Dish washing machine for daily life

A technology of daily life and dishwasher, which is applied in the washing machine/rinsing machine of tableware, parts and applications of washing machine/rinsing and rinsing machine of tableware, etc. It can solve the problems of incomplete cleaning of the back of tableware and waste of water resources, etc. Achieve the effect of facilitating secondary utilization and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

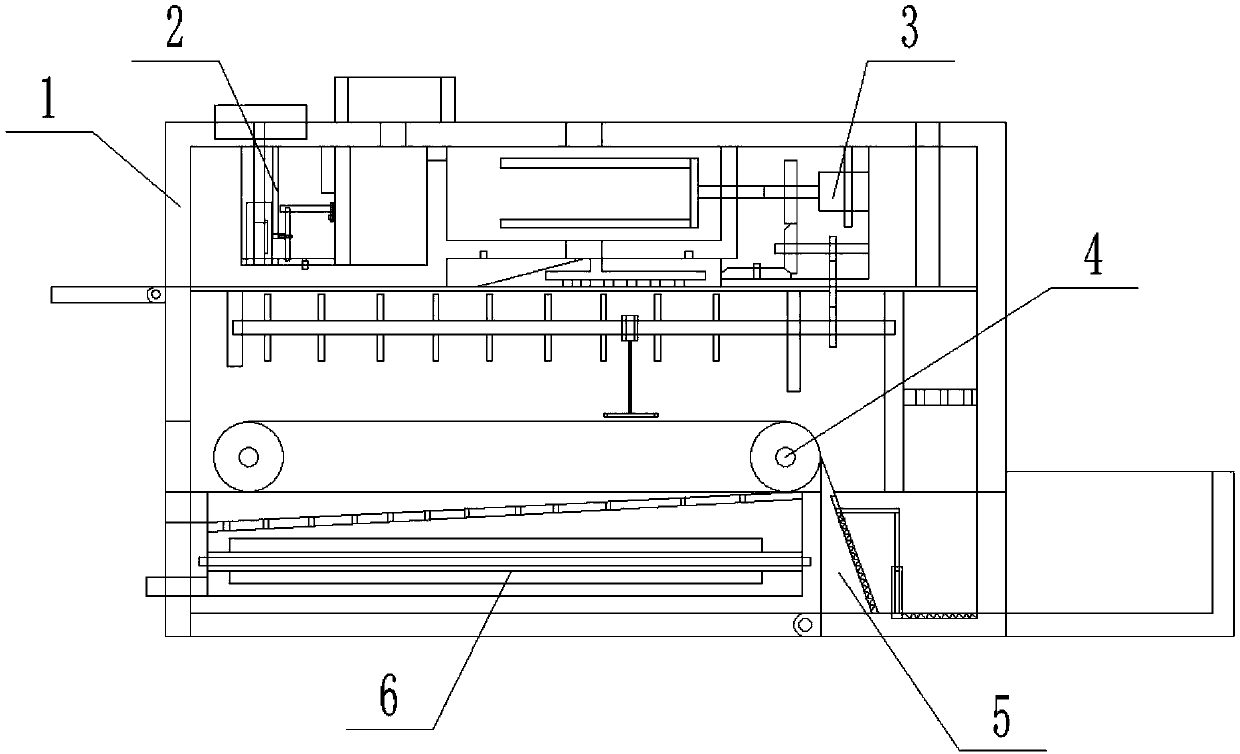

[0034] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 illustrate this embodiment. The present invention relates to a dishwasher, more specifically a dishwasher for daily life, including a shell 1. Extruding device 2, power device 3, conveyor belt 4, shock absorbing device 5, filter device 6, stepping motor 7, not only can squeeze out dishwashing liquid, but also can automatically turn over plates, bowls and other tableware, and can also filter water , It is convenient for the secondary utilization of waste water and saves water resources.

