An intelligent monitoring device for leakage of oil conservator

An intelligent monitoring and oil conservator technology, applied in circuits, electrical components, transformer/inductor cooling, etc., can solve problems such as reducing the insulation performance of transformer oil, handling measures for unfavorable judgments, and contact between transformer oil and air. The effect of low maintenance cost, simple structure, and reduced burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

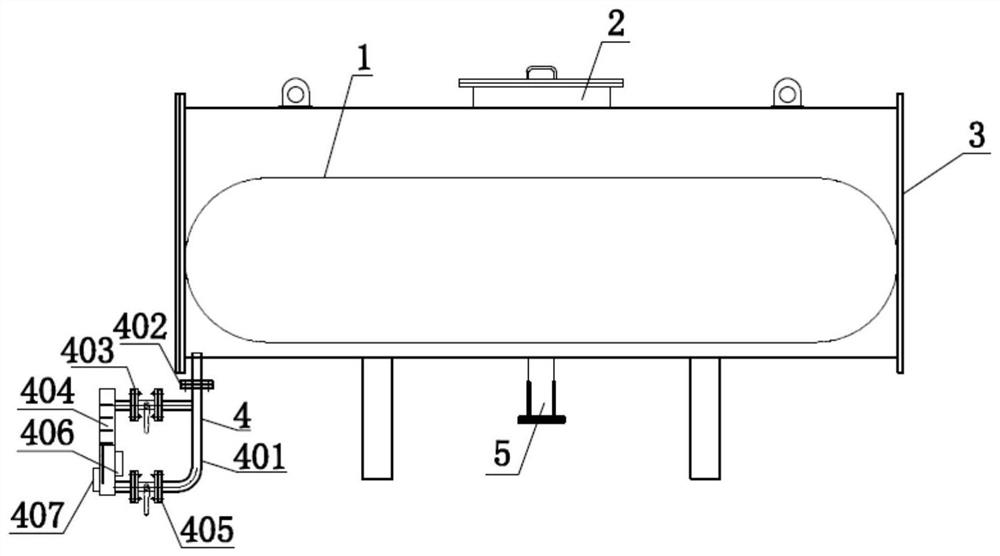

[0022] Example 1, refer to figure 1 and 2 , an intelligent monitoring device for oil conservator leakage, comprising a transformer capsule 1, a first valve pipe 2, an oil conservator 3 and a first valve pipe 5, the bottom end of the inner cavity of the oil conservator 3 is clamped along the left and right directions with Transformer capsule 1, the outer wall of the oil storage tank 3 is sprayed with a corrosion-resistant coating. The upper and lower ends of the cabinet 3 are respectively welded with a first valve pipe 2 and a second valve pipe 5, and a monitoring mechanism 4 is welded on the left side of the bottom end of the oil storage tank 3;

