Cigarette outer package changing system

A technology for outer packaging and cigarettes, applied in the directions of packaging, packaging cigarettes, transportation and packaging, etc., can solve the problems of lack of aesthetics in packaging design, unreliable guarantee of work efficiency and quality, and easy deformation of cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

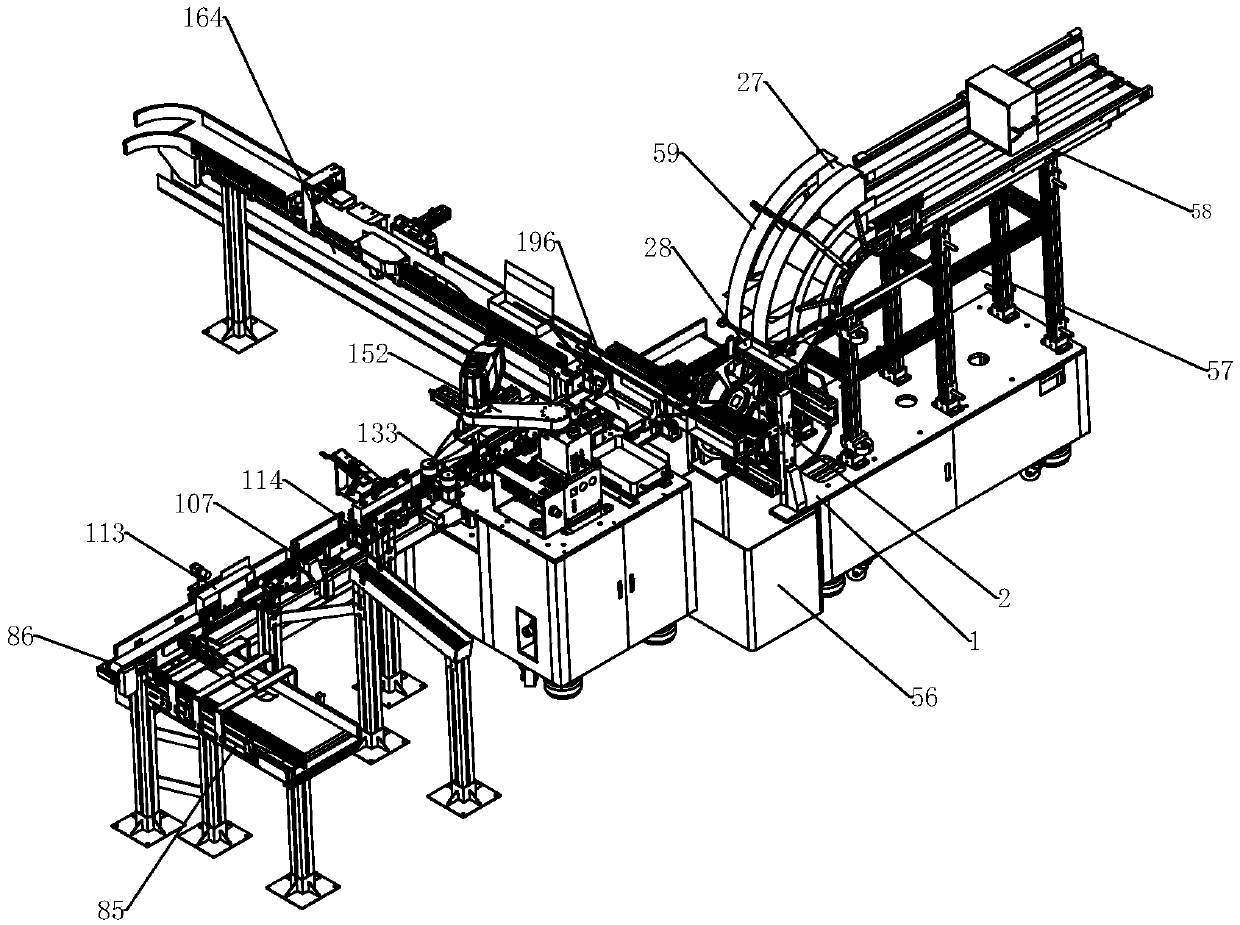

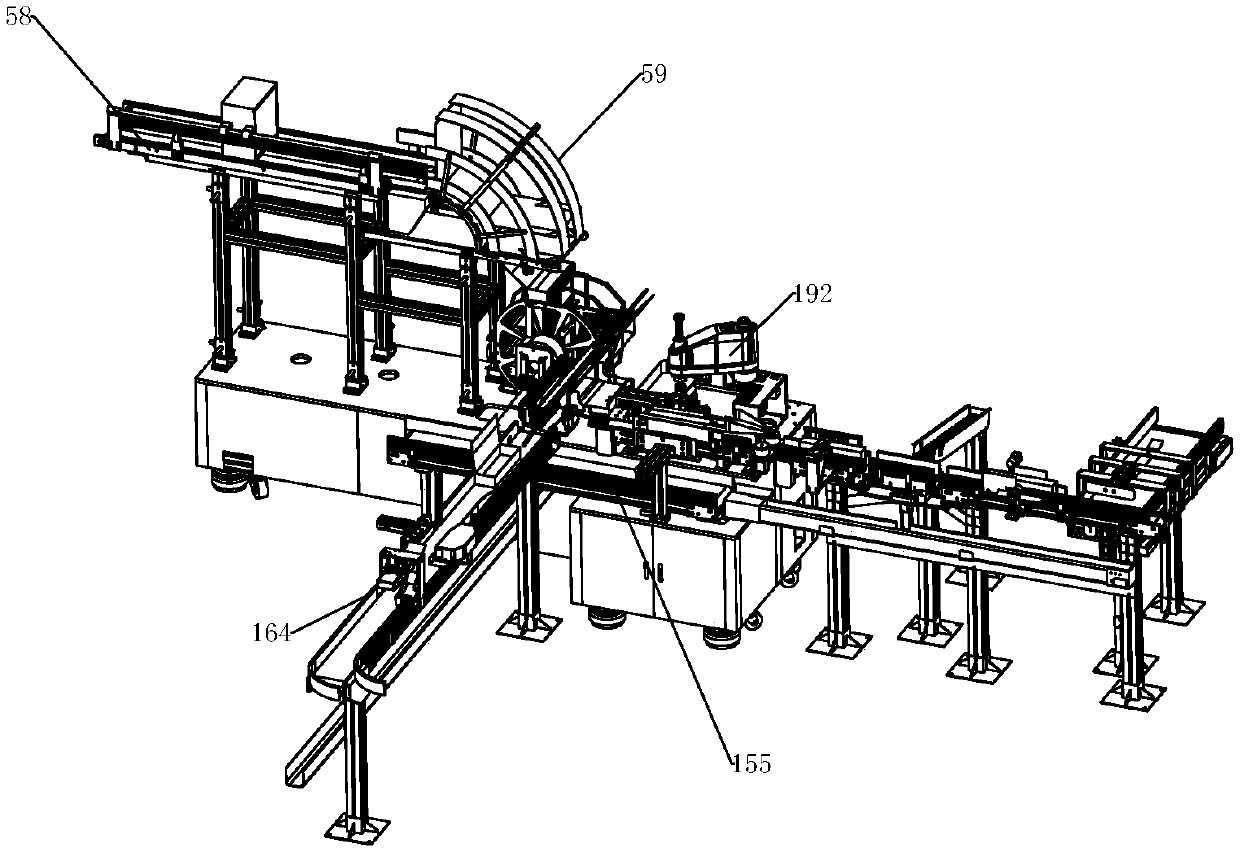

[0101] like Figure 1 to Figure 39 As shown, the cigarette outer packaging replacement system includes a hard outer packaging plastic box transmission line, a soft outer packaging tear-off lid separation transmission line, a cigarette box packing unit and a hard outer packaging closed box transmission line;

