Water flow garbage collecting structure of small-size water channel

A technology of garbage collection and water channel, applied in the field of water channel, can solve the problems such as the inability of the garbage collection device to facilitate the flow of water, the inconvenience of the use of the garbage collection device, the uncontrollable flow velocity of the water flow in the water channel, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

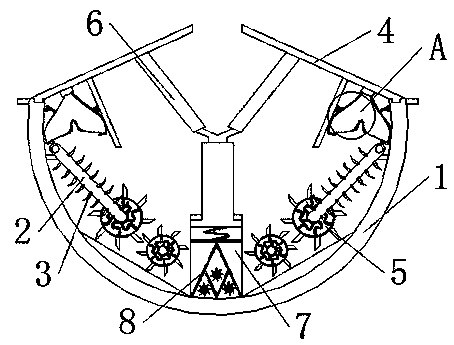

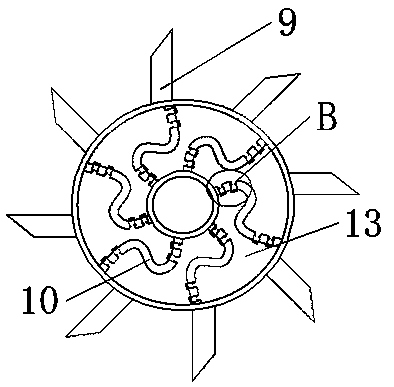

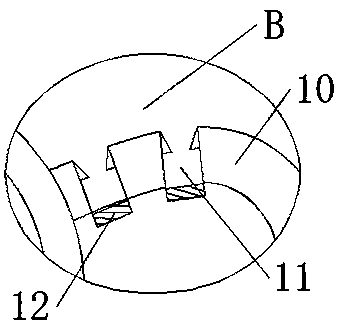

[0029] Embodiment: A small water canal water flow garbage collection structure, including a water canal 1, conveying crawlers 2 are provided on both sides inside the canal 1, fixed hooks 3 are evenly distributed on the outside of the conveying crawler 2, and bearings 5 are rotated on one side of the conveying crawler 2 , the outer side of the bearing 5 is provided with a tooth piece 9, the inside of the bearing 5 is distributed with a connecting rod 10, the outer side of the connecting rod 10 runs through a water channel 13, the inside of the connecting rod 10 runs through a water port 11, and one side of the water port 11 is movable There is a movable cover 12, the other side of the conveying track 2 corresponds to a collection bag 15, the inside of the collection bag 15 has an inlet 16, one side of the collection bag 15 is nested with a fixed plate 17, and the upper end of the collection bag 15 is movable A movable plate 4 is nested, and one end of the movable plate 4 is el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com