Method for recovering resistance value of magnetic core of common-mode inductor

A technology of common-mode inductance and impedance value, which is applied in the field of common-mode inductance core processing, can solve the problems of rework, waste, and substandard performance of core A, and achieve the effects of ensuring production efficiency, restoring impedance value, and avoiding rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

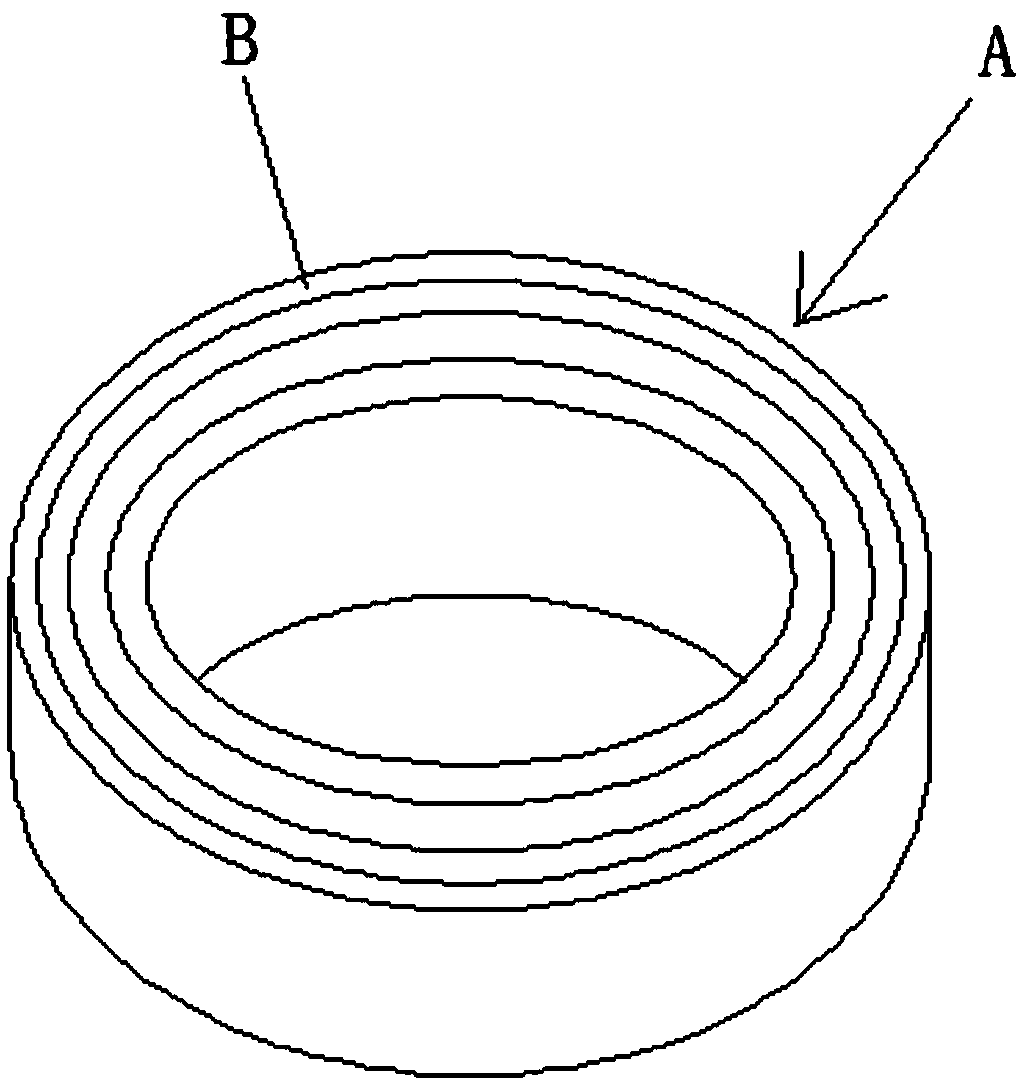

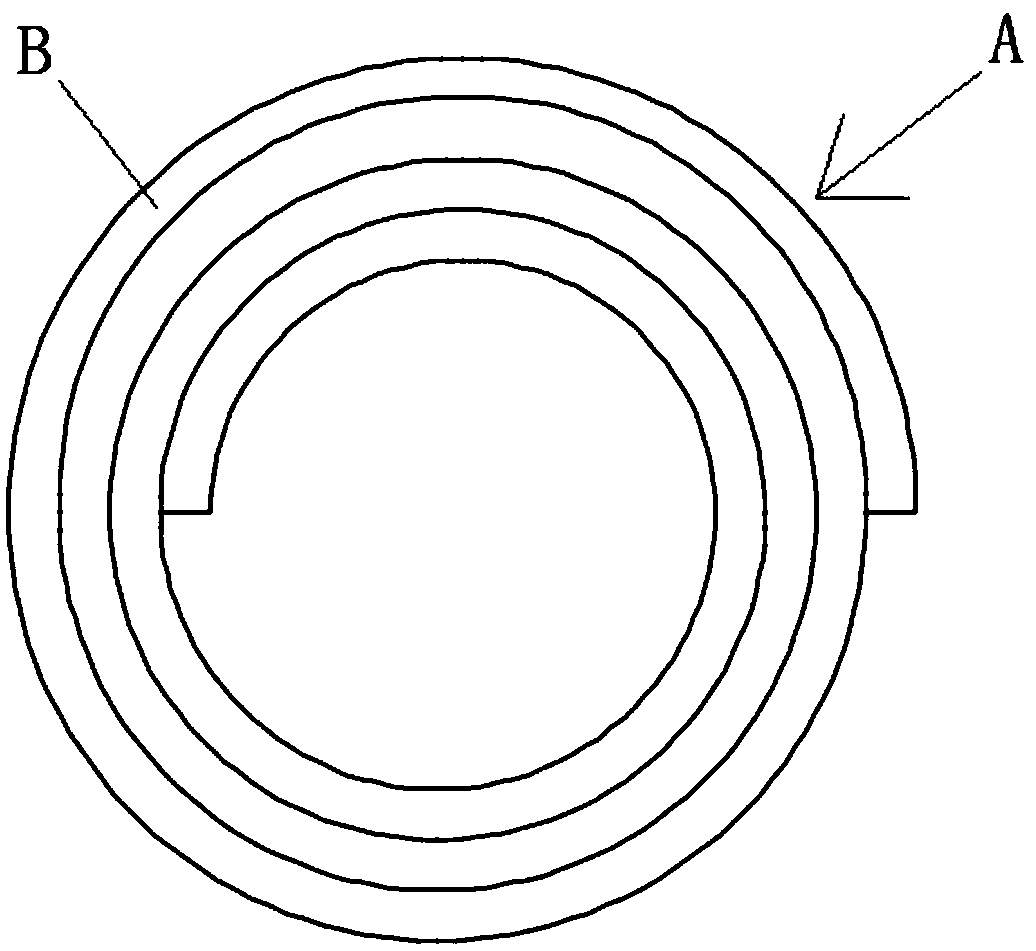

[0018] refer to Figure 1-2 A method for recovering the impedance value of a common-mode inductance magnetic core, the method is to process the magnetic core in a mechanical deformation manner within the elastic deformation range of the magnetic core, so that the stress of the magnetic core is released, and the magnetic core of the recovered impedance value is obtained.

[0019] One way to process the magnetic core is to radially extrude the magnetic core to deform it and then restore the original shape until the number of extrusions reaches the preset number of extrusions. The preset number of extrusions can be set according to the deviation of the impedance value , the position of each extrusion can be different to ensure that the core stress is fully released, and the extrusion process cannot destroy the solder joints on the outer layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com