Novel self-locking nut

A self-locking nut, a new type of technology, applied in the direction of nuts, screws, bolts, etc., can solve the problem of not being fastened, and achieve the effect of reasonable structure, convenient use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

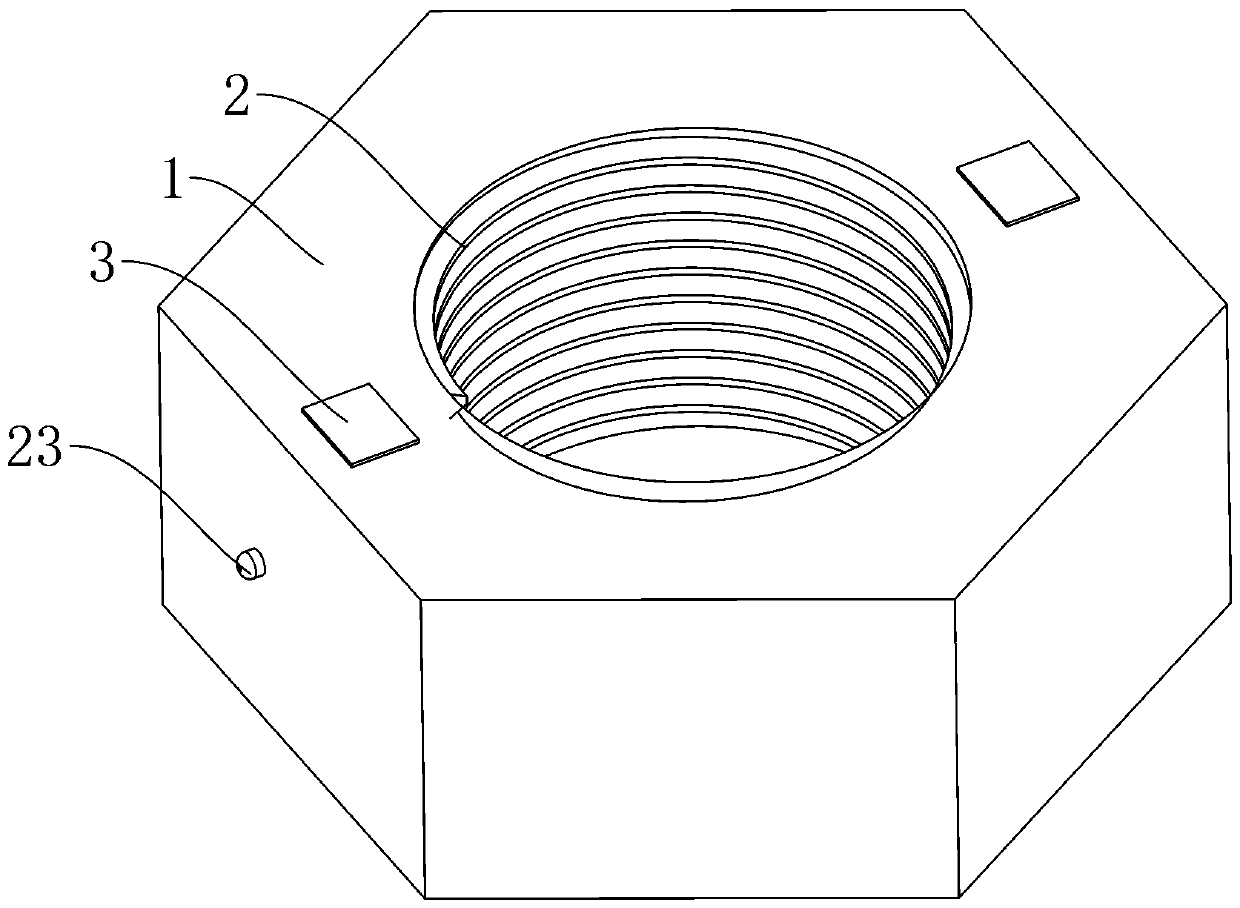

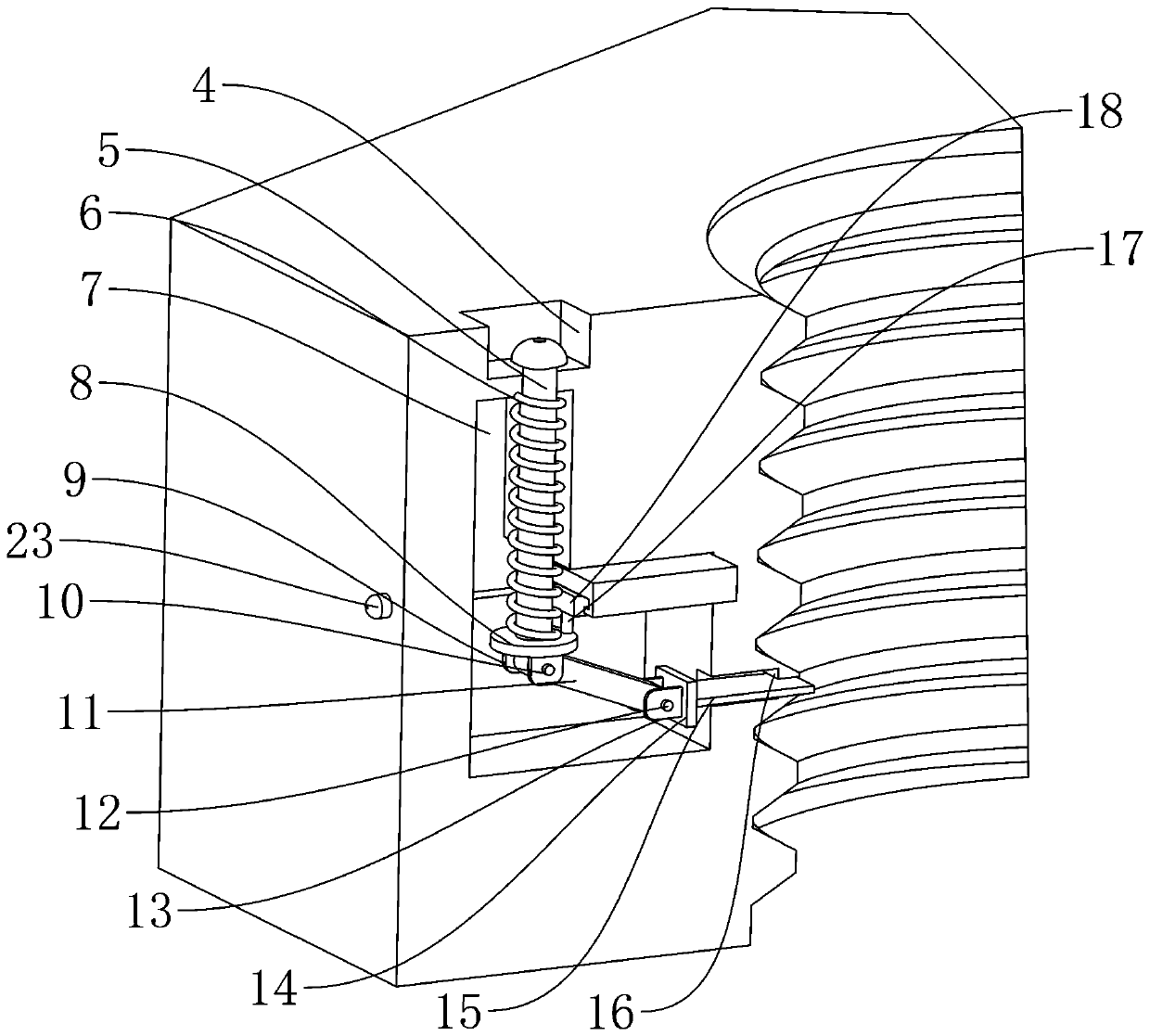

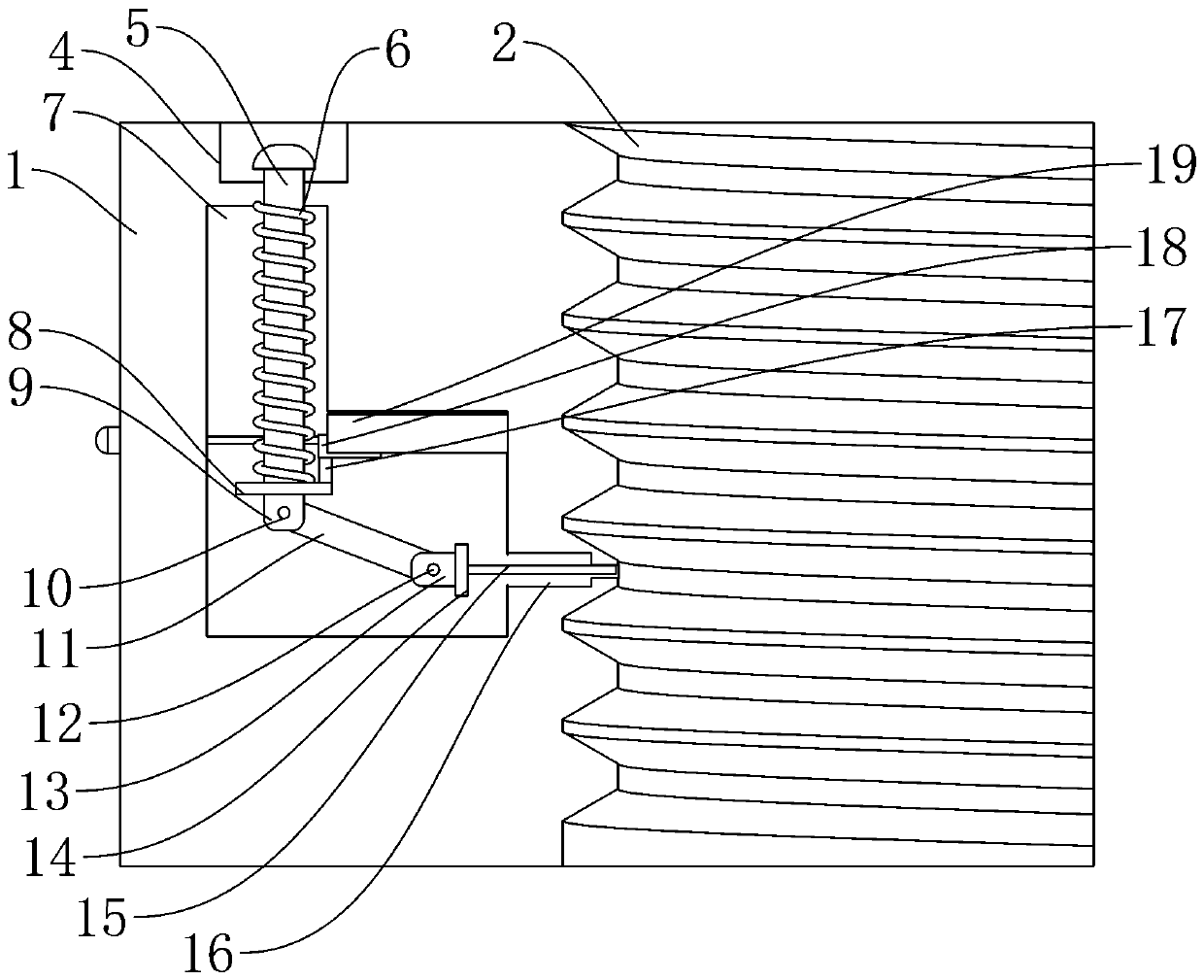

[0033] Such as Figure 1-Figure 5 As shown, a new type of self-locking nut includes a nut 1, an inner groove 7, a limit plate 15, and a stopper 19. The inner side of the nut 1 is processed with an internal thread 2, and the inner side of the nut 1 is processed with a groove 4. The function of the groove 4 is to It is convenient to operate the first connecting rod 5, the groove 4 is provided with