Round head button hole sewing machine

A sewing machine, buttonhole technology, applied in the direction of sewing machine components, program-controlled sewing machines, sewing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

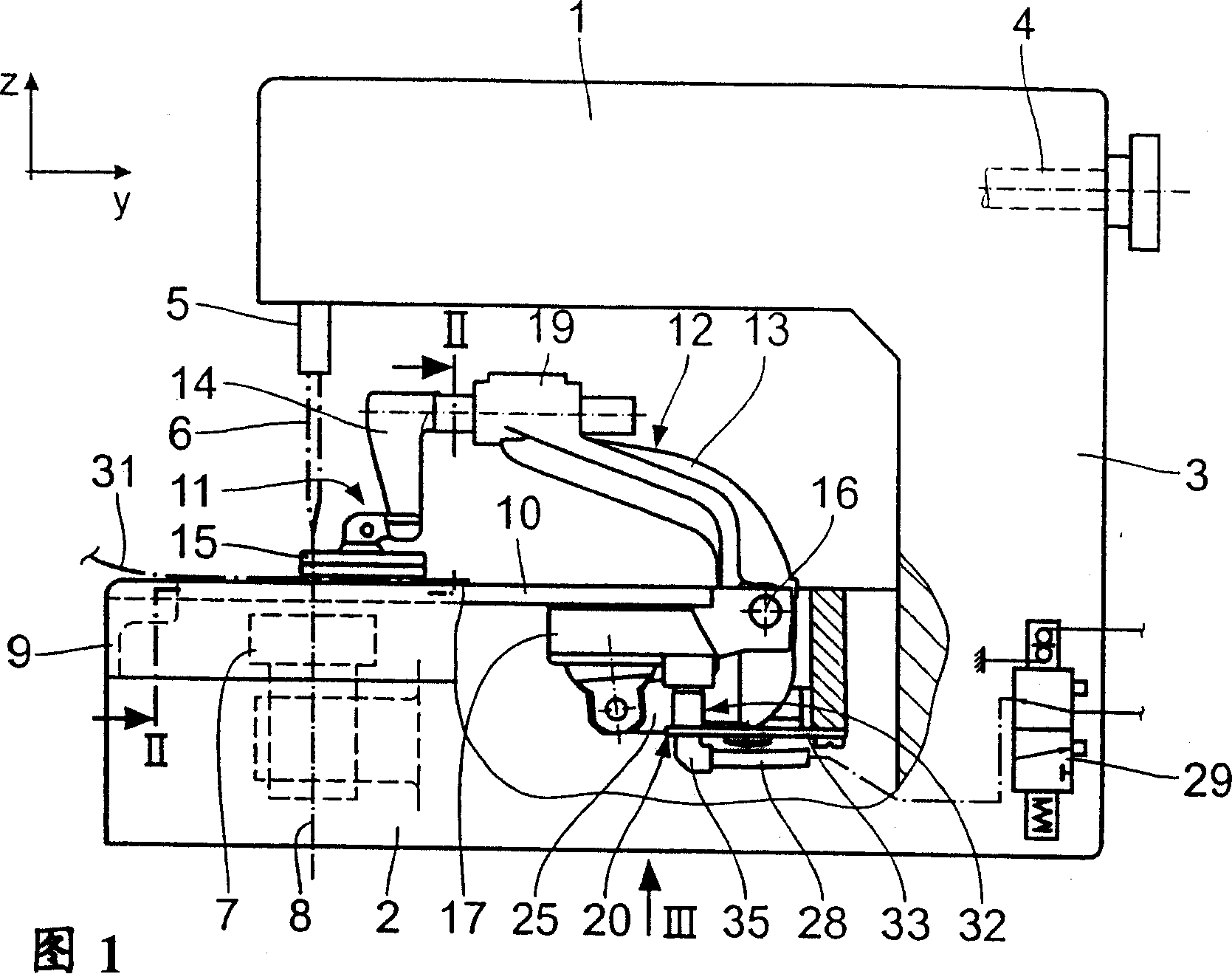

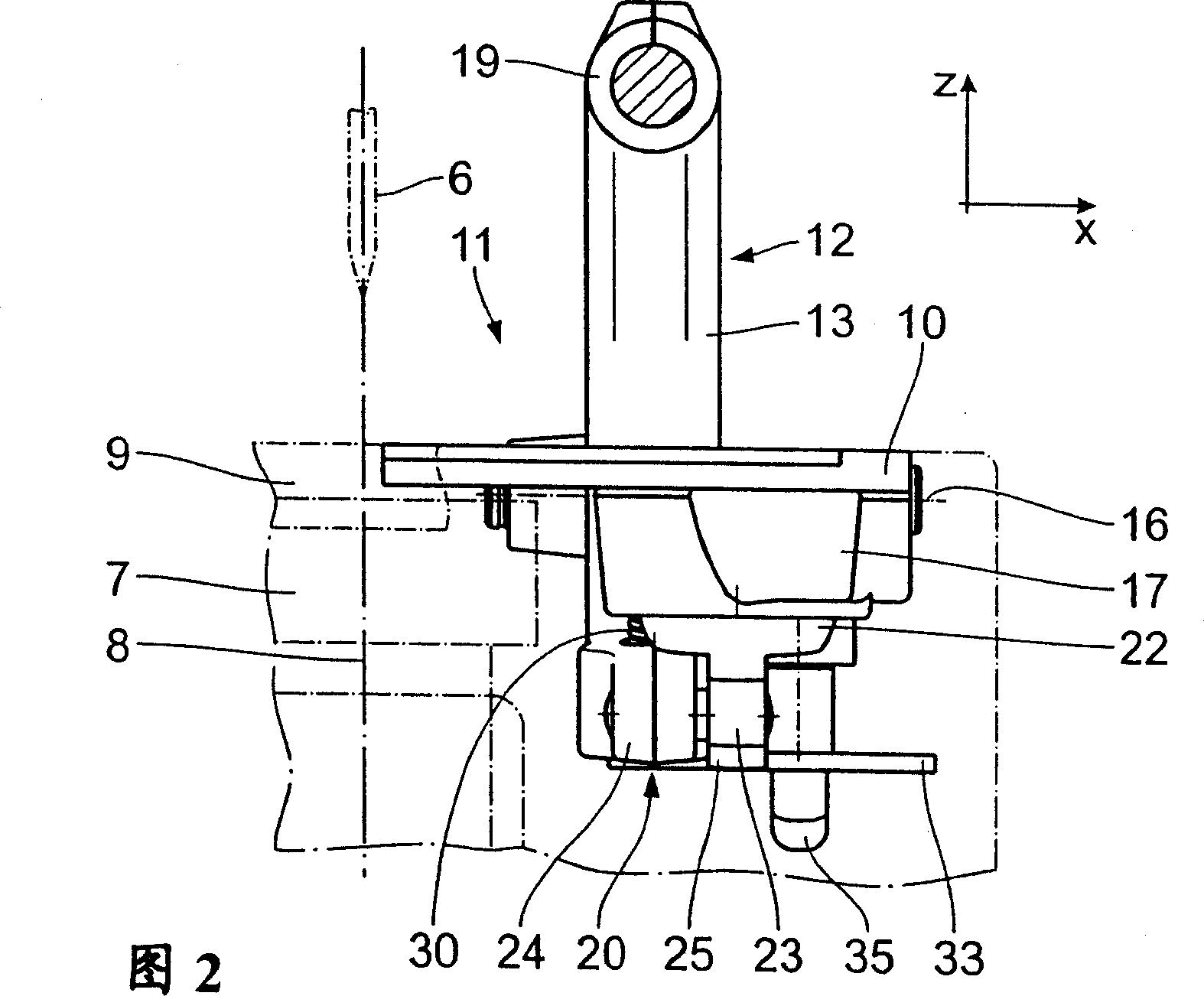

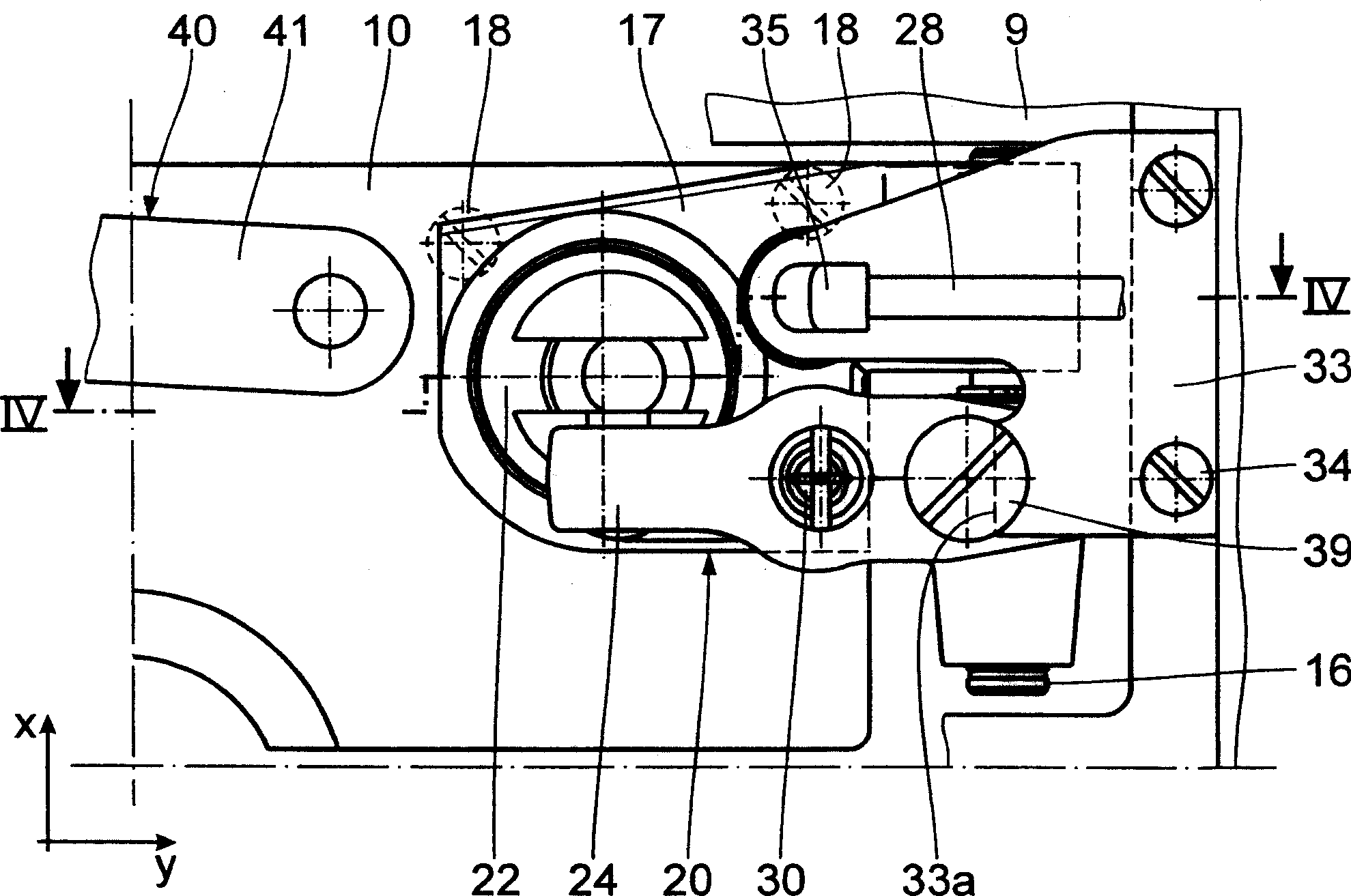

[0023] As shown in FIG. 1 , a buttonhole sewing machine with a round head is designed in a C shape, which has a top arm 1 , a shell-shaped bottom base plate 2 and an approximately vertical column 3 connecting the top arm and the bottom base plate. An arm shaft 4 is arranged in the arm 1 in a conventional manner; it can be driven by a drive motor (not shown). The drive for the needle bar 5 , which is movable vertically in the z direction and has a needle 6 , as well as its reciprocating / pivoting drive originate in the usual manner from the arm shaft 4 . Below the needle bar 5 and the needle 6 there is arranged in the base plate 2 a wire hook support 7 ; it can be driven to rotate about a vertical axis 8 . The drive for the wire hook support 7 originates from the arm shaft 4 in a conventional manner.

[0024] An x-y worktable 9 is arranged on the base plate 2; the worktable is a cross slide that can move along two horizontal coordinate directions, namely the x direction and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com