Steel bar cutter for well lid installing

A technology for cutting and installing steel bars, which is applied in the field of steel bar cutters for manhole cover installation. It can solve the problems of low cutting efficiency of steel bars and easy sore arms, and achieve the effect of improving cutting efficiency, preventing arm soreness, and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

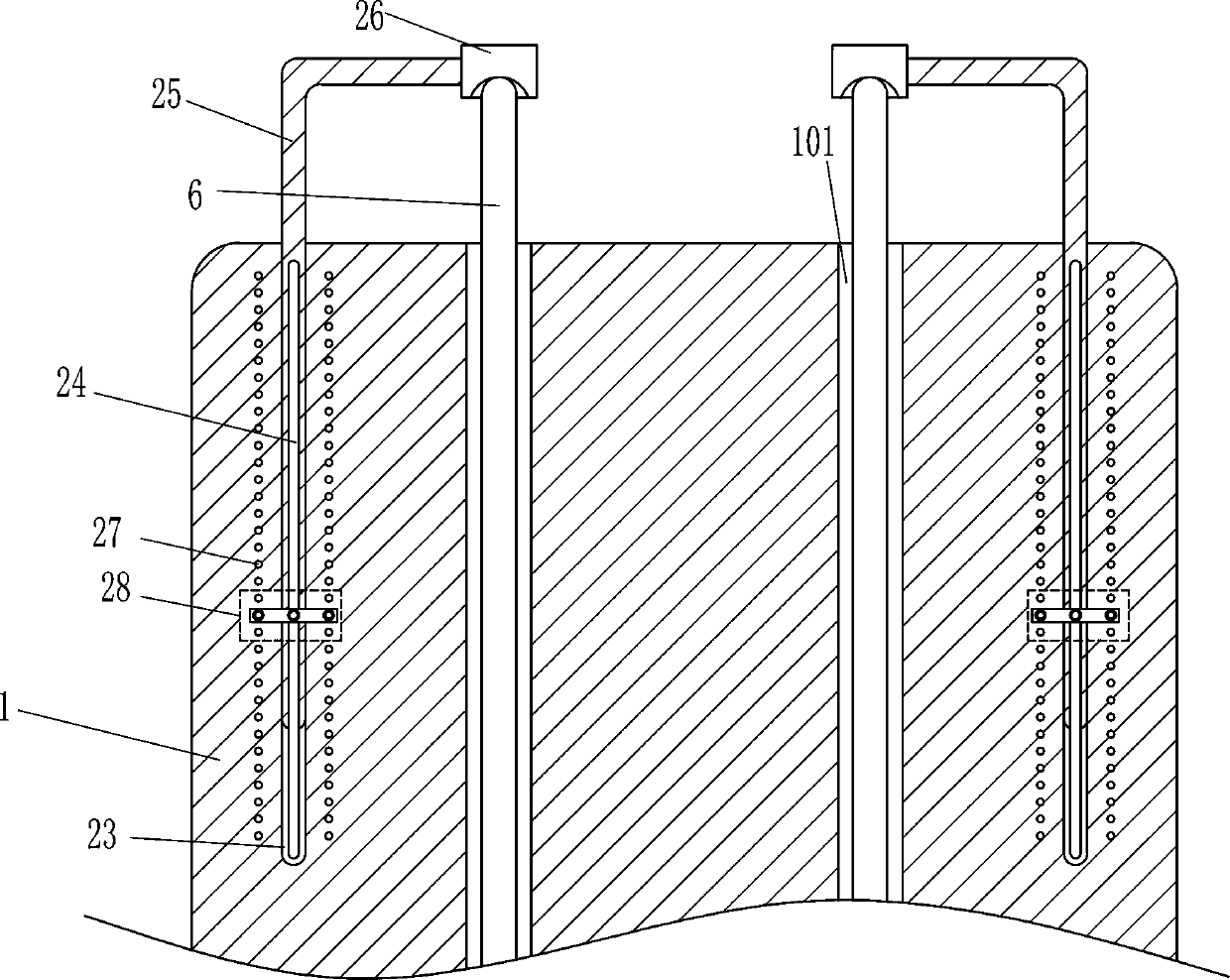

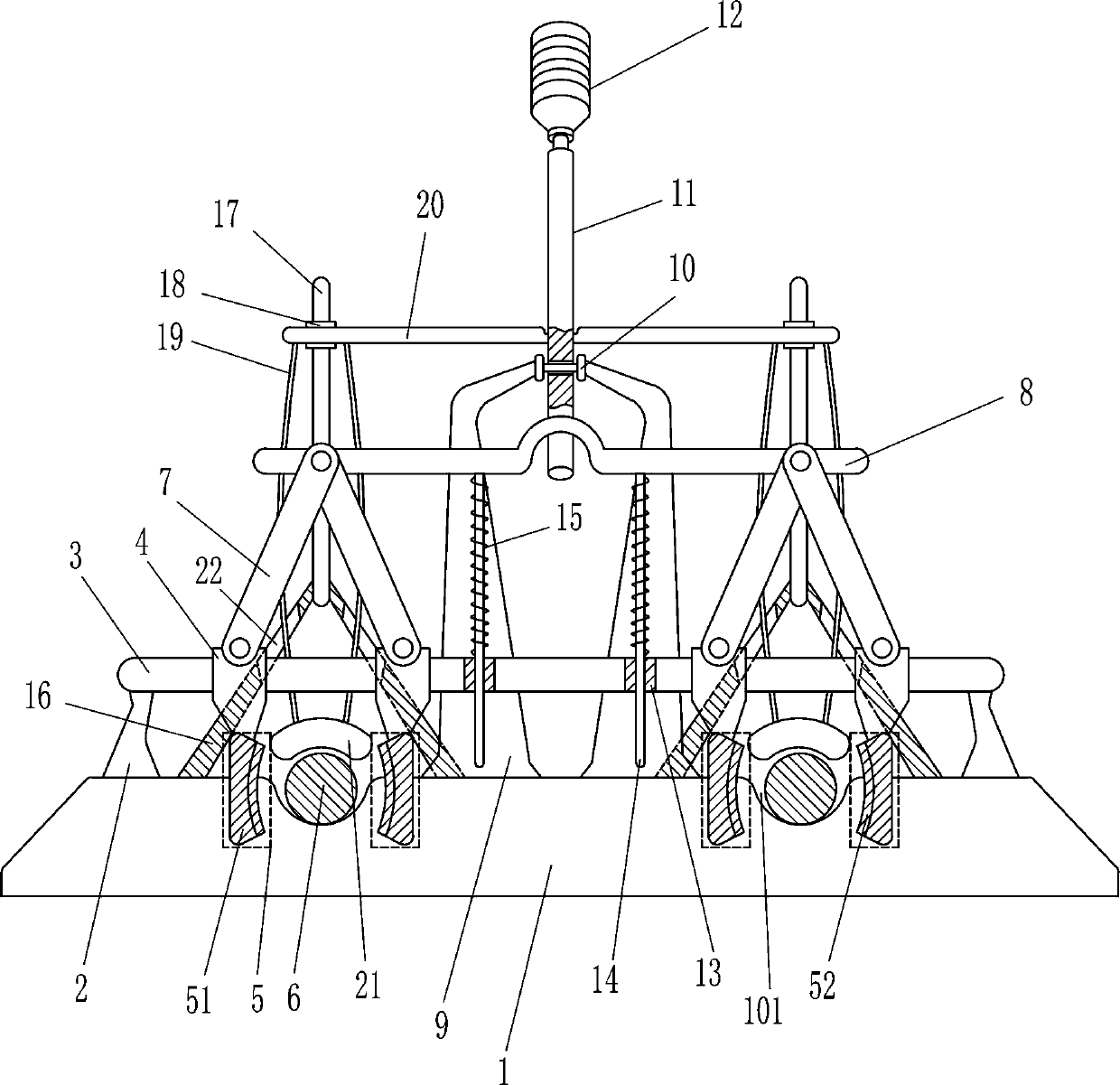

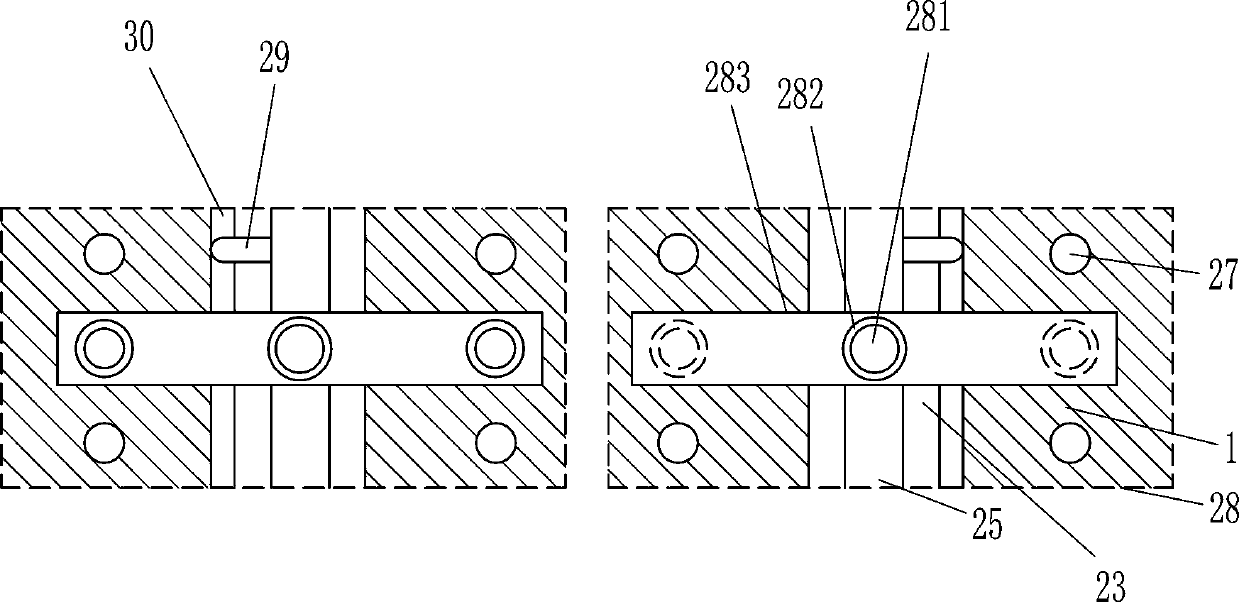

[0016] A steel bar cutter for well cover installation, such as figure 1 As shown, it includes a bottom plate 1, a pole 2, a guide rail 3, a guide block 4, a cutting device 5, a steel bar body 6, a connecting rod 7, a concave rod 8, a connecting plate 9, a rotary joint 10, a telescopic rod 11, and a handle 12. Guide sleeve 13, guide rod 14 and spring 15, the left and right sides of the top of the bottom plate 1 are provided with placement grooves 101 for placing the steel bar body 6, the left and right sides of the top of the bottom plate 1 are fixed with poles 2, and the bottom plate 1 passes through The way of bolt connection is connected with the support rod 