Floating block structure and mold

A floating block and mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of loose block 30', hurting people, mold damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

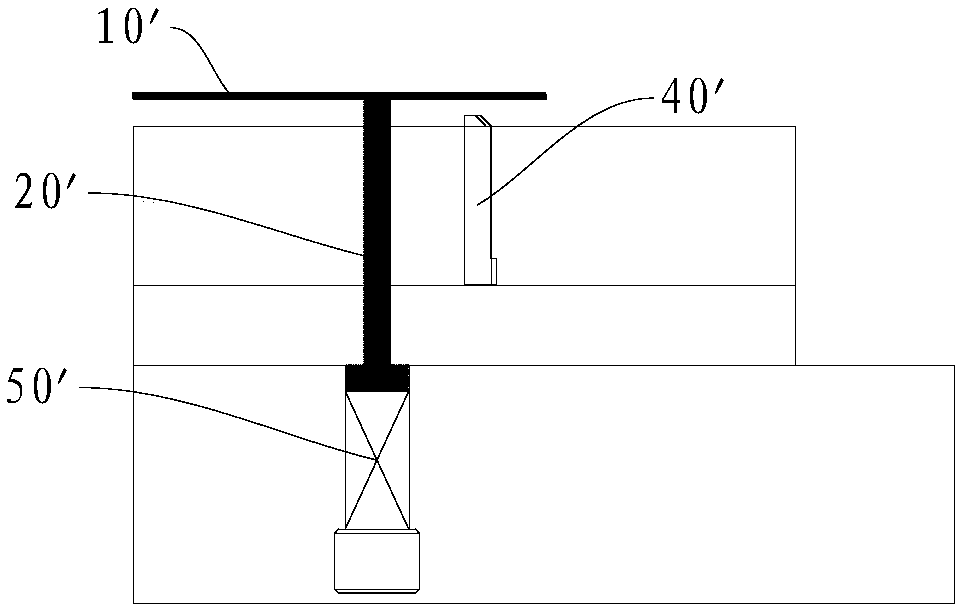

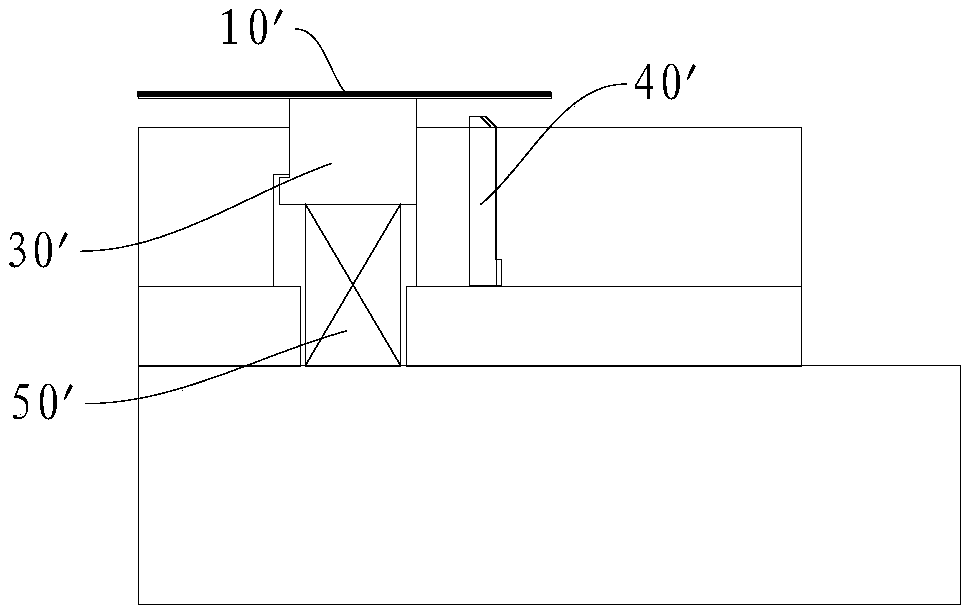

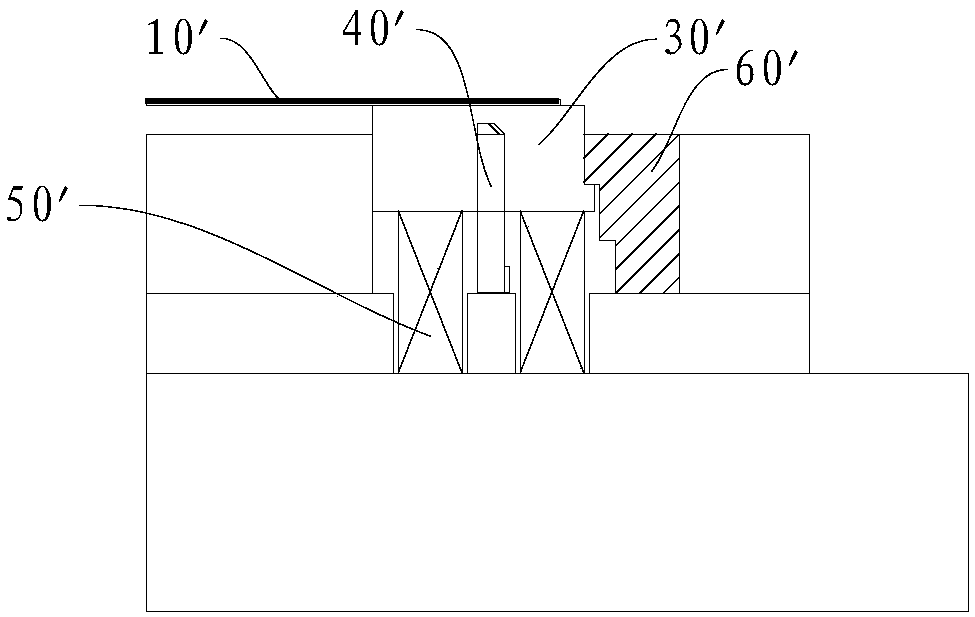

[0032] refer to Figure 4-Figure 6 , the floating block structure in one embodiment of the present invention is set on the lower mold 100 of the mold for stripping. The floating block structure includes a floating block 200 , a pressing block 300 and an ejector pin assembly 400 . The floating block 200 is movably arranged on the lower mold 100, and the floating block 200 has a floating block stopper 210, which cooperates with the floating block stopper fitting part 310 on the pressing block 300 to limit the upward displacement of the floating block 200 and prevent the floating block from 200 is deviated from lower mold 100. The ejector pin assembly 400 includes an ejector pin 410 and an elastic member 420 , the ejector pin 410 is dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com