Conveying line for molding and shaping hard outer packages

A technology of outer packaging and conveying line, applied in packaging and other directions, can solve the problems of heavy workload of operators, unreliable guarantee of efficiency and quality of plastic boxes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

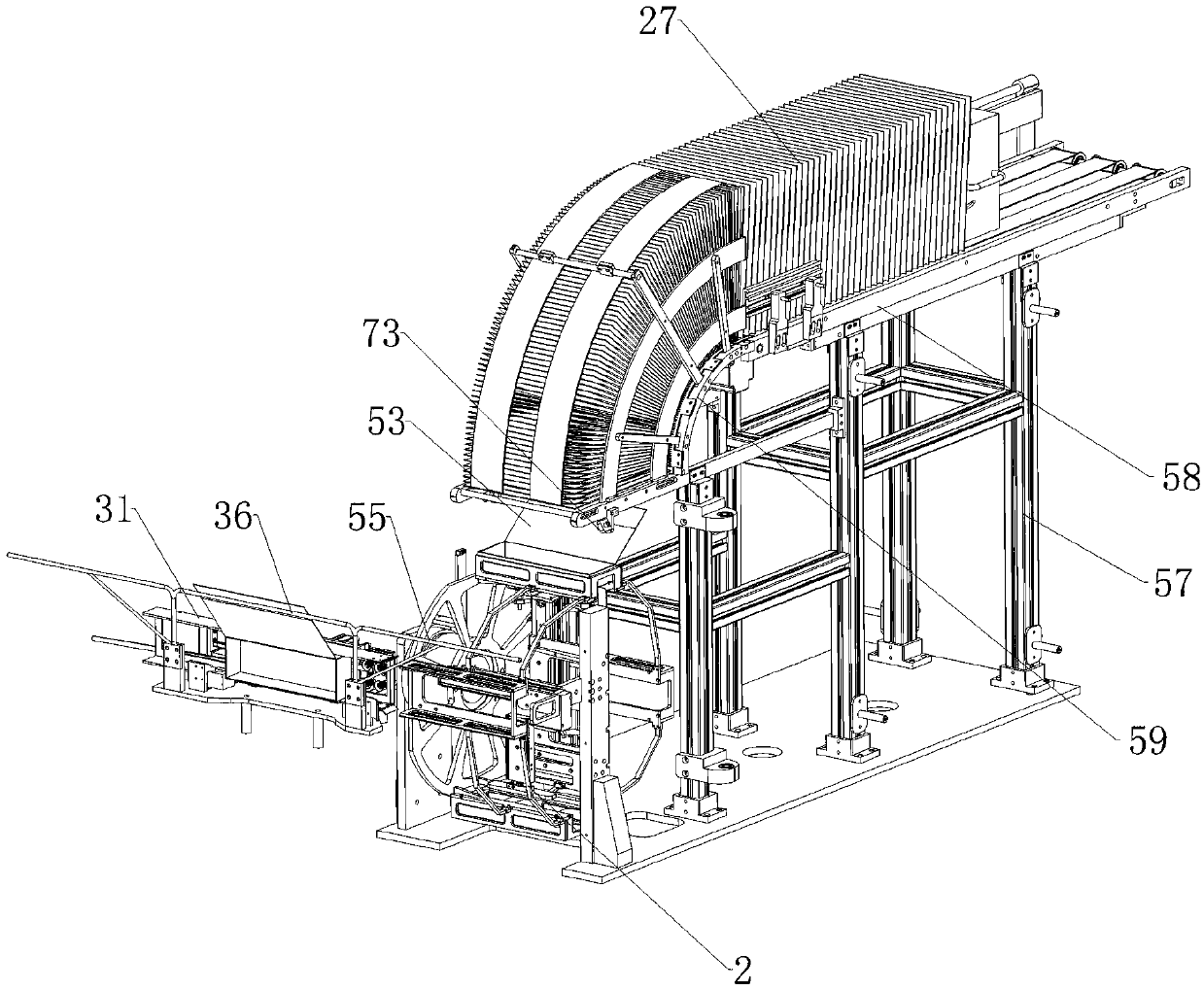

[0085] Such as Figure 1 to Figure 15 As shown in the figure, the conveyor line used for shaping and shaping rigid outer packaging includes a plastic box feeding unit, a shaping unit and a shaping unit;

