A crank-floating cabin door actuating mechanism

An actuating mechanism, floating technology, applied in the field of aviation electromechanical, can solve the problems of unreliable action, complex structure, many components, etc., to achieve the effect of rapid intermediate movement, soft start and position, and few components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to understand the purpose, technical solutions and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

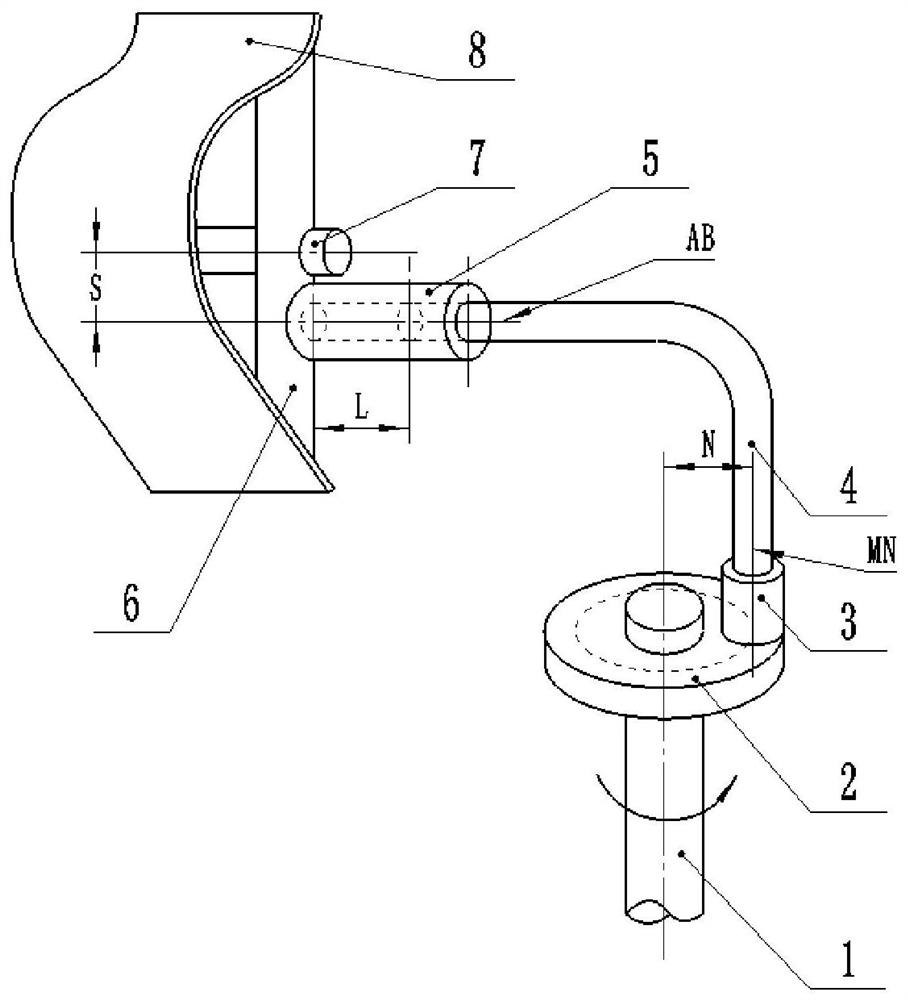

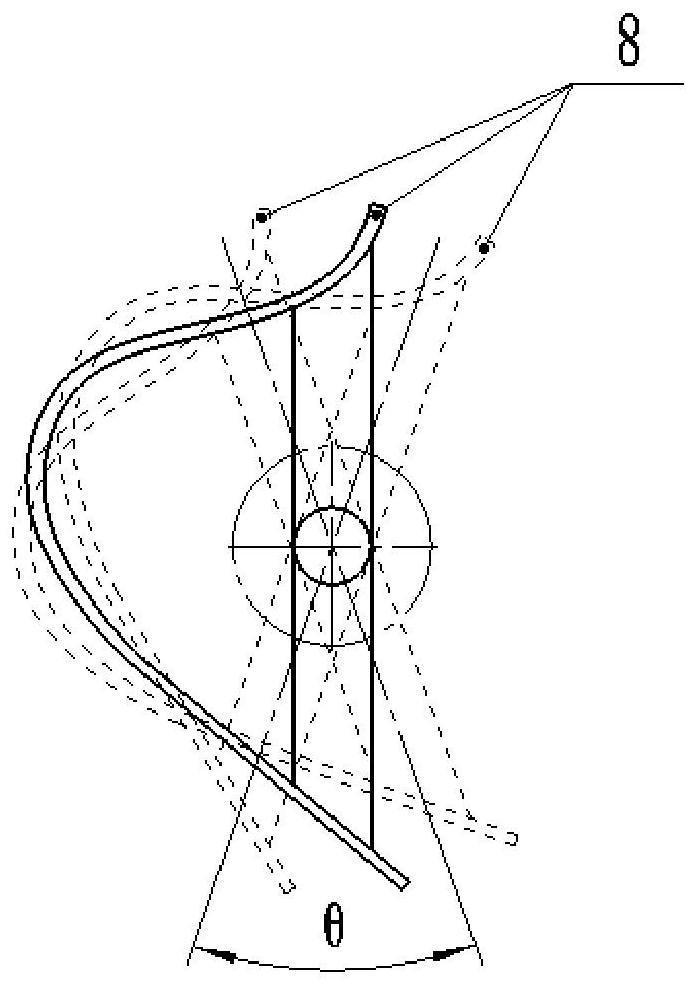

[0013] figure 1 It is a structural schematic diagram of the crank-floating hatch door actuating mechanism of the present invention. Such as figure 1 , the crank floating hatch door actuating mechanism of the present invention comprises a drive shaft 1, a connector 2 (in this embodiment, a ring is used), a cylinder 3, a crank 4, a sleeve 5, a support rod 6 and a hatch shaft 7. The drive shaft 1 is perpendicular to the hatch shaft 7 . The ring 2 is coaxially installed on the drive shaft 1. The drive shaft 1, the ring 2 and the cylinder 3 are connected to form a rigid body, and the axis MN of the cylinder 3 is parallel to the axis of the drive shaft 1 with a distance N. The sleeve 5, the support rod 6 and the hatch 8 are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com