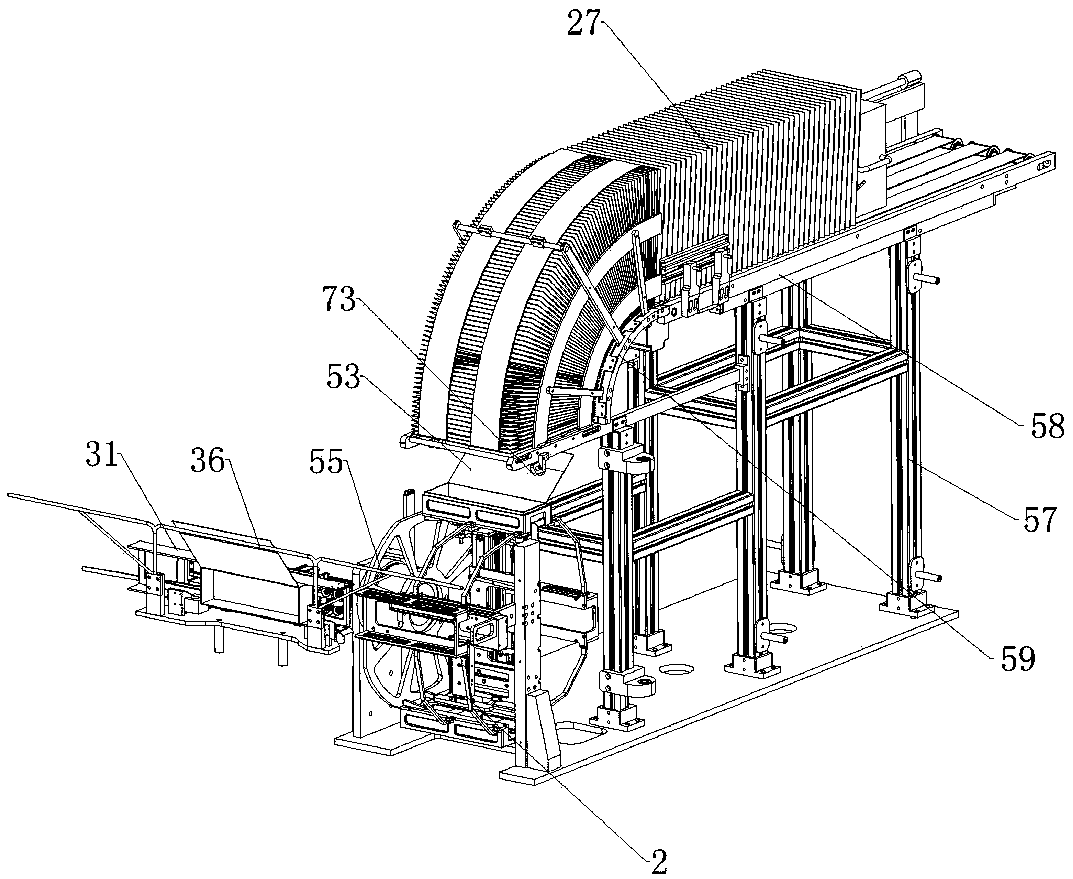

[0102] The hard outer packaging plastic box transmission line includes a plastic box feeding unit, a molding unit and a shaping unit; the plastic box feeding unit includes a plastic box feeding frame 58 and a bogie 5, and the plastic box feeding frame 58 is provided with a feeding Endless belt 65, be used to support the feeding support plate 60 of feeding endless belt 65 and be used to drive the plastic box conveying drive assembly of feeding endless belt 65 transmission, also be provided with on the feeding supporting plate 60 and be placed on for supplying The counterweight 66 on the material endless belt 65, the bogie 59 has the feed inlet 67 that is vertically arrange...

Embodiment 2

[0128] This embodiment makes the following further limitations on the basis of Embodiment 1: the top of the plastic box mold has a concave molding cavity 4, and the bottom end of the plastic box mold is provided with a plastic sucker communicating with the molding cavity 4 Inlet 5, the left end of the plastic box mold is provided with a molding push rod inlet 6 communicating with the molding cavity 4, and the right end of the plastic box mold is provided with a molding outlet 7 communicating with the molding cavity 4;

[0129] The output end of the plastic sucker frame driving device 10 is connected with a plastic suction cup frame 8, the plastic suction cup frame 8 is provided with the plastic suction cup 11, and the plastic suction cup frame driving device 10 acts on the plastic suction cup frame 8, The plastic suction cup 11 can pass through the plastic suction cup inlet 5 of the highest plastic box mold among several plastic box molds, and can move up and down relative to t...

Embodiment 3

[0151] This embodiment makes the following further limitations on the basis of Embodiment 1: the front end of the shaping frame 31 is concaved with a shaping groove 33, the rear end of the shaping frame 31 is provided with a shaping opening 32 communicating with the shaping groove 33, and the shaping frame The left and right ends of 31 are respectively provided with a sizing feed inlet 34 and a sizing discharge port 35, the sizing feed inlet 34 and the sizing discharge port 35 are all communicated with the sizing frame 31, and the sizing feed inlet 35 can be connected with several plastic box moulds. The molding outlet 7 of the plastic box mould, which is located at the front end, is connected;

[0152] Described stereotyped suction cup drive assembly comprises stereotyped connecting frame driving device 40 and the stereotyped suction cup frame driving device 37 that is connected at the output end of stereotyped connecting frame driving device 40, and the output end of stereoty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com