A construction method for double-sided excavation of pilot tunnels in tunnels

A construction method and technology for tunnels, which are used in tunnels, earth-moving drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with accompanying drawing.

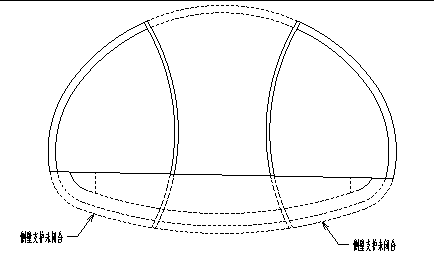

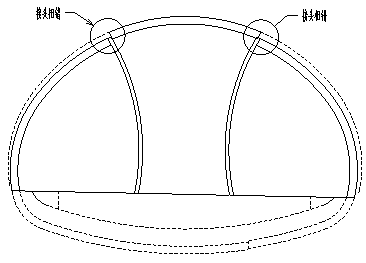

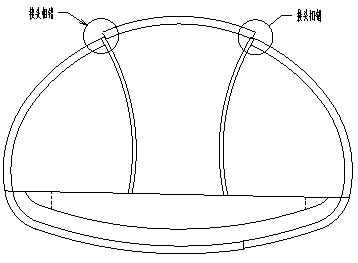

[0031] Such as Figure 4 , 5 As shown, the excavation width 4 of the central pilot tunnel 1 is generally not greater than the width of an ordinary two-lane or two-lane tunnel, and is determined according to the calculation of the "load-structure" model according to the full design load borne by the initial support; the excavation width of the side tunnel should be To meet the space required for the bolting operation of the tunnel system and the space required for the slag loading and transportation machinery; the intermediate pilot tunnel is constructed by the step method, and the maximum distance between the initial support and the face of the pilot tunnel should not be greater than 1.5 times the excavation width of the pilot tunnel; The pilot tunnel shall be constructed first, and the construction of the side tunnel shall start after the initial support is closed for more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com