A curing room for testing concrete specimens

A concrete test piece and curing room technology, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of easy confusion of concrete test blocks, easy confusion of concrete test blocks, etc., so as to improve indoor moisturizing effect, realize correct maintenance, and improve convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

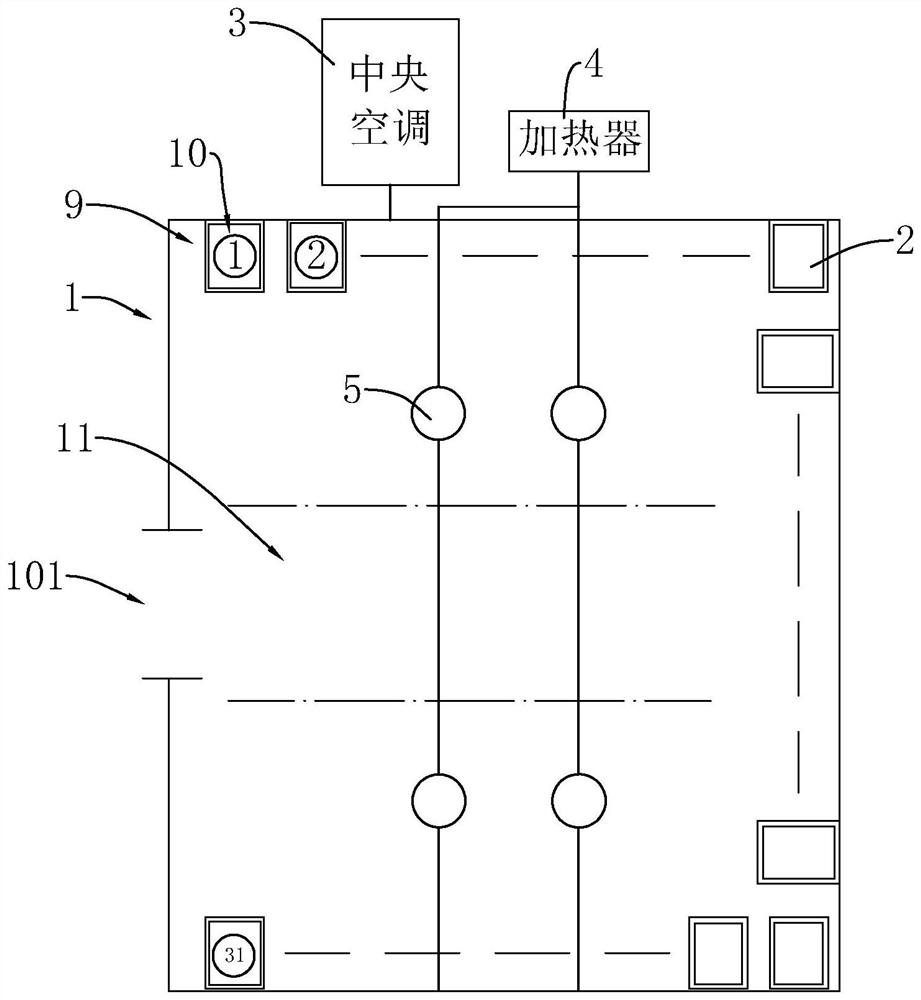

[0034] See attached figure 1 , a curing room for the detection of concrete specimens, comprising a curing room body 1, one side of the curing room body 1 is provided with a curing entrance 101, and a temperature control device and a moisturizing device are also arranged in the curing room body 1; temperature control The device can control the internal temperature of the curing room body 1 in real time, so that the internal temperature of the curing room body 1 is kept at 20±2°C; the moisturizing device can monitor and adjust the internal humidity of the curing room body 1 in real time, and control the internal humidity of the curing room body 1 at 95% about. At the same time, a number of curing racks 2 are arranged in the curing room body 1, and each curing rack 2 can be used for displaying concrete specimens to be tested. According to the standard,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com