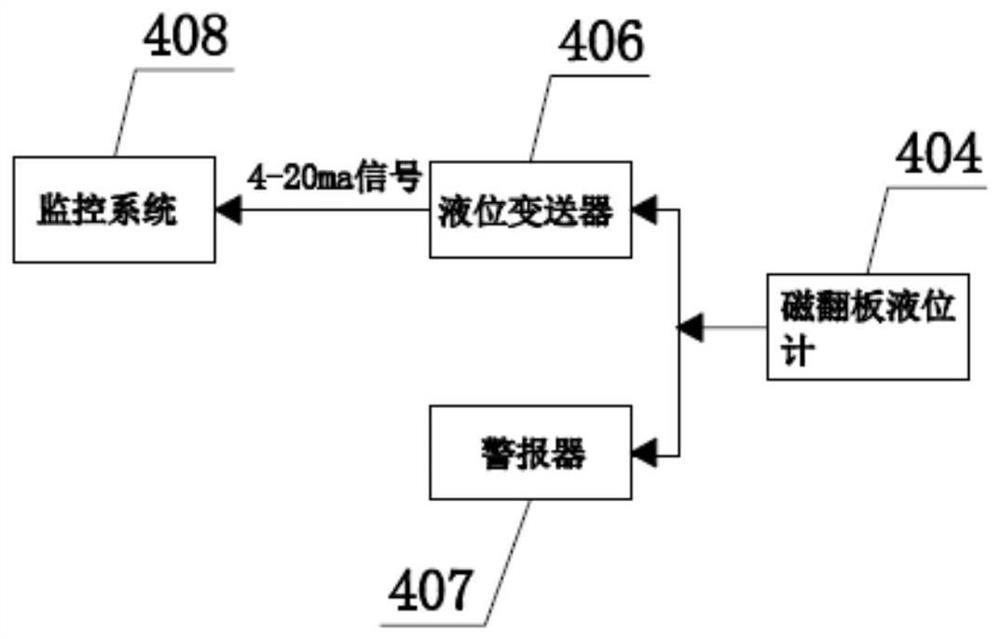

[0023] The monitoring mechanism 4 includes a standpipe 401, the top of the standpipe 401 is welded with the oil conservator 3, the outer wall of the standpipe 401 is flanged with a valve 402, and the bottom end of the standpipe 401 is welded with a valve 402. The lower communication valve 405, the upper communication valve 403 is w...

Embodiment 2

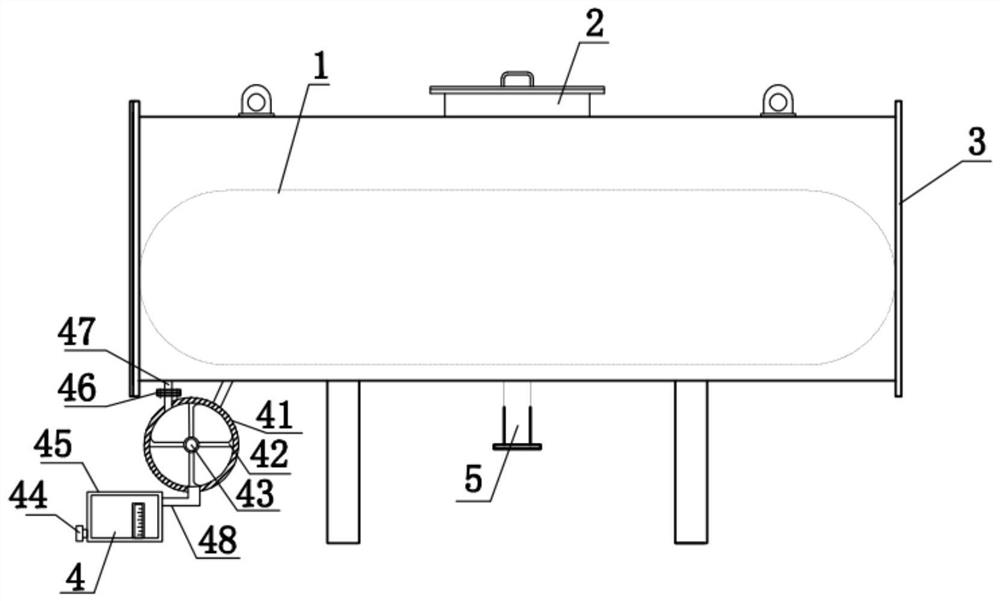

[0026] Example 2, refer to figure 2 , 3 and 5, an intelligent monitoring device for oil conservator leakage, comprising a transformer capsule 1, a first valve pipe 2, an oil conservator 3 and a first valve pipe 5, wherein the bottom end of the inner cavity of the oil conservator 3 is clamped in the left-right direction. The transformer capsule 1 is connected, and the outer wall of the oil conservator 3 is sprayed with a corrosion-resistant coating. The upper and lower ends of the oil conservator 3 are respectively welded with a first valve pipe 2 and a second valve pipe 5, and a monitoring mechanism 4 is welded on the left side of the bottom end of the oil conservator 3;

[0027] The monitoring mechanism 4 includes a cylindrical barrel 41, the cylindrical barrel 41 is welded with the oil conservator 3 through a strut, and a riser 47 is welded on the left side of the top end of the cylindrical barrel 41, and the top end of the riser pipe 47 extends into the tank 3. Oil conse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com