Adjustable check valve

A check valve, adjustable technology, applied in the direction of lift valve, valve detail, control valve, etc., can solve the problems of large installation space, increase user equipment expenses and maintenance costs, etc., achieve small pressure loss, good sealing, The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be clearly and completely described below in conjunction with the accompanying drawings.

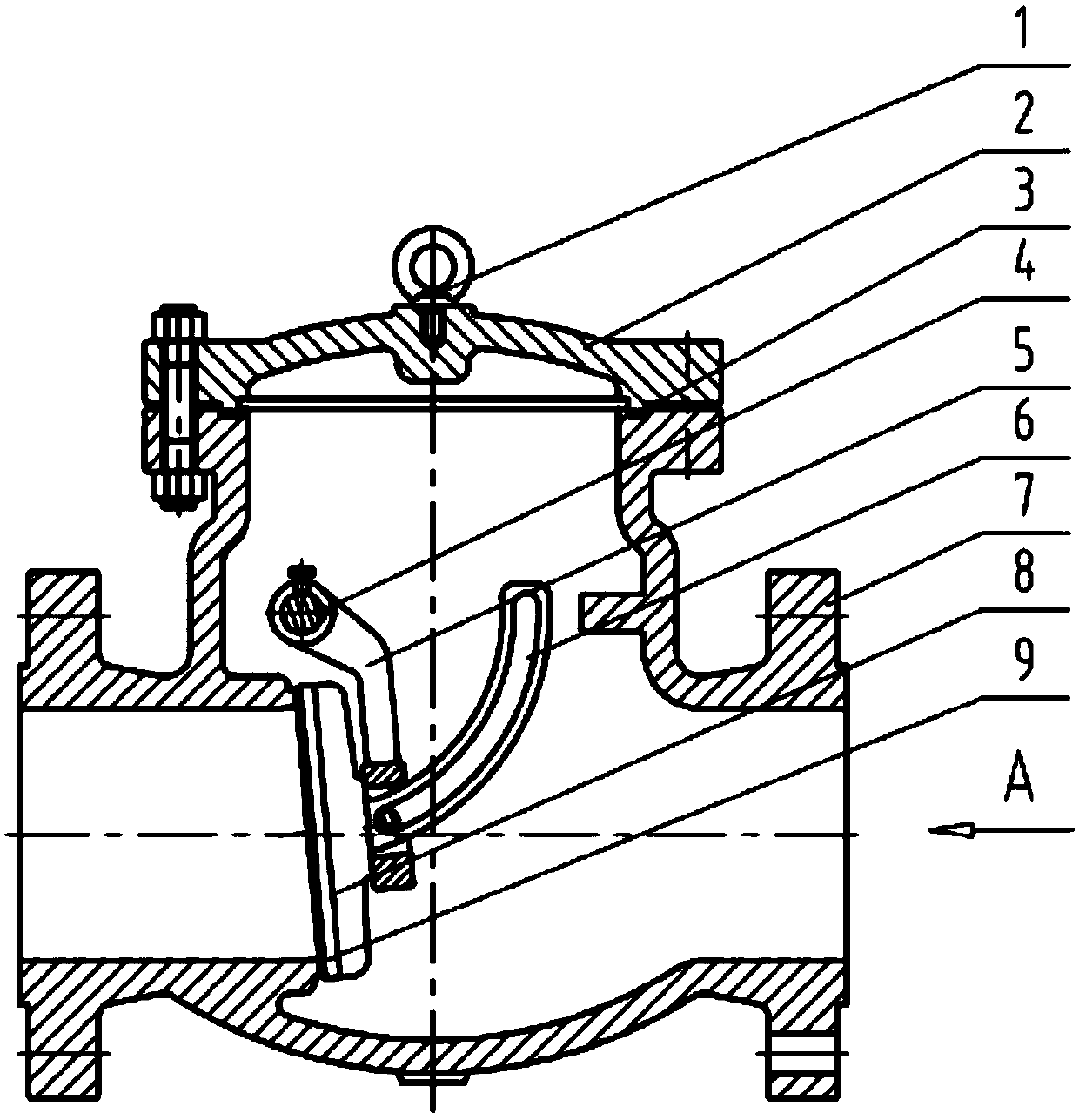

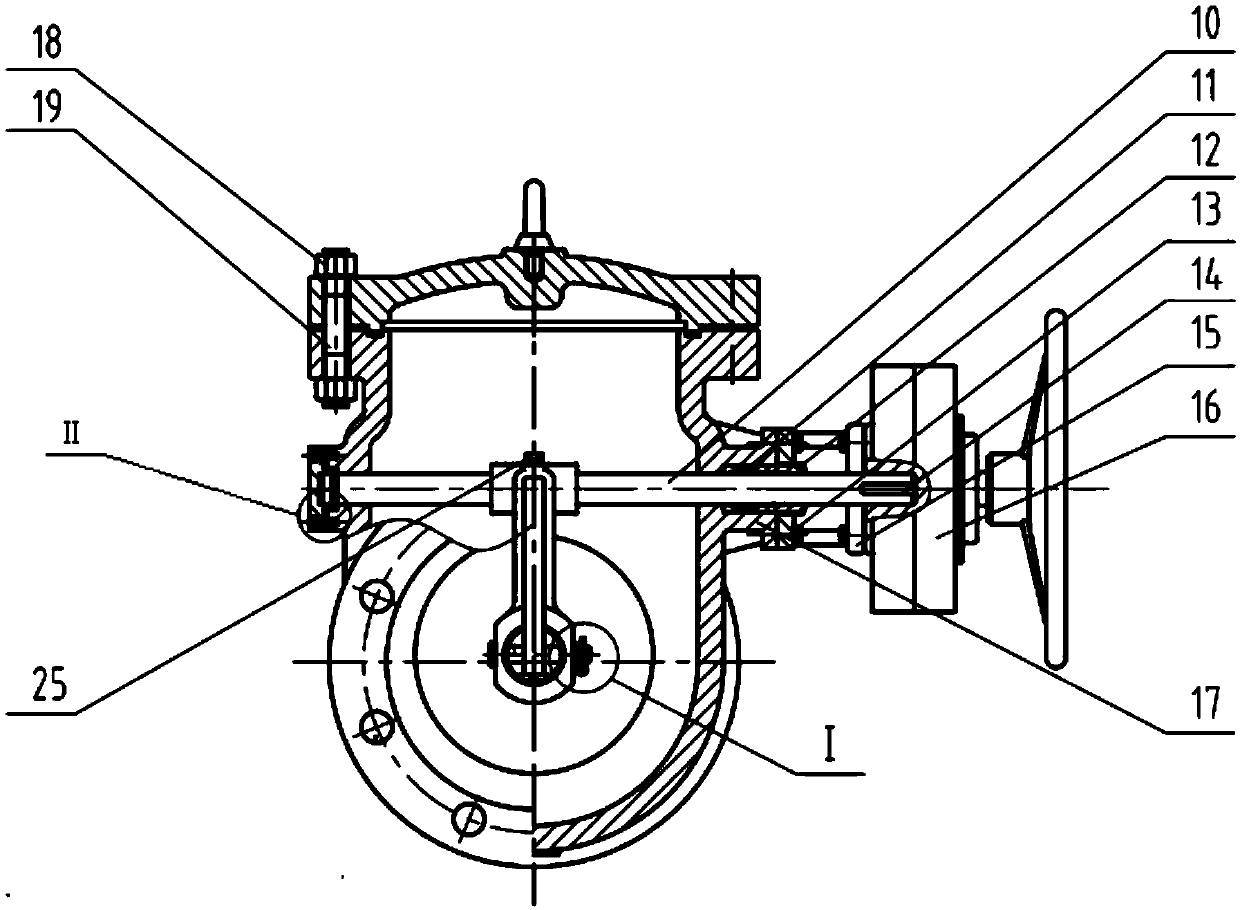

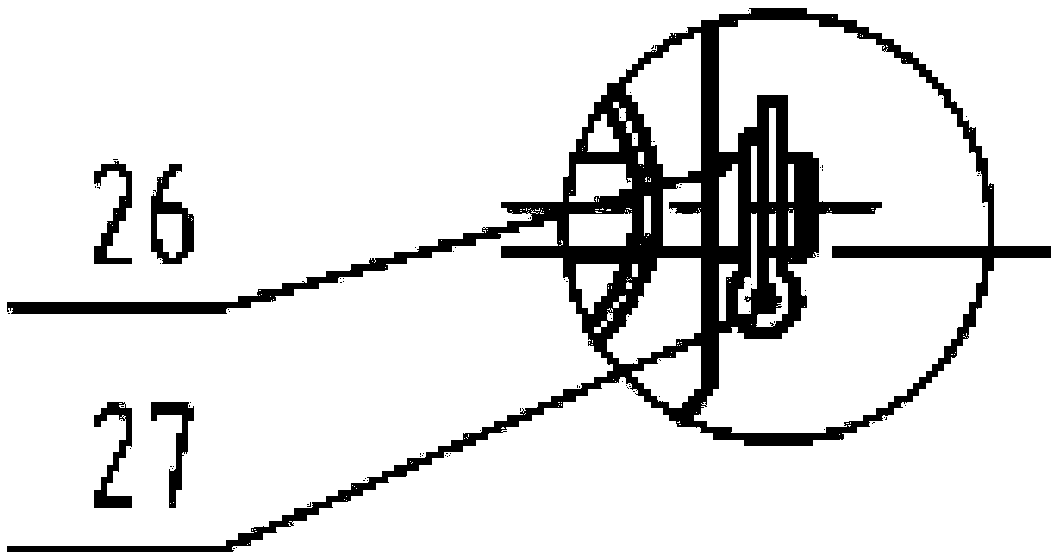

[0034] like figure 1 As shown, the adjustable check valve of the present invention includes a valve body 7, a valve cover 2, a valve disc 8, a rocker 5, a valve stem 10, a worm gear head 16 and other components.

[0035] The valve body 7 is a three-way type, and the two sides of the valve body 7 are respectively provided with a fluid inlet channel and a fluid outlet channel, and both the fluid inlet channel and the fluid outlet channel are connected with the upper cavity of the valve body 7;

[0036] The lifting ring screw 1 is set on the valve cover 2, which is convenient for lifting and installation; the valve cover 2 is set on the upper end of the valve body 7, and is tightly connected with the valve body 7 through nuts 18 and second bolts 19 to close the upper port of the valve body 7 ; There is also a gasket 3 between the valve cover 2 and the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com