Cigarette packet six-face detection device

A technology for surface inspection and cigarette packs, applied in the field of cigarette packaging production quality inspection, can solve the problems of large friction force of transparent glass plates, affecting imaging inspection accuracy, and reducing transparency of transparent plates, etc., and achieves high inspection success rate, cost saving and maintenance. Maintenance simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

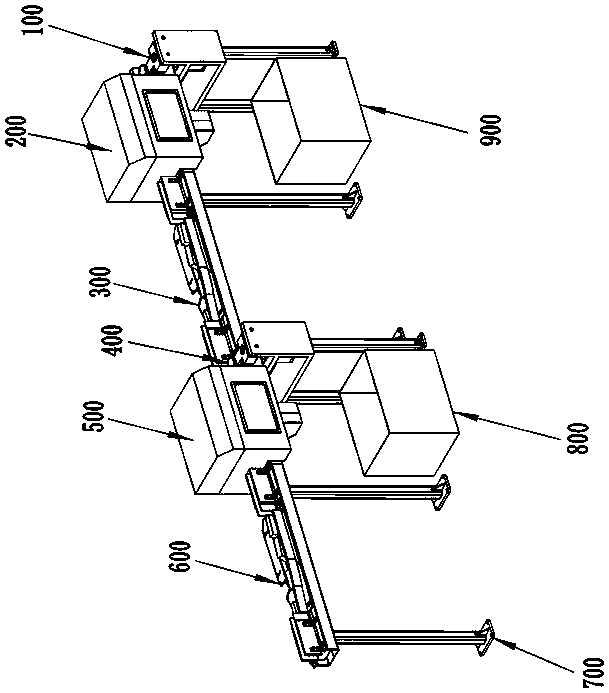

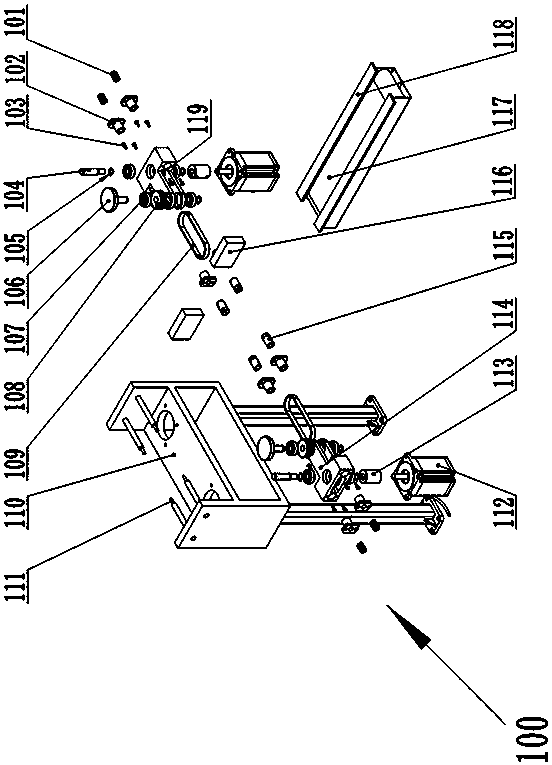

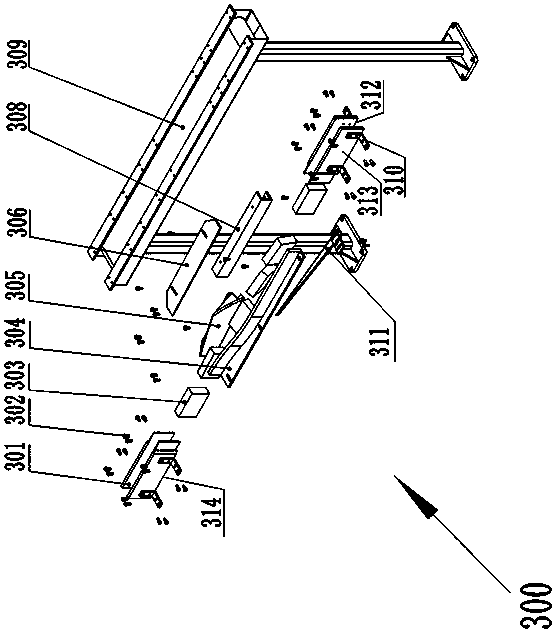

[0023] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached Figure 1 ~ Figure 3 The present invention will be further described in detail with specific embodiments.

[0024] The six-sided inspection device for cigarette packs adopted in this embodiment includes a packer 100, an imaging detection system 200, a turner 300, a packer 400, an imaging detection system 500, and a turner 600 arranged sequentially on a conveyor frame. The above-mentioned structure is a combination alternately arranged on the conveyor frame 700 to realize the detection of cigarette packs.

[0025] The packer 100 is used to divide the continuous packs of cigarettes into single packs one by one and enter the first imaging detection system;

[0026] The imaging detection system 200 is used to detect the three sides of the cigarette package;

[0027] The flipper 300 is used to flip the cigarette pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com