Patents

Literature

42 results about "Component alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Component alignment apparatuses and methods

A component transfer apparatus is provided. The component transfer apparatus comprises a pick and place machine having a component feed source and a movable pick head having access to the component feed source. A component alignment detector is directed toward the component feed source and a controller is coupled to the component alignment detector. The controller contains instructions which, when executed by the controller, cause the controller to compare the detected component alignment with a known component alignment.

Owner:MICRON TECH INC

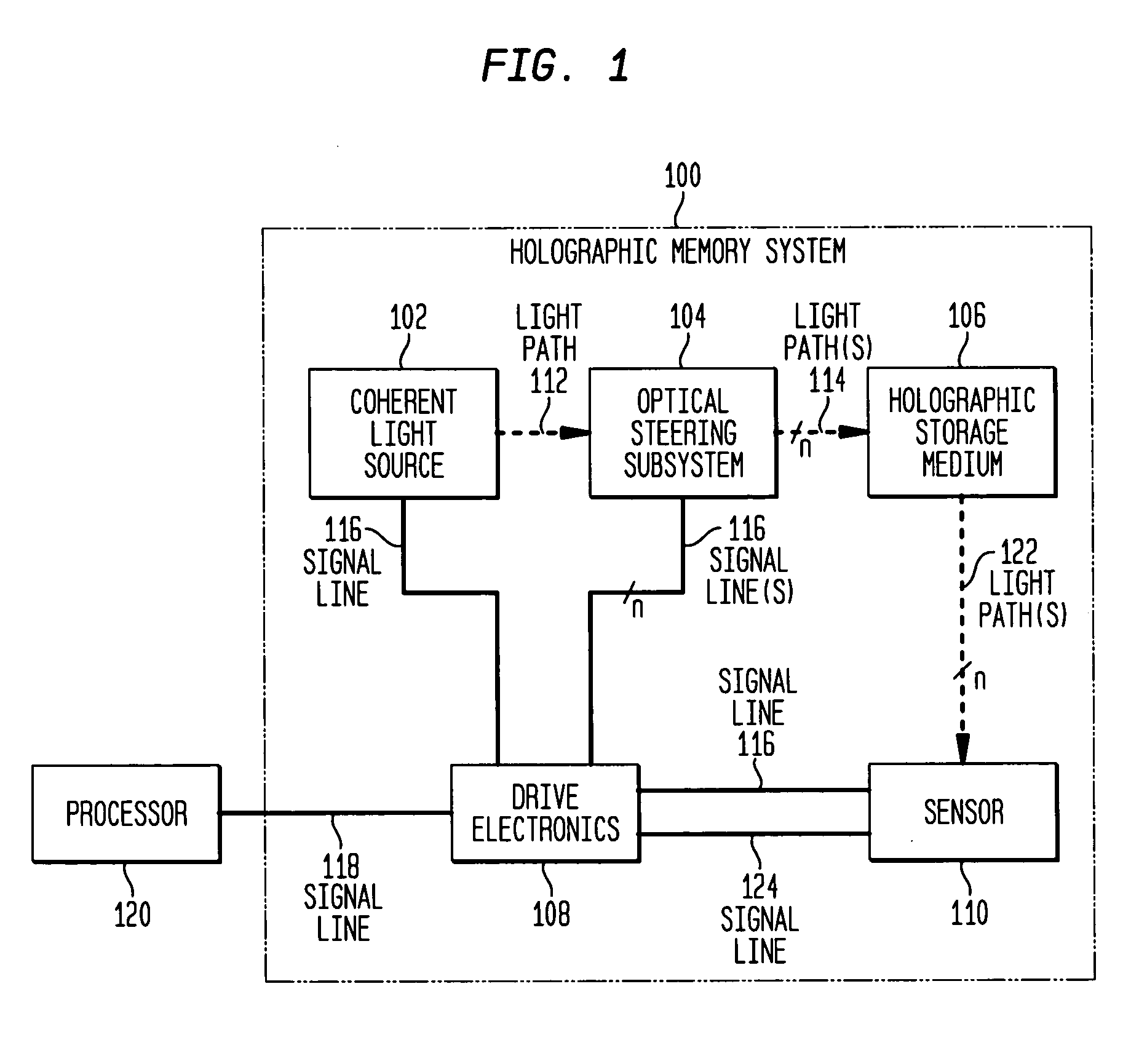

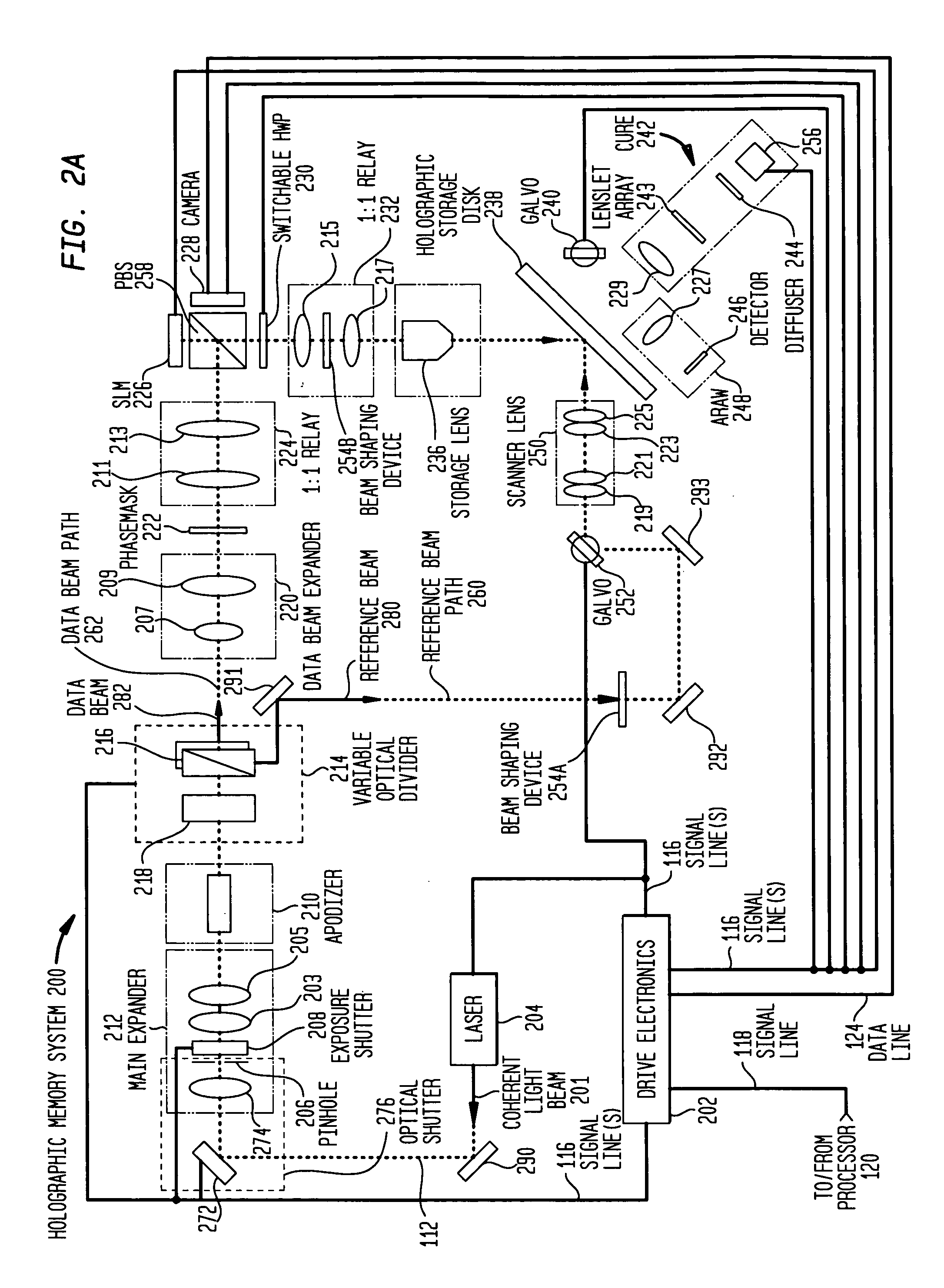

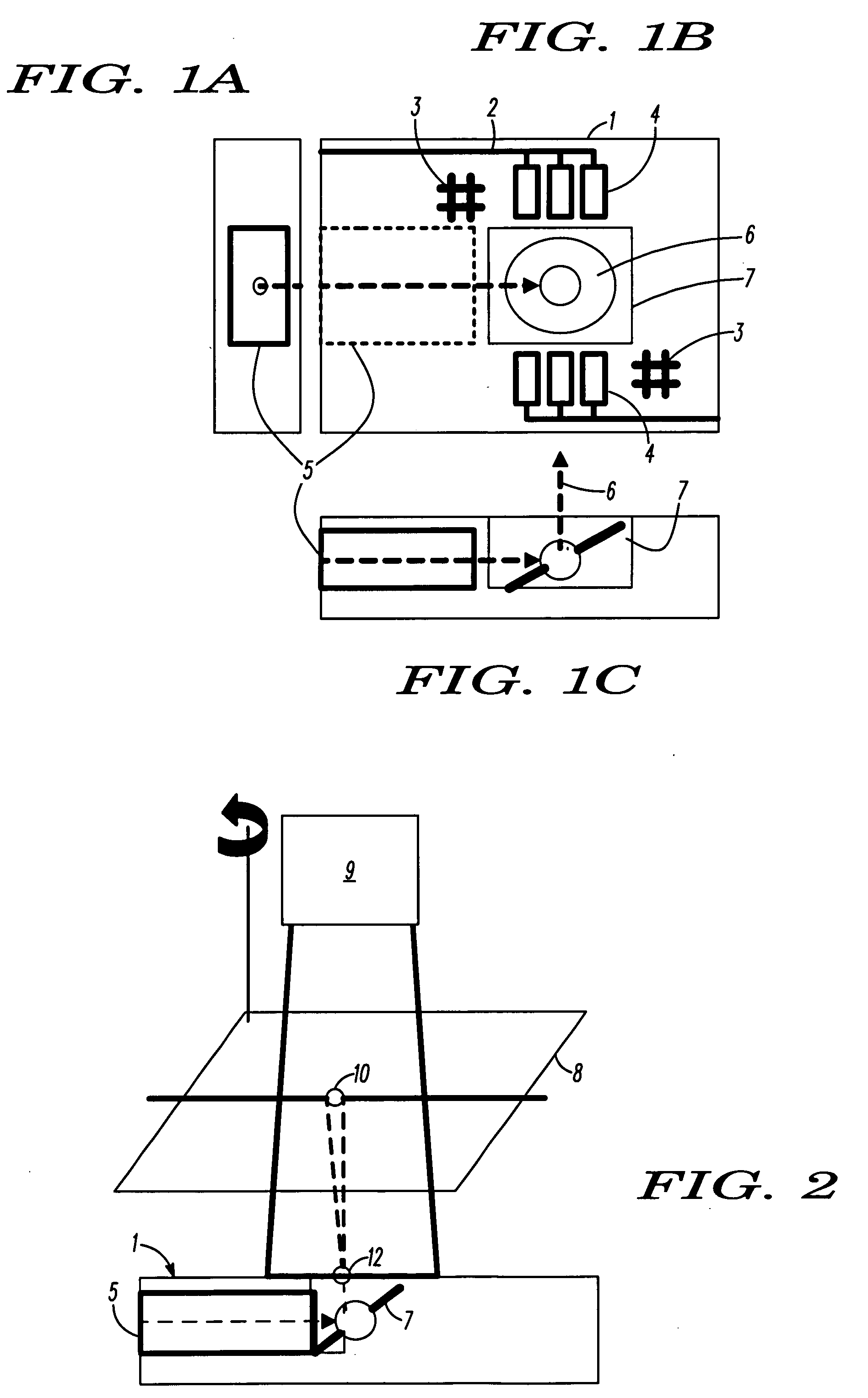

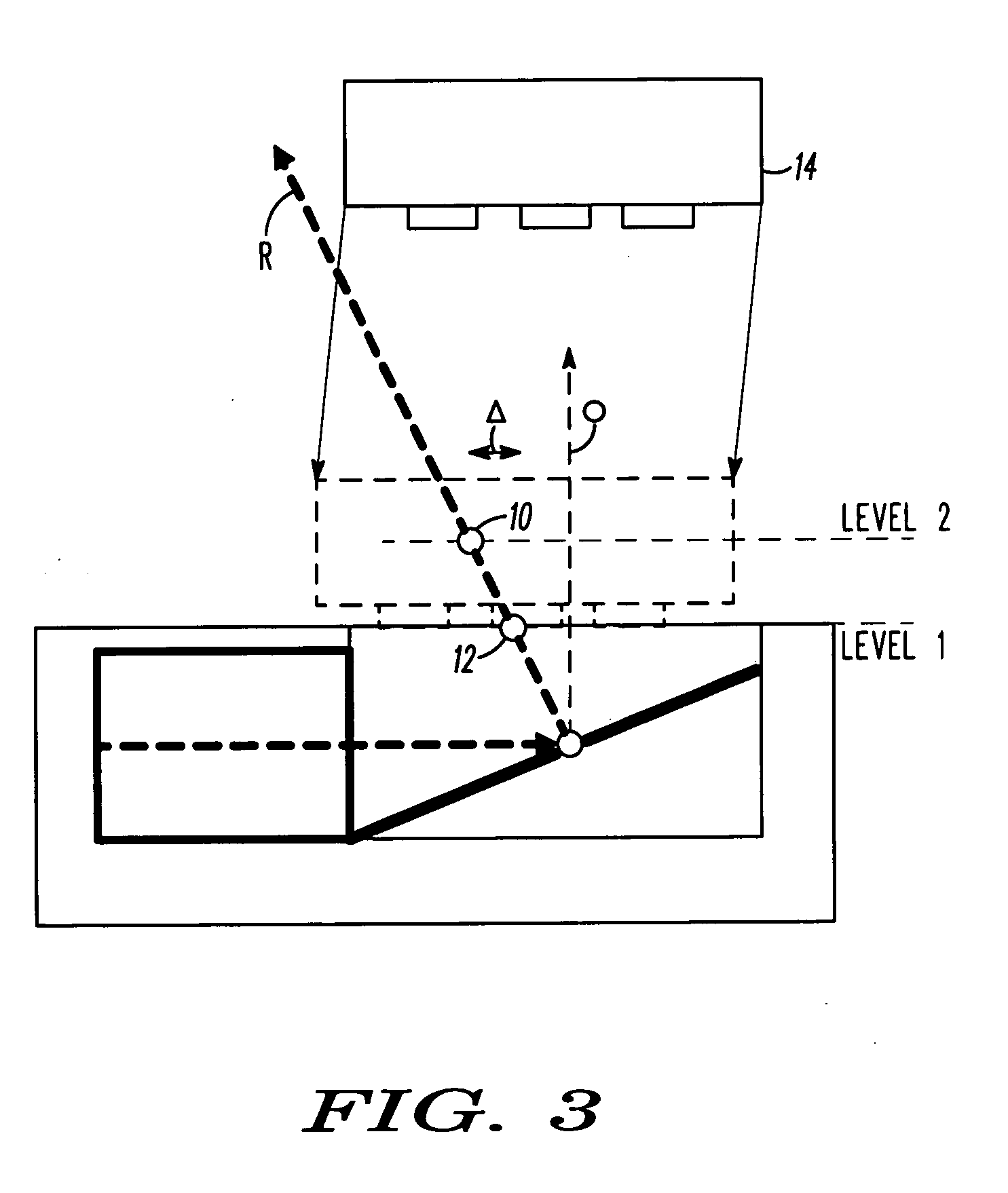

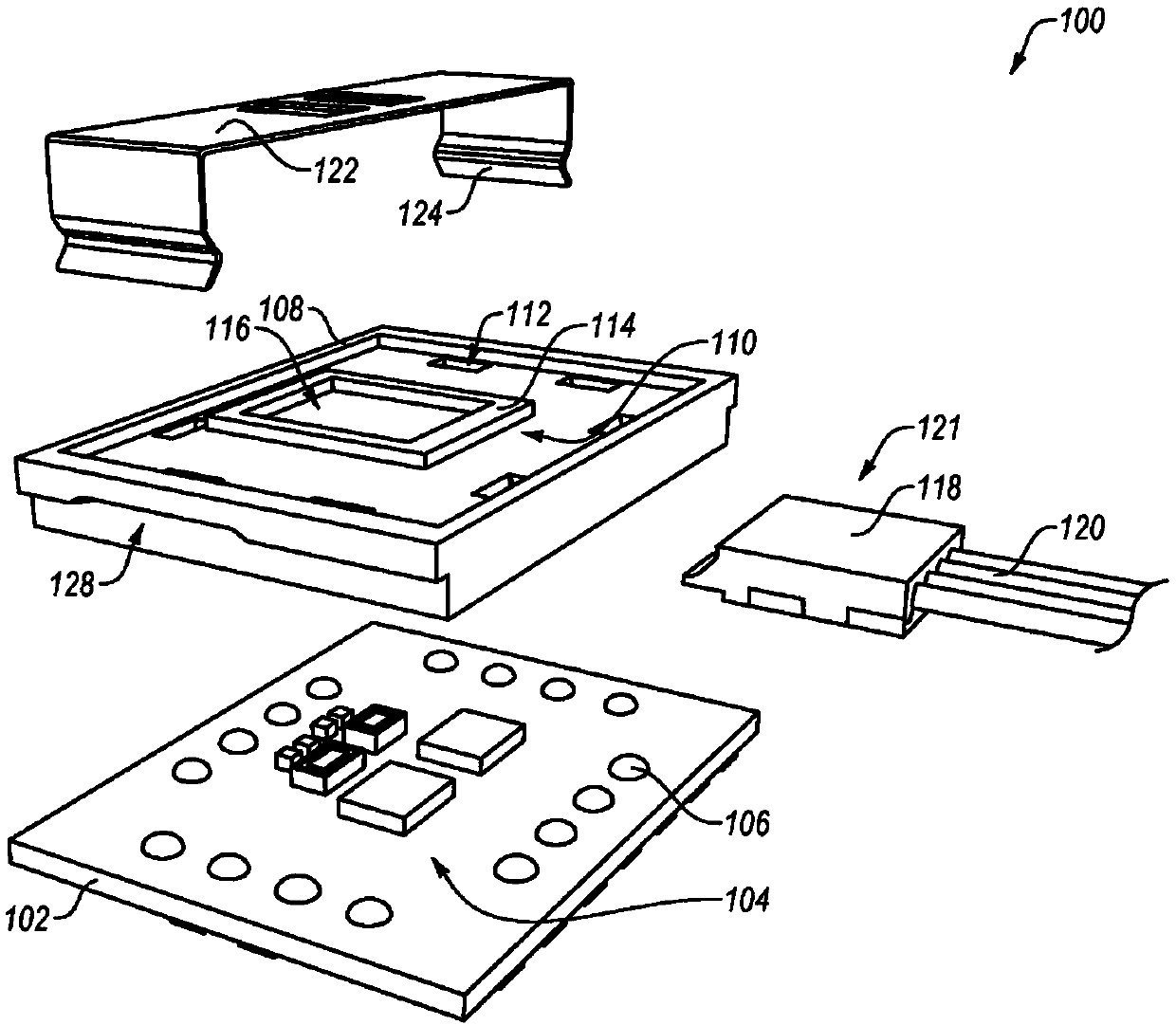

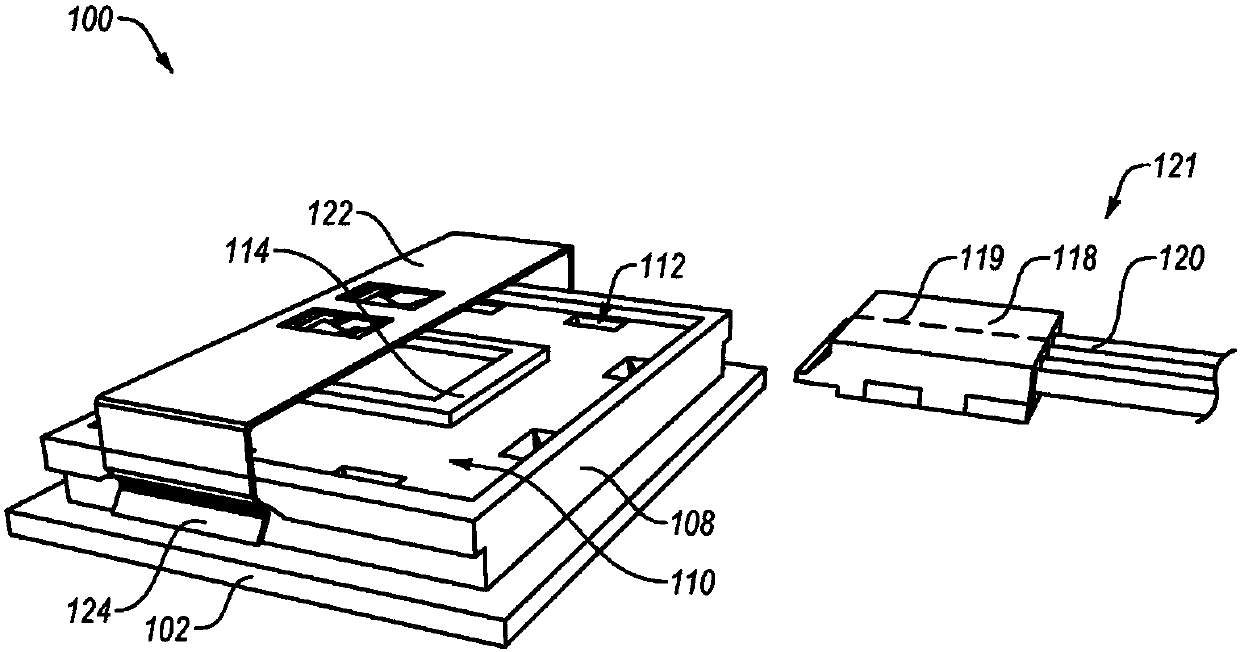

Holographic drive head and component alignment

InactiveUS20060274394A1Reduce reflectionMinimize impactRecord information storageOptical head manufactureBeam splitterSpatial light modulator

The present invention relates to embodiments of: (1) a unitary holographic drive head assembly mounting structure; (2) an assembly comprising a unitary holographic drive head assembly mounting structure and a plurality of holographic drive head components and / or subassemblies; (3) a subassembly comprising a spatial light modulator, detector array, and a beam splitter; (4) a device comprising a spatial light modulator and a physical aperture positioned over or an imaged aperture projected onto the photoactive area of the spatial light modulator; (5) a system for optically aligning or