Detection mechanism and detection method of the isolation ring of the manipulator

A detection mechanism and manipulator technology, applied in the direction of mechanical measuring devices, adopting mechanical devices, measuring devices, etc., can solve the problems of laborious accuracy and achieve the effect of good stability and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

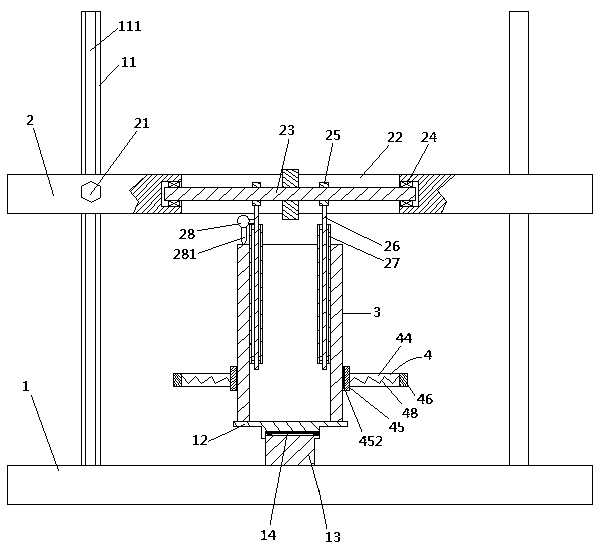

[0018] see figure 1 and figure 2 , a manipulator isolation ring detection mechanism, including a panel 1, a lifting plate 2 and a rubbing drive mechanism 4. At least two vertical sliding bars 11 are arranged on the panel. The upper end of the vertical slide bar 11 is pierced on the lifting plate. A locking groove 111 extending up and down is provided on the surface of a vertical slide bar. Lifting plate is threadedly connected with locking bolt 21. The locking bolt abuts against the locking groove to fix the lifting plate and the vertical slide bar together. A base 13 is fixedly connected to the panel. The base is rotatably connected with a tray 12 through a plane bearing 15 .

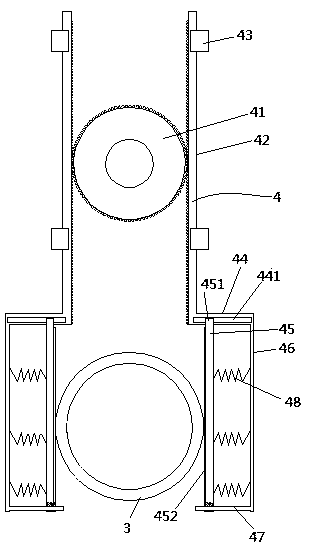

[0019] The rubbing drive mechanism 4 includes a vertical drive gear 41 and two opposite racks 42 engaged on the drive gear. The two ends of the rack are slidably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com