A new gravure printing machine

A kind of gravure printing machine, a new type of technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of low installation accuracy, different sizes of paper guide shafts, and mechanical transmission technology not suitable for modern production, etc., to achieve elimination External force, weakening the effect of external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

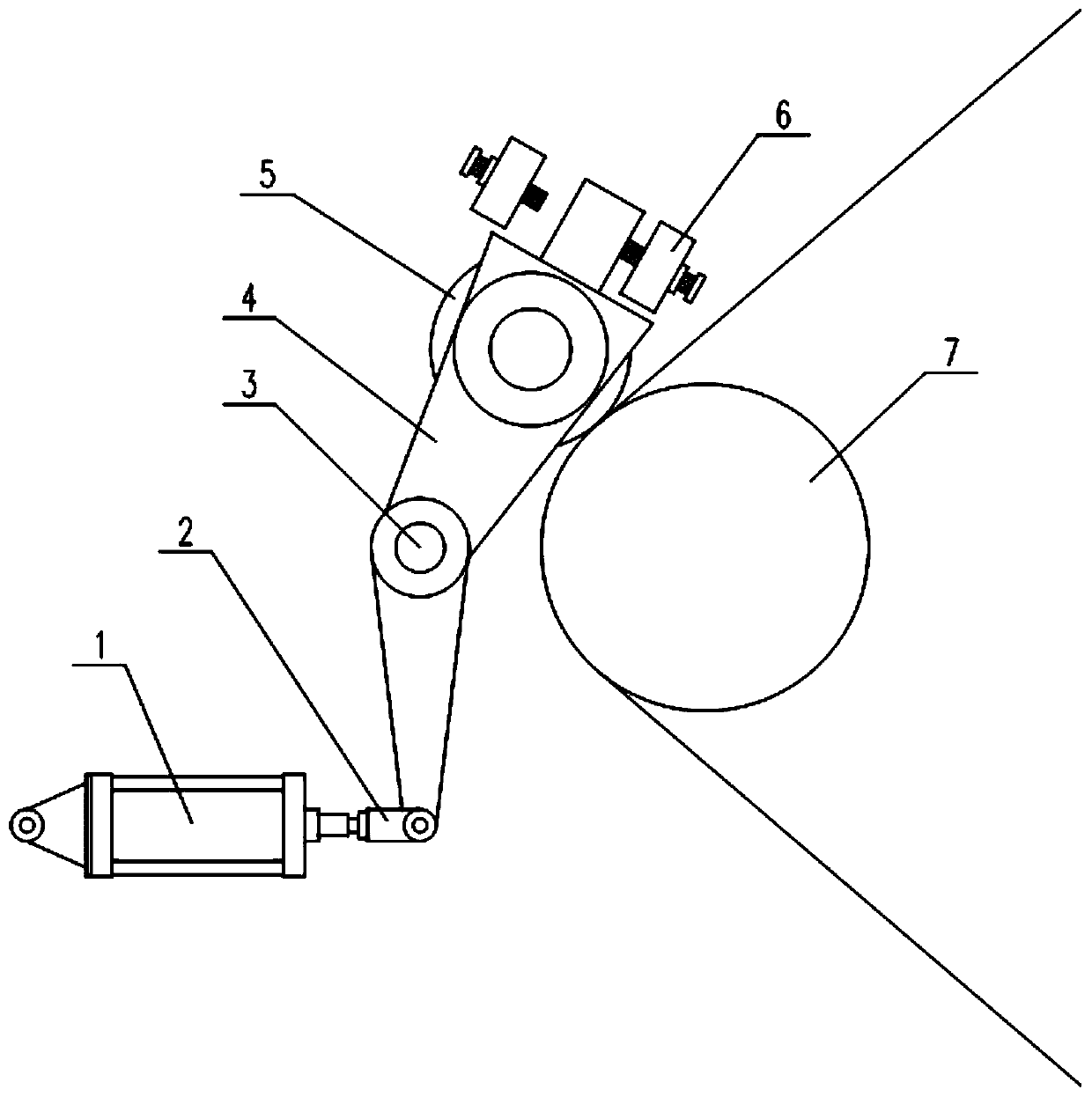

[0026] A new type of gravure printing machine provided by the preferred embodiment of the present invention includes a buffer structure 1 and a force transmission structure 2; the buffer structure 1 includes a No. 1 runner and a No. 1 transmission block; The shaft is fixedly connected; the outside of the No. 1 runner is connected to one side of the No. 1 transmission block; the other side of the No. 1 transmission block is connected to one end of the spring; the other end of the spring is connected to one side of the force transmission structure 2; the force transmission Structure 2 includes the No. 2 transmission block and the No. 1 runner; one side of the No. 2 transmission block is connected with the other end of the spring, and the other side is connected with the No. 1 runner; the geometric center point of the No. 1 runner, the No. 1 transmission block The line between the geometric center point of the drive block and the geometric center point of the second transmission b...

Embodiment 2

[0030] In this embodiment, on the basis of Embodiment 1, preferably, the diameter of the No. 1 runner is smaller than the diameter of the No. 2 runner; the diameter of the No. 2 runner is smaller than the diameter of the No. 3 runner 5; the diameter of the No. 3 runner 5 Smaller than the diameter of the drum 7, it is convenient for the transmission and weakening of the external force.

[0031] Preferably, the diameter of the No. 1 rotating shaft is smaller than that of the No. 2 rotating shaft; the diameter of the No. 2 rotating shaft is smaller than the diameter of the No. 3 rotating shaft, so as to better weaken the external force.

[0032] Preferably, the linkage rod is perpendicular to the horizontal plane, so as to fully transmit the external force to the stressed structure.

[0033] Preferably, the included angle between the linkage plate 4 and the horizontal plane is 60°, so that after the No. 3 roller 5 is stressed, part of the external force is applied to the linkage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com