pointing a laser in a holographic drive head assembly; (6) a light source subassembly comprising a laser, a fiber coupling lens; and an optical fiber having a fiber connector ready output end; and (7) a light source subsystem comprising a laser source, beam conditioning optics, fiber coupling optics for receiving the conditioned light beam, and a fiber optic connector for receiving the conditioned light beam from the fiber coupling optics.

Owner:AKONIA HOLOGRAPHICS

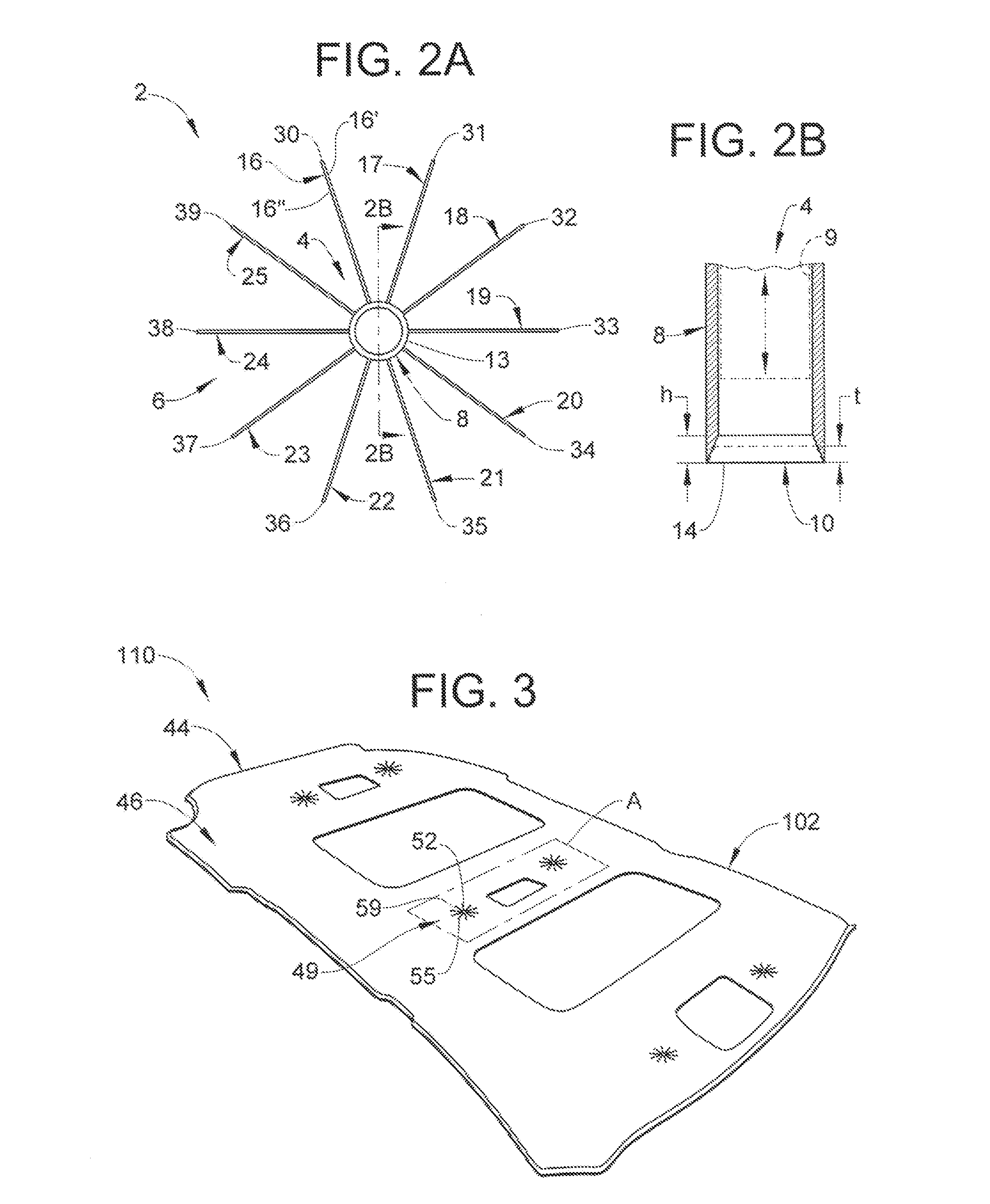

Elastic averaging alignment system, method of making the same and cutting punch therefor

InactiveUS20140298962A1Cross-cut reciprocating sawsMetal working apparatusComponent alignmentBiomedical engineering

An elastic averaging alignment system includes a first component comprising a surface, a thickness and a plurality of elastically deformable apertures spaced apart on the surface and extending through the thickness, each of the elastically deformable apertures comprising an aperture peripheral shape and having at least one slit extending radially-outwardly therefrom defining at least one elastically deformable wedge member. A method of making a component alignment system includes providing a first component having a surface and a thickness. The method also includes forming a plurality of alignment features through the thickness of the first component, the alignment features comprising a plurality of elastically deformable apertures spaced-apart on the surface and extending through the thickness, each of the elastically deformable apertures comprising an aperture peripheral shape and having at least one slit extending radially-outwardly therefrom defining at least one elastically deformable wedge member.

