An independent smoke inlet integrated stove

An integrated stove and smoke inlet technology, which is applied in the field of integrated stoves, can solve the problems of affecting the smoke exhaust performance of integrated stoves, being unable to be adjusted by users, and inconvenient to use, etc., and achieving a simple structure, avoiding smokeless exhaust, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

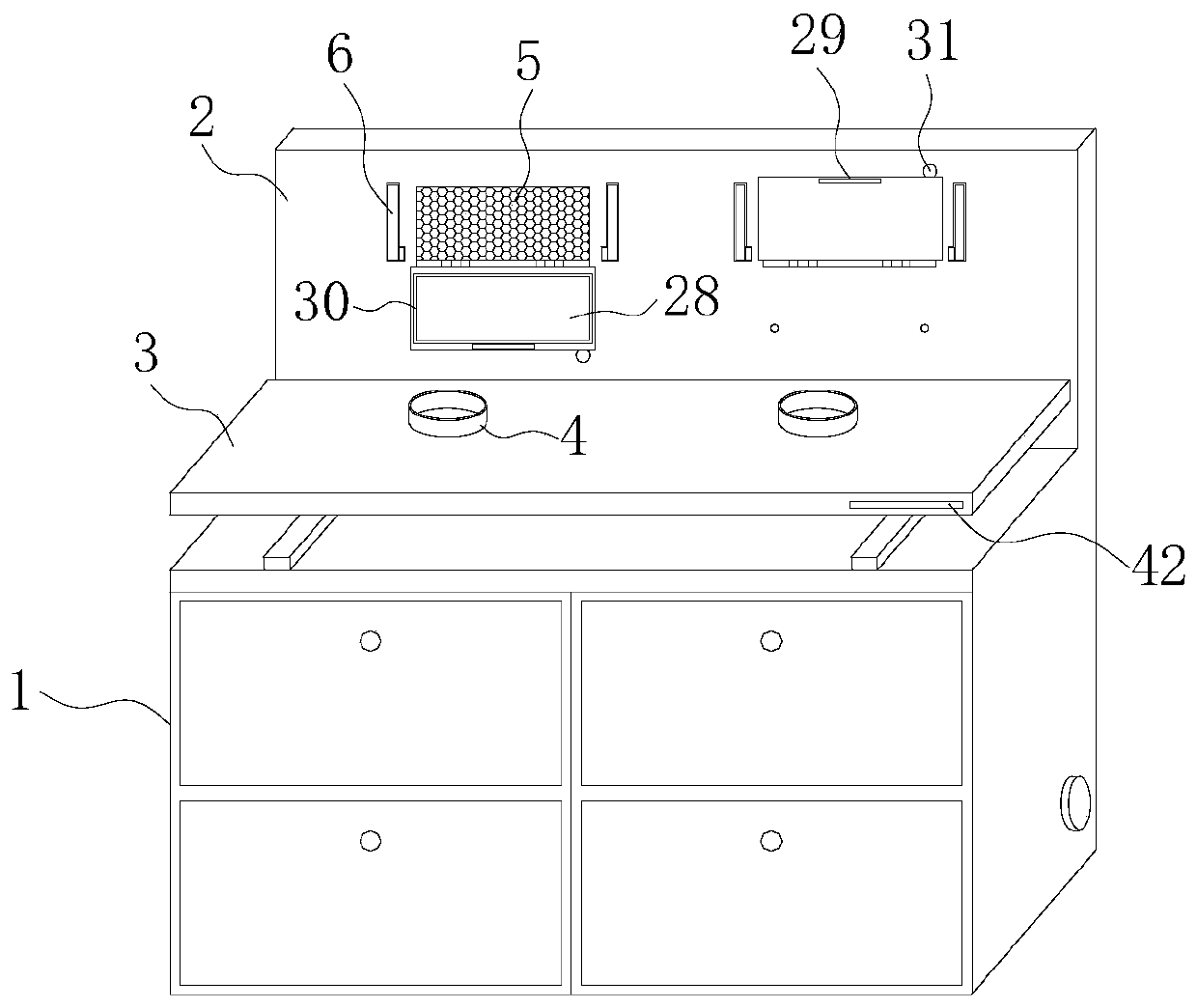

[0026] like Figure 1-10 Compared with the traditional integrated stove, the one shown is an integrated stove with independent smoke intake. The present invention also includes an integrated stove cabinet 1 and a smoke collecting hood 2 arranged on the upper rear side of the cabinet 1. Inside the cabinet 1, there is also a There is a smoke exhaust system composed of bellows, smoke exhaust fans, etc., and a functional partition system composed of disinfection cabinets, pot and bowl racks, etc., and the smoke collection hood 2 is connected with the smoke exhaust system for extracting oil fume. The top of the cabinet 1 is provided with a cooktop 3, and the cooktop 3 is provided with two burners 4, the burners 4 are used to place pots for cooking, and the gas pipelines of the burners 4 are connected to the gas source .

[0027] But the present invention compares with traditional integrated range, difference is: as figure 1 As shown, the front side of the smoke collecting hood 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com