Motor for deep well pump

A technology using motors and deep well pumps, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as reducing the stability of motors, and achieve the effects of improving balance, improving sealing, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

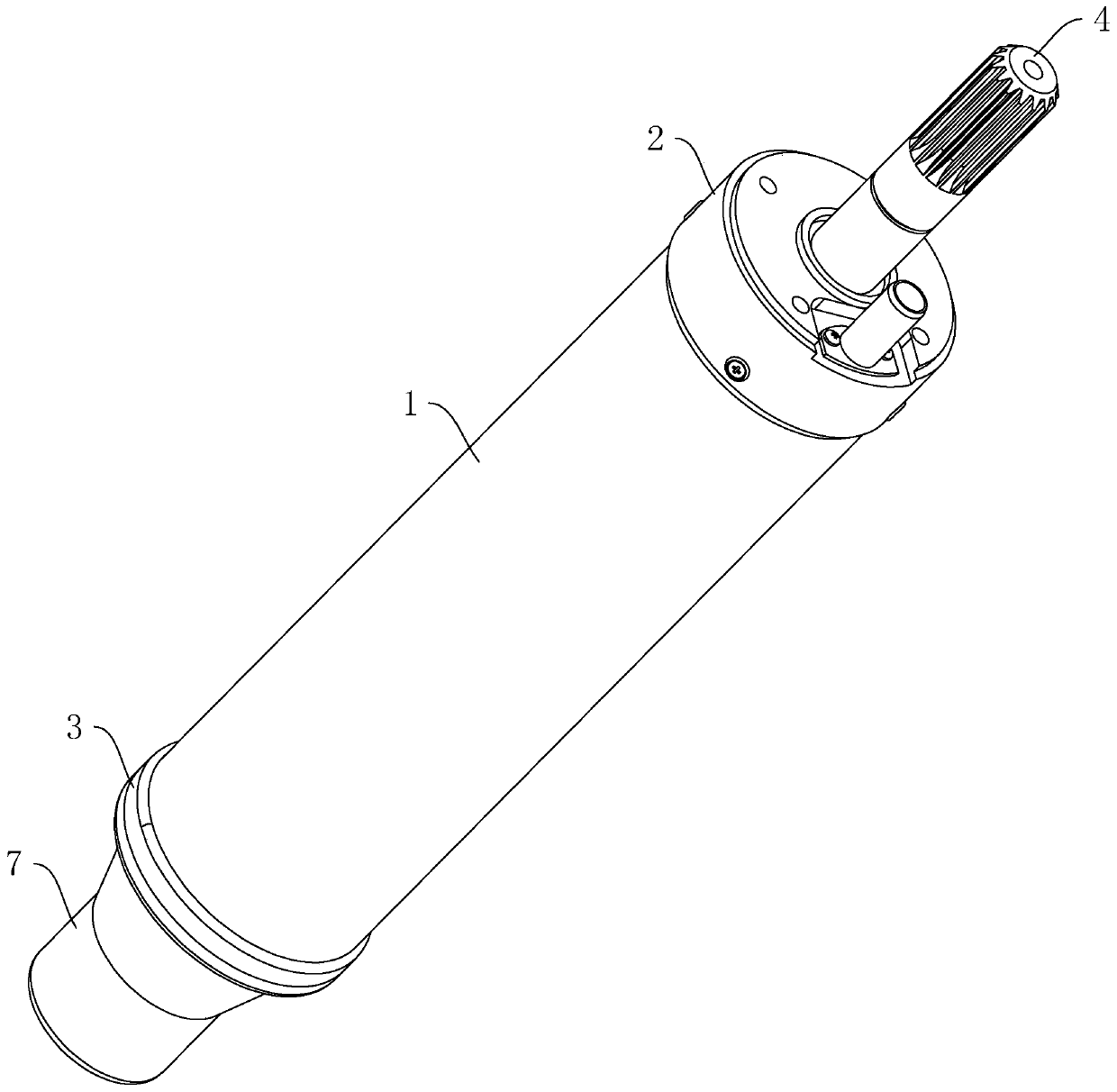

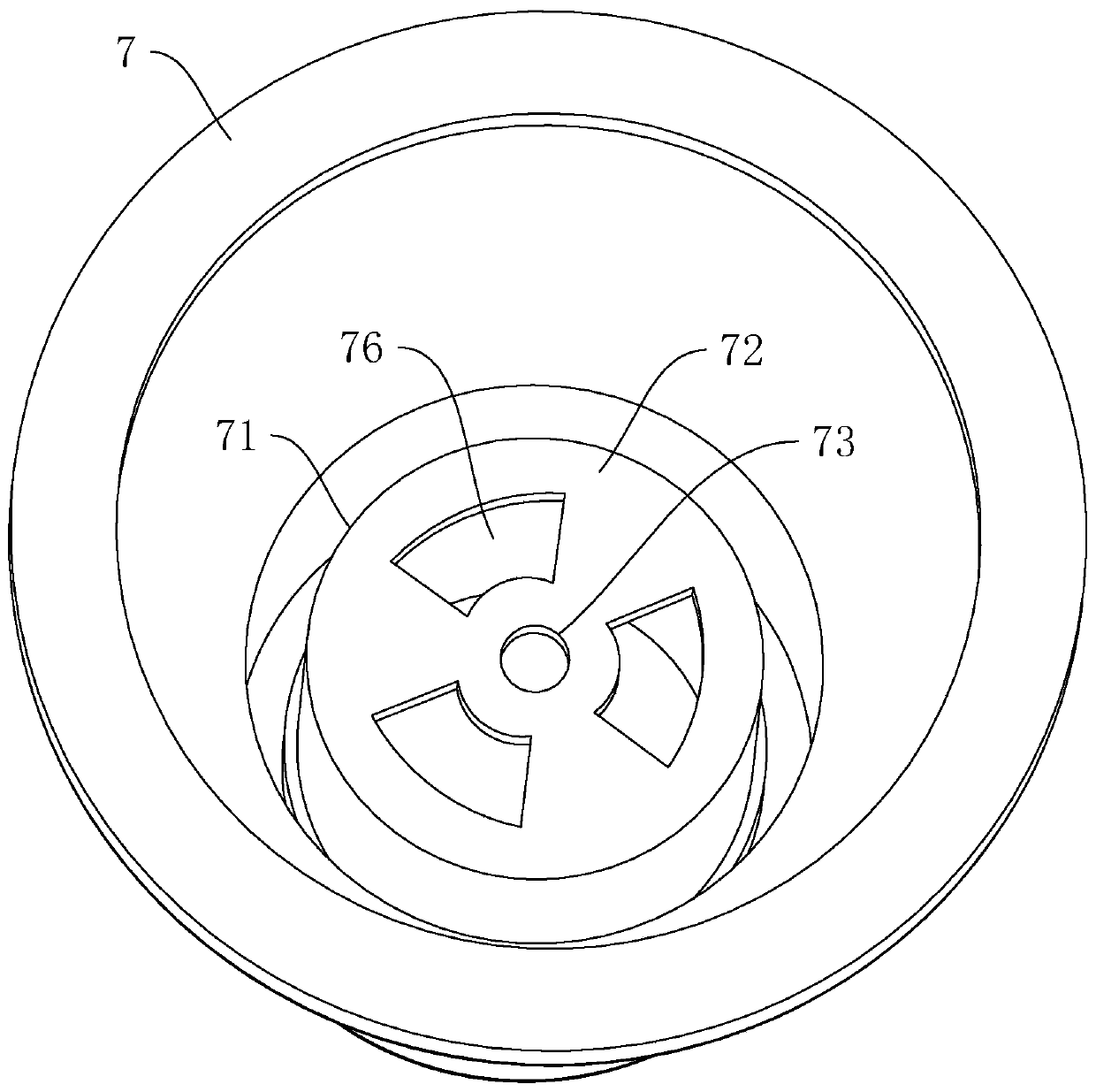

[0037] Such as figure 1 , figure 2 As shown, a motor for a deep well pump includes a machine barrel 1 , a front end cover 2 and a rear end cover 3 arranged at both ends of the machine barrel 1 . The barrel 1 is rotatably connected with the organic shaft 4, the front end of the shaft 4 is located outside the barrel 1 after passing through the front end cover 2, and the rear end of the shaft 4 is located outside the barrel 1 after passing through the rear end cover 3.