Owner:GM GLOBAL TECH OPERATIONS LLC

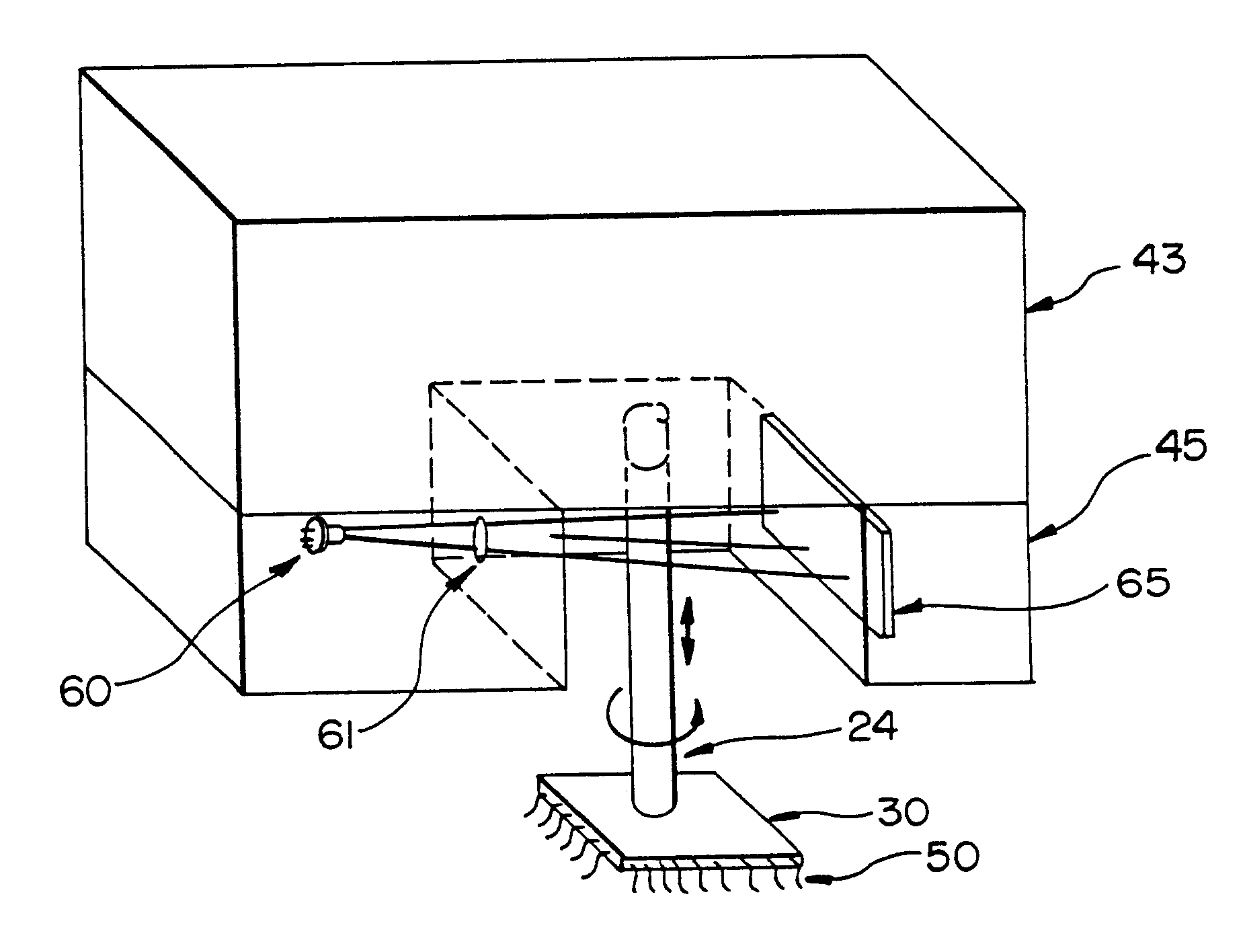

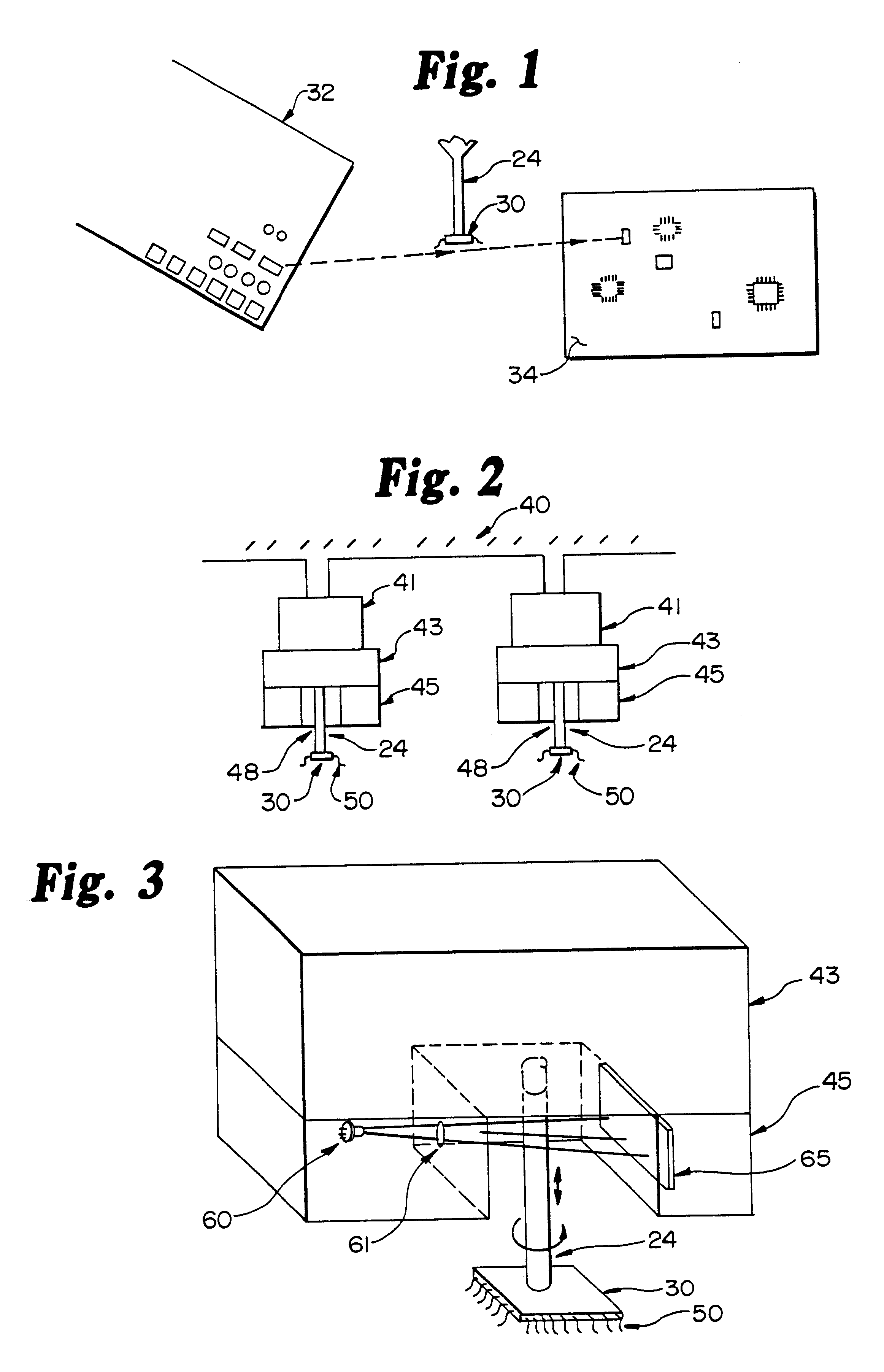

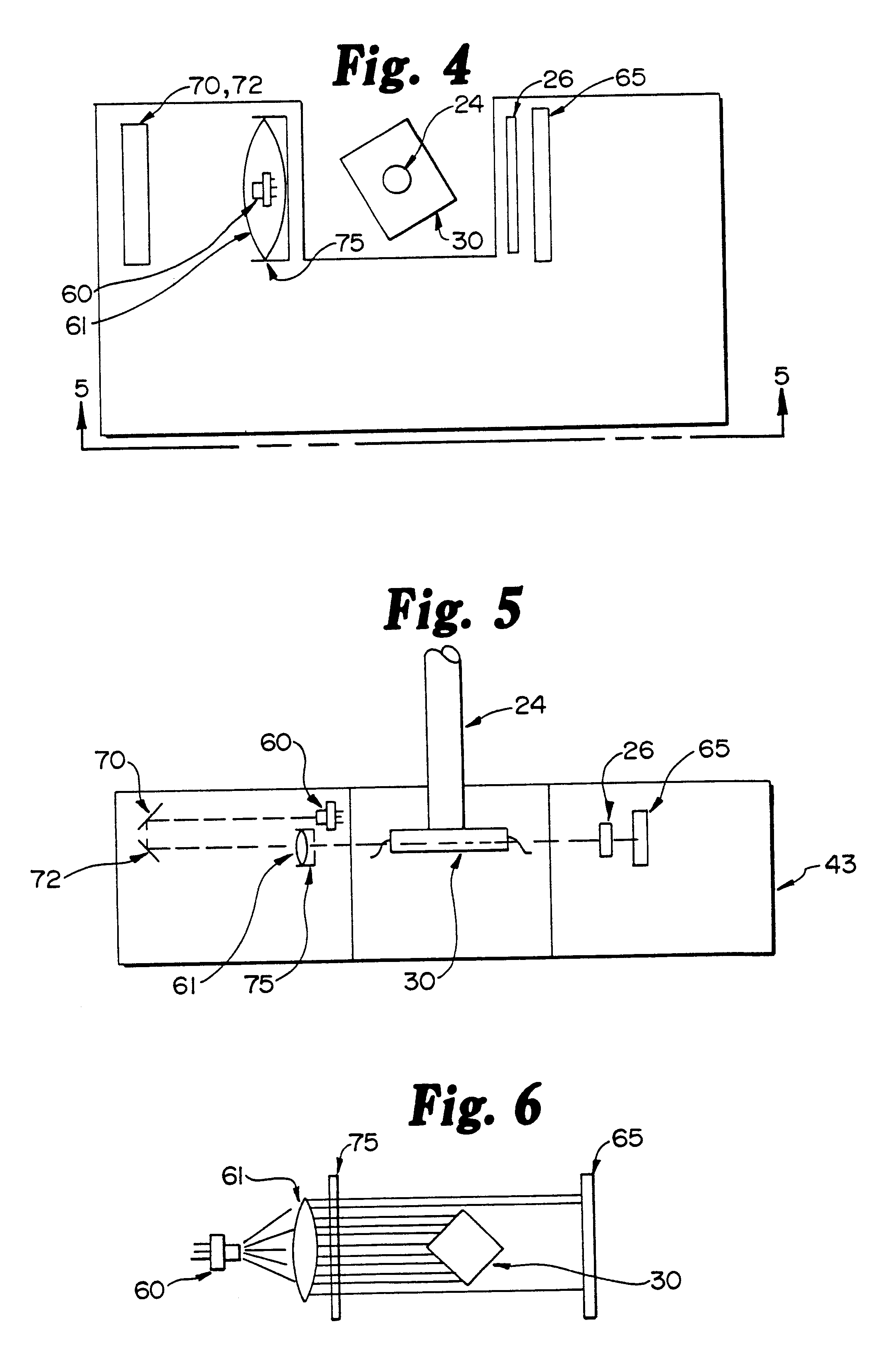

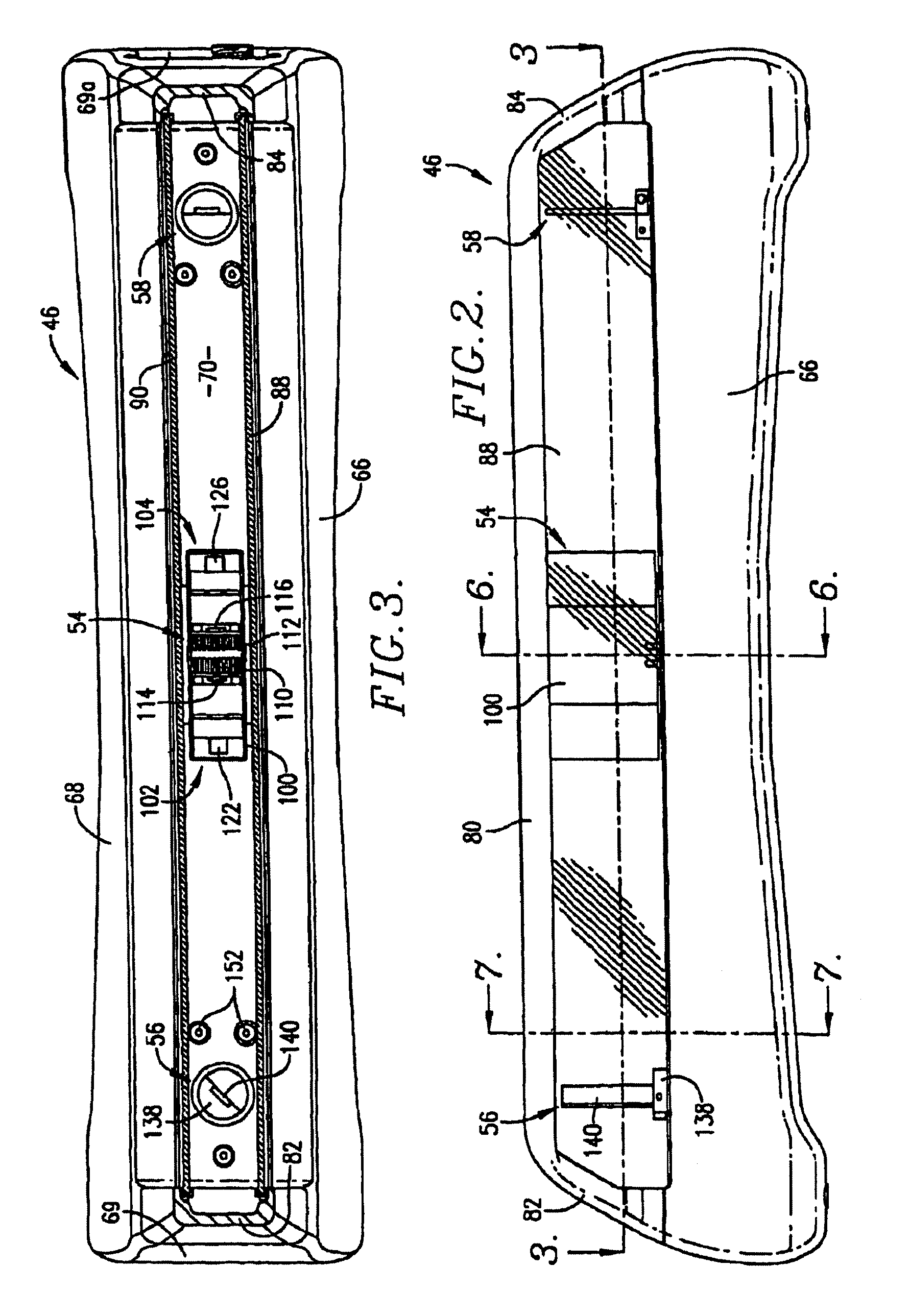

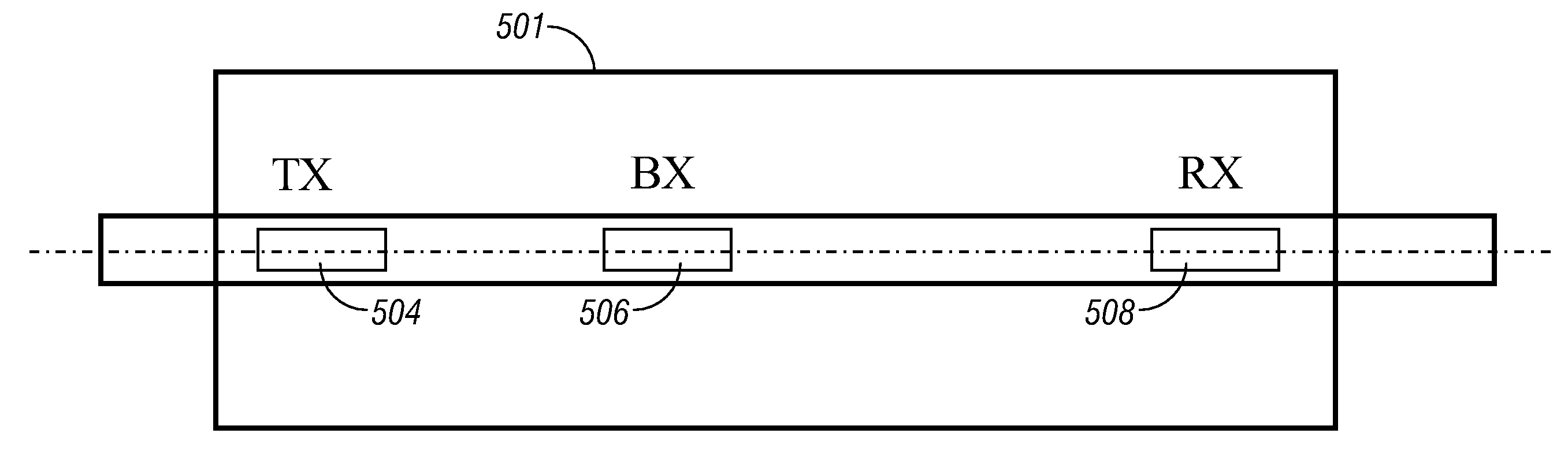

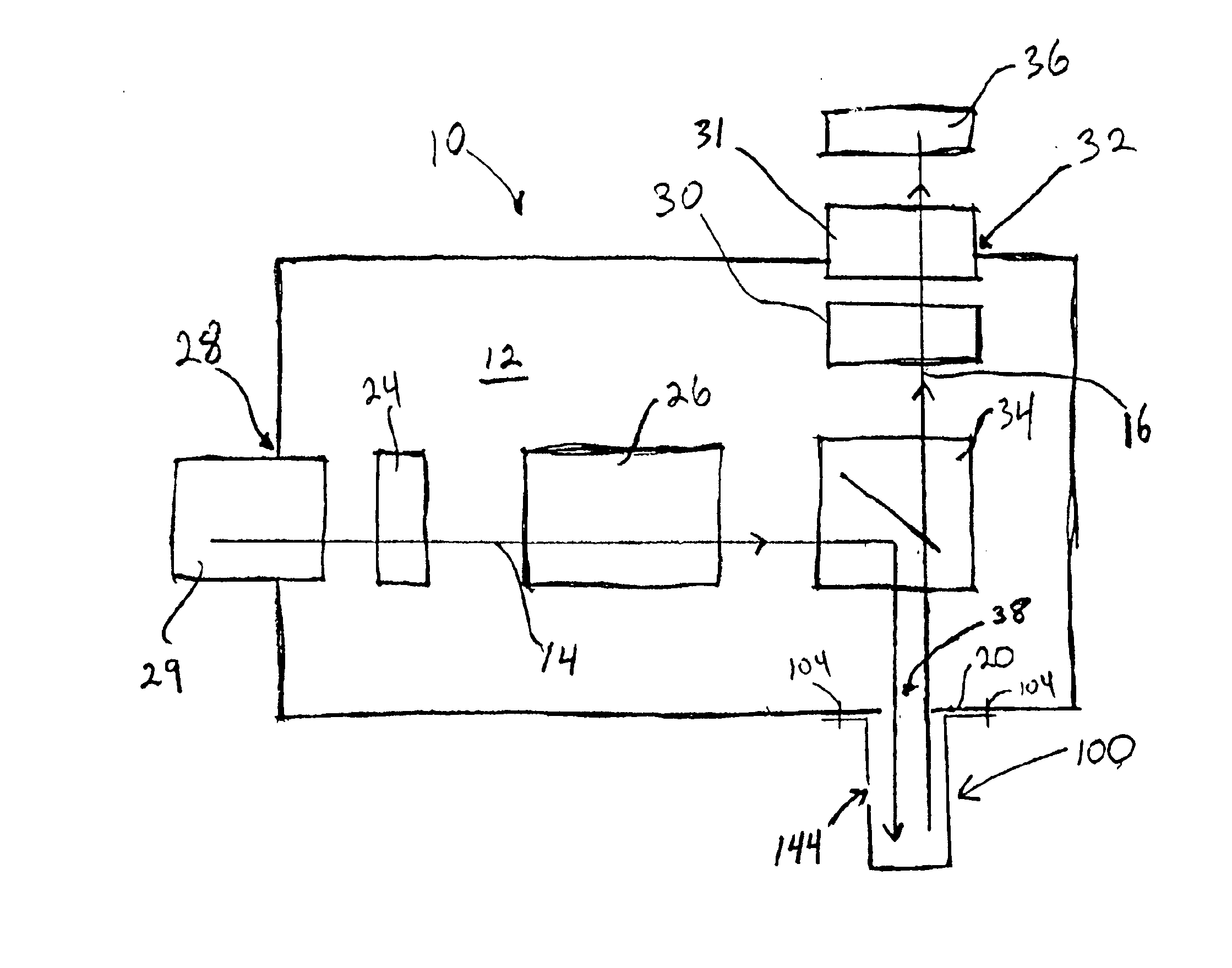

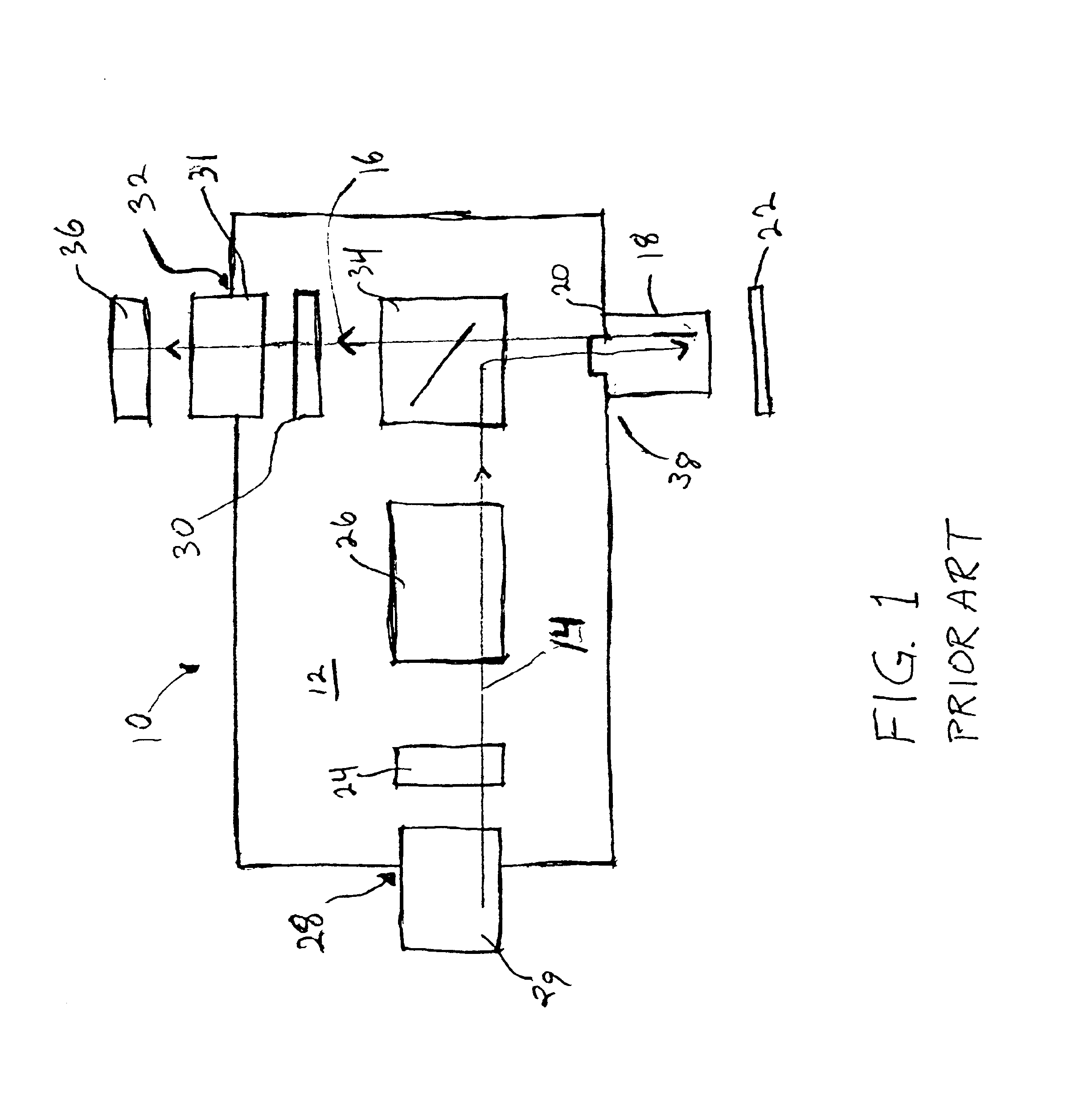

High precision component alignment sensor system

InactiveUSRE38025E1Accurately precisely determineAccurately determineUsing optical meansElectrical componentsSensor arrayComponent alignment

A high speed high precision laser based alignment sensor system for use on surface mount component placement machines. A laser system is utilized to correctly align and position component parts which range between 0.02 inches and 2.0 inches in size. The laser sensor system consists of a laser light source which is passed through a collimating lens and then through an aperture to create a stripe of collimated laser light which is focused past the component being aligned to strike a multi-element CCD sensor array. The sensor system is mounted directly on the carrying mechanism for the surface mount component placement machine. During transit of the component between the bin of components is to be placed, the component is rotated and the shadow which falls on the detector array is monitored. When the minimum width of shadow is detected, the correct angular orientation is determined, the average of the edges of the shadow when compared with the center of the quill determines the coordinate (X,Y) location of the component on the quill. Two alignments normally occur displayed by 90°. Thereafter, the sensor sends correcting signals to the component placement machine to assure the correct angular orientation and the correct X,Y position for the component to be placed on the circuit board by the component placement machine.

Owner:CYBEROPTICS

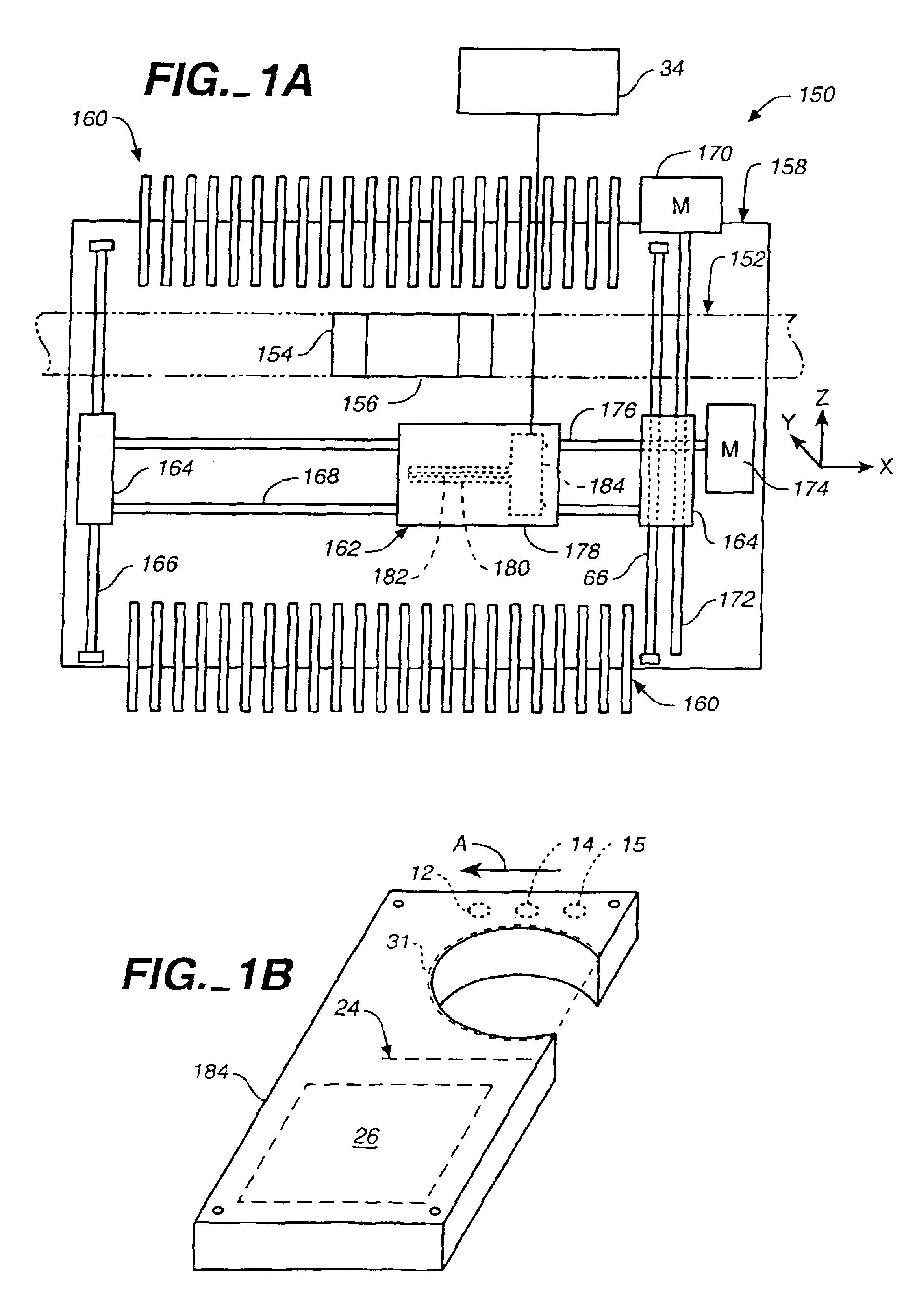

Methods and apparatus for determining component alignment

ActiveUS7103233B2Image enhancementMaterial analysis using wave/particle radiationComponent alignmentComputer science

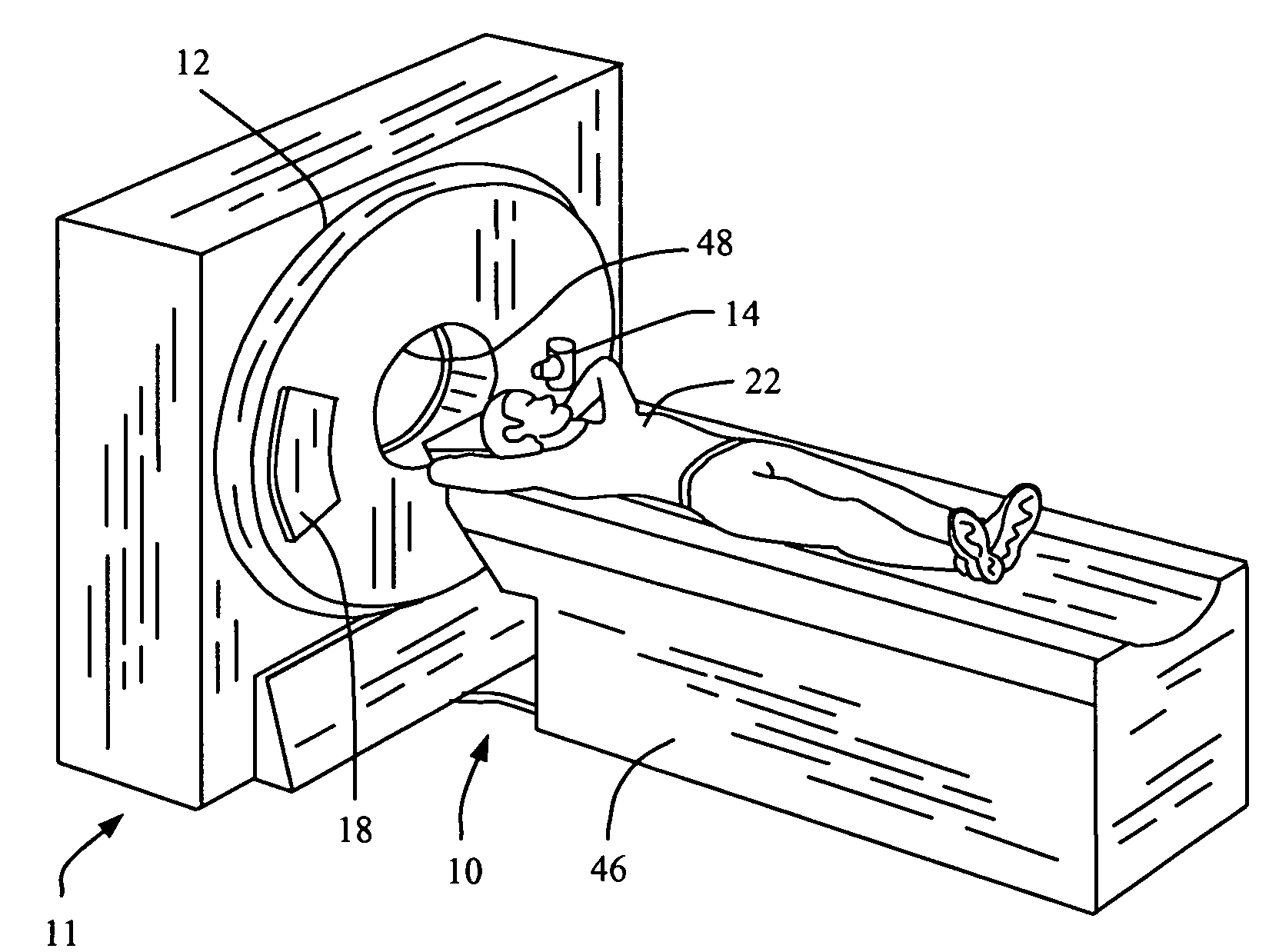

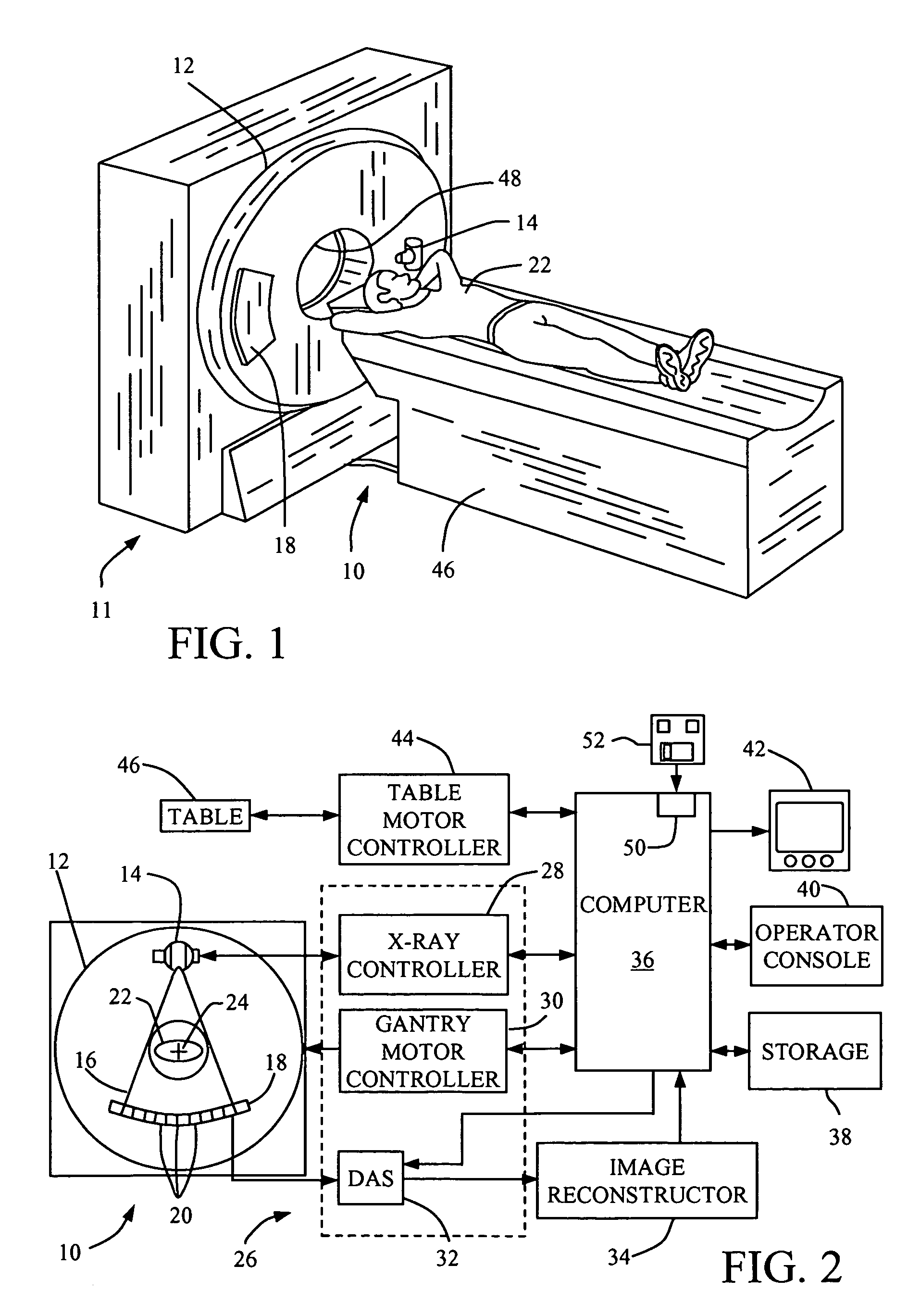

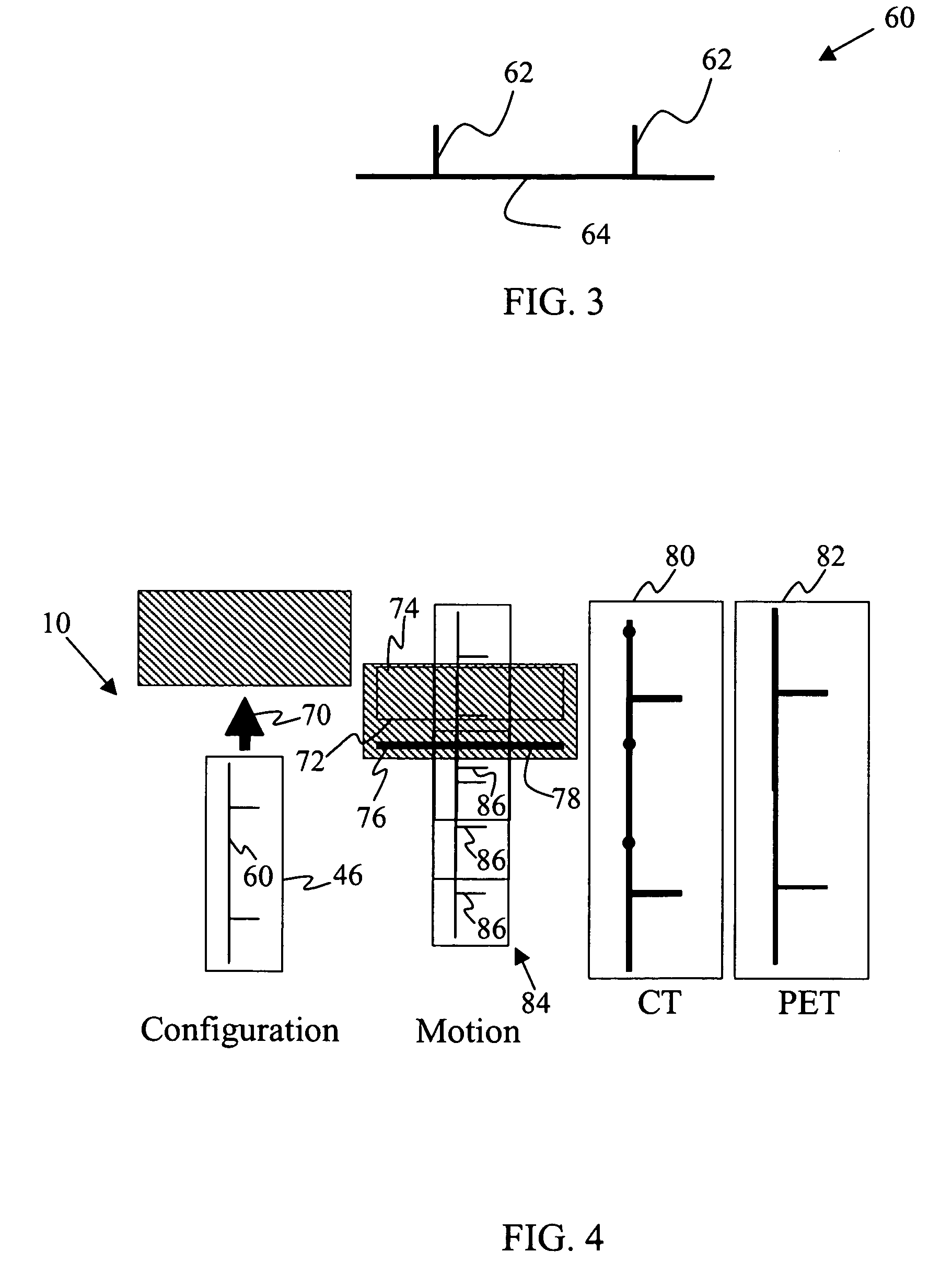

A method for determining component misalignment in a multi-modality imaging system including a first modality unit, a second modality unit, and a table, includes imaging an object with the first modality unit to generate a first image, imaging the object with the second modality unit to generate a second image, and determining a table alignment status using the first and second images.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

