Intelligent flexible heat preservation single tube winding mechanism and winding method

A winding mechanism, intelligent and flexible technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of reducing production efficiency, wasting time and manpower, etc., and achieve the purpose of improving production efficiency, improving efficiency, The effect of the right amount of traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

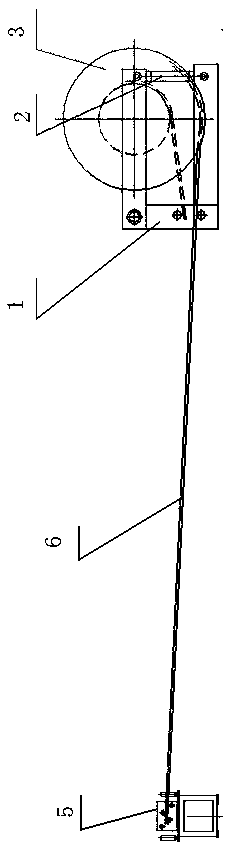

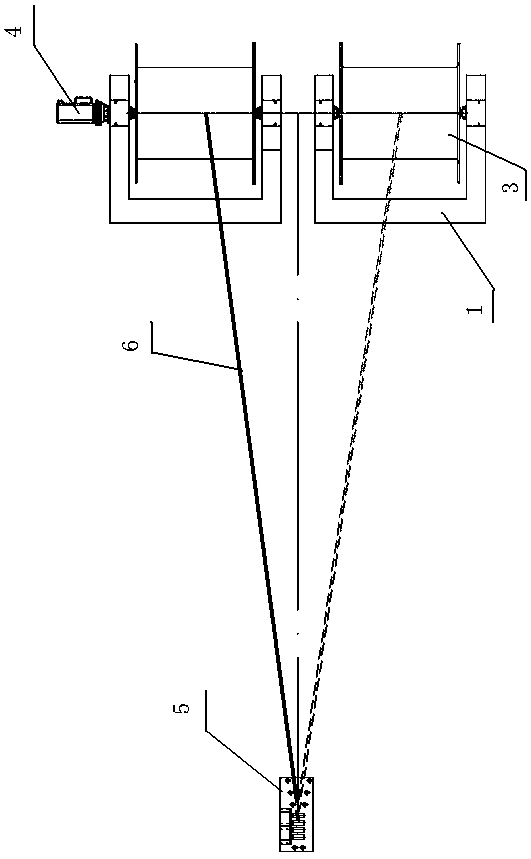

[0019] An intelligent flexible thermal insulation single-tube rewinding mechanism, which consists of: a rewinding actuator 3, a guide mechanism 5, a rewinding platform 1, a cylinder 2 and a motor 4, the rewinding platform and the rewinding actuator A thermal insulation pipe rewinding mechanism is formed, the rewinding actuator is respectively equipped with a control panel, the cylinder and the motor, the output shaft of the motor is connected to the center of the actuator, The executive mechanism is connected with the guide mechanism through the working pipe 6 .

Embodiment 2

[0021] According to the intelligent flexible thermal insulation single-tube rewinding mechanism described in Example 1, the rewinding platform is welded by 8 pieces of 400*200 square steel, and then welded with a 4mm thick baffle to form the rewinding platform.

Embodiment 3

[0023] According to the intelligent flexible thermal insulation single-tube rewinding mechanism described in Embodiment 1 or 2, the rewinding actuator is composed of 12 U-shaped groove supports, and the U-shaped groove is 10mm wide and 8mm deep.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com