Low-speed permanent-magnet motor rotor

A technology for permanent magnet motors and rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of complete machine scrapping, motor jamming, and affecting the performance of motor rotors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

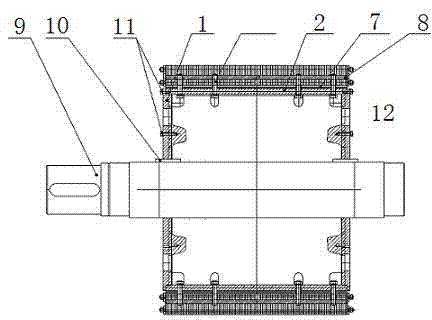

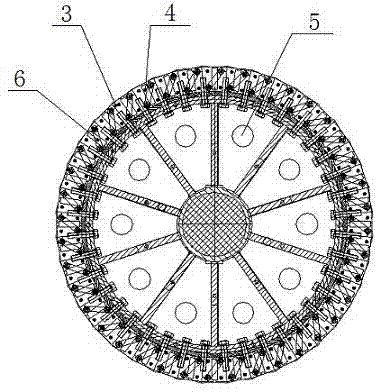

[0013] Such as figure 1 with figure 2 As shown, the low-speed permanent magnet motor rotor includes an end plate 1, a rotor inner sleeve 2, a magnetic pole 3, a permanent magnet block 4, and a ventilation hole 5. The magnetic pole 3 is connected to the rotor inner sleeve 2 by a tightening bolt 12, and the two magnetic poles 3 are opposite to each other. The frame is inlaid with permanent magnet blocks 4, the ventilation holes 5 are arranged on the rotor end plate 1, each magnetic pole 3 is connected by a magnetic pole pad 6, and the lower end of the magnetic pole 3 is provided with a magnetic isolation pad 7, and each magnetic pole 3 contains multiple permanent magnet blocks In series combination, the magnetic pole 3 is provided with a square key 8, the rotor is fixed on the motor shaft 9, an anti-twist key 10 is provided between the rotor and the motor shaft 9, and a fixing bolt 11 is provided on the rotor end plate 1. The low-speed permanent magnet of the present invention T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com