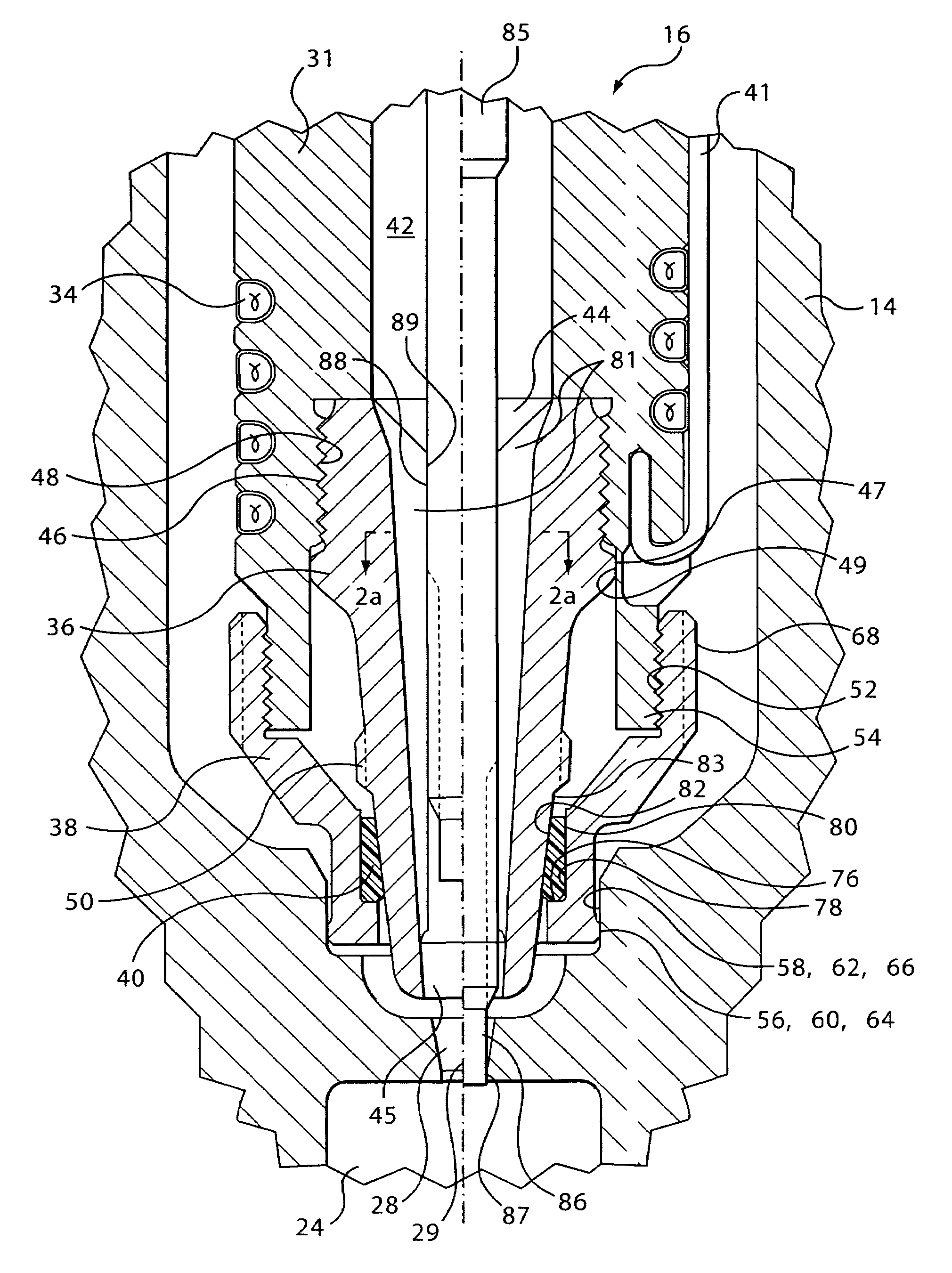

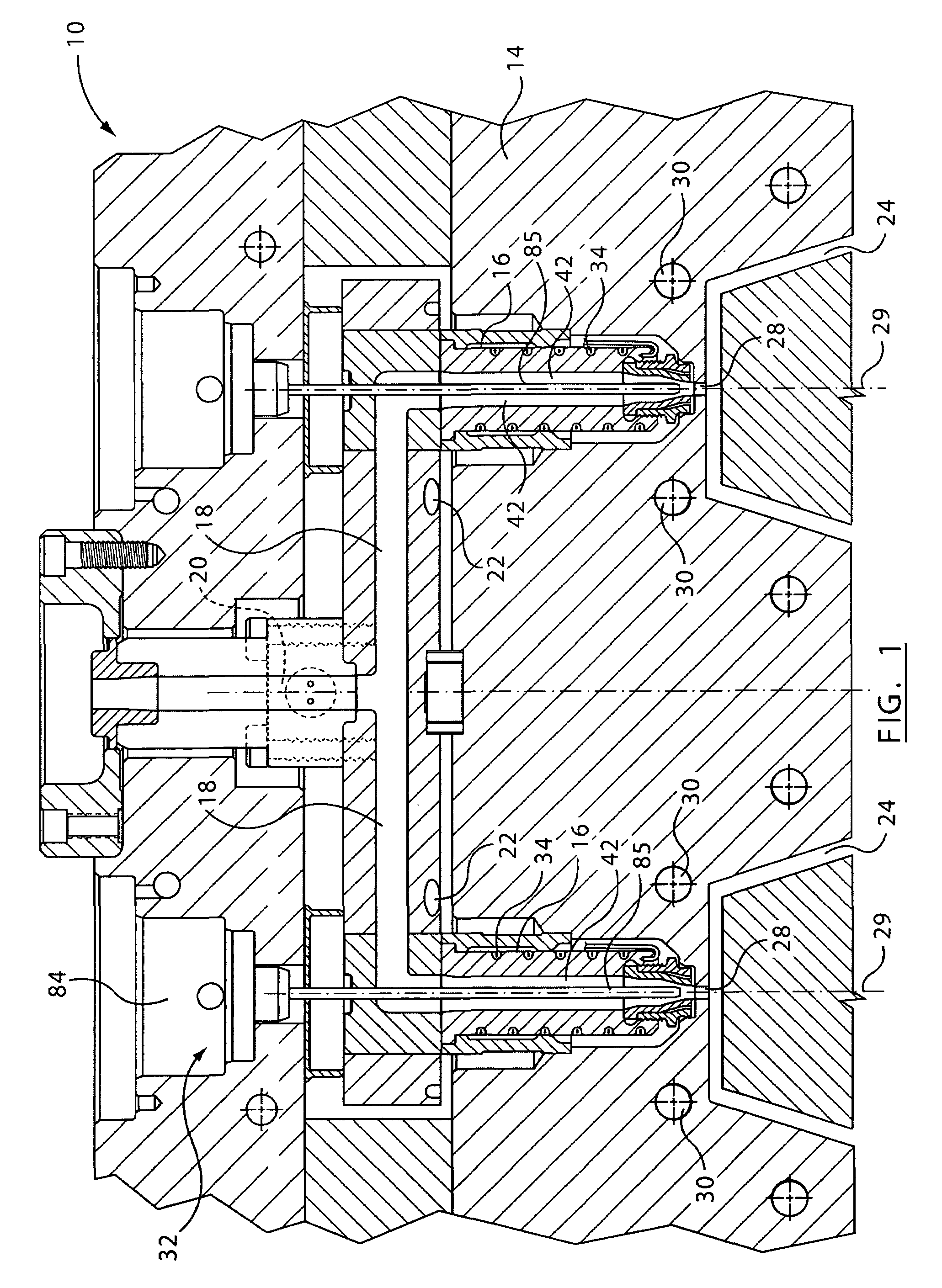

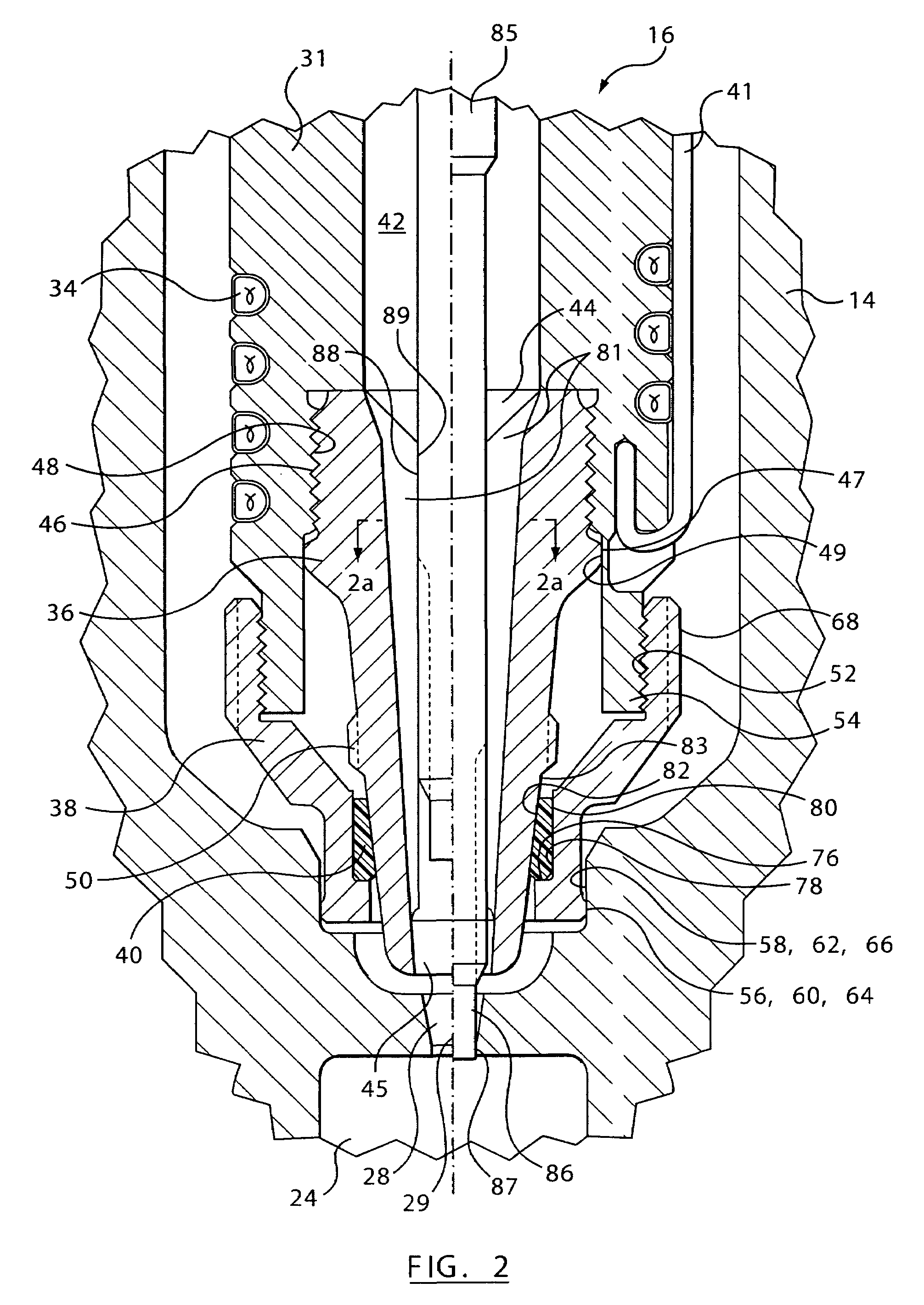

Hot runner nozzle with a tip, a tip surrounding piece and an alignment piece

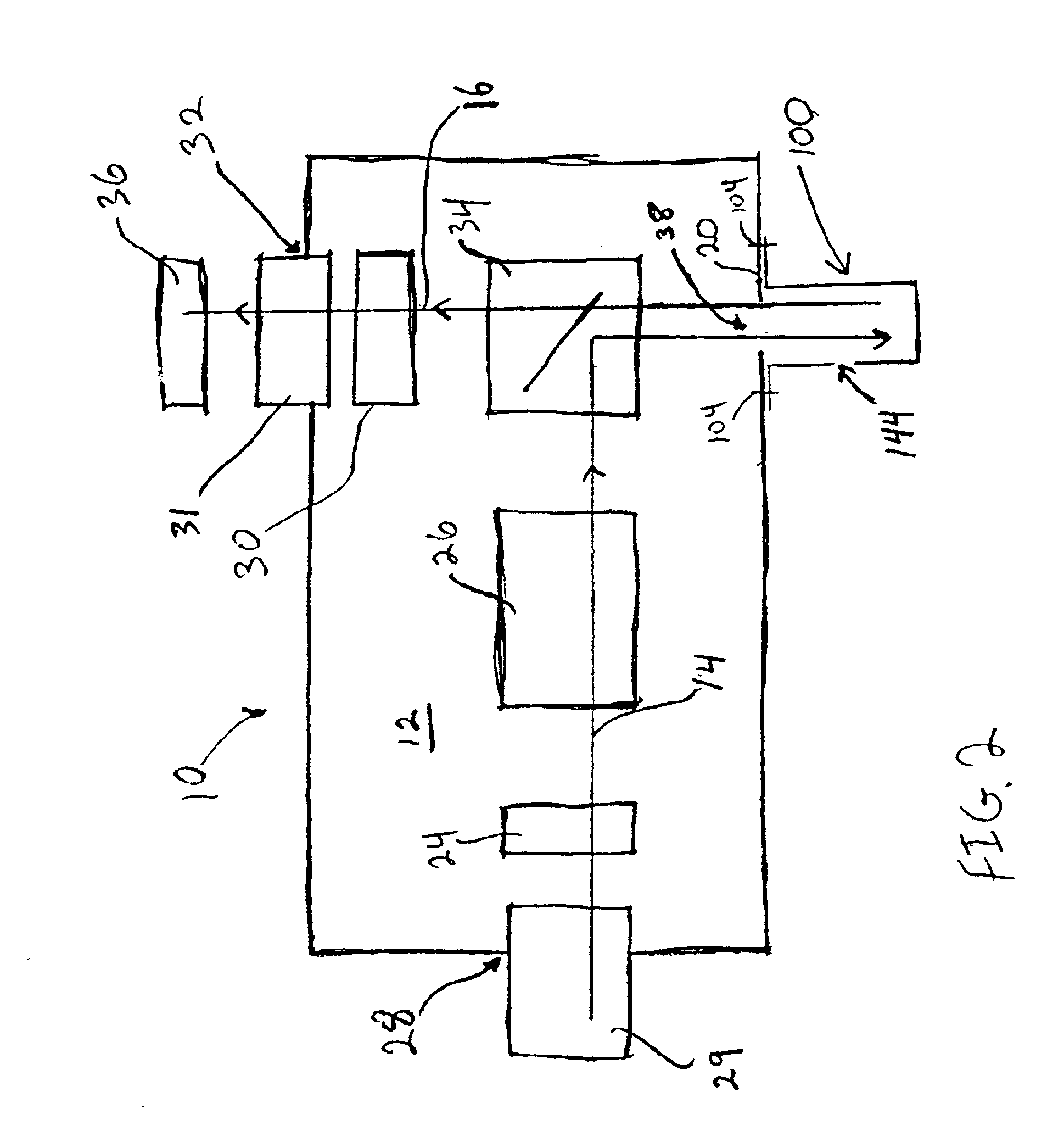

A nozzle for an injection molding apparatus is provided. The injection molding apparatus includes a manifold and a mold component. The manifold has at least one runner therein that is downstream from a melt source. The mold component defines at least one mold cavity and defining a gate into each mold cavity. The gate defines an axis. The mold component has a mold component alignment surface thereon. The nozzle includes a nozzle body, a tip, a tip surrounding piece and an alignment piece. The nozzle body defines a nozzle body melt passage, which is adapted to be in fluid communication and downstream from the at least one runner. The tip is removably connected to the nozzle body. The tip defines a tip melt passage therethrough. The tip melt passage is downstream from and in fluid communication with the nozzle body melt passage, and is upstream from and in fluid communication with the gate. The tip surrounding piece is removably connected with respect to the nozzle body. The alignment piece is positioned between the tip and the tip surrounding piece. The tip contacts the alignment piece to align the tip with respect to the alignment piece. The alignment piece contacts the tip surrounding piece to align the alignment piece with respect to the tip surrounding piece. The tip surrounding piece is adapted to contact the mold component to align the tip surrounding piece with respect to the gate, so that the tip is aligned with respect to the gate. The contact between the tip, the alignment piece, the tip surrounding piece and the mold component is adapted to be axially proximate the gate.

