Perforation completion method adopting hydraulic jetting to directly penetrate cement sheaths and rock

A technology of hydraulic jetting and cement sheath, which is applied in drilling with liquid/gas jet, earth-moving drilling, wellbore/well components, etc. The effect of penetrating depth and improving the efficiency of hydraulic jetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

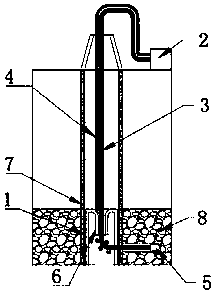

[0025] In the following, the new technology for directly penetrating the cement sheath and oil and gas reservoir rocks by means of hydraulic injection will be further described in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 As shown, the technology of the present invention mainly uses soluble aluminum-based metal to dissolve the hole-forming casing to form holes in the downhole, and the opening of the casing is determined by an automatic positioning device, and the lowered high-pressure hose is sent into the opening of the casing. The surface pressurization device is injected with water to pressurize the high-pressure hose, and the high-speed water jet generated penetrates the cement sheath and rocks of oil and gas reservoirs.

[0027] The realization of new metals using hydrojet to directly penetrate the cement sheath and reservoir rock of oil and gas reservoirs requires the following steps:

[0028] (1) Lowering the soluble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com