High-efficiency drilling device for stone engraving

A drilling device and high technology, applied in the field of drilling devices for stone carving, can solve the problems of inability to guarantee drilling efficiency and inability to control the temperature at the drilling site in real time, so as to improve the effect and reliability, and improve the drilling efficiency. , the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

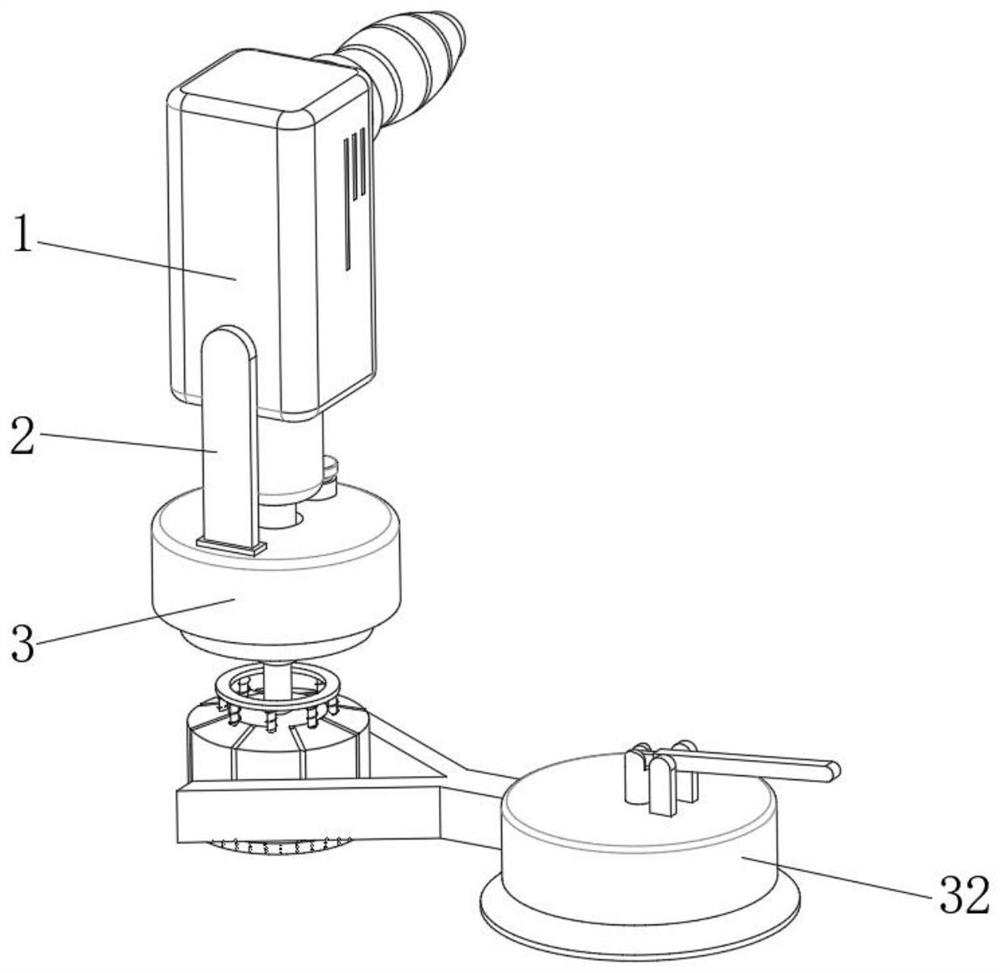

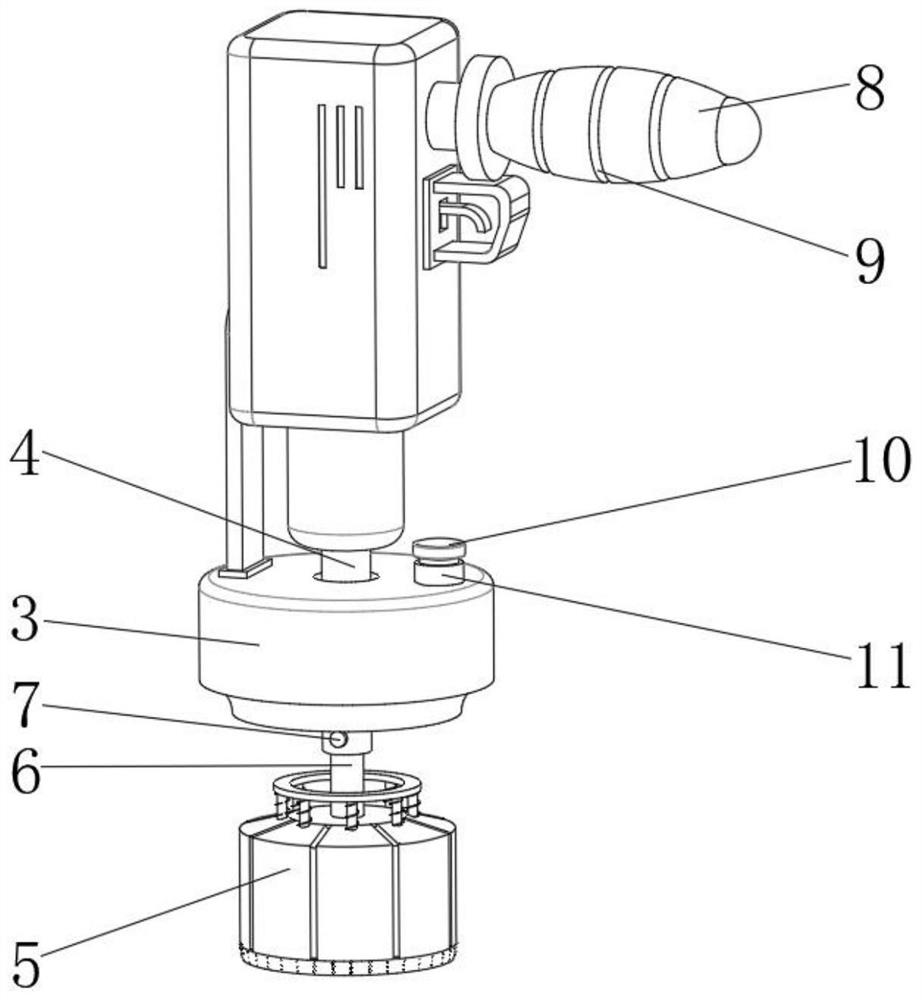

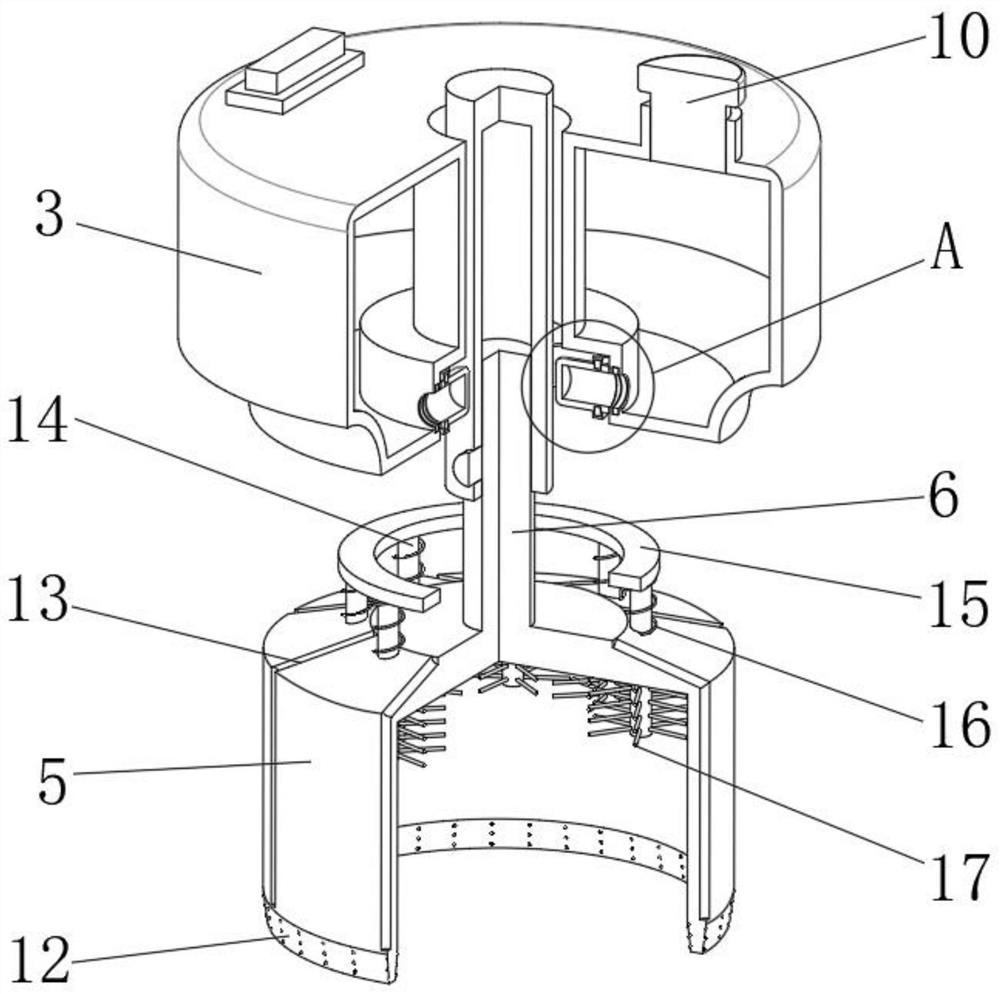

[0033] A more efficient drilling device for stone carving, such as Figure 1-6 As shown, it includes a drill main body 1 and a positioning mechanism 32. An output shaft 4 is provided on one side of the drill main body 1. The output shaft 4 is connected to a connecting shaft 6 through a fixed pin 7. The connecting shaft 6 passes through the fixed pin 7 and the output shaft. 4 After transmission, driven by the motor in the main body 1 of the drill, the outer wall of the bottom of the connecting shaft 6 is welded with an annular tool seat 5, and the outer wall of the bottom of the annular tool seat 5 is integrally provided with an annular drill 12. The main body of the drill gun 1 is The side outer wall is equipped with a water storage box 3 through the connecting frame 2, the water storage box 3 is located outside the output shaft 4, and the inner wall of the circumference of the water storage box 3 close to the output shaft 4 is integrally provided with a linkage rubber head 19,...

Embodiment 2

[0041] A more efficient drilling device for stone carving, such as figure 1 , Figure 5 As shown, in order to facilitate positioning; this embodiment makes the following improvements on the basis of Embodiment 1: the positioning mechanism 32 includes a positioning bracket 29 and a fixing seat 21, and the positioning bracket 29 is fixed to the outer wall of the side of the fixing seat 21 by screws. The shape of the bracket 29 is adapted to the annular knife seat 5, and the bottom of the fixed seat 21 is bonded with a suction cup 28; by setting the positioning bracket 29, the fixed seat 21 and other structures, the annular knife seat 5 can be limited, thereby improving the accuracy of drilling. Spend.

[0042] In order to further improve the positioning effect; such as Figure 5 As shown, the inner wall of the bottom of the fixed seat 21 is sealed and movable connected with a lifting plug 27, and the outer wall of the top of the lifting plug 27 is fixed with a lifting rod 22 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com