Sludge treatment device for separating slurry and water

A technology for sludge treatment and sludge-water separation, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficult sludge-water separation and low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

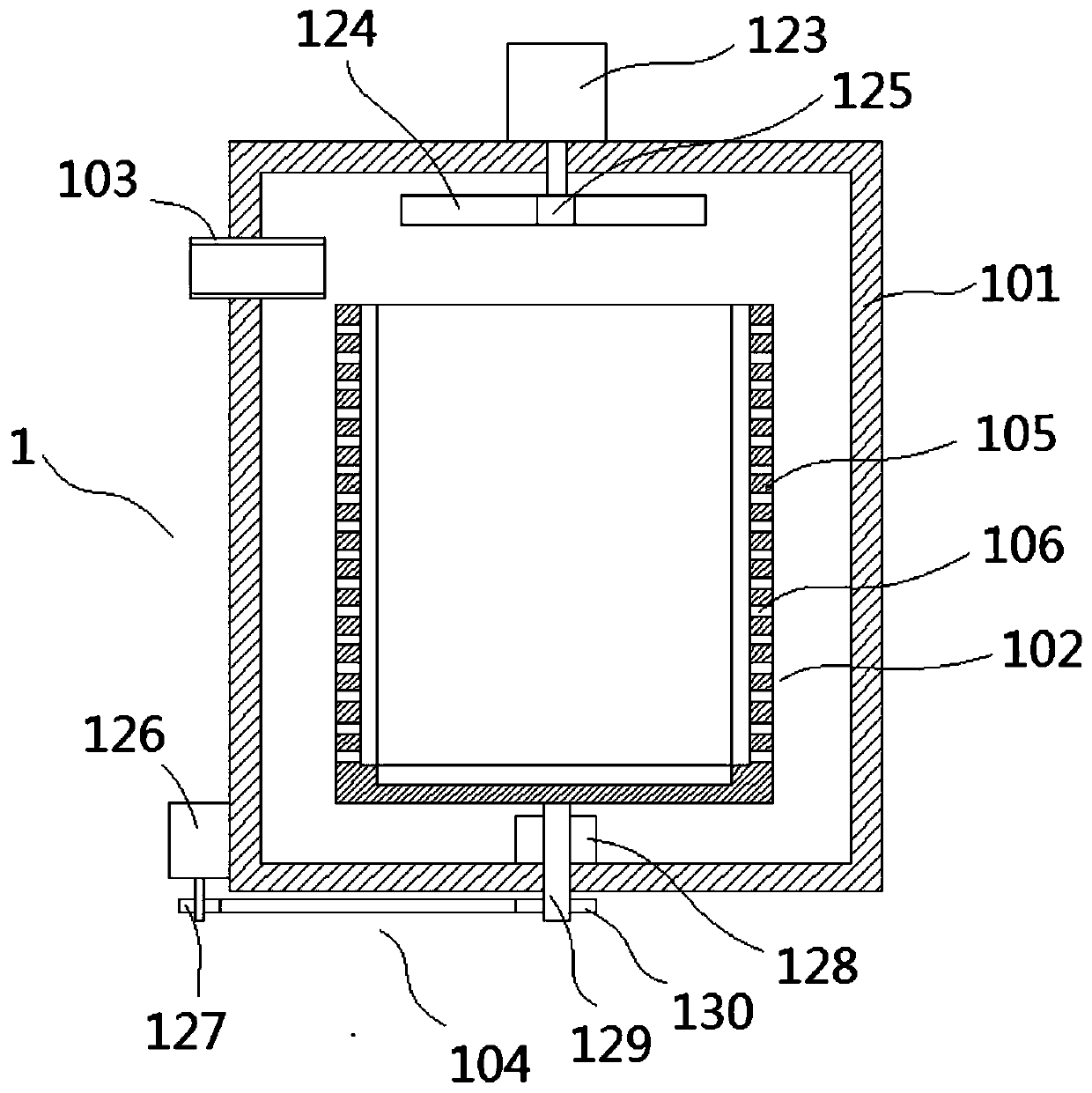

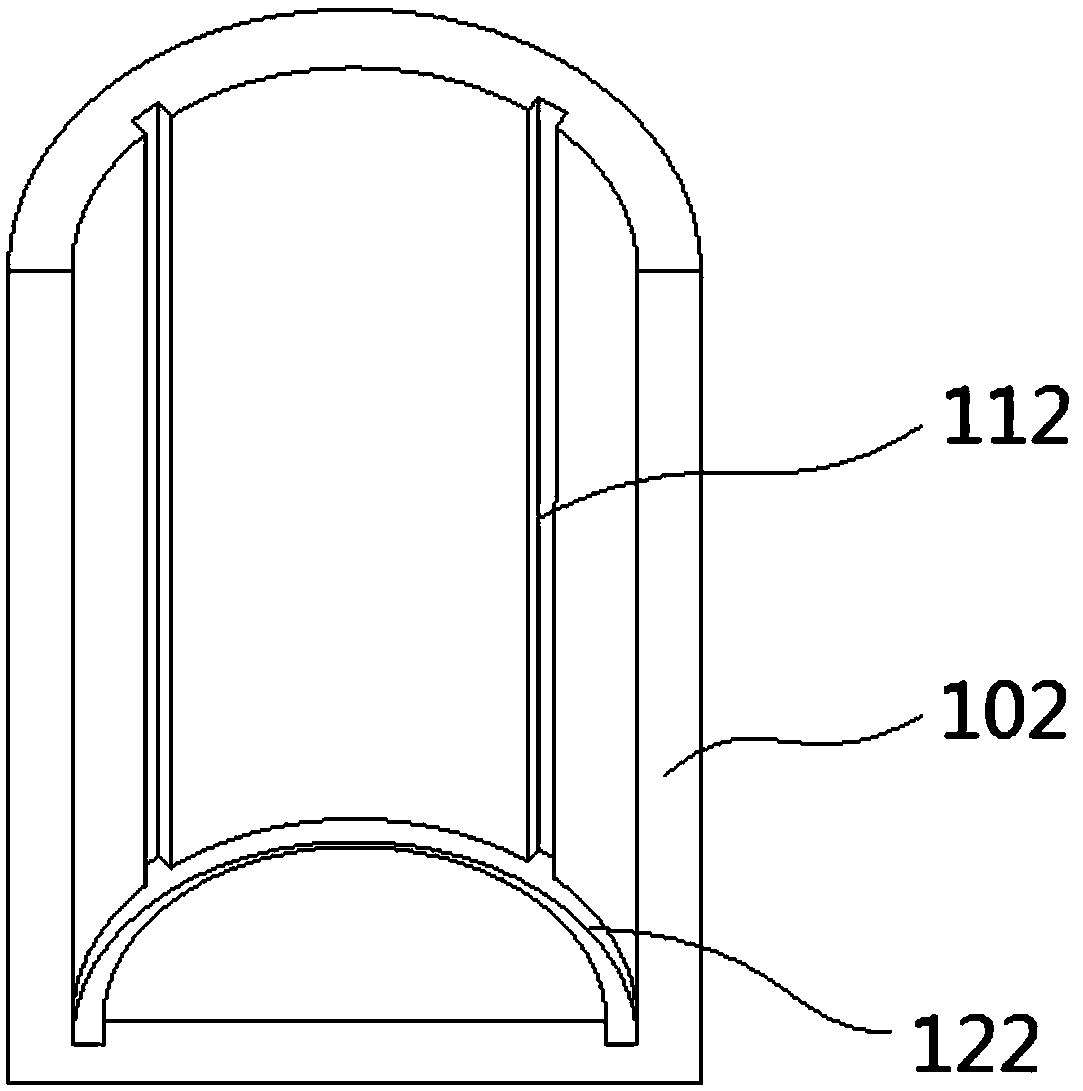

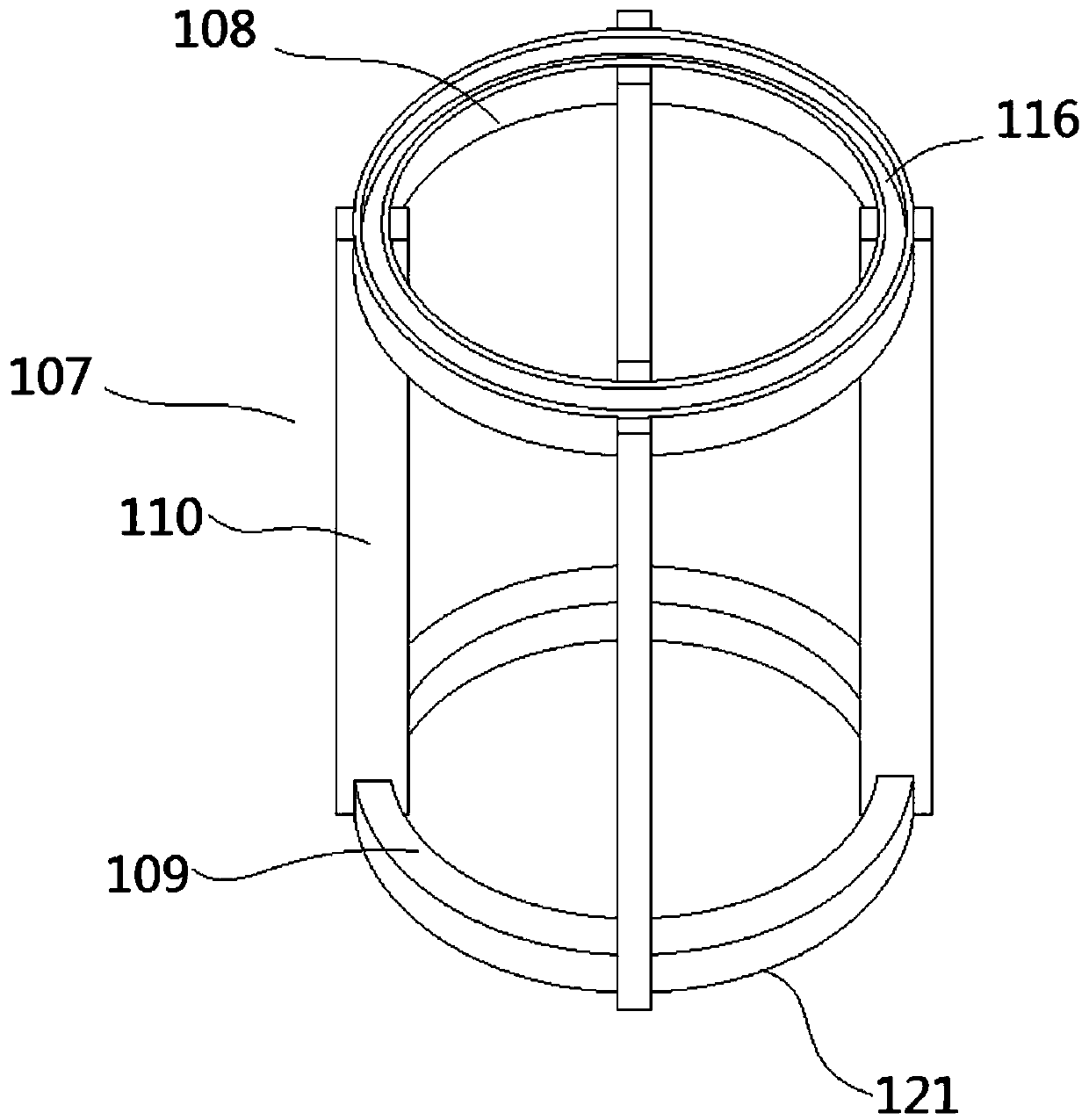

[0031] Sludge treatment devices that facilitate the separation of mud and water, such as Figure 1-Figure 6 As shown, a centrifugal device 1 is included, and the centrifugal device 1 includes an outer cylinder 101 and an inner cylinder 102 arranged in the outer cylinder 101, and the outer cylinder 101 is provided with a mud inlet pipe for transporting raw sludge into the inner cylinder 102 103 and a transmission mechanism 