High-efficiency paper box edge folding and defoaming machine

A carton, high-efficiency technology, applied in the direction of papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of cardboard rebound, affecting the process, and low efficiency of manual defoaming, so as to prevent cardboard rebound and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

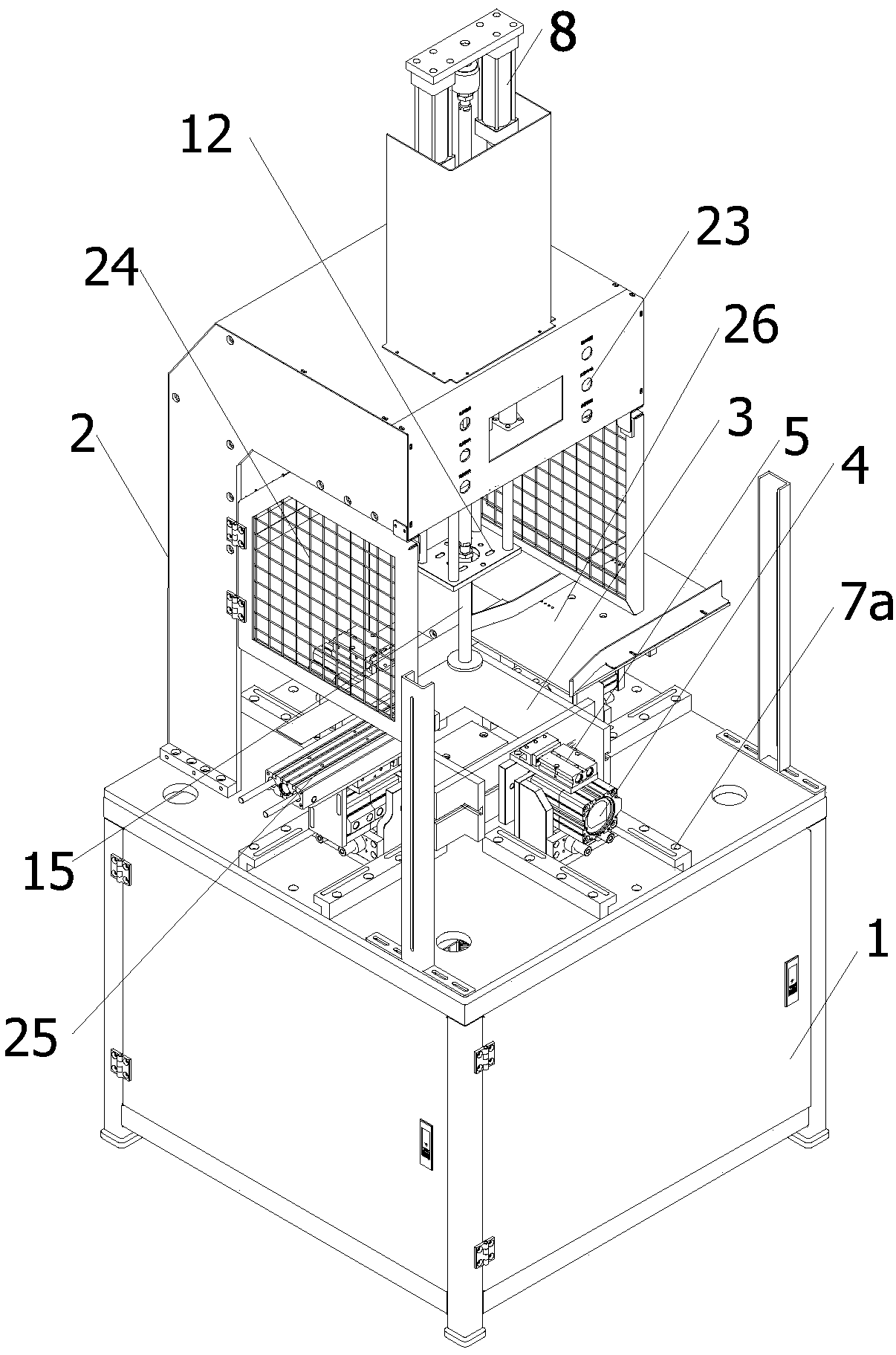

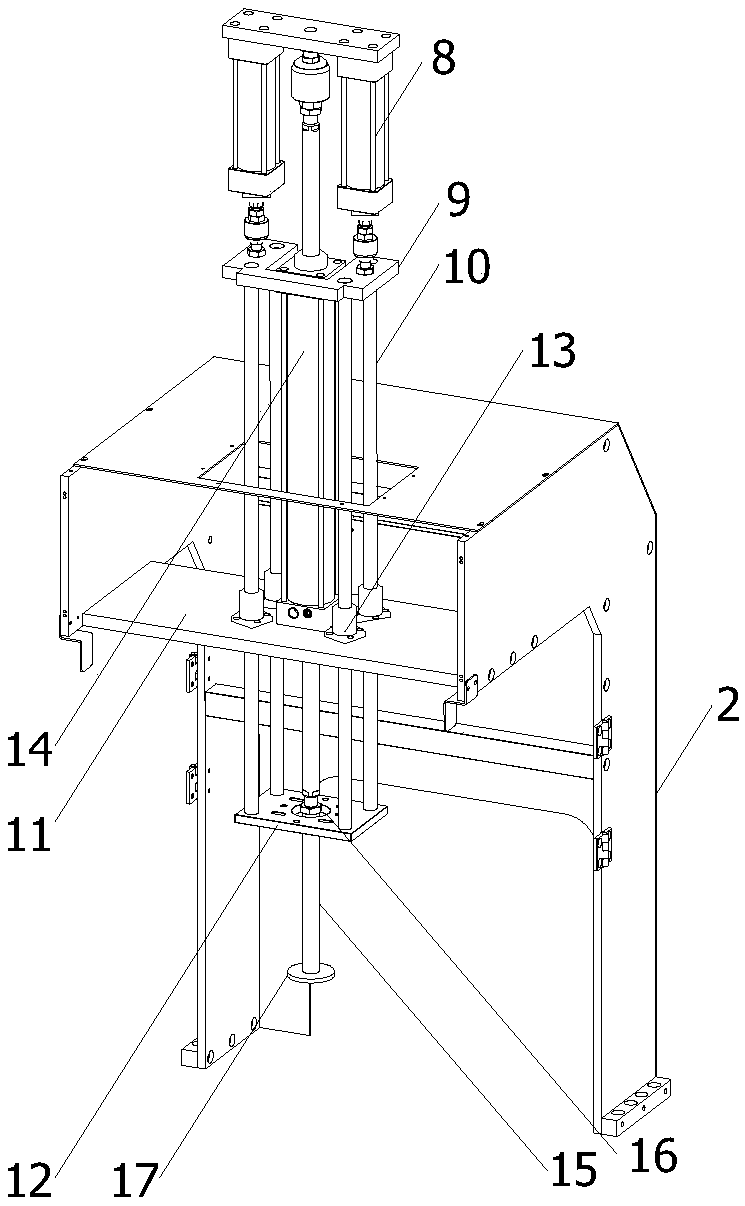

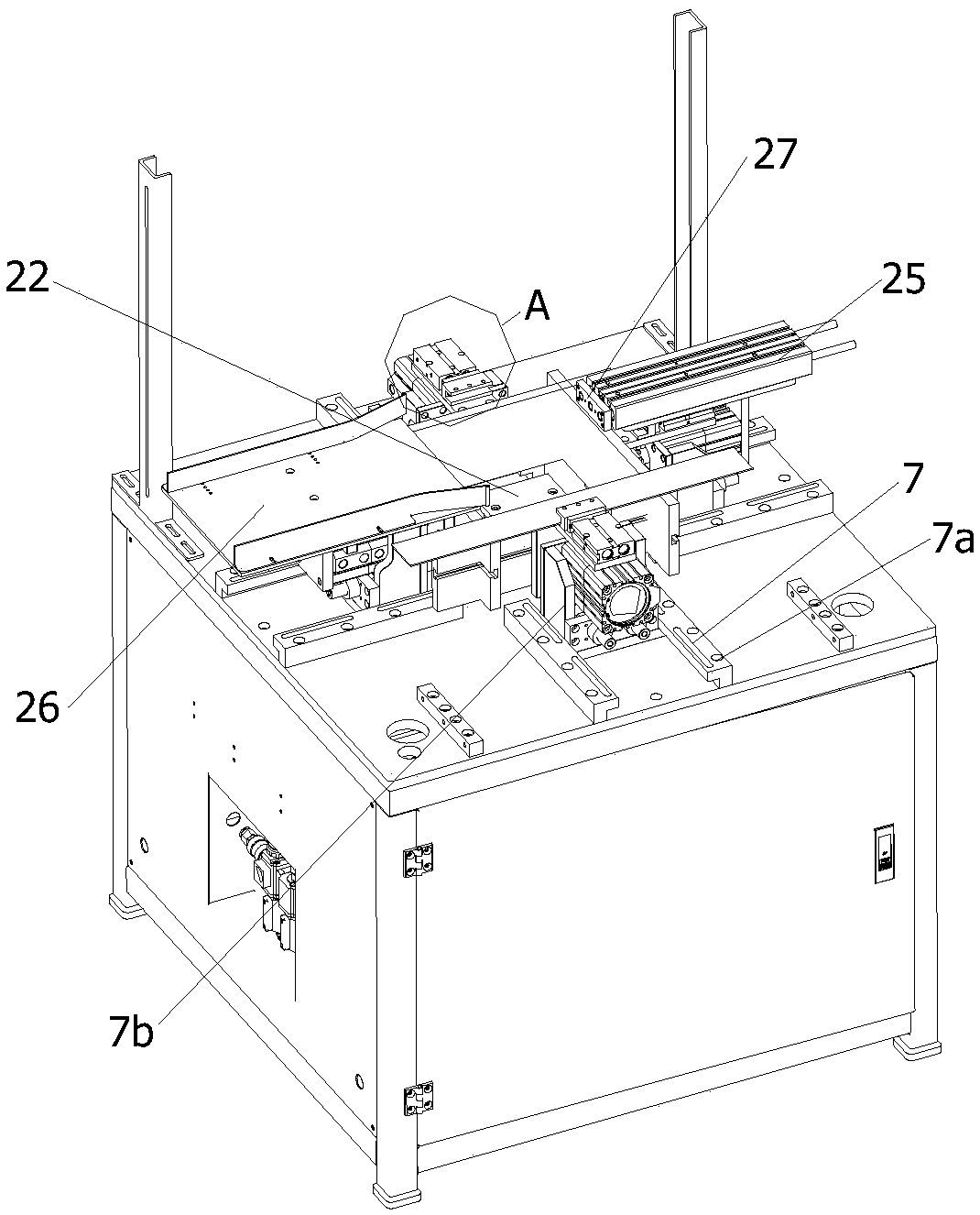

[0024] Example: Combine Figure 1 to Figure 6 The shown high-efficiency carton folding and defoaming machine includes a machine platform 1 and a bracket 2 installed on the top of the machine platform 1, and the top of the machine platform 1 is also horizontally installed with a height lower than the height of the bracket 2. Push the flanging mechanism, and a stamping defoaming mechanism and a pressing mechanism are vertically installed on the support 2 .

[0025] The push hemming mechanism includes a sizing frame 3 detachably mounted on the top of the machine 1 and a push driver connected to the side of the sizing frame 3. In this embodiment, the push driver is a push motor 4, and the sizing frame 3 includes a first side, a second side, a third side and a fourth side that are arranged horizontally and connected in sequence, and there are two push motors 4, which are respectively horizontally connected to the first side and the third side for relative movement, The top of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com