an outer cover 3, the function of the outer cover 3 is to close the groove 4, the outer cover 3 and the nut 1 are connected by a card slot, and the inner groove 7 is arranged under the groove 4 , the function of the inner groove 7 is to install the self-locking device, the first connecting rod 5 is arranged in the inner groove 7 and the groove 4, the function of the first connecting rod 5 is to set the first mounting plate 8, and the outer side of the first connecting rod 5 is provided with a second A spring 6, the function of the first spring 6 is to reset the first connecting rod 5, ...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is:

[0036] One side of the moving block 22 is provided with a second connecting rod 23, which is threadedly connected between the second connecting rod 23 and the moving block 22. The second connecting rod 23 communicates with the inner wall of the nut 1 and extends outside the nut 1. The second connecting rod 23 is fixed on one side of the moving block 22 , and the second connecting rod 23 can be operated outside the nut 1 .

[0037] Working principle: first fit the threaded rod into the internal thread 2, when self-locking, press the first connecting rod 5, the limit plate 15 will be pushed to the internal thread 2, and the baffle 18 will follow the first connecting rod 5 down, the second spring 21 in the block 19 pushes the moving block 22, and when the operator releases his hands, the baffle plate 18 will press the lower end of the moving block 22, thereby realizing the fixing of the position of the limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com