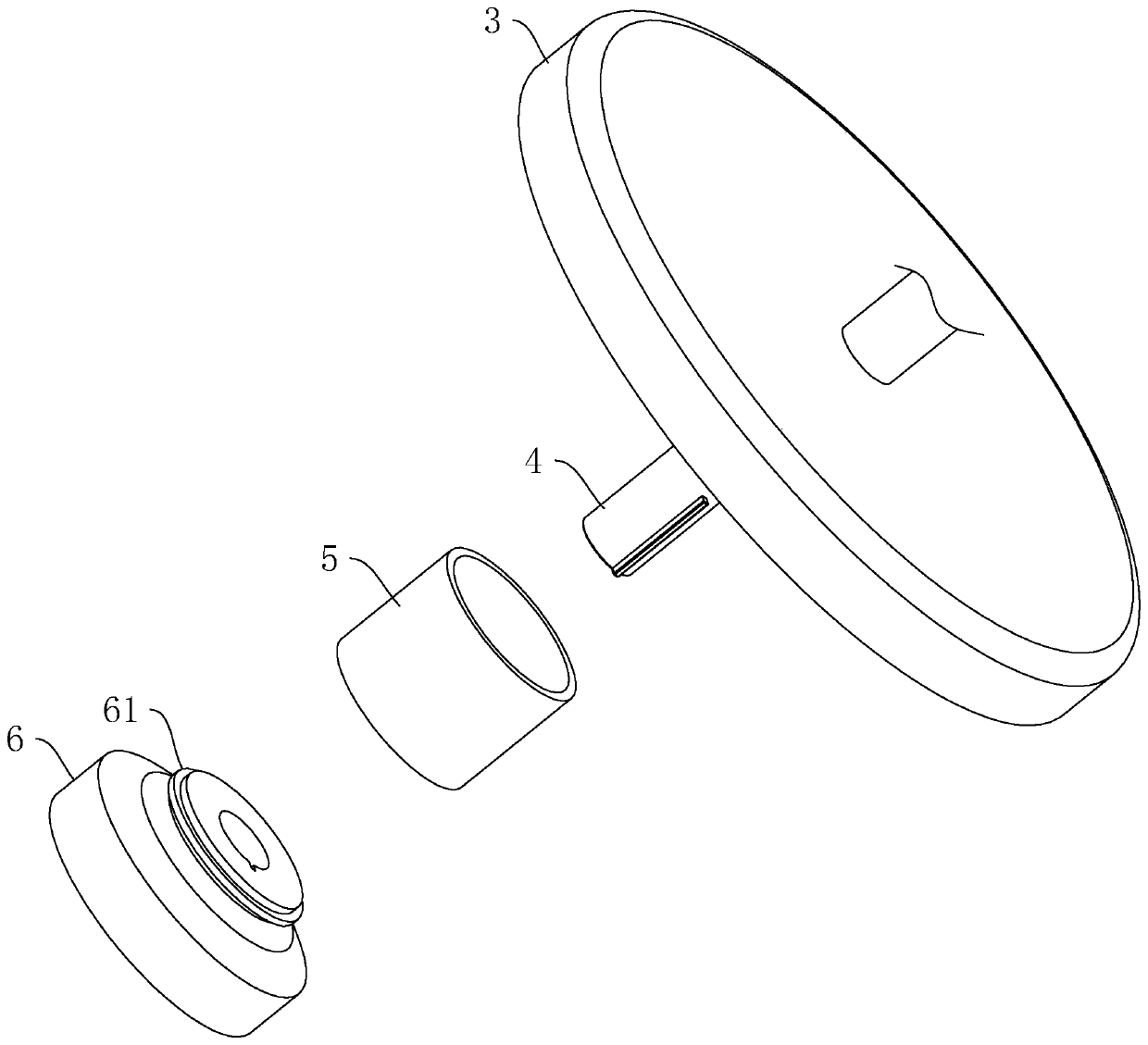

[0038] Such as figure 1 , figure 2 As shown, the outer wall of the rear end of the crankshaft 4 is successively covered with a graphite protective sleeve 5 and a graphite sleeve 6, and the outer wall of the graphite sleeve 6 is provided with a ring 61, and the upper surface of the graphite protective sleeve 5 is in contact with the rear end cover 3 and lowered. The end face is in contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com