104 for rotating the inner cylinder body 102, wherein the mud inlet pipe 103 is a mud delivery hose, which extends into the inner cylinder body 102 from the side wall of the outer cylinder body 101, and the mud delivery hose needs to be inserted into the inner cylinder body 102 during use. Insert the mouth of the mud inlet pipe 103 on the outer cylinder 101, and allow the end of the mud delivery hose to penetrate into the inner cylinder 102. At this time, the upper extrusion plate 124 is at the highest point, and the upper part performs extrusion.

[0032] Th...

Embodiment 2

[0047] Same as embodiment 1, such as Figure 11 , Figure 12 As shown, the difference is that the mud inlet pipe 103 in this embodiment includes an outer tube 131 fixed on the side wall of the outer cylinder 101 and an inner tube 132 whose end is inserted into the outer tube 131 and can slide axially along the inner wall of the outer tube 131, The inner wall of the outer tube 131 is provided with an annular spring seat 133, the annular spring seat 133 is connected with a spring 134 arranged axially along the outer tube 131, and the end of the spring 134 away from the annular spring seat 133 is connected to the inner tube 132 inserted into the outer tube 131 on the end. The end of the inner tube 132 inserted into the outer tube 131 is fixed with a pressure plate 135. The pressure plate 135 includes an annular plate 136 and a circular plate 138 connected to the middle of the annular plate 136 by two connecting rods 137. The upper surface of the annular plate 136 is provided wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap