Hot nozzle structure of hot runner mold

A hot runner and mold technology, which is applied in the field of hot nozzle structure of hot runner molds, can solve the problems of broken nozzle, mold damage, unqualified injection products, etc., and achieve the effect of preventing the displacement of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

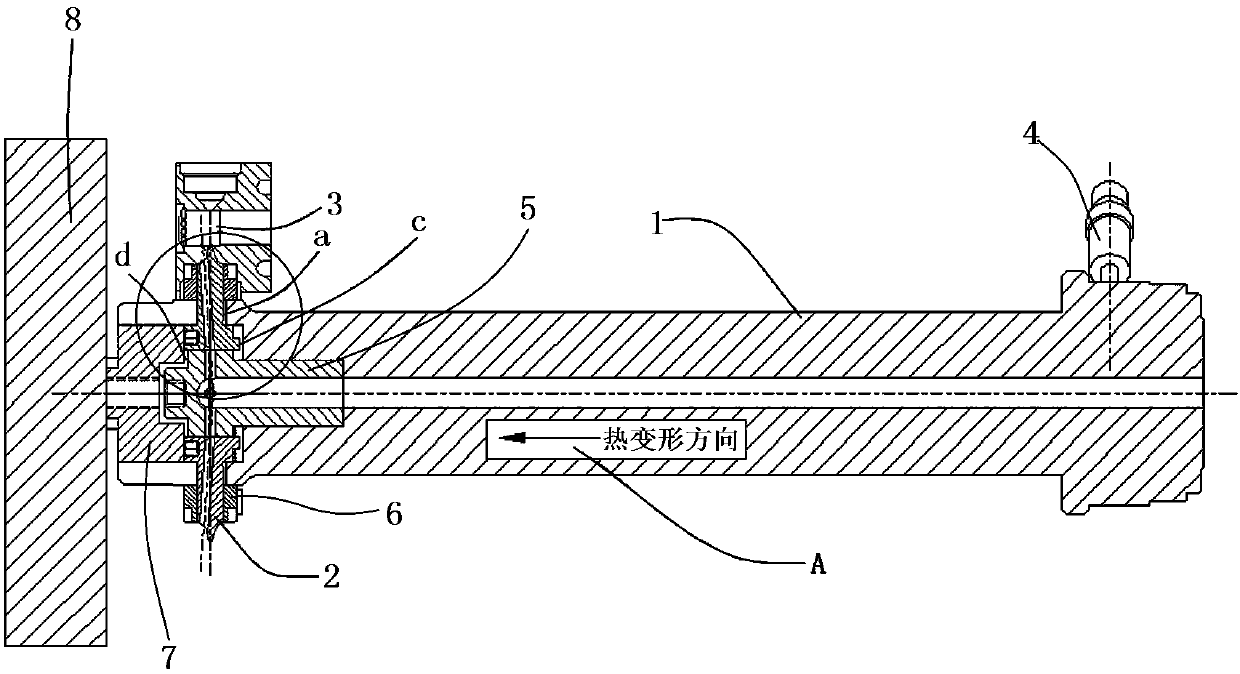

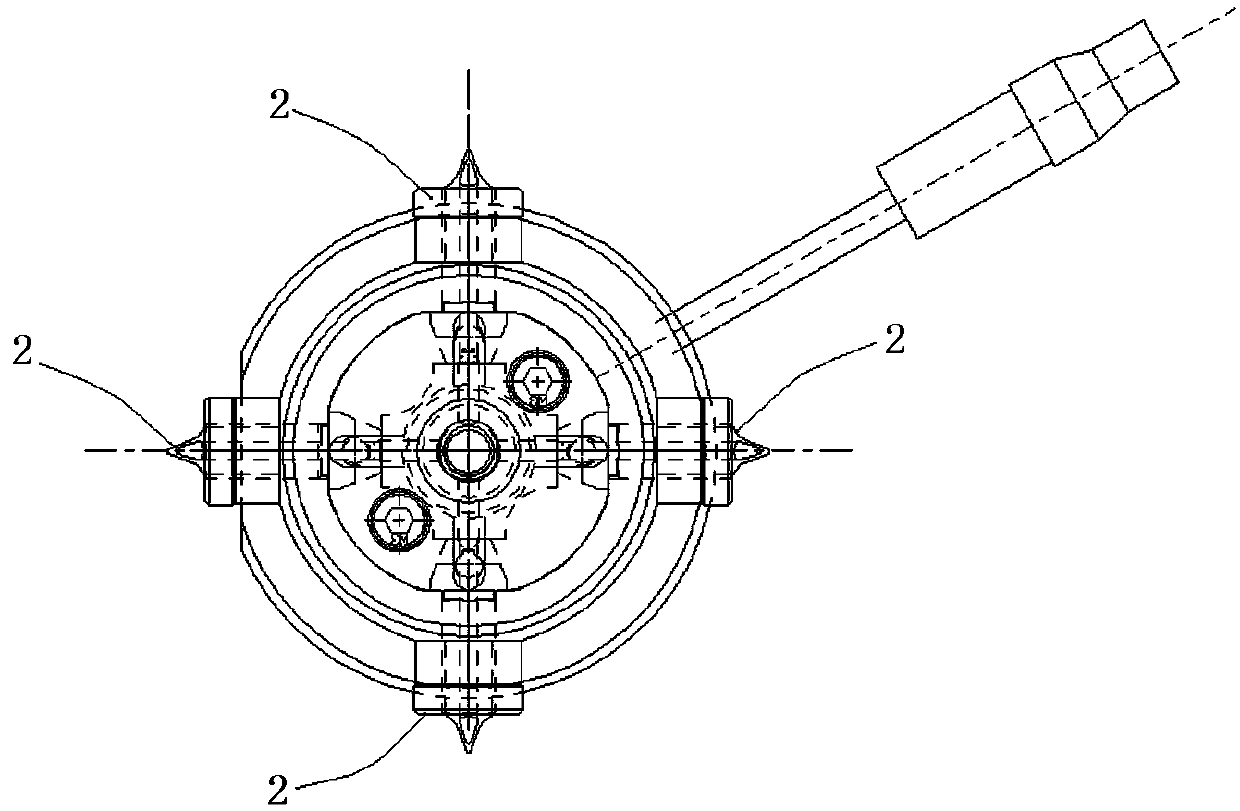

[0029] see figure 1 and figure 2 , a hot nozzle structure of a hot runner mold, including a hot nozzle body 1 and a nozzle 2 .

