Constant force control method and device for robotic abrasive belt grinding based on one-dimensional force sensor

A technology of robot abrasive belt and control method, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of unfavorable application of adaptive gain parameters, and achieve the effect of avoiding high cost problems, compensating errors, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

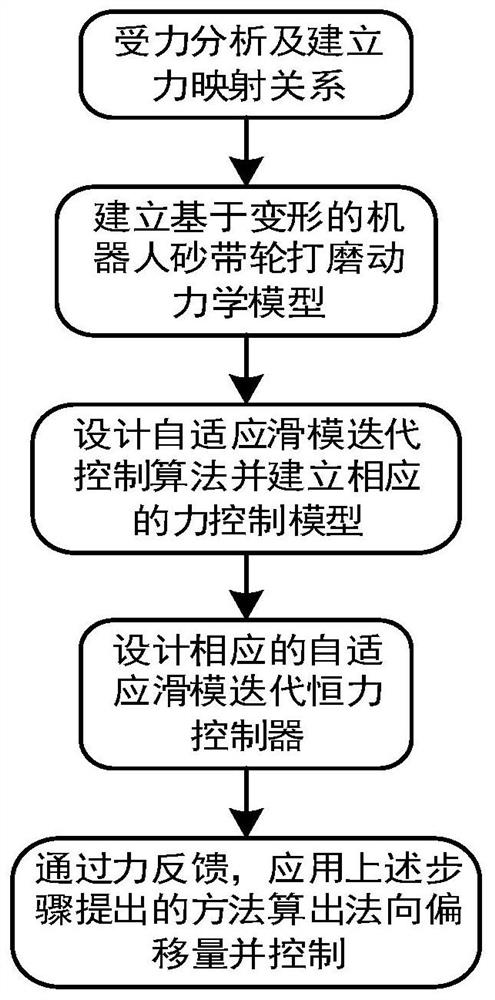

[0094] A constant force control method for robotic abrasive belt grinding based on a one-dimensional force sensor, such as figure 1 as shown,

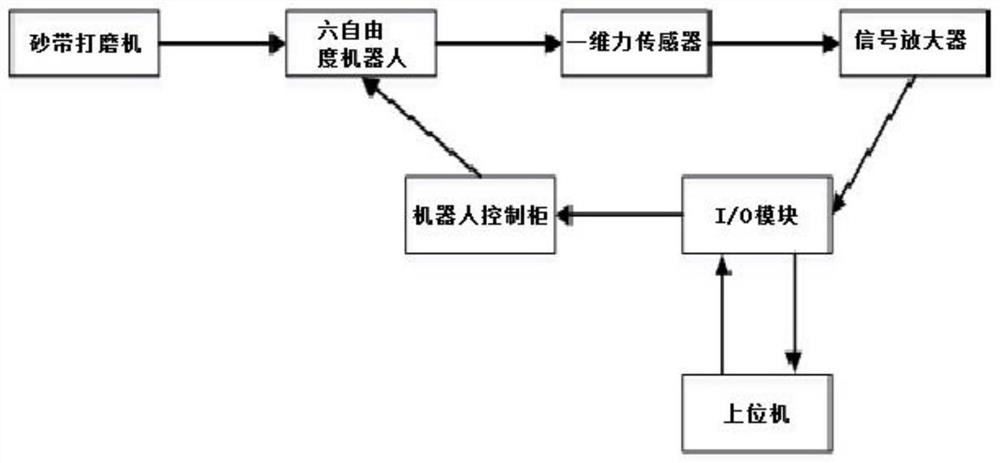

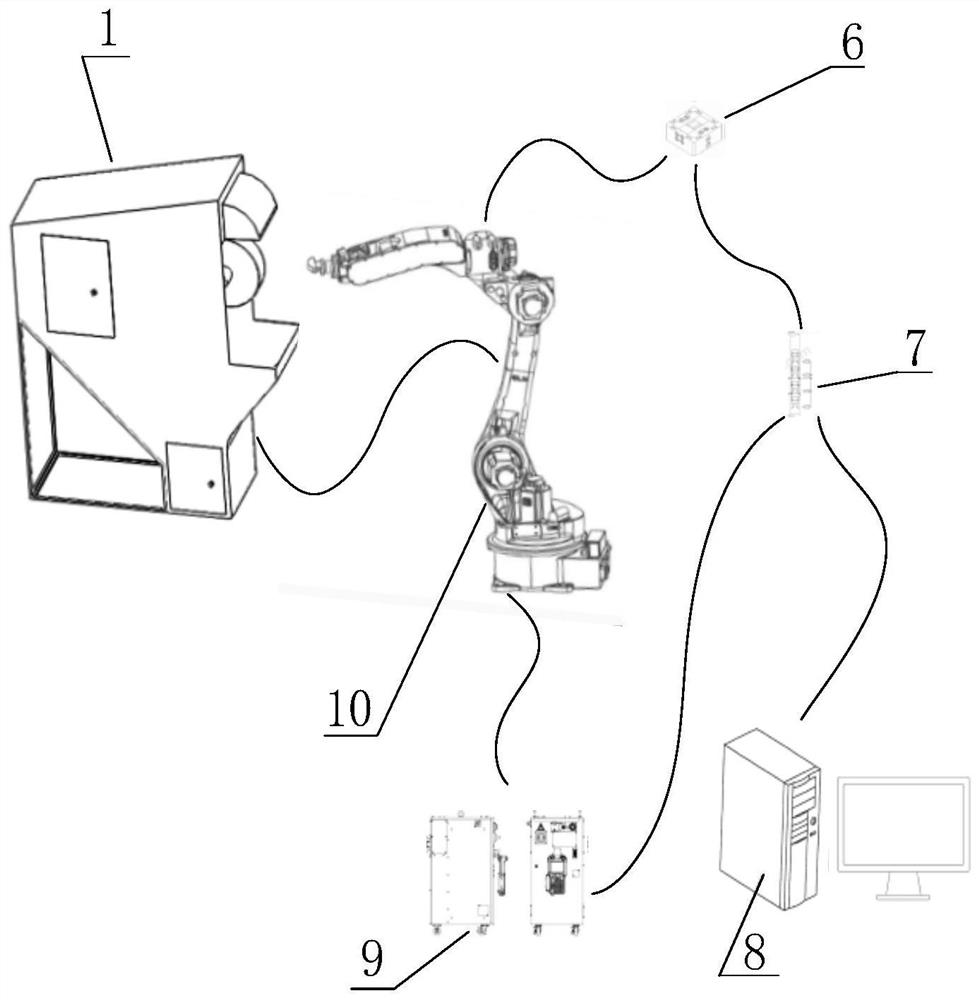

[0095] figure 2 Shown is the signal transmission diagram of the constant force control algorithm for robotic abrasive belt grinding based on the one-dimensional force sensor; image 3 It is a structural diagram of a robot abrasive belt grinding constant force control device based on a one-dimensional force sensor; Figure 4 It is a partial enlarged view of the end of the robot in the constant force control device for robot abrasive belt grinding based on the one-dimensional force sensor. The specific application steps of the device are as follows: first, run the embedded real-time control system on the PC host and turn on the relay; the robot grips the workpiece and walks the pre-planned trajectory for grinding; the analog signal collected on the force sensor is converted into digital signal and transmit the signal to the embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com