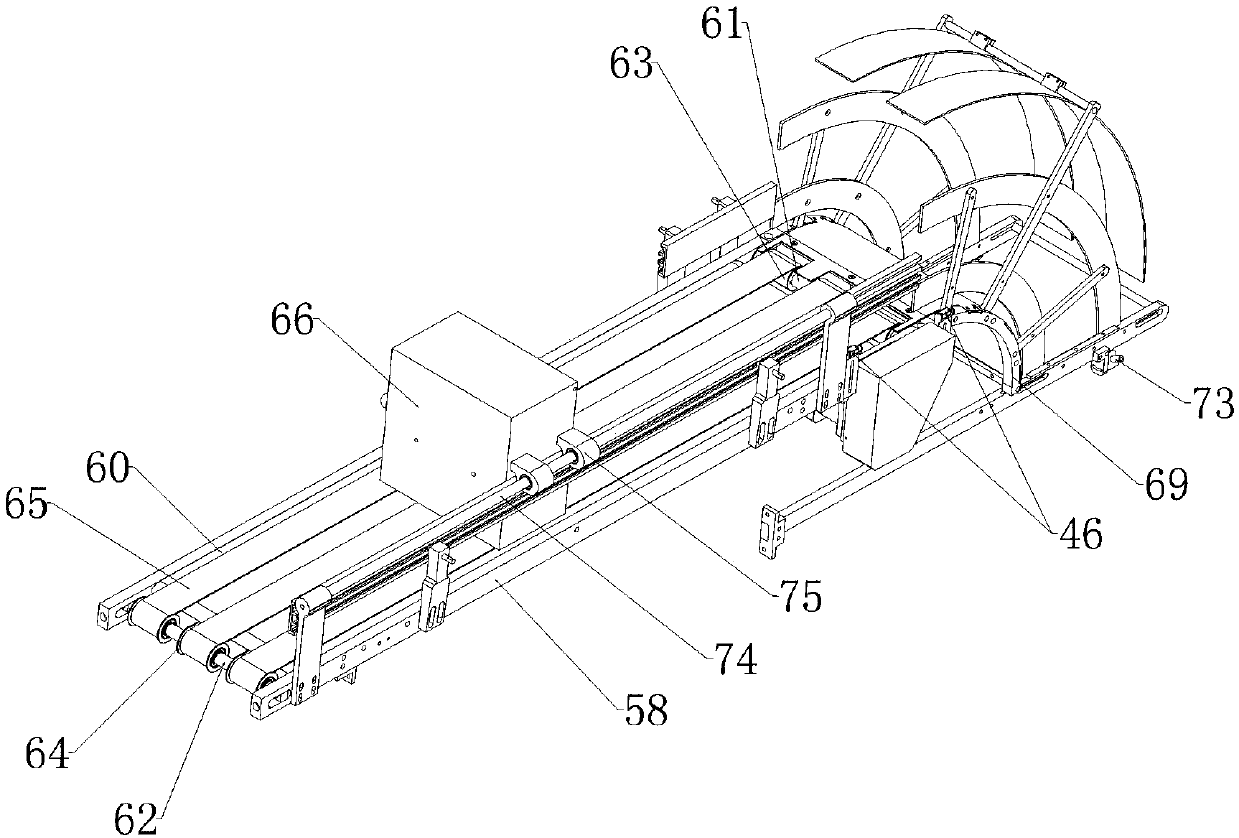

[0086] The plastic box feeding unit comprises a plastic box feeding rack 58 and a bogie 59, the plastic box feeding rack 58 is provided with a feeding endless belt 65, a feeding support plate 60 for supporting the feeding endless belt 65 and a In order to drive the plastic box transmission drive assembly driven by the feeding endless belt 65, the feeding support plate 60 is also provided with a counterweight 66 placed on the feeding endless belt 65, and the bogie 599 has a vertically arranged feeding The material input port 67 and the material supply output port 68 that is horizontally arranged, the opening area of the supply material output port 68 is smaller than the opening area of the supply material input port 67;

[0087] The molding unit includes a rotary frame 2 ...