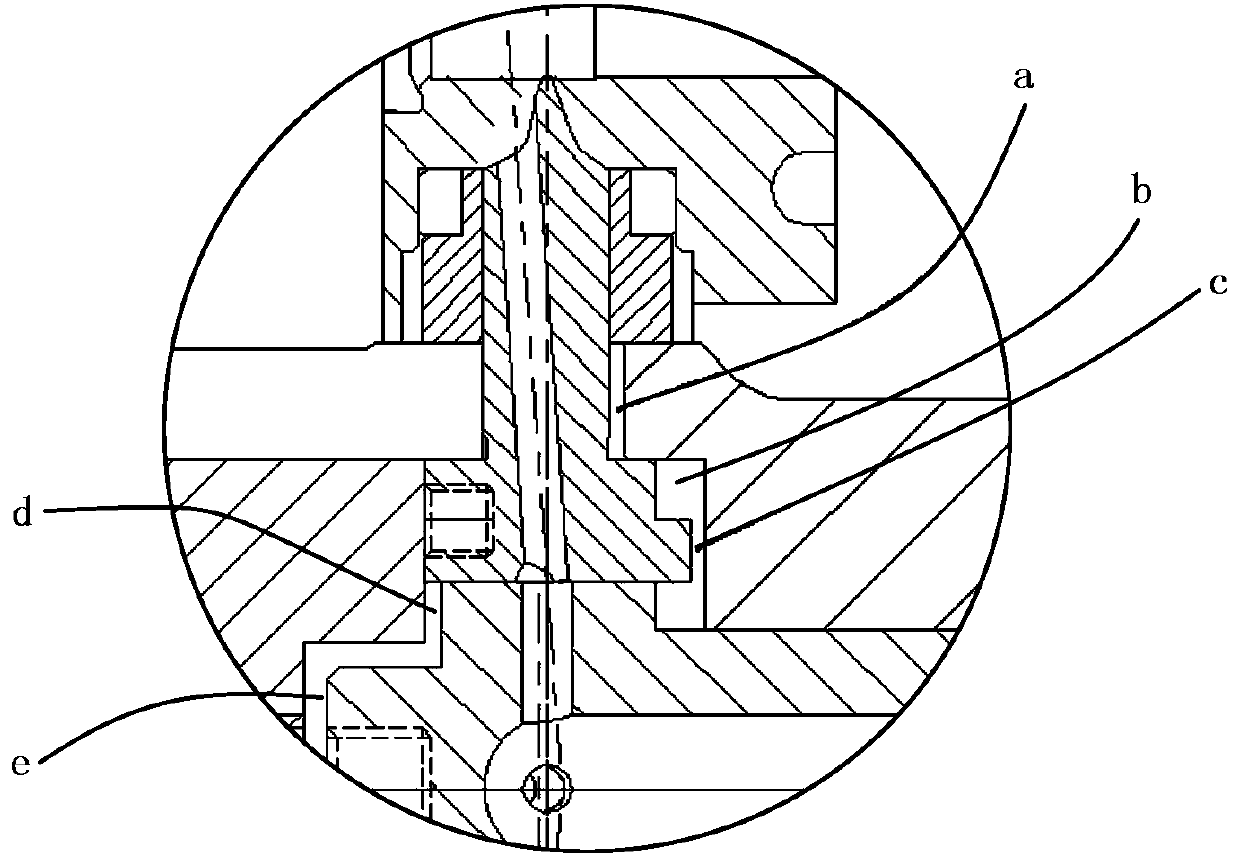

[0030] The hot nozzle body 1 is in the shape of a cylinder. The hot nozzle body 1 is arranged perpendicular to the cavity plate 3 of the hot runner mould. The head end of the hot nozzle body 1 is provided with a heater 4 . Through the main channel at both ends, a material transition sleeve 5 and four material nozzles 2 are provided at the tail end of the hot nozzle body 1 .

[0031] The material transition sleeve 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com