Label receiving and aligning mechanism

A label and receiving device technology, which is applied in the direction of stacking receiving device, thin material handling, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of convenient grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

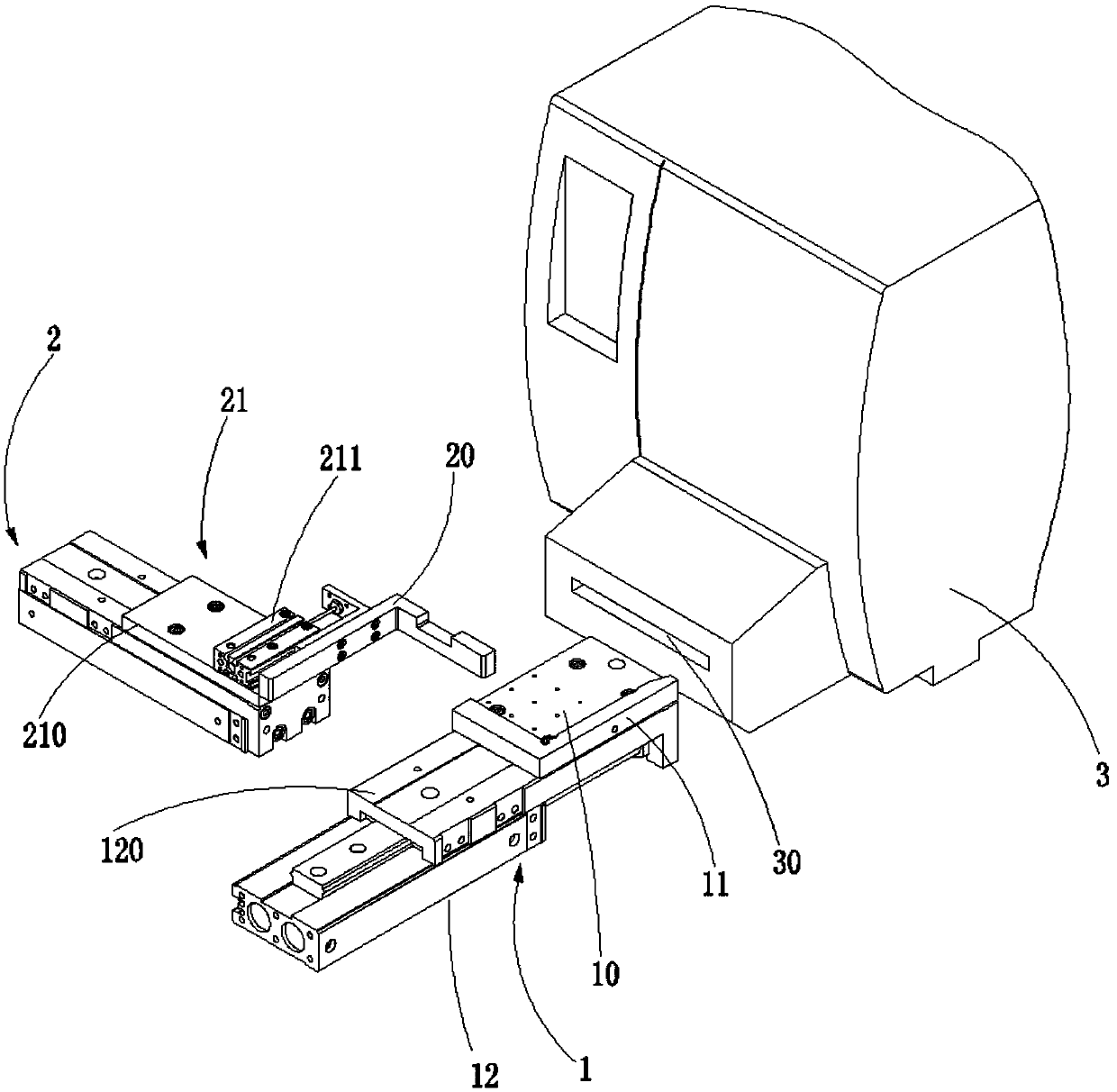

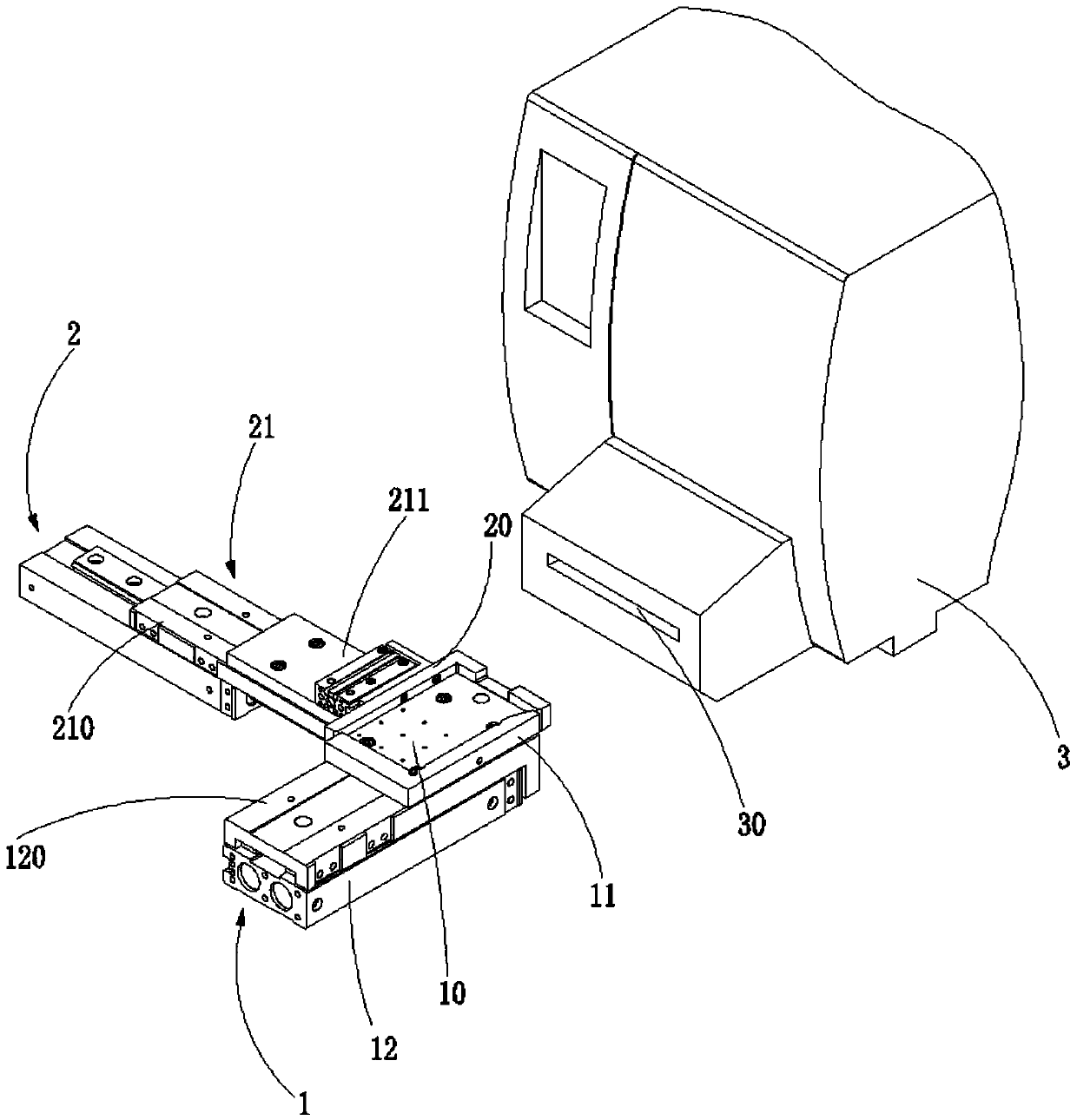

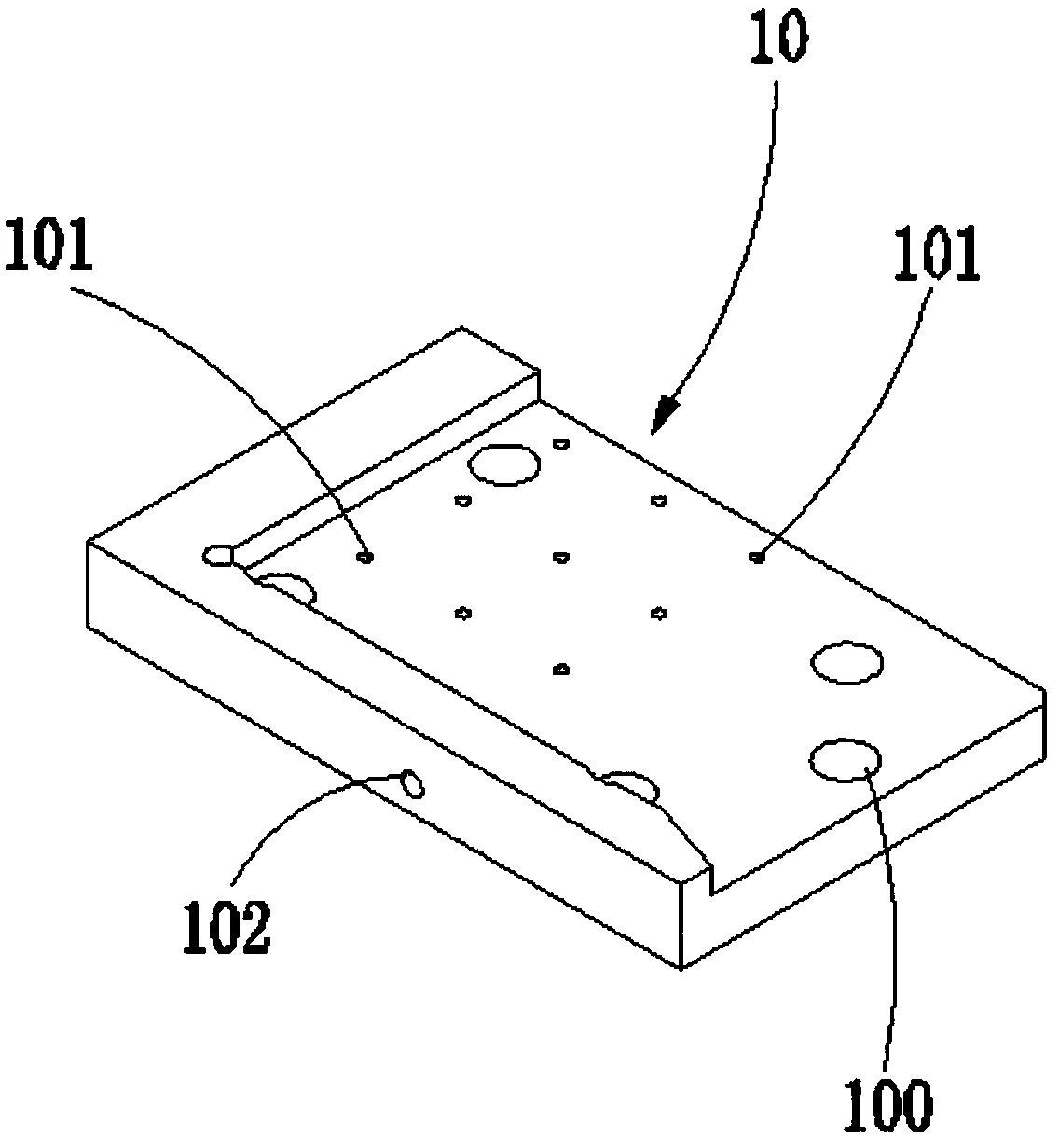

[0020] see Figure 1-4 , the embodiment of the present invention provides a label receiving and aligning mechanism, a receiving device 1 for receiving a label 4 printed by a printer 3 and an alignment device 2 for aligning the label 4, the receiving device 1 has a On the receiving platform 10 receiving the label 4, the receiving platform 10 is provided with a fence 11, and the alignment device 2 includes an alignment push plate 20 that can align the label 4 with the fence 11 and is used to drive the The first driving assembly 21 that aligns the push plate 20 to move horizontally and vertically. In this embodiment, the printer 3 prints a label 4 and cuts it out, and the receiving platform 10 of the receiving device 1 receives the label 4. The receiving platform 10 is provided with a fence 11 to prevent the label 4 from falling, and then The alignment push plate 20 of the alignment device 2 moves horizontally and vertically (gradually approaching the receiving platform 10). Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com