Embodiment 2

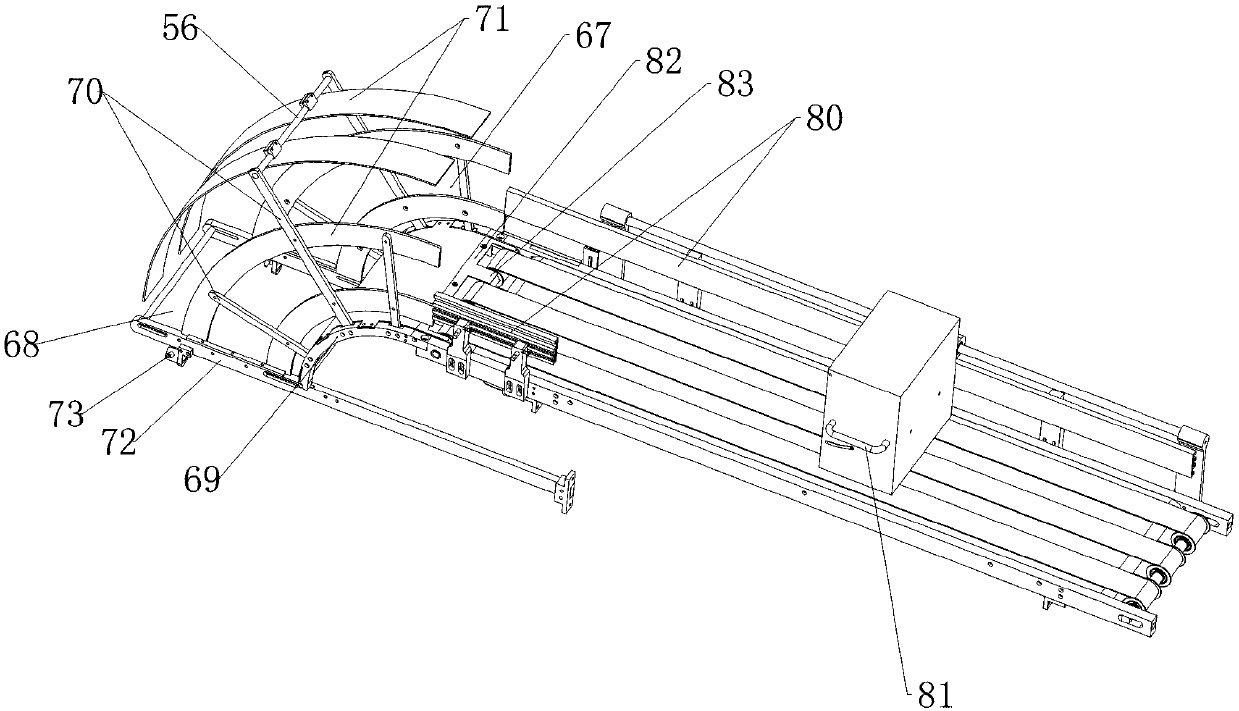

[0091] This embodiment makes the following further limitations on the basis of Embodiment 1: the top of the plastic box mold has a concave molding cavity 4, and the bottom end of the plastic box mold is provided with a plastic sucker communicating with the molding cavity 4 Inlet 5, the left end of the plastic box mold is provided with a molding push rod inlet 6 communicating with the molding cavity 4, and the right end of the plastic box mold is provided with a molding outlet 7 communicating with the molding cavity 4;

[0092] The output end of the plastic sucker frame driving device 10 is connected with a plastic suction cup frame 8, the plastic suction cup frame 8 is provided with the plastic suction cup 11, and the plastic suction cup frame driving device 10 acts on the plastic suction cup frame 8, The plastic suction cup 11 can pass through the plastic suction cup inlet 5 of the highest plastic box mold among several plastic box molds, and can move up and down relative to t...

Embodiment 3

[0096] This embodiment makes the following further limitations on the basis of Embodiment 2: the inlet 6 of the molding push rod communicates with the inlet 5 of the molding suction cup;

[0097] The molding push rod 13 has a pushing section 14 that can pass through the molding push rod inlet 6 and move in the molding suction cup inlet 5 .

[0098] In this embodiment, in order to reduce the weight of the plastic push rod 13 , the push section 14 may be provided with a plastic push rod hollow 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com