Automatic zero point tracking algorithm against zero drift of sensor

A tracking algorithm and sensor technology, which is applied in the field of sensor calibration, can solve problems that affect the accuracy of wheel axle identifiers and rarely track zero points, and achieve the effects of accurate identification, elimination of influence, and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

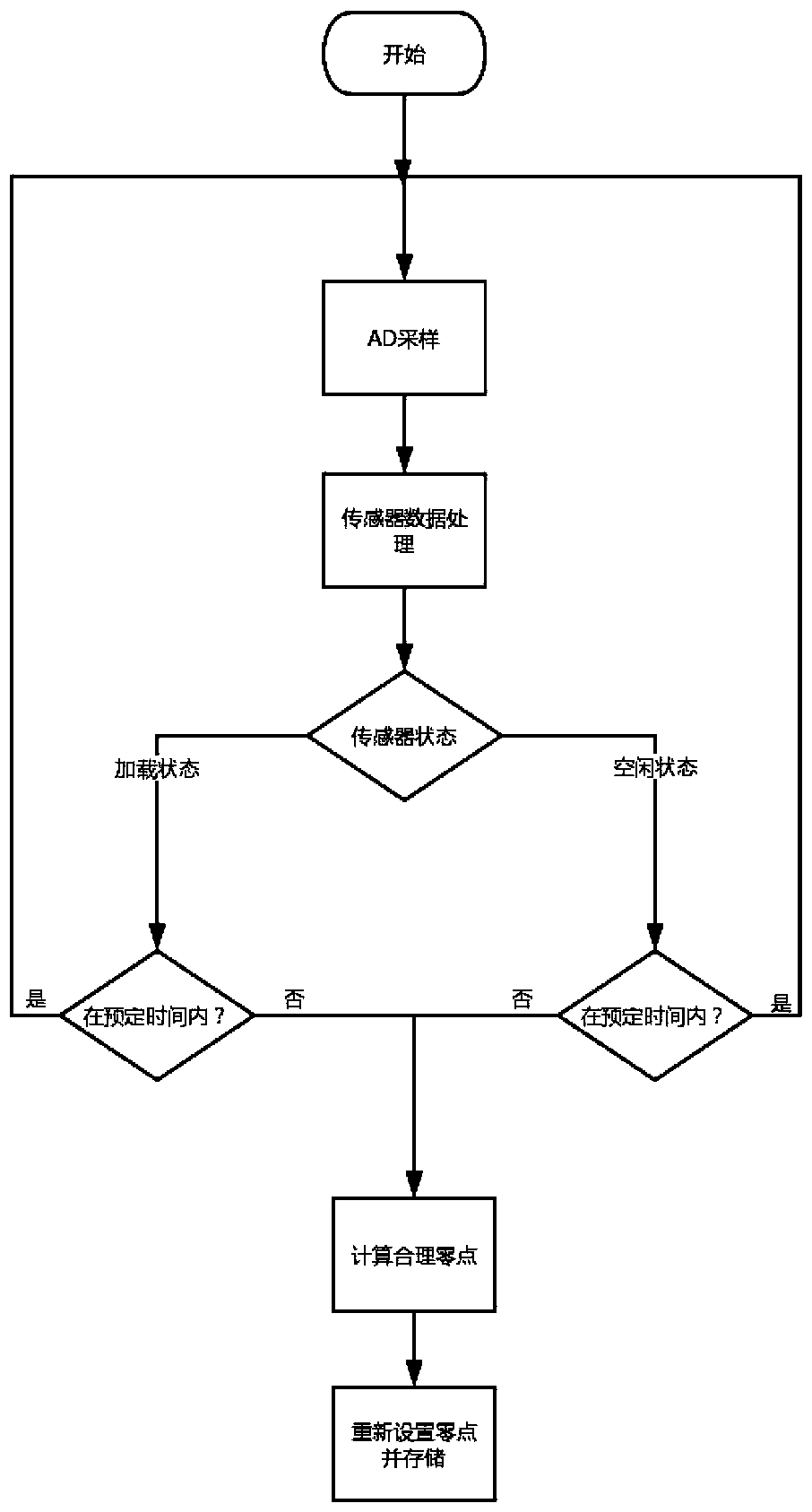

[0009] as attached figure 1 As shown, an automatic zero point tracking algorithm for suppressing sensor zero drift includes the following steps:

[0010] Step 1, collect the real-time AD value of the piezoelectric sensor with pressure point structure and perform data processing, and judge the current state of the piezoelectric sensor as a loading state or an idle state;

[0011] Step 2, judging whether the duration of the current state of the piezoelectric sensor exceeds a predetermined time value;

[0012] Step 3, if the duration of the current state exceeds the predetermined time value, trigger the zero point tracking program, calculate the current zero point value, correct and store it, otherwise return to step 1.

[0013] The invention can realize the self-adaptation of the zero point drift, automatically start the zero point tracki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com