Owner:MOLD MASTERS 2007

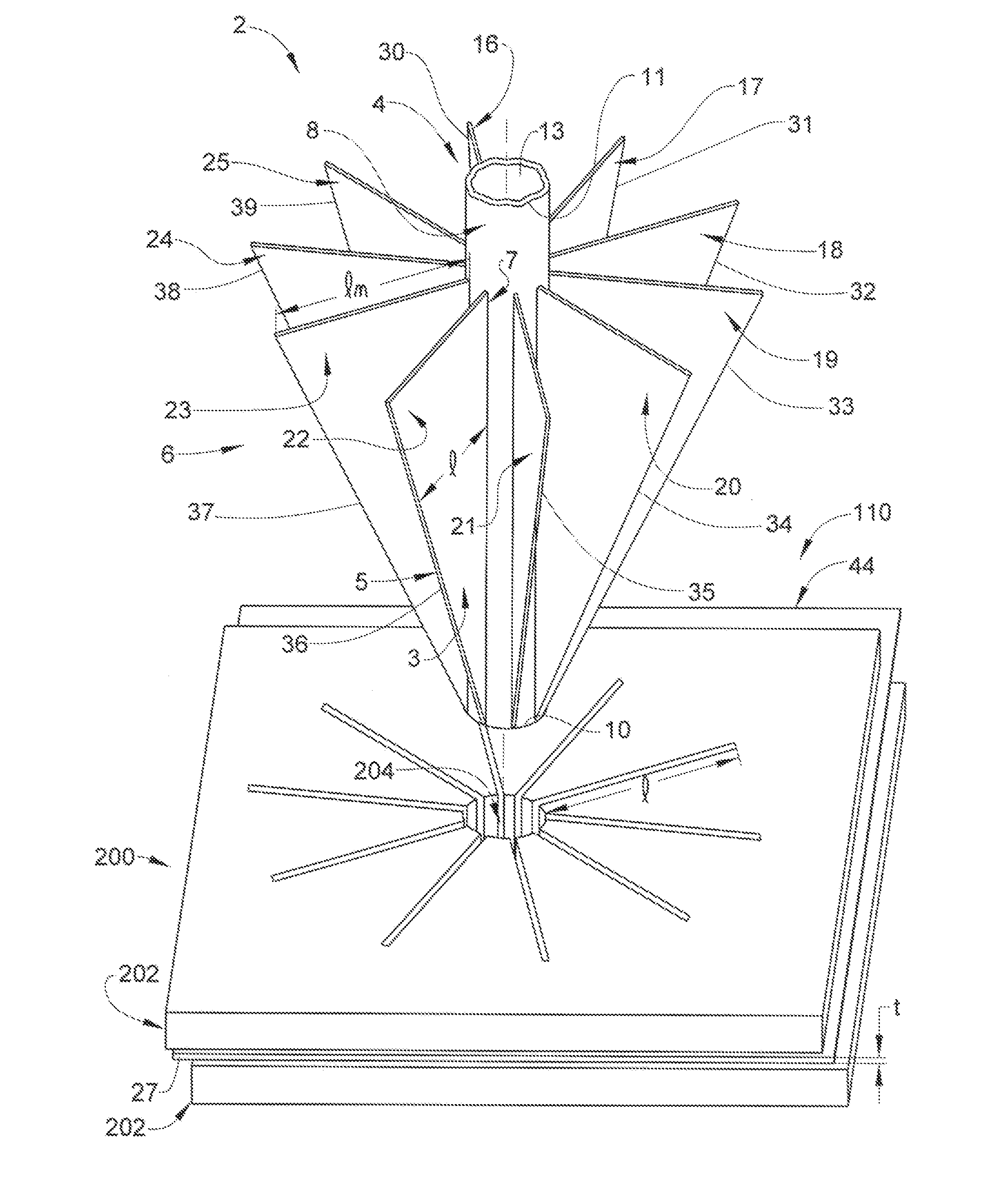

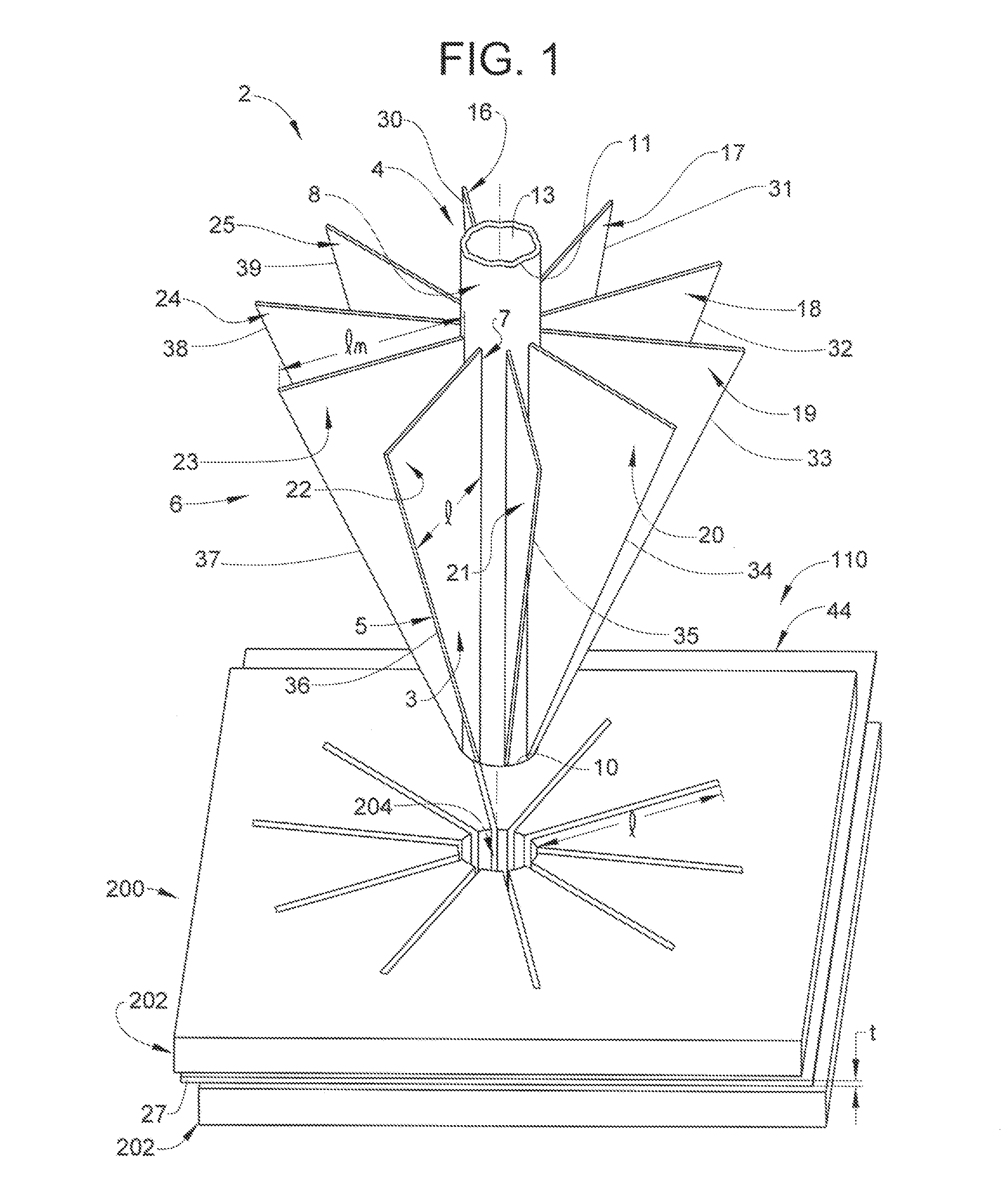

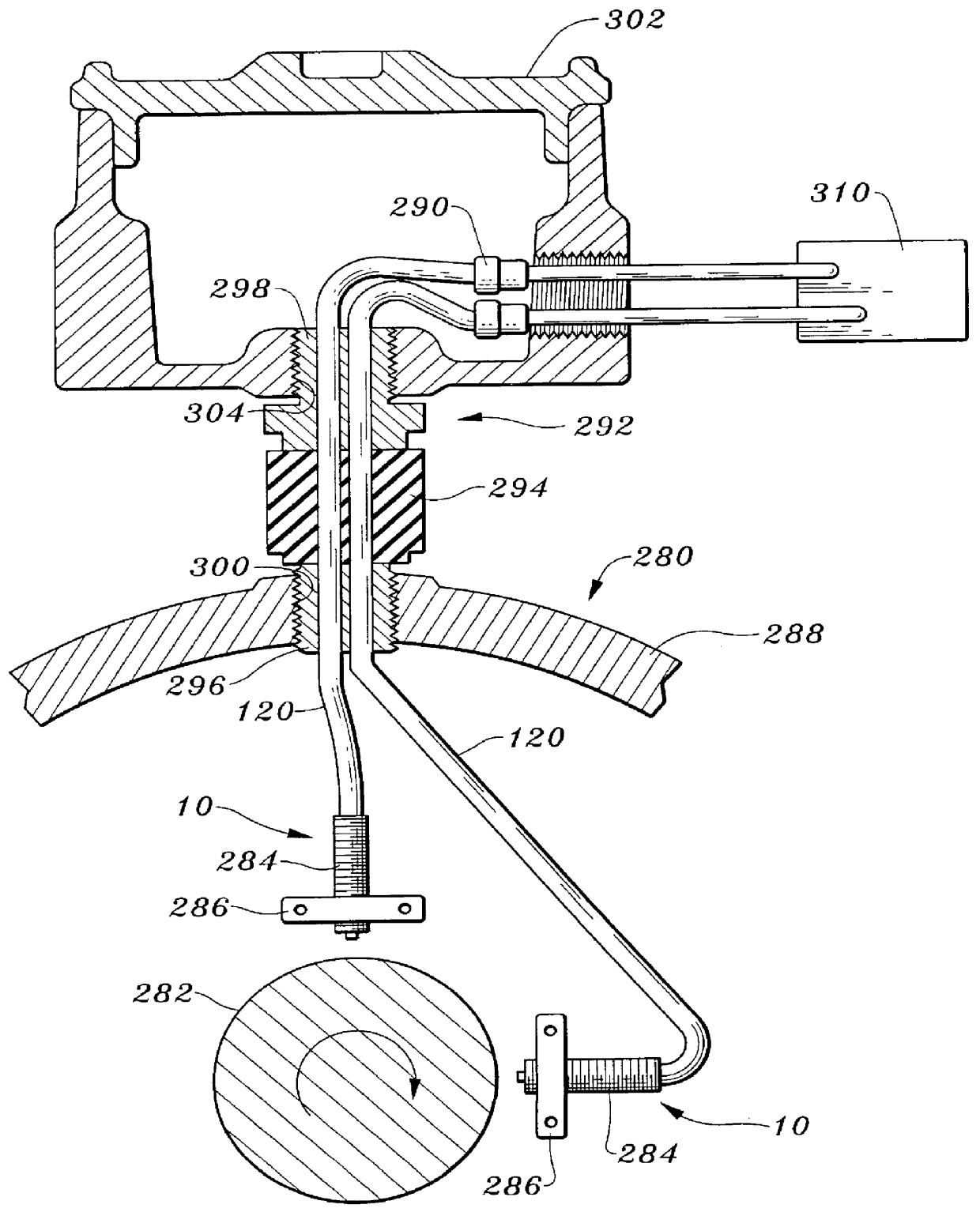

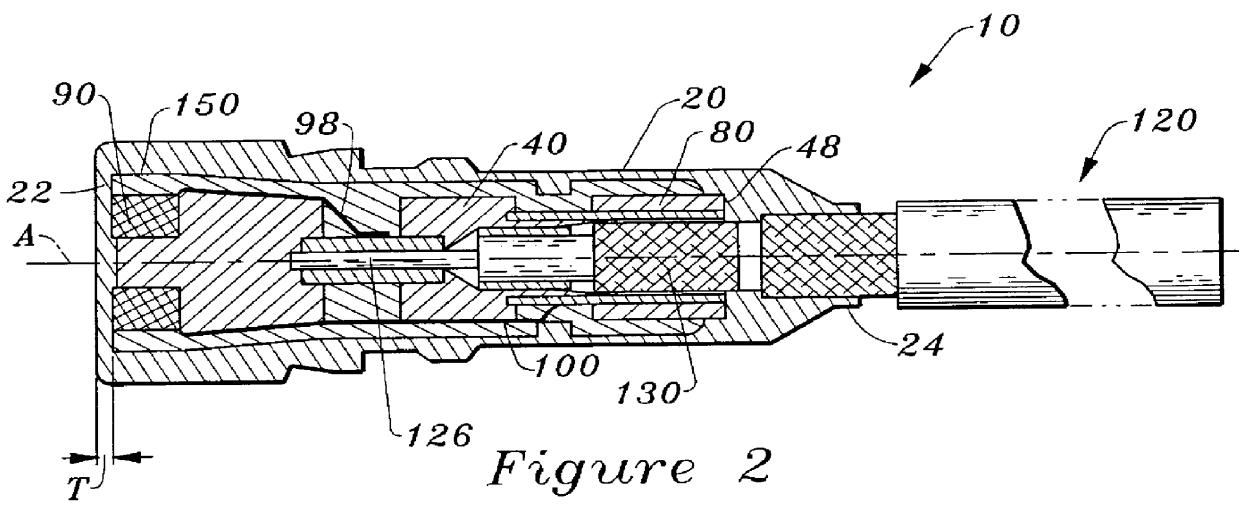

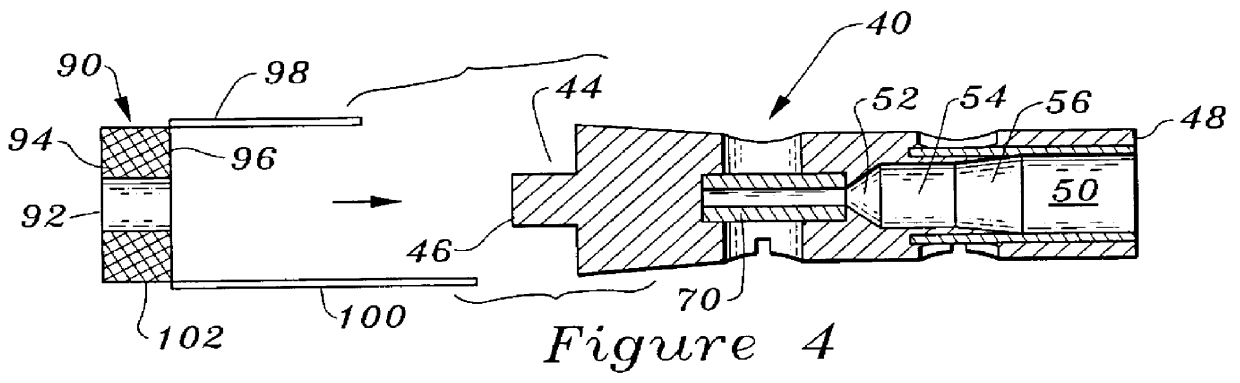

Method of manufacturing an encapsulated transducer with an integrally formed full length sleeve and a component alignment preform

An encapsulated transducer (10) includes an injection molded encapsulation (20) having front end (22) and back end (24). The encapsulation (20) is a monolith of cured moldable material ensconcing a sensing element or coil (90) proximate front end (22) and a portion of an information transmitting medium (120) emanating from back end (24). A component alignment preform (40) operatively couples sensing element (90) with information transmitting medium (120). A protective sleeve (150) is transfer molded over coil (90) and interlocked with preform (40) thereby forming a sleeved coil and cable assembly (170). This sleeved coil and cable assembly (170) is encapsulated by an injection molding process which provides the durable encapsulation (20). The sleeved coil and cable assembly (170) is symmetrically disposed within the encapsulation (20) and the encapsulation (20) includes an integrally formed protective wall having a uniform thickness "T" along a forwardmost portion of sensing element (90) and integrally transitioning into an uninterrupted side wall circumscribing the sensing element and a portion of the cable.

Owner:BENTLY NEVADA INC

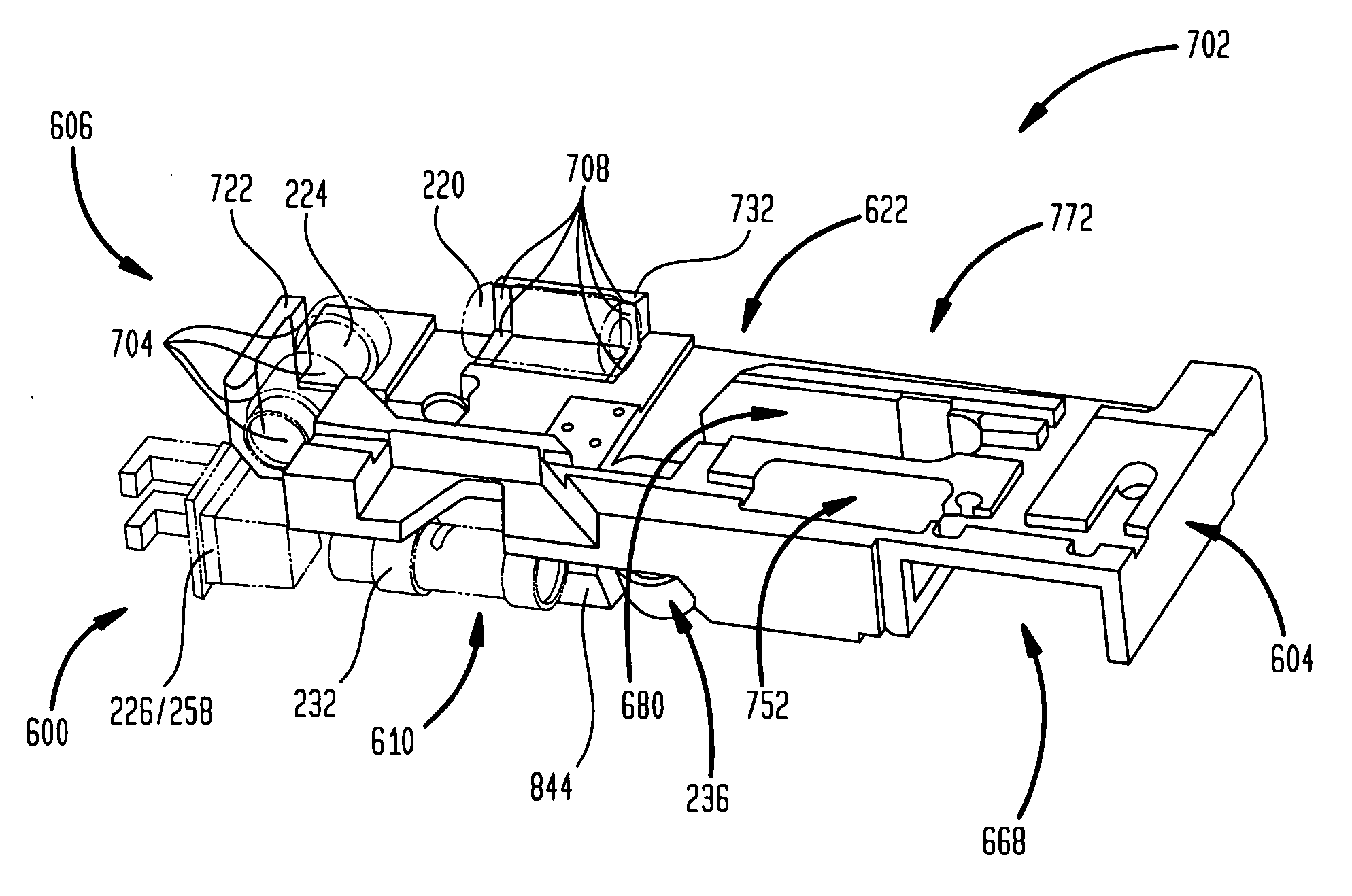

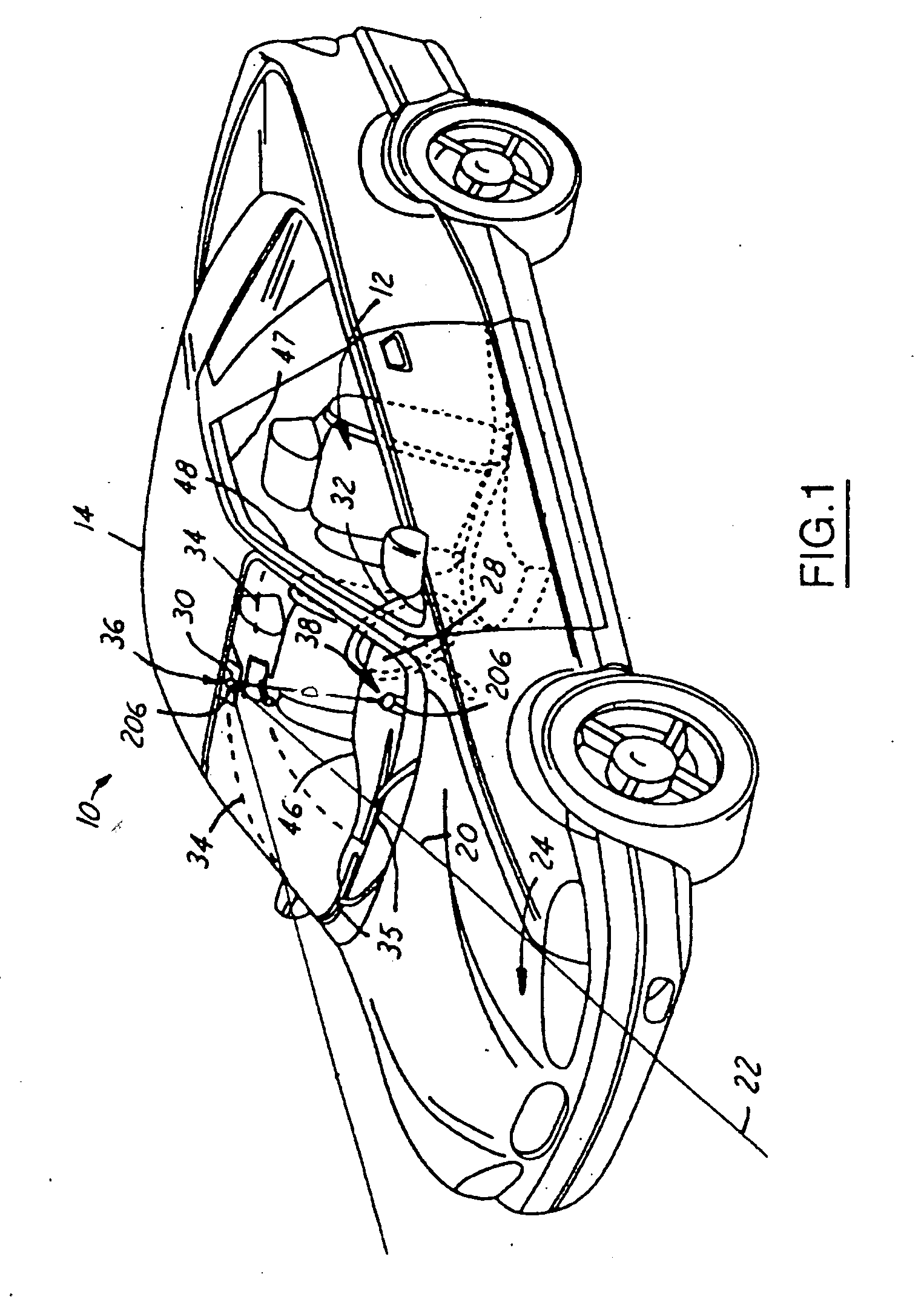

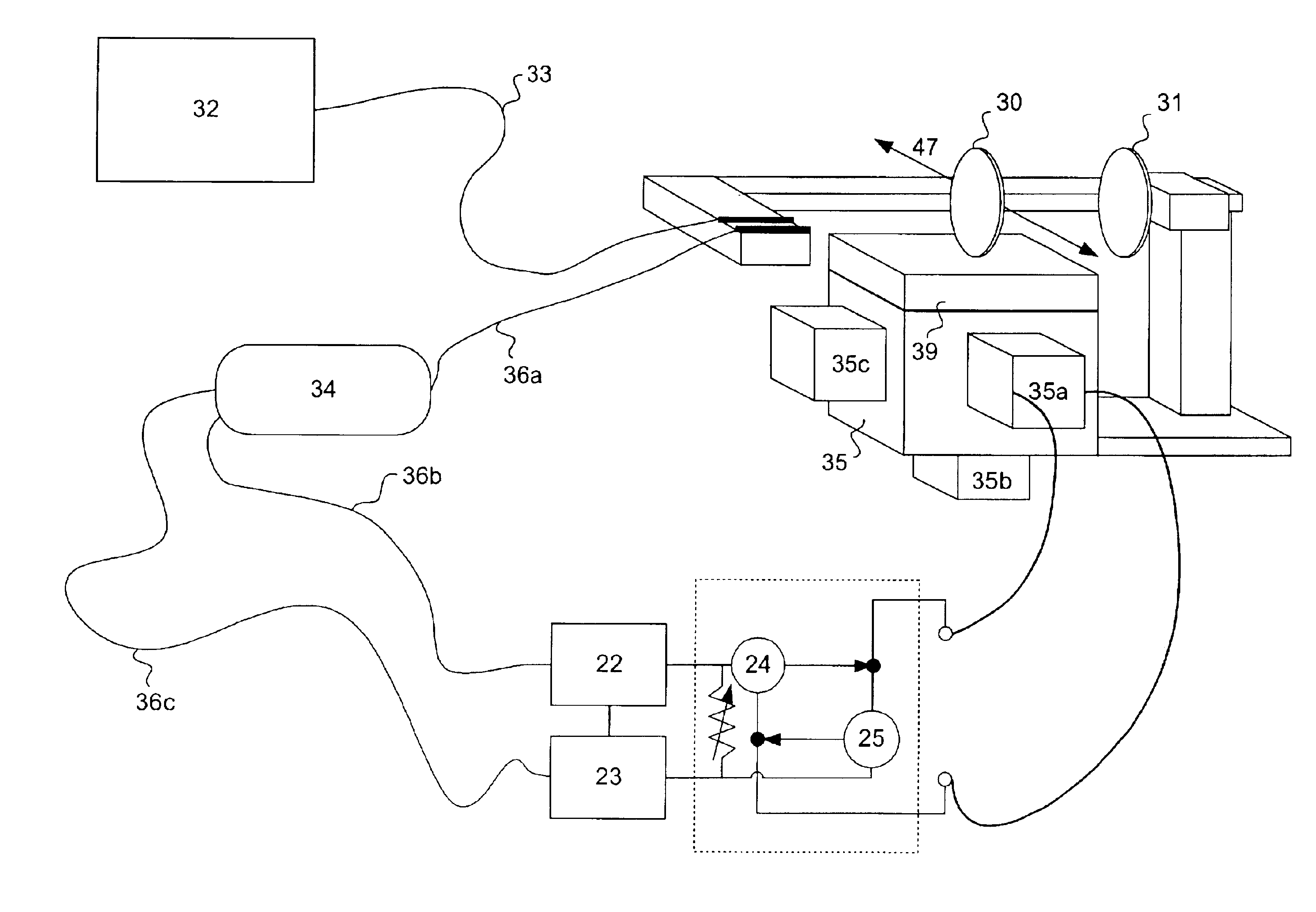

Laser scanning apparatus with improved optical features

InactiveUS7570352B2Easy and reliable mechanismReduce in quantityUsing optical meansMechanical measuring arrangementsFiberData averaging

