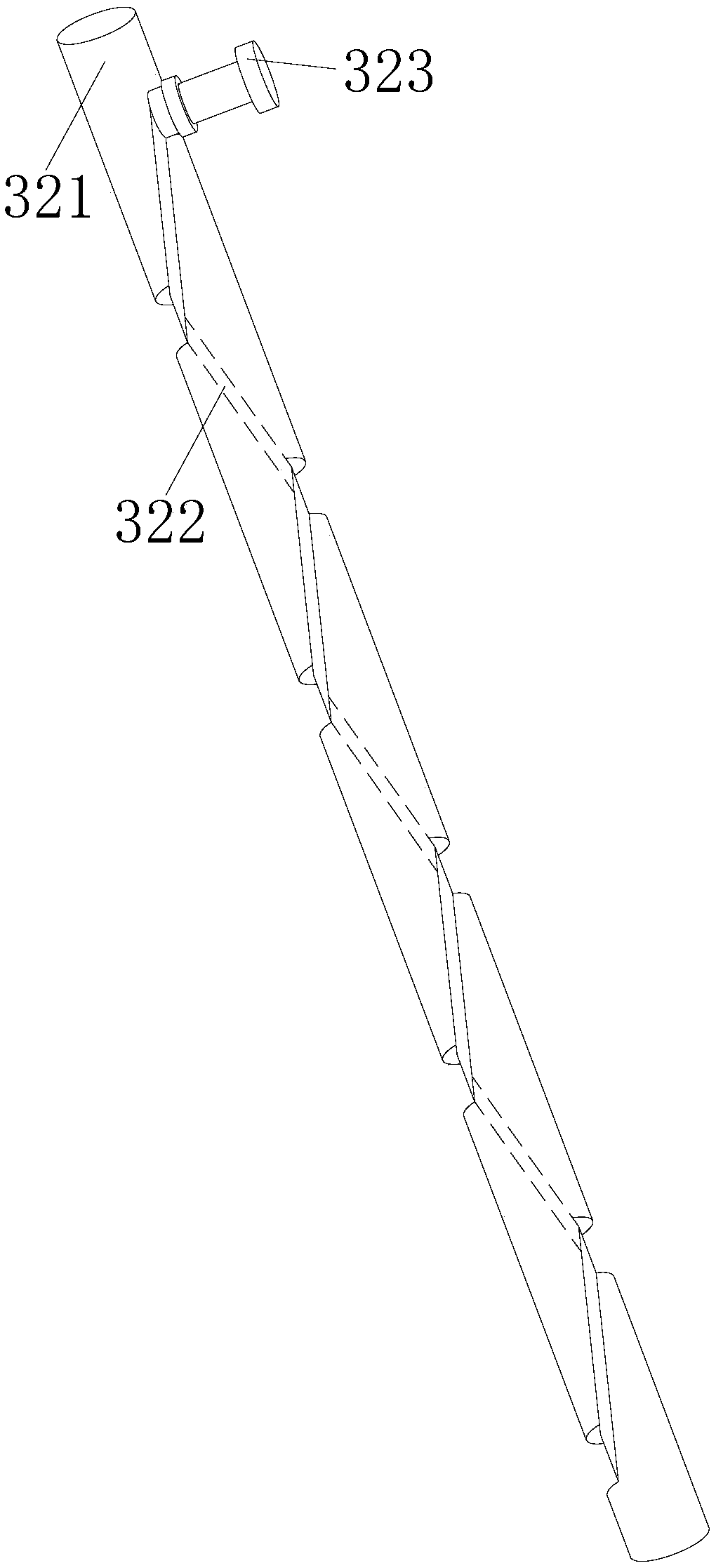

[0022] see Figure 1-Figure 9 , the present invention is a reel for textile machinery that is convenient for thread clamping. Its structure includes a hydraulic adjustment rod 1, a fixing plate 2 at both ends of the reel, an anti-double-layer reel 3, and a textile fixing frame 4. The hydraulic adjustment rod 1 The lower end is fixedly installed on the fixing plates 2 at both ends of the reel. The end is fixedly installed on the middle end of the textile fixing frame 4, and the top end of the hydraulic adjustment rod 1 is fixedly installed on the upper end of the textile fixing frame 4. The expansion structure 33, the transverse ring cutting structure 32 penetrates the inside of the reel shell 31 and is mechanically connected, the two ends of the transverse ring cutting structure 32 are installed on the fixing plates 2 at both ends of the drum, and the wear traction expansion structure There are two 33 and they are fixedly installed at the left and right ends of the transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com