Cable conductor stranding and drawing forming device capable of adjusting number of input bundles based on press fitting achieved by rollers

A cable conductor and forming device technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable supply device, used to reduce the size of conductor/cable, etc., which can solve the problem of cable breakage, increase the difficulty of equipment maintenance, and the inability to inspect the cable and other problems to achieve the effect of preventing cable entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

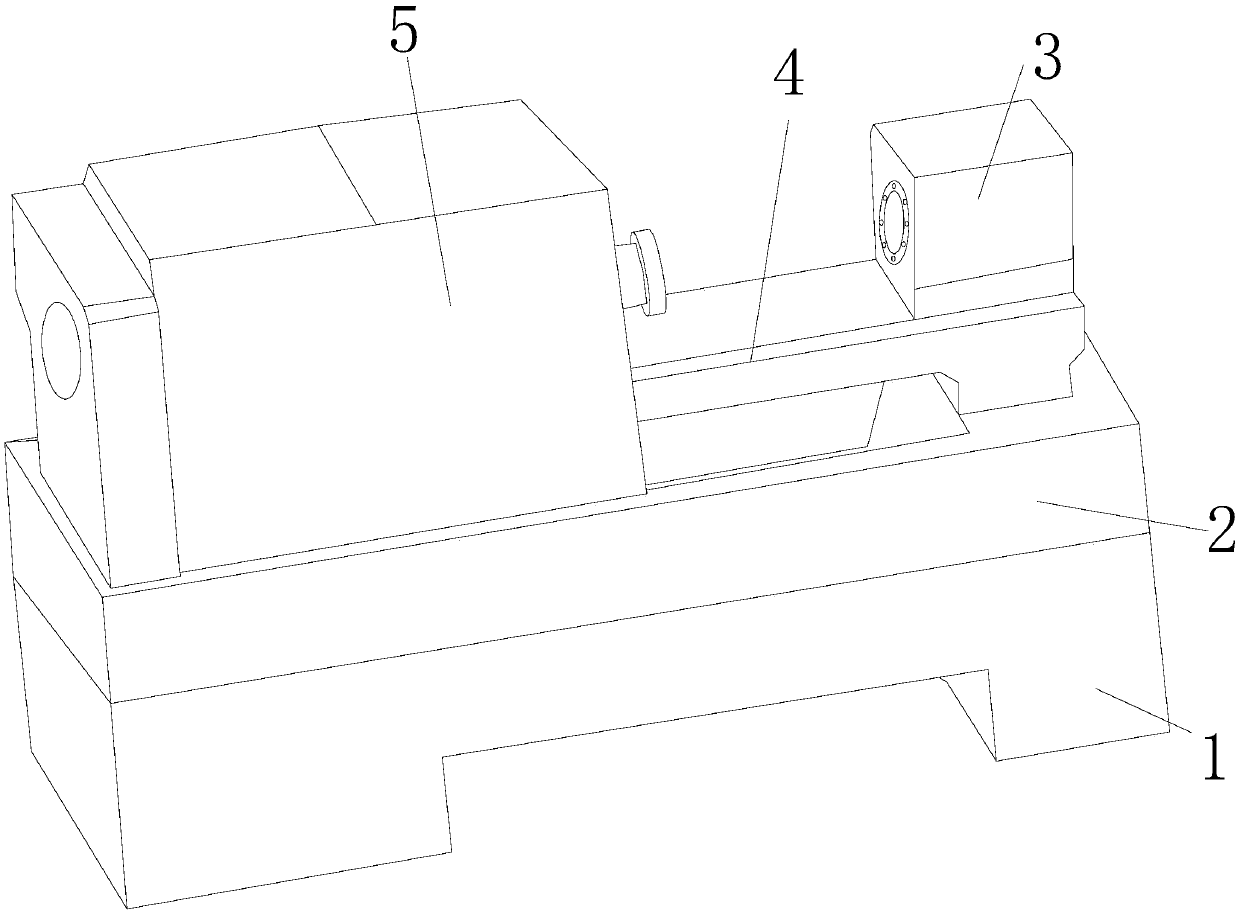

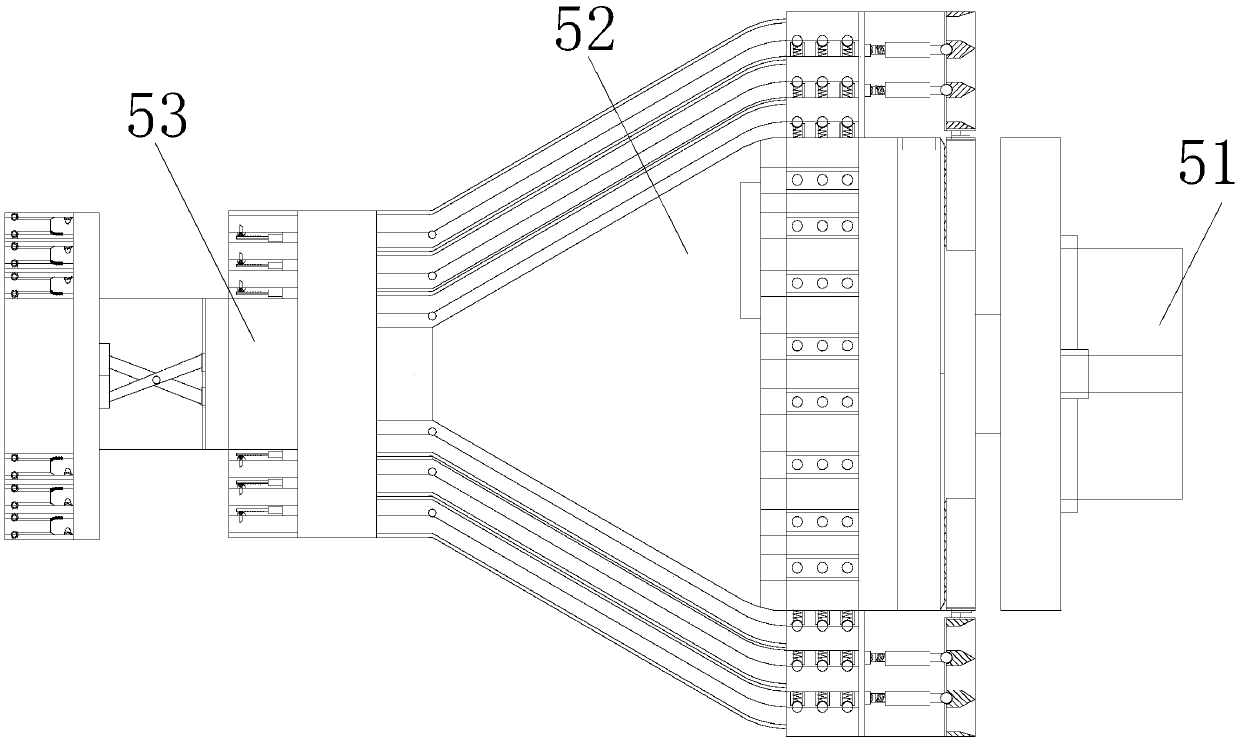

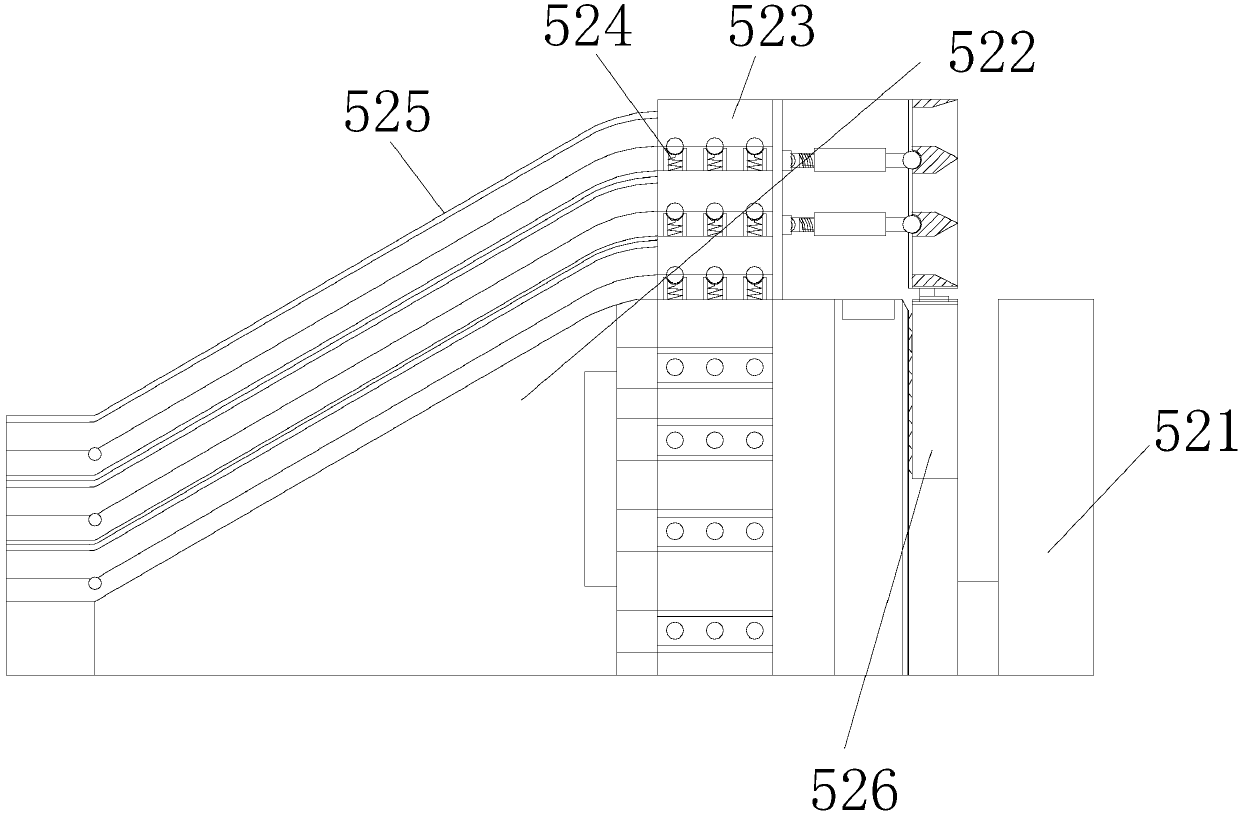

[0029] see figure 1 , the present invention provides a cable conductor stranding and drawing forming device that can adjust the number of input bundles by roller pressing, and its structure includes: a base 1, a worktable 2, a movable frame 3, a displacement table 4, and an intelligent output device 5. The platform 2 is arranged on the upper end surface of the base 1 and is connected to the base 1 by welding. The displacement platform 4 is located on the upper end surface of the workbench 2 and is joined together with the working platform 2 by means of bolts. The intelligent output device 5 is arranged on the left end face of the displacement platform 4 and is clamped together with the displacement platform 4 by a clearance fit, and the movable frame 3 and the intelligent output device 5 are parallel to each other and are slidingly connected with the displacement platform 4 in surface contact. , the inside of the movable frame 3 is provided with a power motor, which provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com