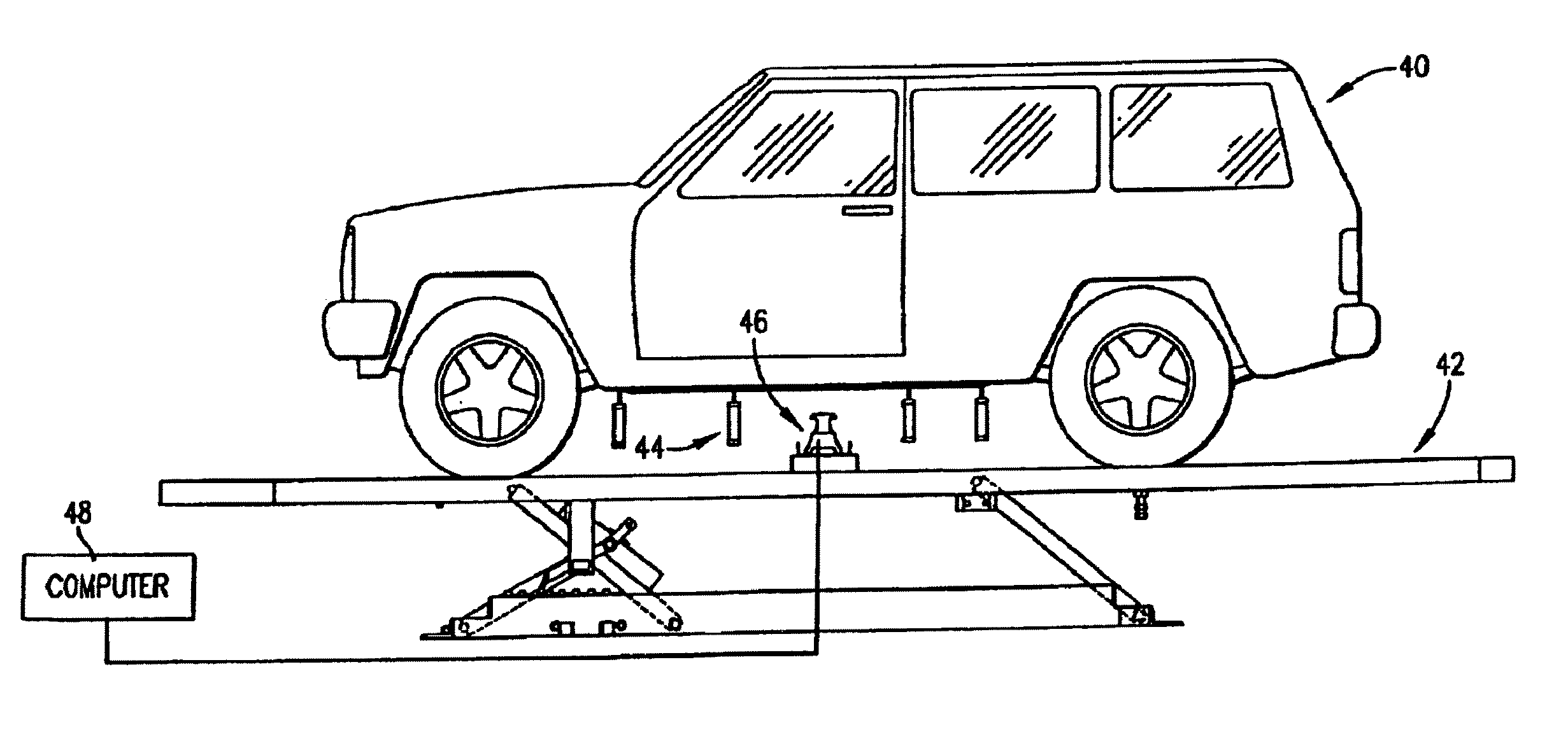

Laser scanners are used for determining deformation in vehicle bodies and the like, using a laser scanning apparatus in conjunction with a plurality of coded targets suspended from (or in known relationship to) known reference points on the vehicle to calculate three dimensional spatial coordinates defining the actual positions of the targets, and to compare such calculated positions with manufacturer-provided specification values. The present invention provides improved signal collection through the use of an independent synchronization circuit that uses a fiber optic cable for signal collection; improved component isolation through the use of a mounting plate and isolation mounts; improved component alignment through the use of easier and more reliable alignment mechanisms; and improved data collection and processing through the use of onboard data averaging and filtering.

Owner:VEHICLE SERVICE GROUP LLC

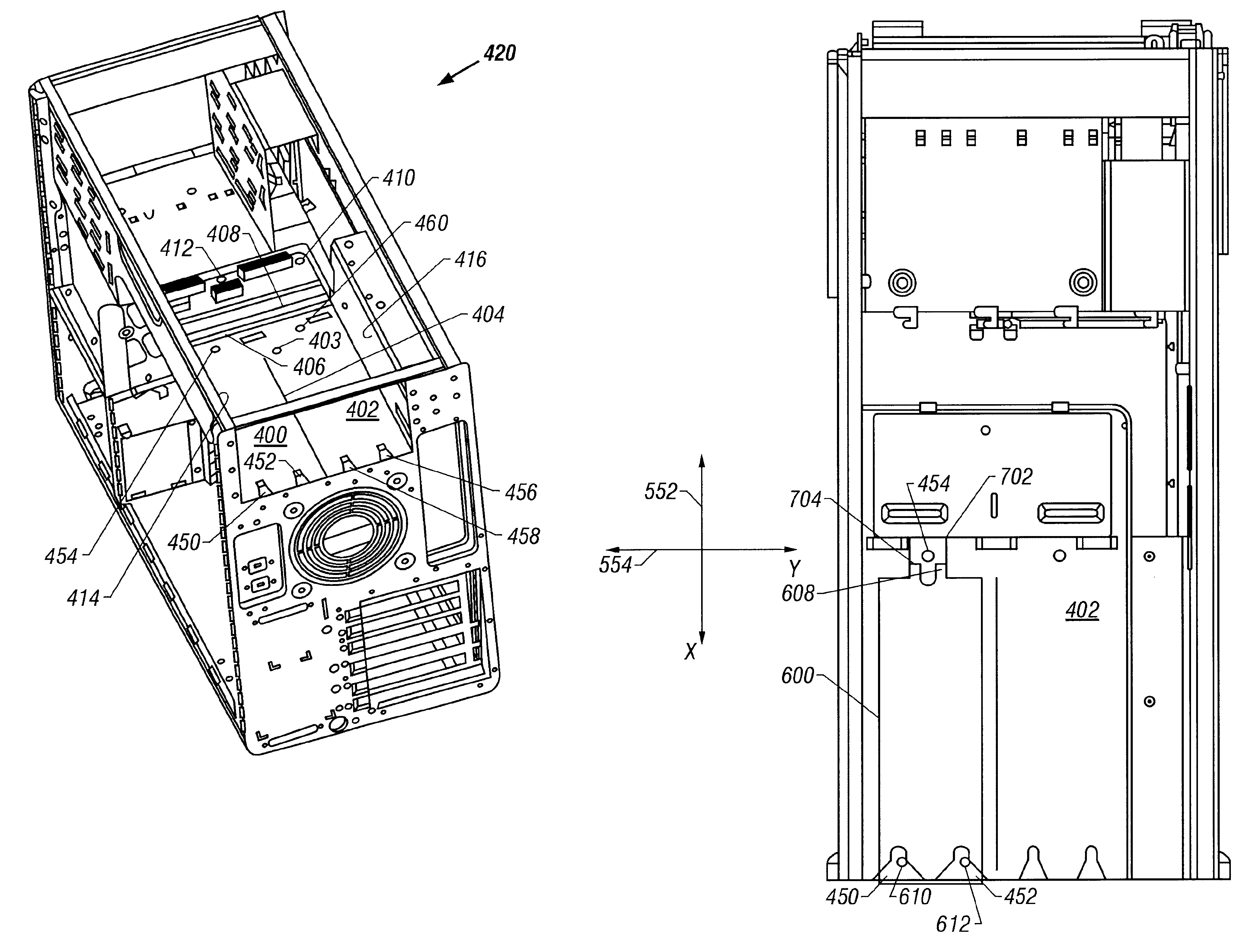

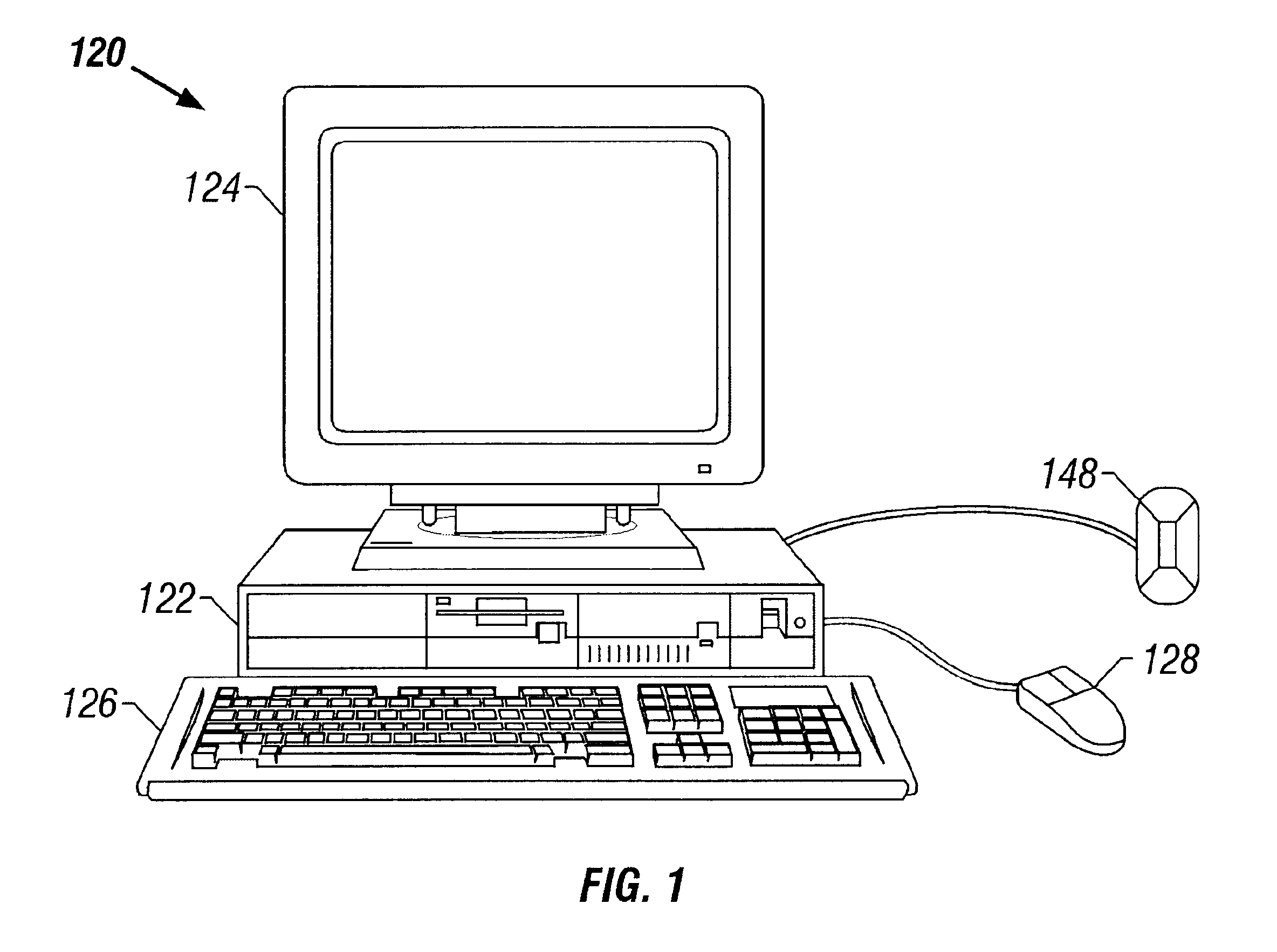

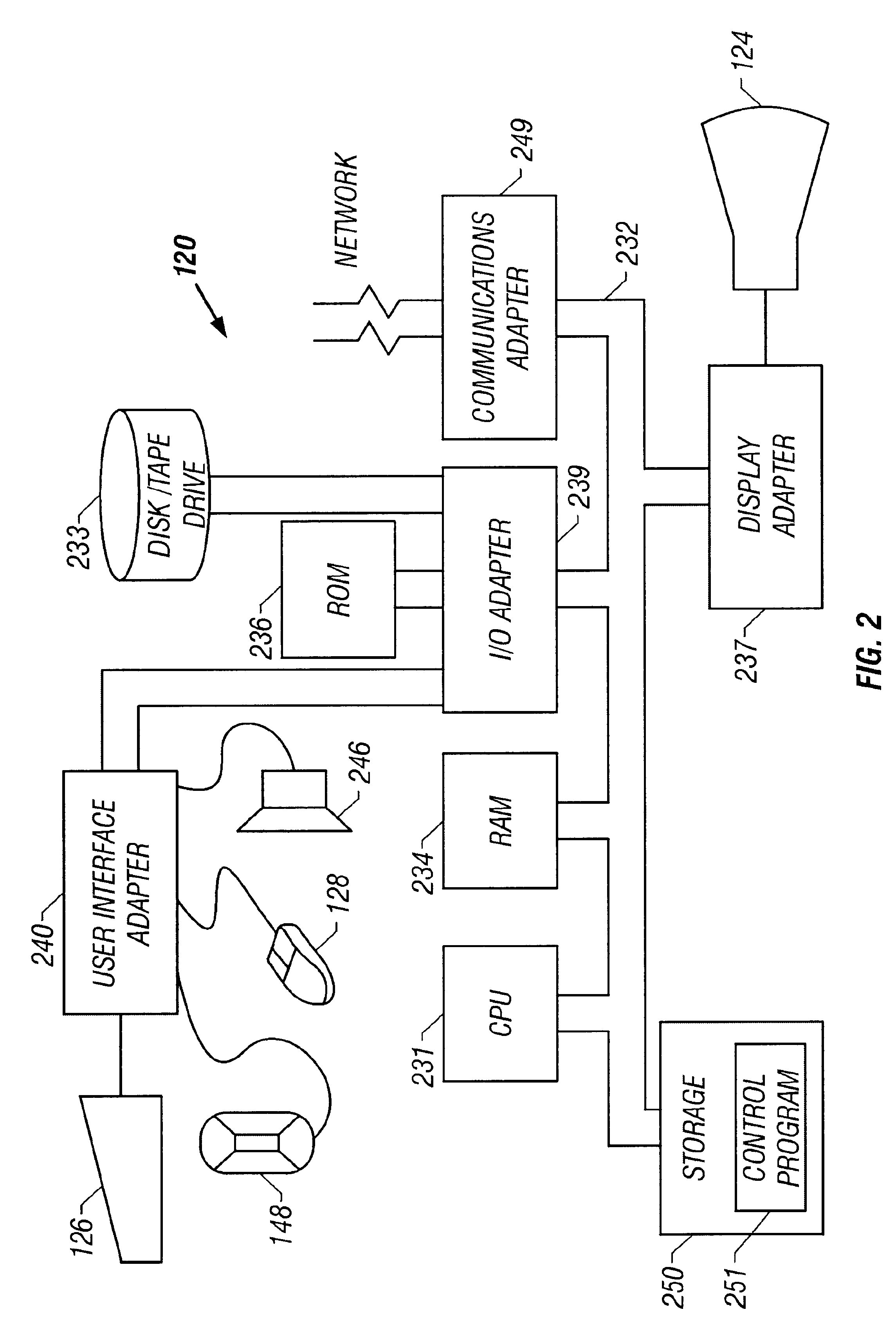

Data processing system component alignment

InactiveUS6354861B2Incorrect coupling preventionDigital data processing detailsData processing systemComponent alignment

A method and apparatus related to a data processing system contiguous-reference connection alignment mechanism. In one embodiment, an apparatus includes but is not limited to a data processing system contiguous-reference connection alignment mechanism, wherein the data processing system contiguous-reference connection alignment mechanism further includes but is not limited to a y-axis direction contiguous-reference alignment mechanism, wherein the y-axis direction contiguous-reference alignment mechanism further includes but is not limited to at least one fore-positioned data processing system connection guidance cylinder slot formed to catch a connection guidance cylinder misaligned in the y-axis direction and guide the connection guidance cylinder into substantial y-axis direction alignment. In one embodiment, a computer system includes but is not limited to a data processing system contiguous-reference alignment mechanism.

