Wheel adjusting device and four-direction carrying vehicle

A technology for adjusting devices and moving vehicles, which is applied in the field of transportation equipment in warehousing and logistics systems, which can solve the problems of large driving force and up and down movement of moving vehicles, and achieve the effect of avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

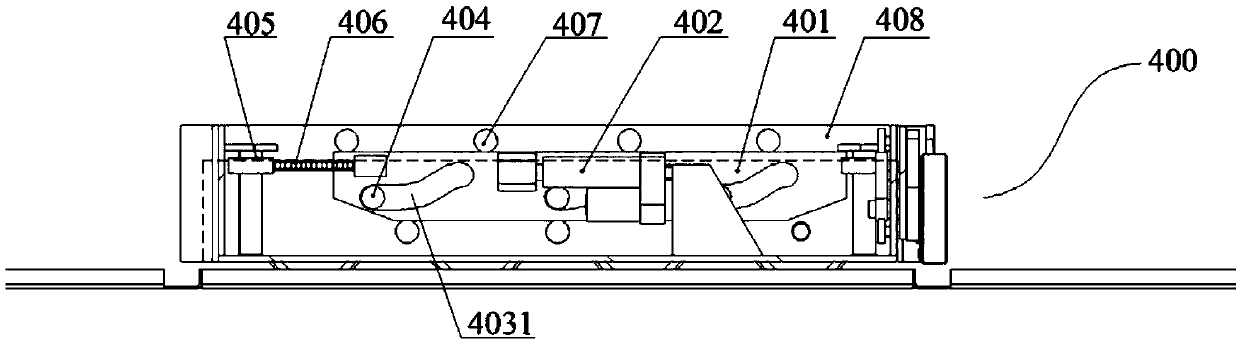

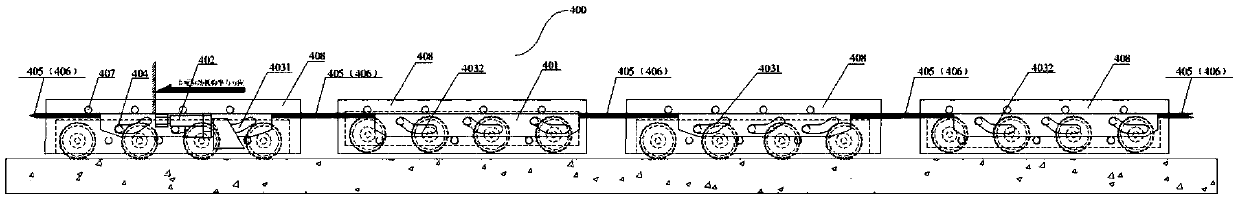

[0037] A wheel adjusting device 400 provided by the present invention, such as figure 2 and image 3 As shown, it includes a guide plate 401 and a height driving mechanism 402. The guide plate 401 is installed on the inner side of the side plate 408 of the four-way truck. The guide plate 401 is connected to the side plate 408 by sliding left and right. Slidingly connected with the wheel assembly 300 up and down, the movement of the guide plate 401 drives the movement of the wheel assembly 300, and the lifting track of the wheel assembly 300 is the same as the movement track of the guide plate 401, that is, the upward movement of the guide plate 401 drives the wheel assembly 300 to move upward, guiding The plate 401 moves downward, driving the wheel assembly 300 to move downward, the wheel assembly 300 on the opposite side moves in the same way, and the adjacent wheel assembly 300 moves in the opposite way, so as to realize the conversion of the direction of the four-way truck...

Embodiment 2

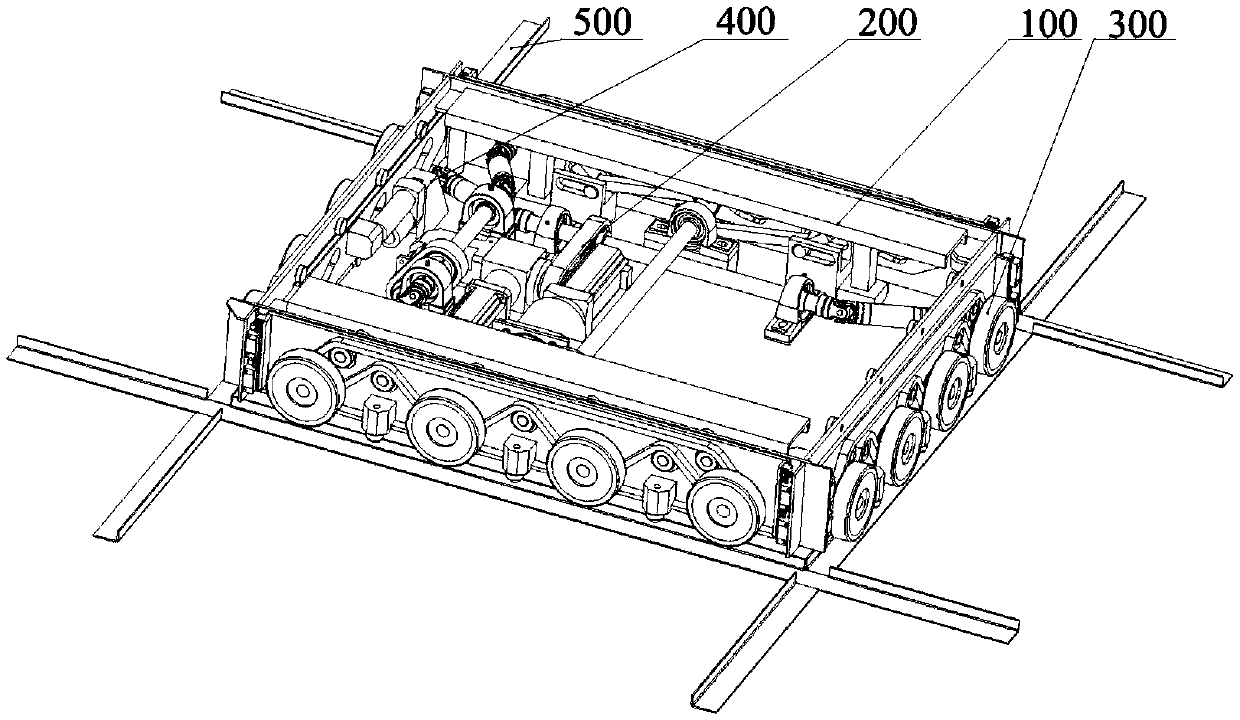

[0050] On the basis of Embodiment 1, this embodiment provides a four-way transport vehicle, such as figure 1 As shown, the above-mentioned wheel adjustment device 400 is included, and the wheel drive mechanism 200, the wheel assembly 300 and the square chassis are also included. The side plates 408 are installed on the outer sides of the upper surface of the square chassis to form a loading and unloading space. The wheel assembly 300 is installed under the square chassis. Around the surface, the wheel adjusting device 400 is correspondingly arranged with the wheel assembly 300, the wheel driving mechanism 200 is installed in the inside of the square chassis and the wheel driving mechanism 200 is drivingly connected with the wheel assembly 300 for driving the rolling of the wheel assembly 300 on the walking guide rail 500 .

[0051] This kind of four-way truck has the wheel adjusting device 400 of Embodiment 1. When the truck is turning to each other in the loading and unloadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com