Comb-tooth-type vertical lifting garage

A vertical lift and comb technology, which is applied in the field of comb vertical lift garages, can solve the problems such as the inability to install the conductive sliding line and the inability to supply power to the garage tray.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

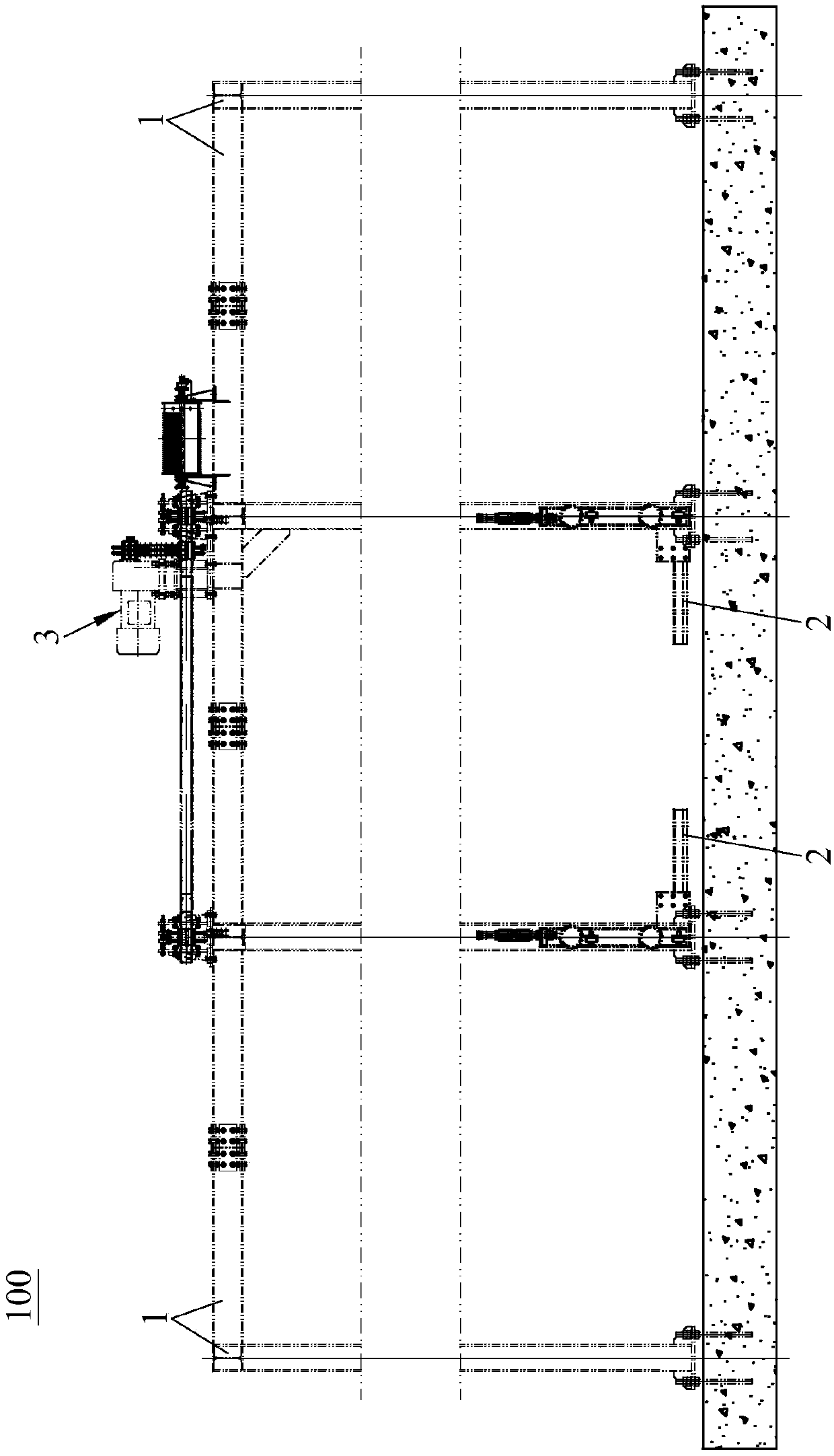

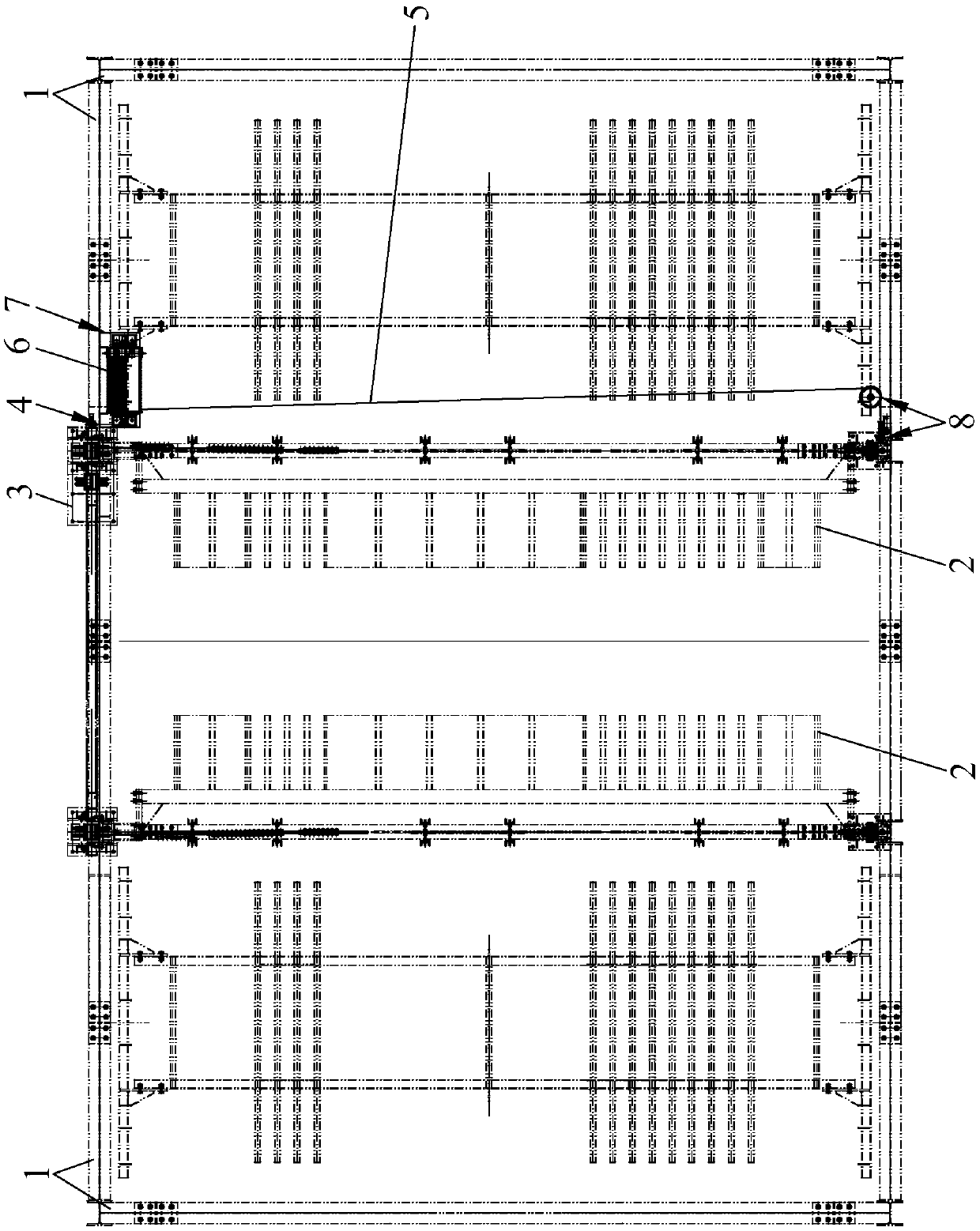

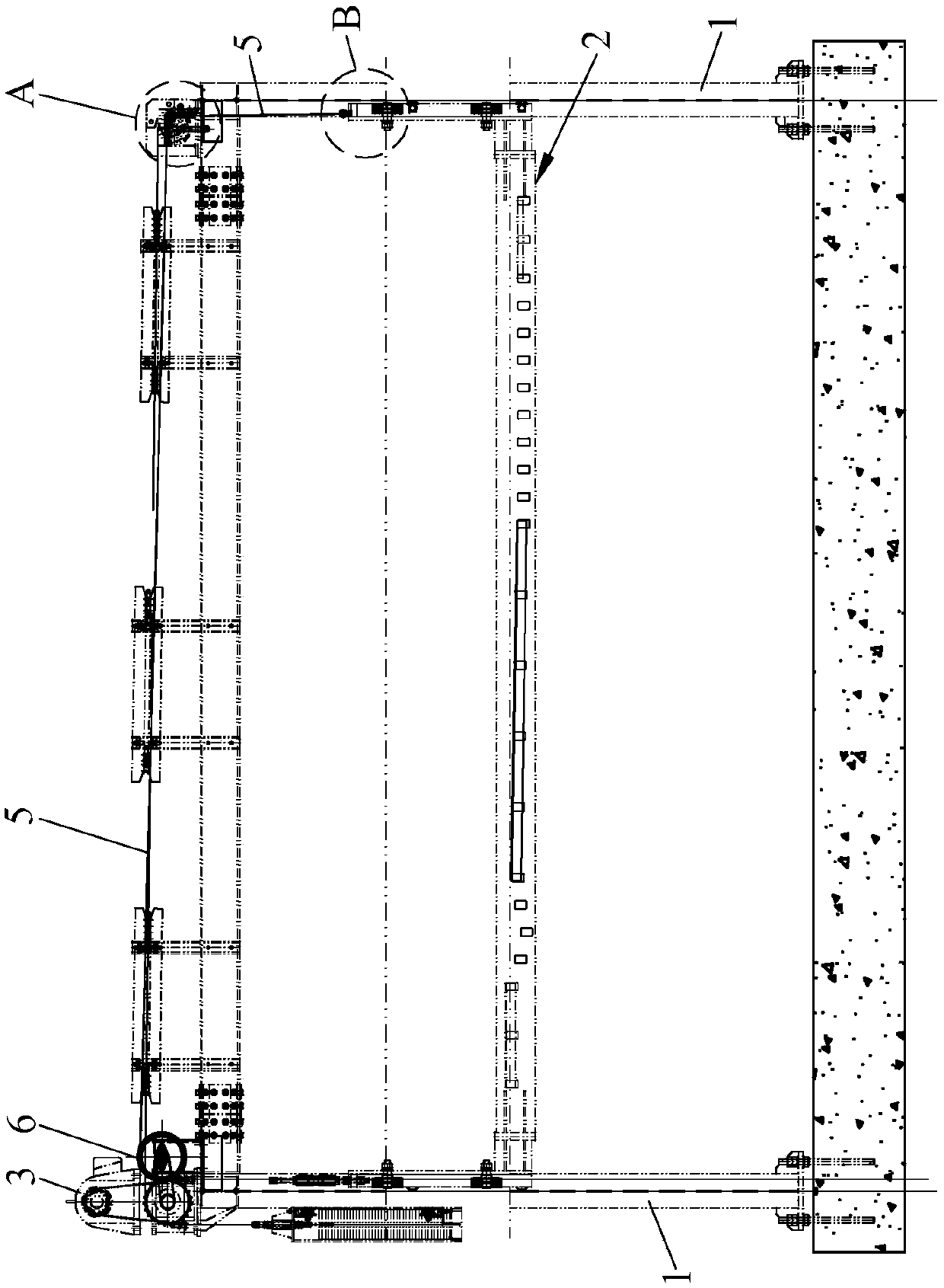

[0021] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0022] see Figure 1 to Figure 3 , the comb-tooth type vertical lift garage 100 of the present invention comprises a frame 1, a pallet 2 and a pallet drive mechanism 3 for driving the pallet 2 to lift relative to the frame 1, the pallet 2 is provided with an anti-falling device, and the anti-falling device is used for To prevent the pallet 2 from falling due to accidents, specifically, the fall prevention device can prevent the pallet 2 from falling by locking the pallet 2 in its current position; see Figure 4 and Figure 5 , the comb-tooth type vertical lifting garage 100 of the present invention also includes a transmission mechanism 4, a cable 5, a reel assembly 6 and a power supply system 7, and the power supply system 7 includes a rotor holder 71, a stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com