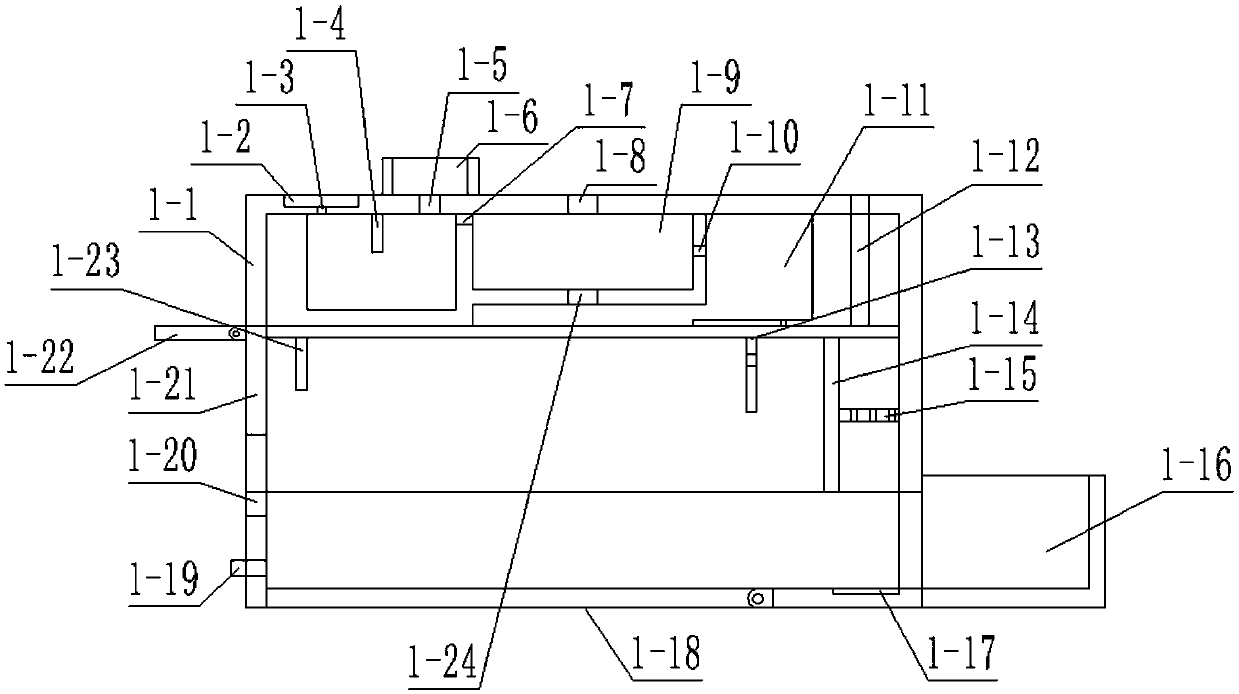

[0035] The shell 1 is composed of a shell body 1-1, a circular groove 1-2, a through hole I1-3, a baffle plate I1-4, a liquid inlet 1-5, a cylinder 1-6, a through hole II1-7, and a water inlet Ⅰ1-8, water tank 1-9, shaft hole 1-10, power chamber 1-11, water inlet Ⅱ1-12, baffle Ⅱ1-13, baffle Ⅲ1-14, filter plate 1-15, collection tank 1-16 , chute 1-17, door I 1-18, plug 1-19, slag outlet 1-20, feed inlet 1-21, door II 1-2...

specific Embodiment approach 2

[0045] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 illustrate this embodiment, and this embodiment further describes Embodiment 1, and the side of the conveyor belt 4 is connected with a stepping motor 7 .

specific Embodiment approach 3

[0046] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The upper left reservoir is the same depth.