2, and the guide rail 3 is arranged between the top ends of the left and right two support rods 2, and the support rod 2 is connected with the guide rail 3 by welding, and there are four guide blocks 4, all of which are sliding On the guide rail 3, the bottom of the guide block 4 is equipped with a cutting device 5 that ...

Embodiment 2

[0018] A steel bar cutter for well cover installation, such as figure 1 As shown, it includes a bottom plate 1, a pole 2, a guide rail 3, a guide block 4, a cutting device 5, a steel bar body 6, a connecting rod 7, a concave rod 8, a connecting plate 9, a rotary joint 10, a telescopic rod 11, and a handle 12. Guide sleeve 13, guide rod 14 and spring 15, the left and right sides of the bottom plate 1 top are all provided with placement grooves 101 for placing the steel bar body 6, the left and right sides of the bottom plate 1 top are all fixed with support rods 2, two left and right A guide rail 3 is arranged between the tops of the struts 2, and four guide blocks 4 are arranged on the guide rails 3, and the bottom of the guide block 4 is equipped with a cutting device 5 that can cut off the steel bar body 6, and the guide block 4 A connecting rod 7 is hinged on the top of the top of the left and right sides, and a concave rod 8 is hingedly connected between the tops of the tw...

Embodiment 3

[0021] A steel bar cutter for well cover installation, such as figure 1 As shown, it includes a bottom plate 1, a pole 2, a guide rail 3, a guide block 4, a cutting device 5, a steel bar body 6, a connecting rod 7, a concave rod 8, a connecting plate 9, a rotary joint 10, a telescopic rod 11, and a handle 12. Guide sleeve 13, guide rod 14 and spring 15, the left and right sides of the bottom plate 1 top are all provided with placement grooves 101 for placing the steel bar body 6, the left and right sides of the bottom plate 1 top are all fixed with support rods 2, two left and right A guide rail 3 is arranged between the tops of the struts 2, and four guide blocks 4 are arranged on the guide rails 3, and the bottom of the guide block 4 is equipped with a cutting device 5 that can cut off the steel bar body 6, and the guide block 4 A connecting rod 7 is hinged on the top of the top of the left and right sides, and a concave rod 8 is hingedly connected between the tops of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com