A water-cooled condenser and washing and drying machine

A condenser and water-cooled technology, which is applied in the field of water-cooled condensers and integrated washing and drying machines, can solve the problems of blocked circulating air, machine failure, and increased wind resistance, so as to reduce wind resistance, improve drying effect, and wash area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved more clearly, the technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

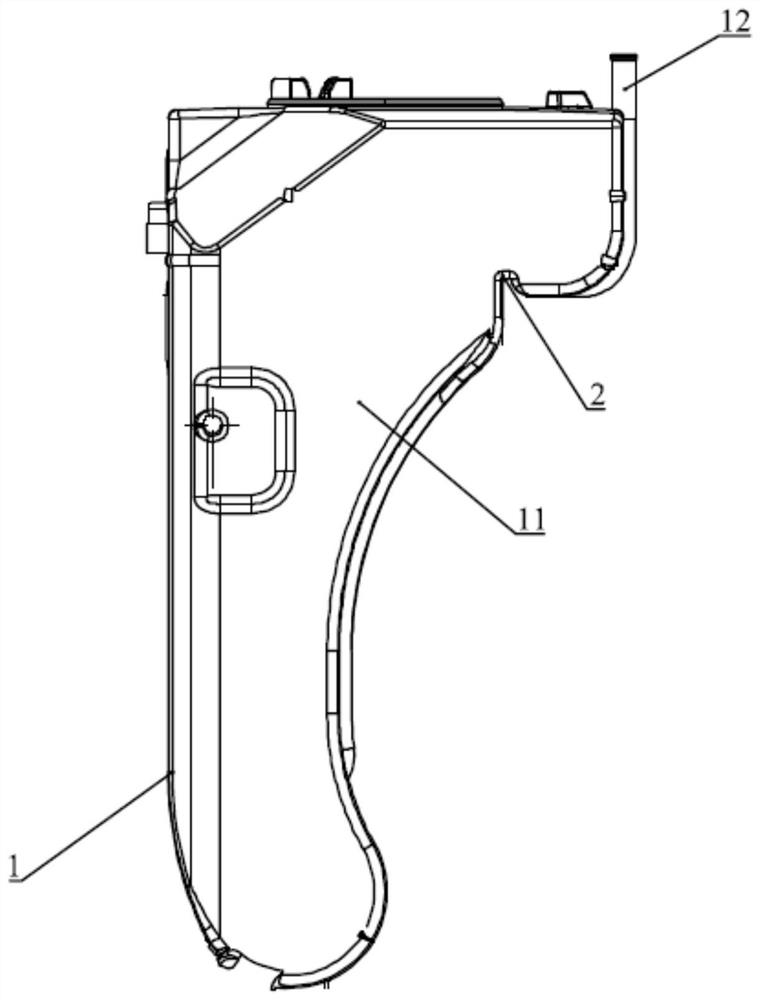

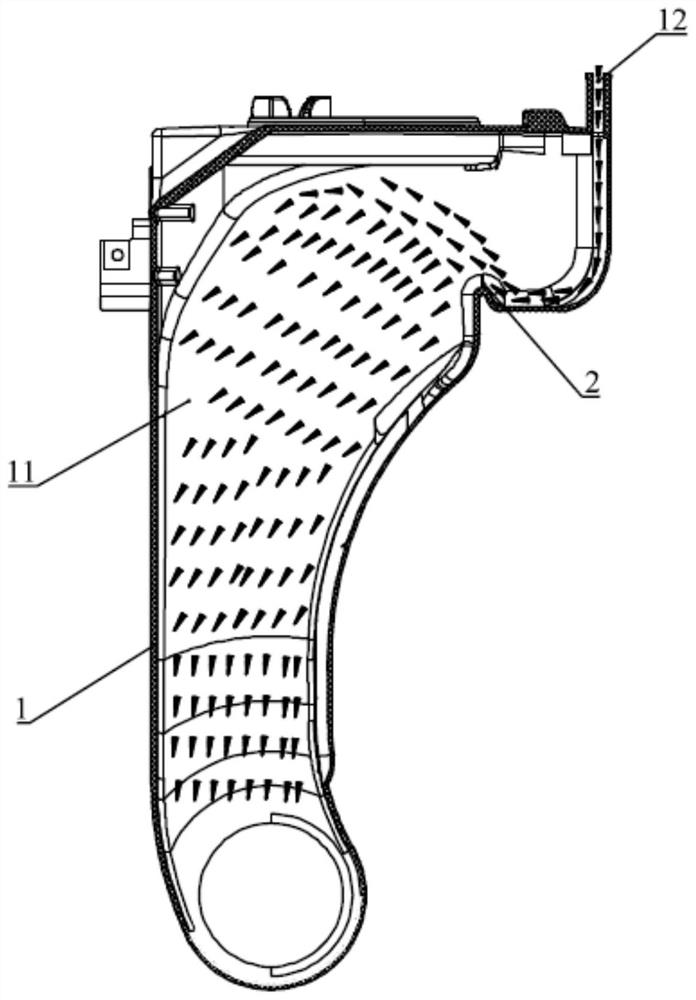

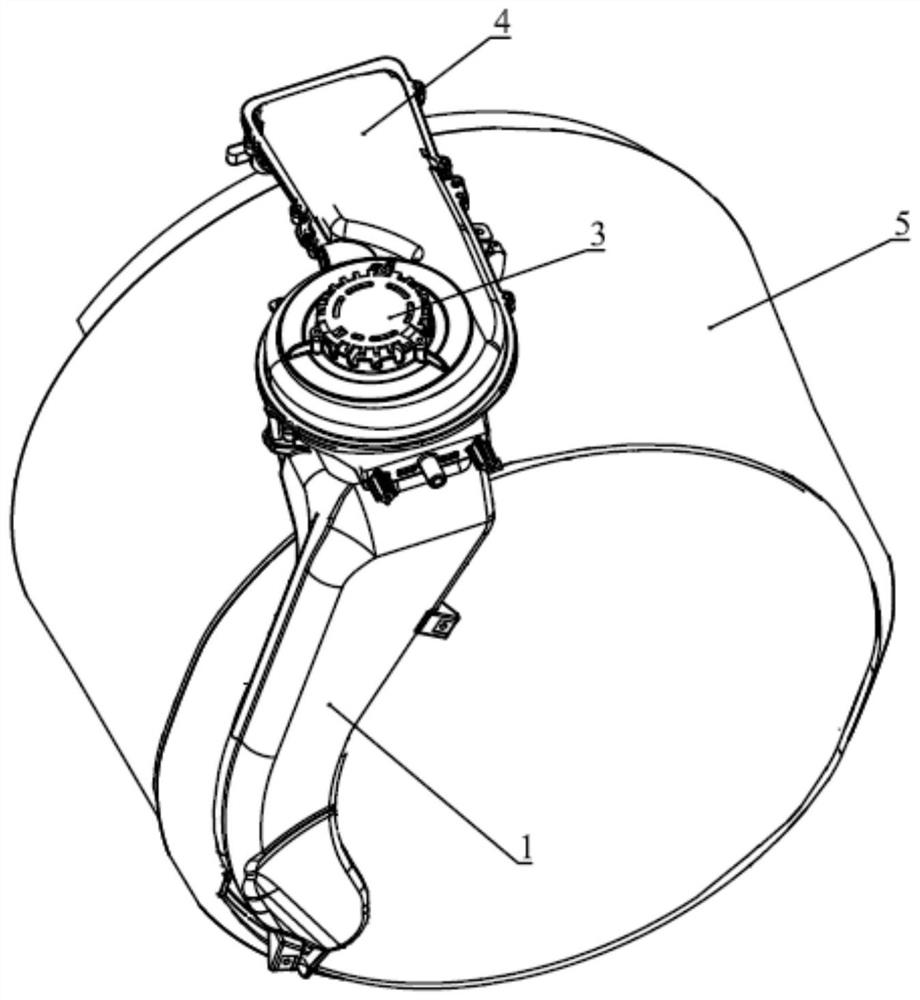

[0032] like figure 1 and figure 2 As shown, this embodiment provides a water-cooled condenser, which can be applied to an integrated washing and drying machine for condensing hot and humid air to achieve the effect of drying.

[0033] The water-cooled condenser includes a condenser body 1 . The interior of the condenser body 1 is hollow to form a cavity 11 . After the humid and hot air enters the chamber 11 from the humid and hot air inlet, it exchanges heat with the condensed water entering the chamber 11 through the condensed water inlet. The air becomes dry air and is discharged from the dry air outlet, which is replaced by the heat exchange process.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com