An Effective Measuring Device for Accuracy Adjustment and Control of Welded Car Body

A technology of measuring device and car body, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of low measurement accuracy, high measurement difficulty and high measurement cost, so as to ensure the accuracy of the car body, improve the accuracy of the car body, and improve the The effect of fitting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

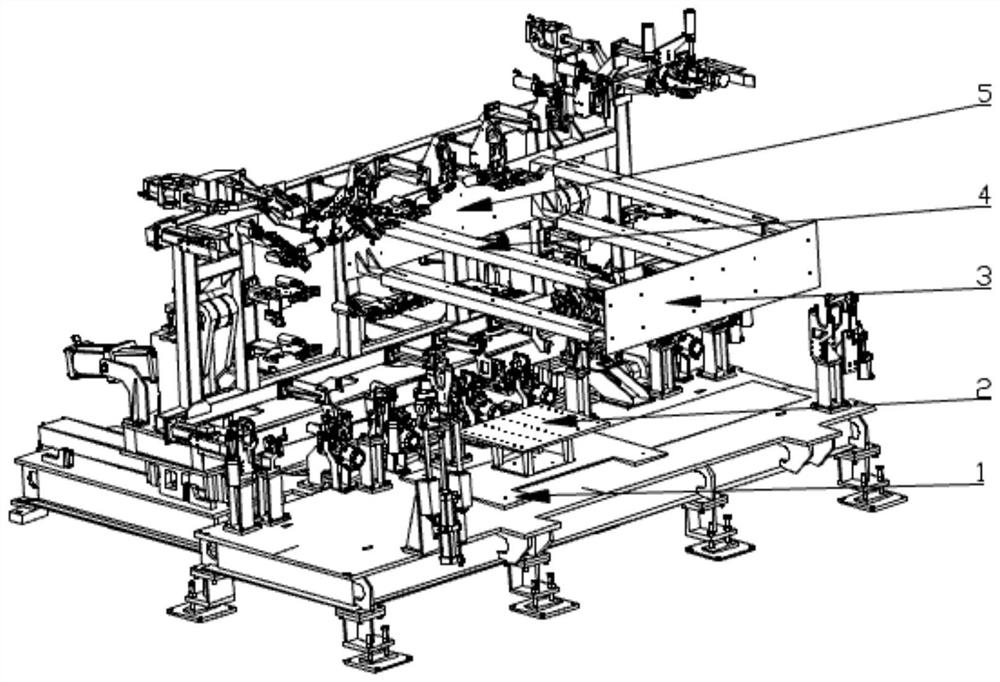

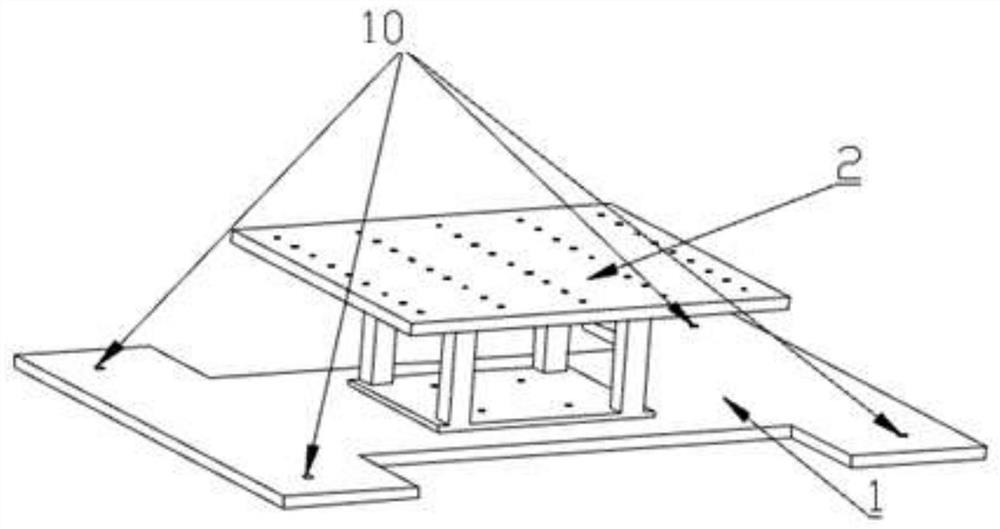

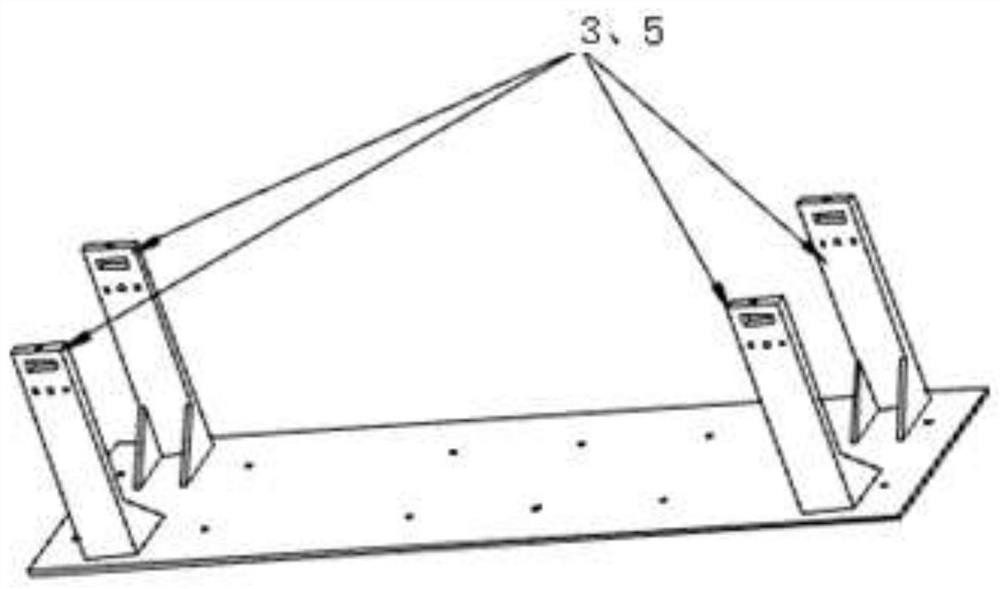

[0016] In view of the length × width × height of the passenger car body size is greater than 8000 × 2500 × 2500, so when the body is assembled and welded, there must be super large welding fixtures to ensure the body size, but this large size is difficult to measure by conventional methods. In order to solve this problem, the over-measurement datum is established by using the datum of the large fixture itself (BASE board), a detachable datum measurement datum is designed on the main datum of the fixture, and a detachable and Fixed datum of measurement.

[0017] On the large fixture installation reference plane, the positioning reference and measurement reference plane of the lower part of the car body can be accurately measured by means of a large three-coordinate measurement and or laser tracker (especially the coordinate hole of the fixture measurement reference plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com