High-speed motor rotor

A high-speed motor and motor shaft technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., to ensure normal operation and prevent copper bars from being thrown out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

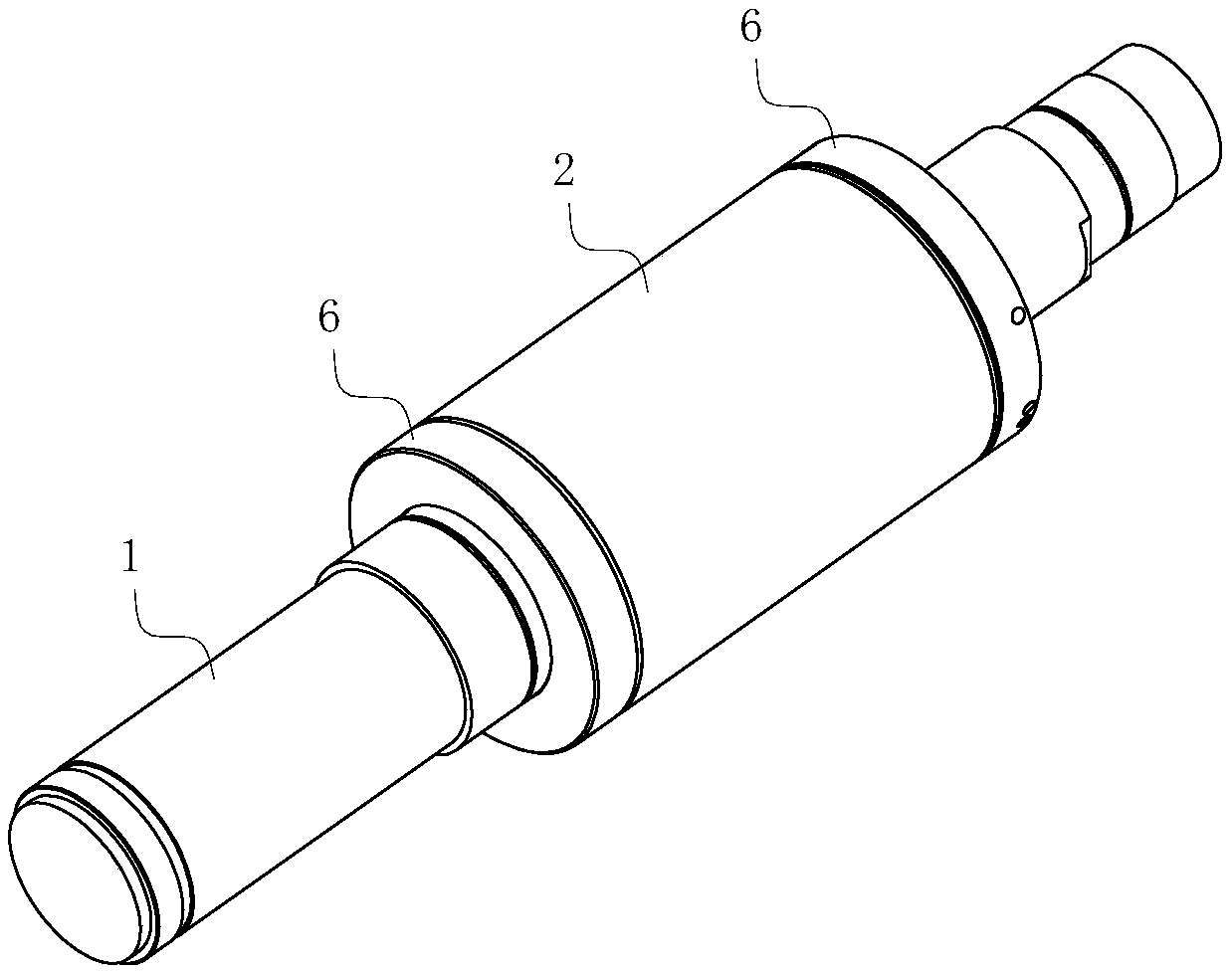

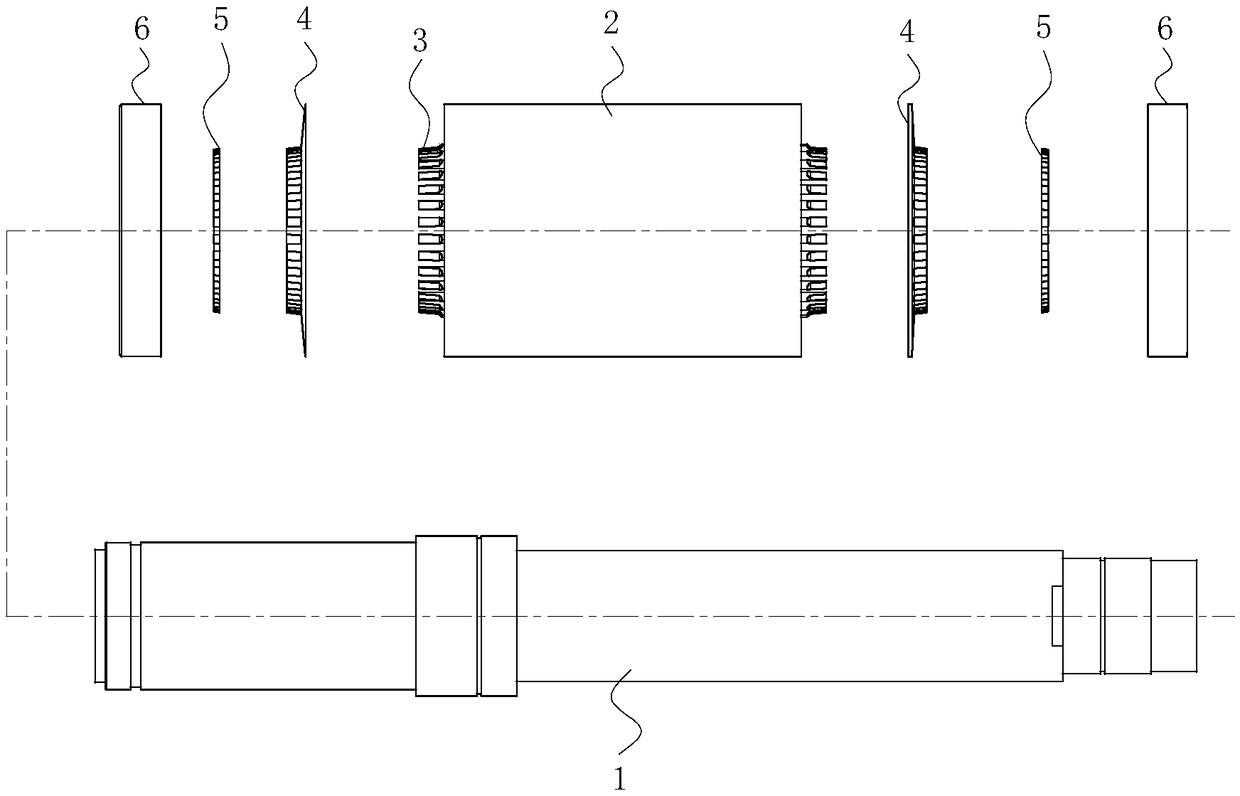

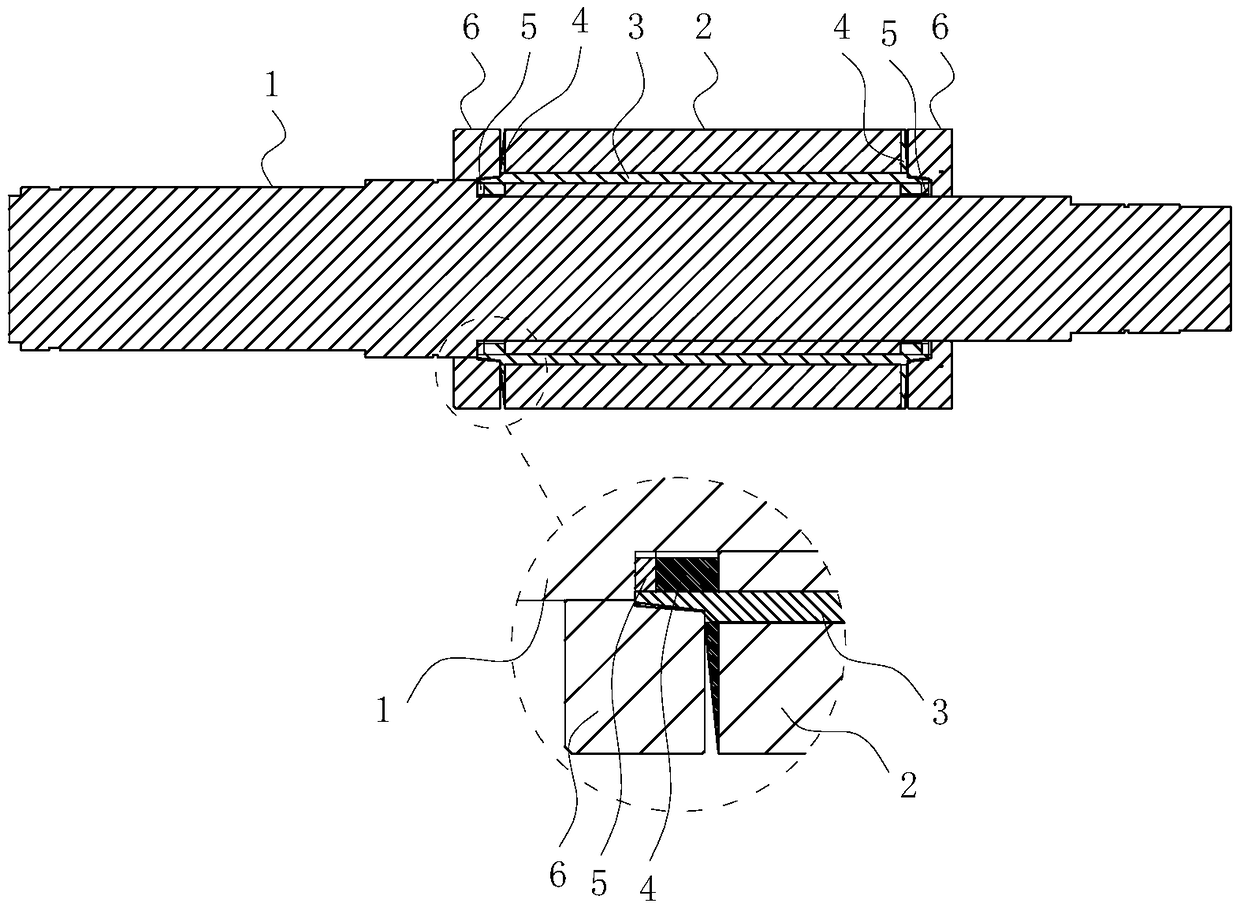

[0036] see Figure 1 to Figure 10 , a high-speed motor rotor according to Embodiment 1 of the present invention, including a motor shaft 1 and a copper bar rotor assembly sleeved on the motor shaft 1, the copper bar rotor assembly includes an iron core 2 and a plurality of shafts arranged in the iron core 2 The two ends of the copper bar 3 are exposed to the iron core 2, and a pair of guard rings 6 are sleeved and fixed on the motor shaft 1, and the guard rings 6 are located outside the two axial ends of the copper bar rotor assembly. , the guard ring 6 is in contact with the copper bar rotor assembly.

[0037] see figure 1 with figure 2 A high-speed motor rotor according to Embodiment 1 of the present invention includes a motor shaft 1 , an iron core 2 , a copper bar 3 , an end ring 4 , a pressure ring 5 and a guard ring 6 . The copper bar rotor assembly includes an iron core 2 , a copper bar 3 , an end ring 4 and a pressure ring 5 .

[0038] see Figure 3 to Figure 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com