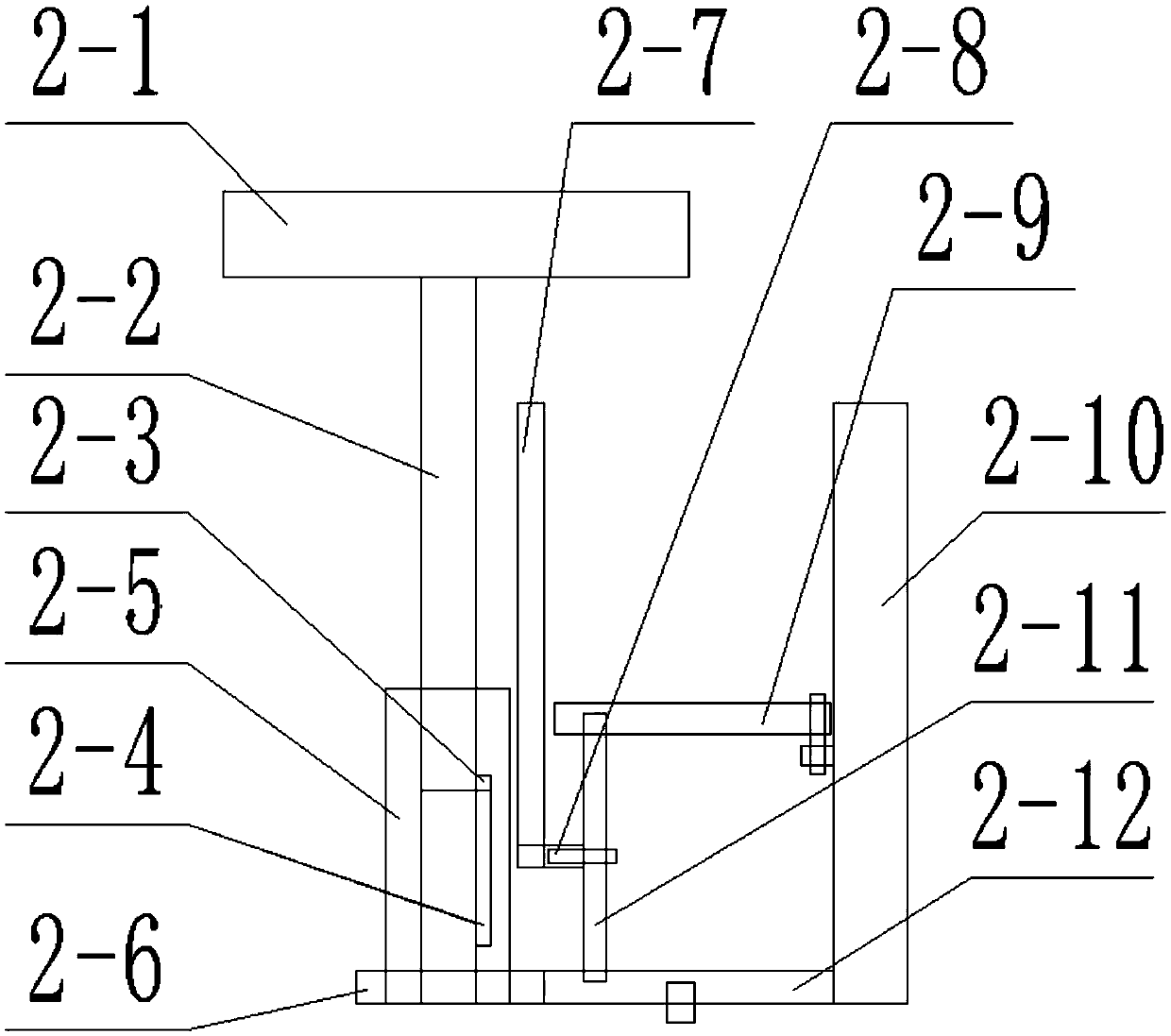

[0047] The working principle of the present invention is: when using this device to wash dishes, first turn the knob 2-1, the knob 2-1 drives the connecting rod I2-2 to rotate, the connecting rod I2-2 drives the cylinder 2-4 to rotate, and the cylinder 2 -4 drives gear Ⅰ2-6 to rotate, gear Ⅰ2-6 drives gear Ⅱ2-12 to rotate, gear Ⅱ2-12 drives connecting rod Ⅲ2-11 to rotate, connecting rod Ⅲ2-11 drives connecting rod Ⅱ2-9 to move, connecting rod Ⅱ2-9 Push the push plate 2-10 to move to the right, squeeze the dishwashing liquid in the liquid storage tank into the water tank 1-9 through the through hole II 1-7, and the upper end of the fixing rod 2-7 is fixedly connected in the shell main body 1-1, The telescopic rod 2-8 can fix the connecting rod Ⅲ 2-11 to prevent it from deflecting;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com