Owner:DELL PROD LP

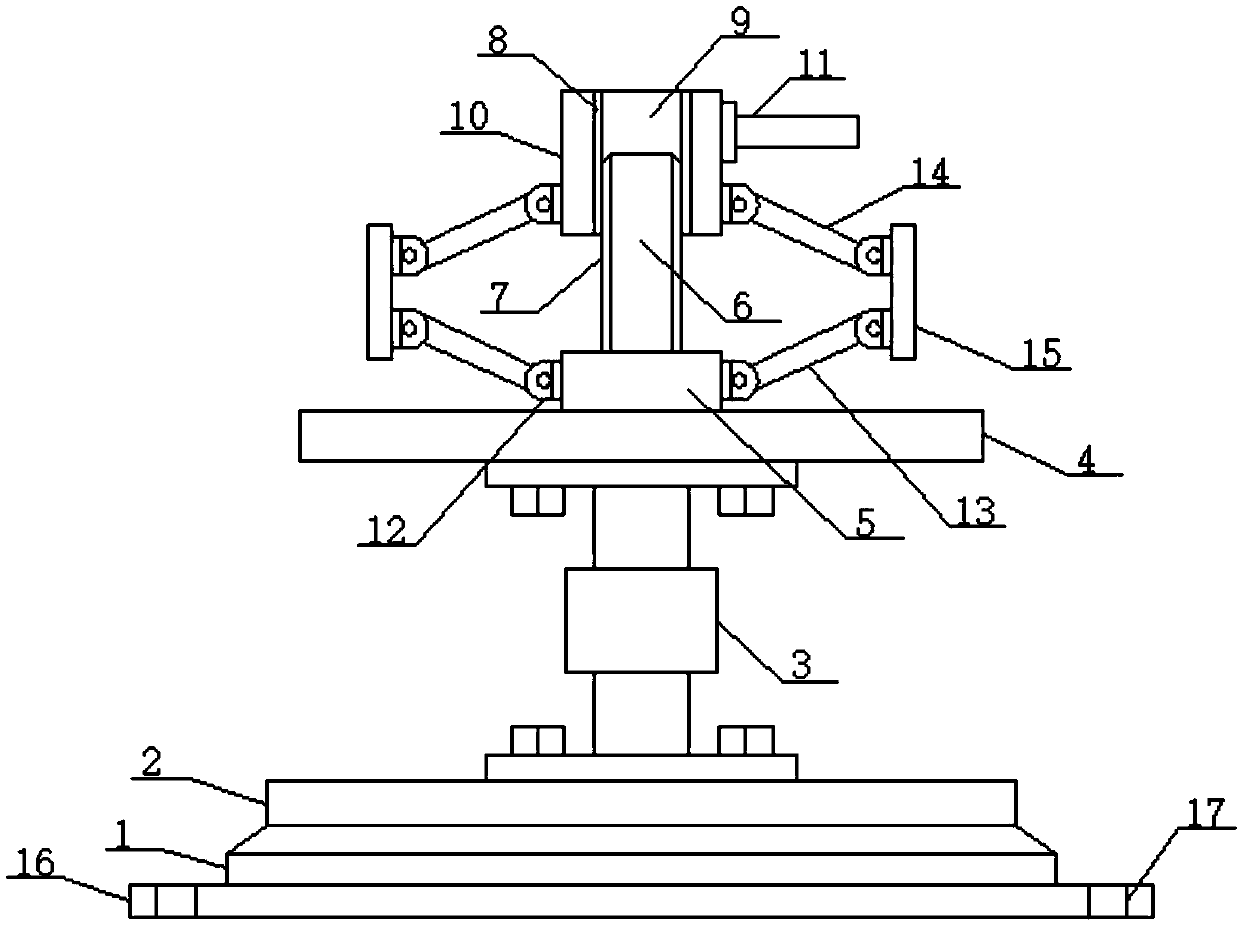

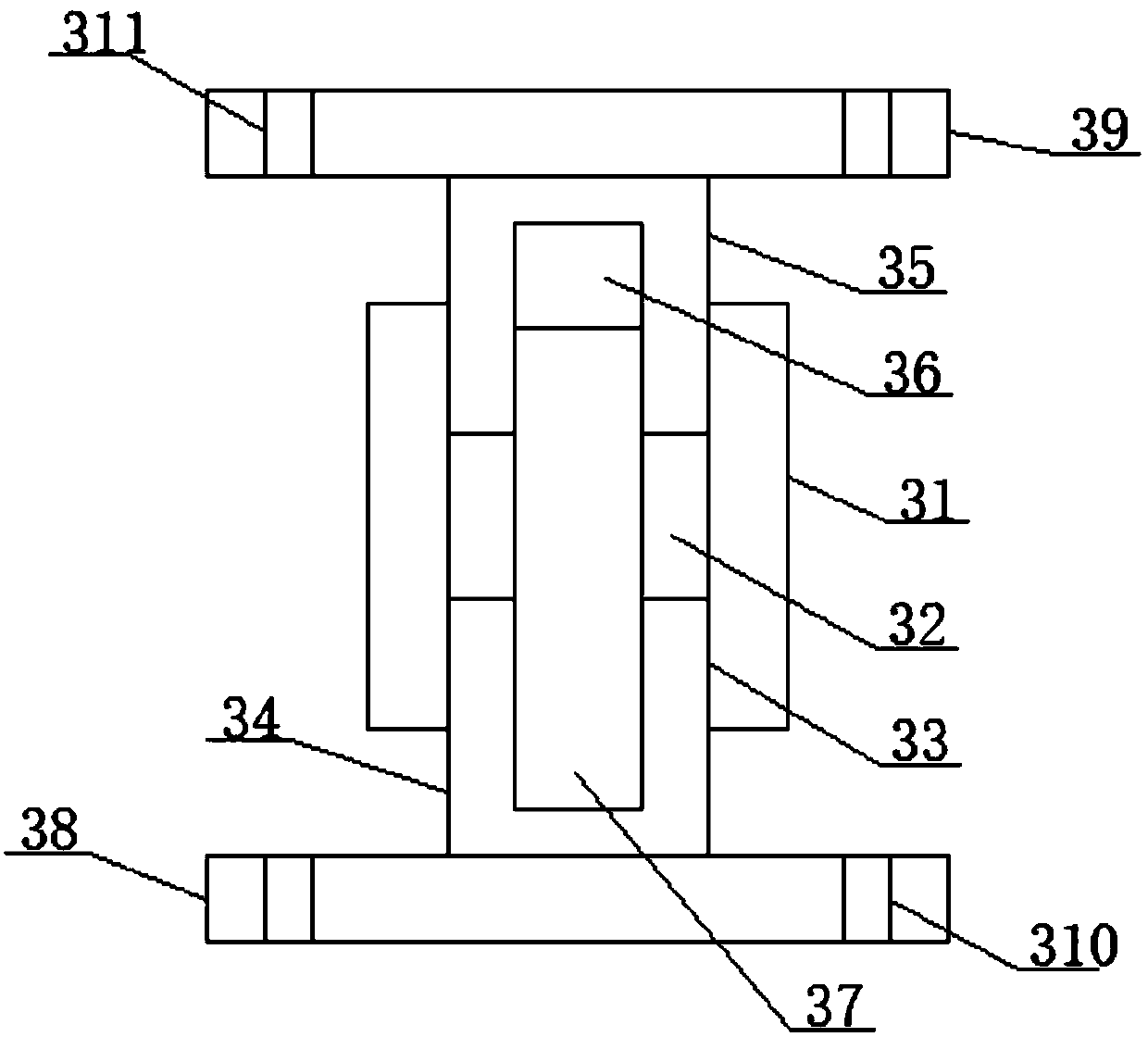

Tire inner sleeve type positioning device for tire peeling machine

InactiveCN109551661AAvoid damageAchieve positioningPlastic recyclingComponent alignmentTriangulation

The invention discloses a tire inner sleeve type positioning device for a tire peeling machine. The tire inner sleeve type positioning device for the tire peeling machine comprises a bottom supportingbase plate. According to the tire inner sleeve type positioning device for the tire peeling machine, a triangulation positioning principle, a thread structure movement principle and a connecting rodtechnology are used, under the action of driving by a thread structure, synchronously driving is carried out on an abutting and contacting plate arranged on an annular array synchronously to realize the positioning effect of a tire inner ring, the operation is simple, and the positioning state is stable; the device is provided with a reverse thread rotating type longitudinal height component alignment mechanism, a rotation principle of a reverse thread structure is used, the longitudinal height can be adjusted, the adjusting action of the longitudinal height of a tire is realized, and workingis convenient; in addition, the device is provided with an inner sleeve annular array spiral spring type maximum rotation strength effective control mechanism, the annular array arrangement is used, the maximum rotation strength can be controlled, the thread structure damage phenomenon due to the fact that the rotation strength is too much is prevented from occuring, and in addition, the device isprovided with a bolt fixed type connecting rod movable link mechanism.

Owner:杨国亭

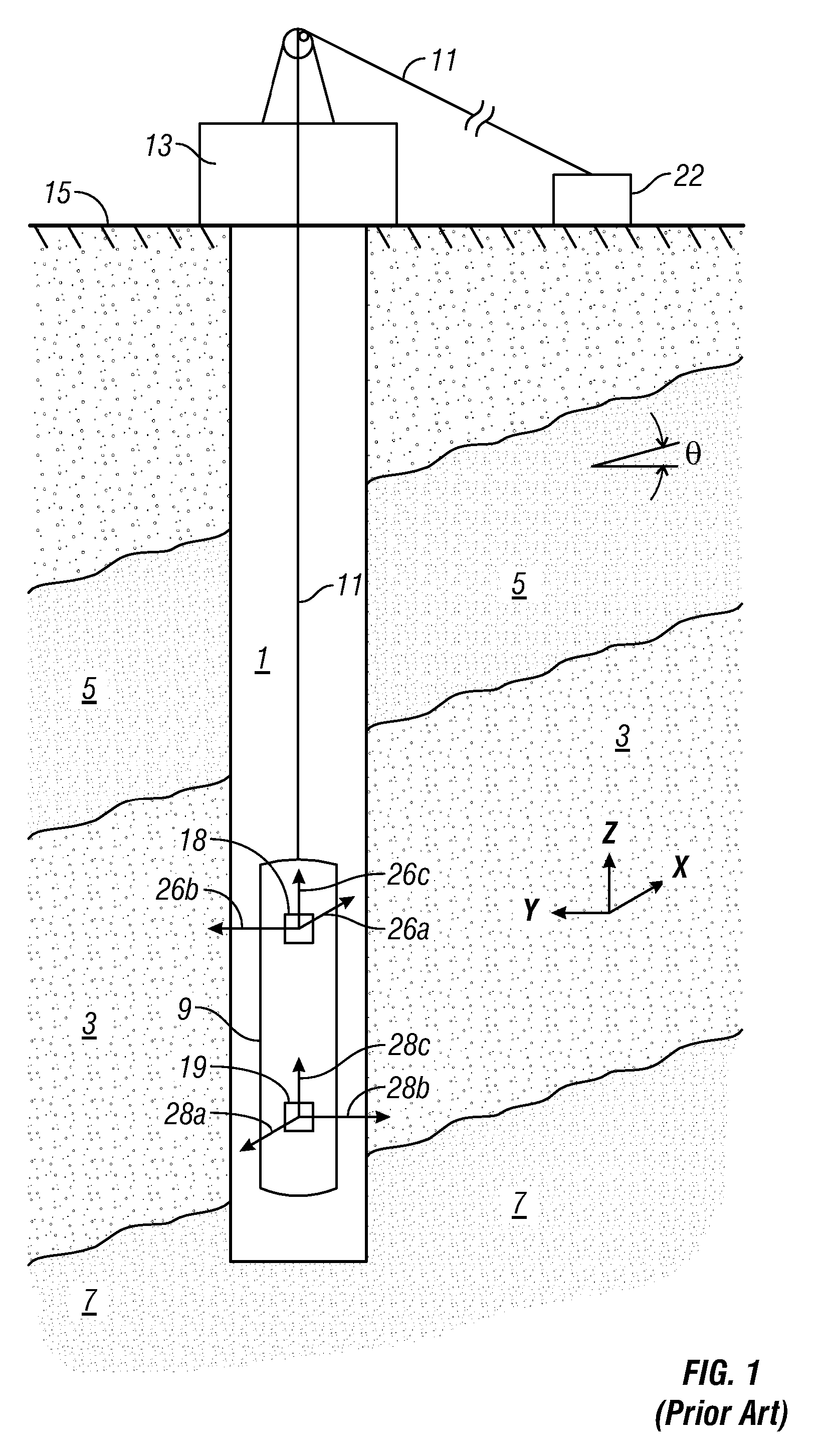

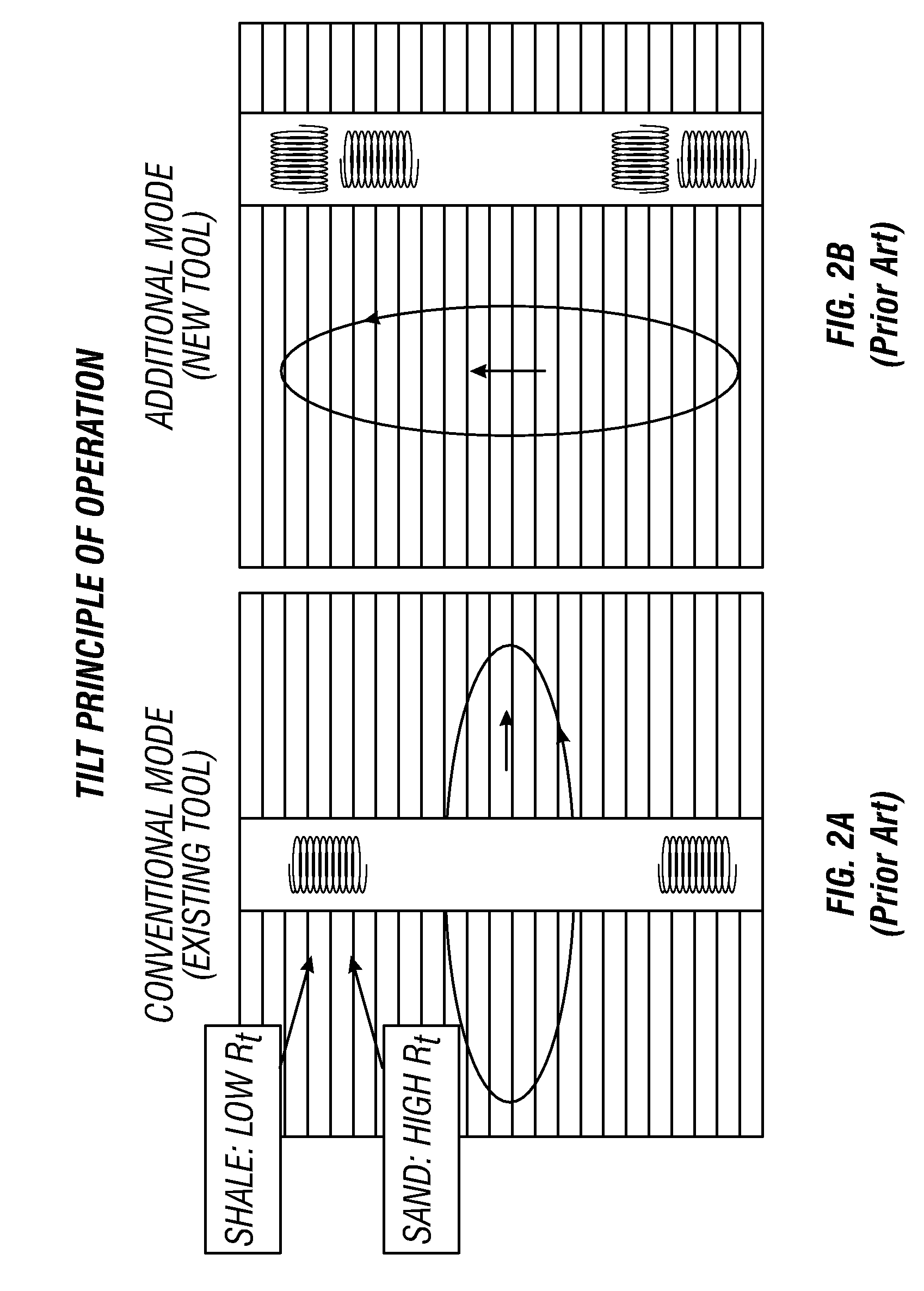

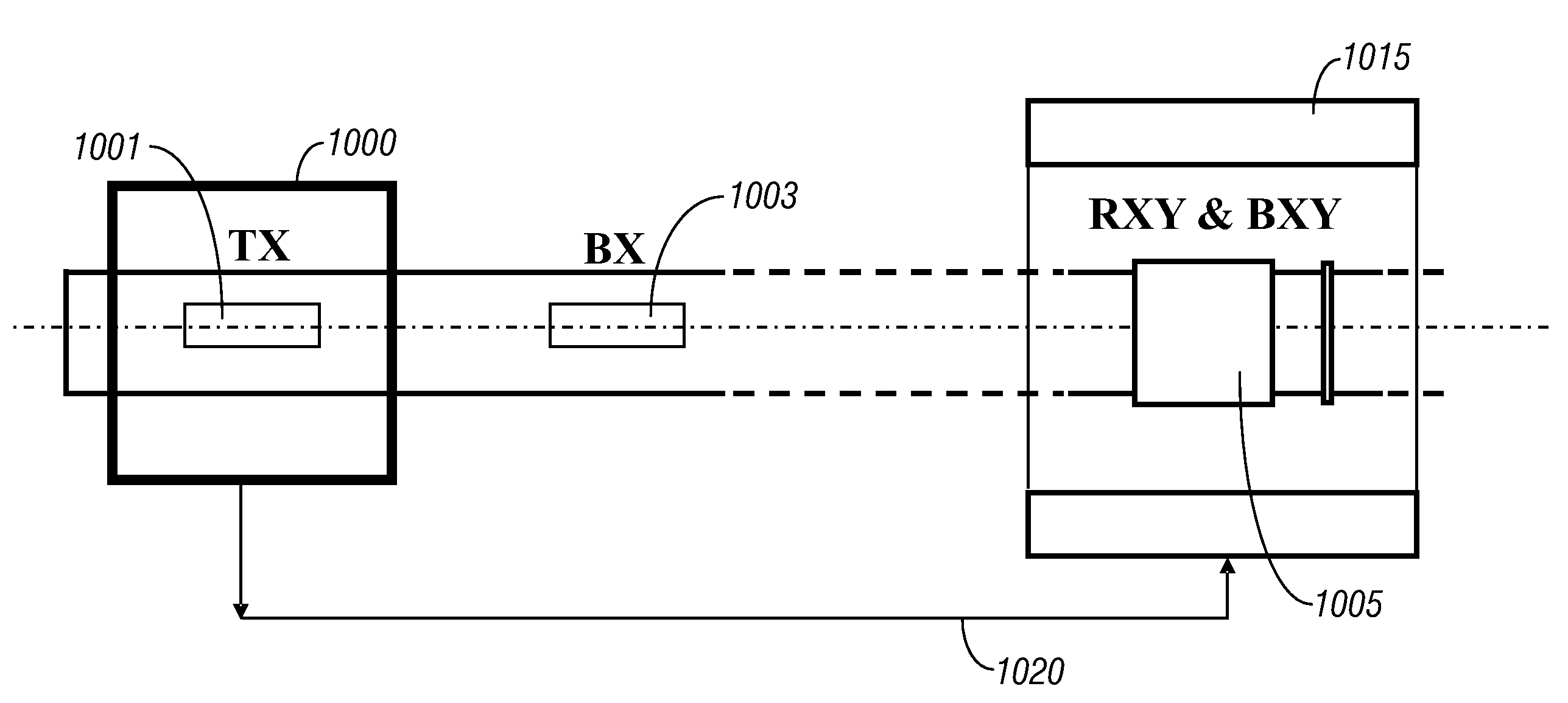

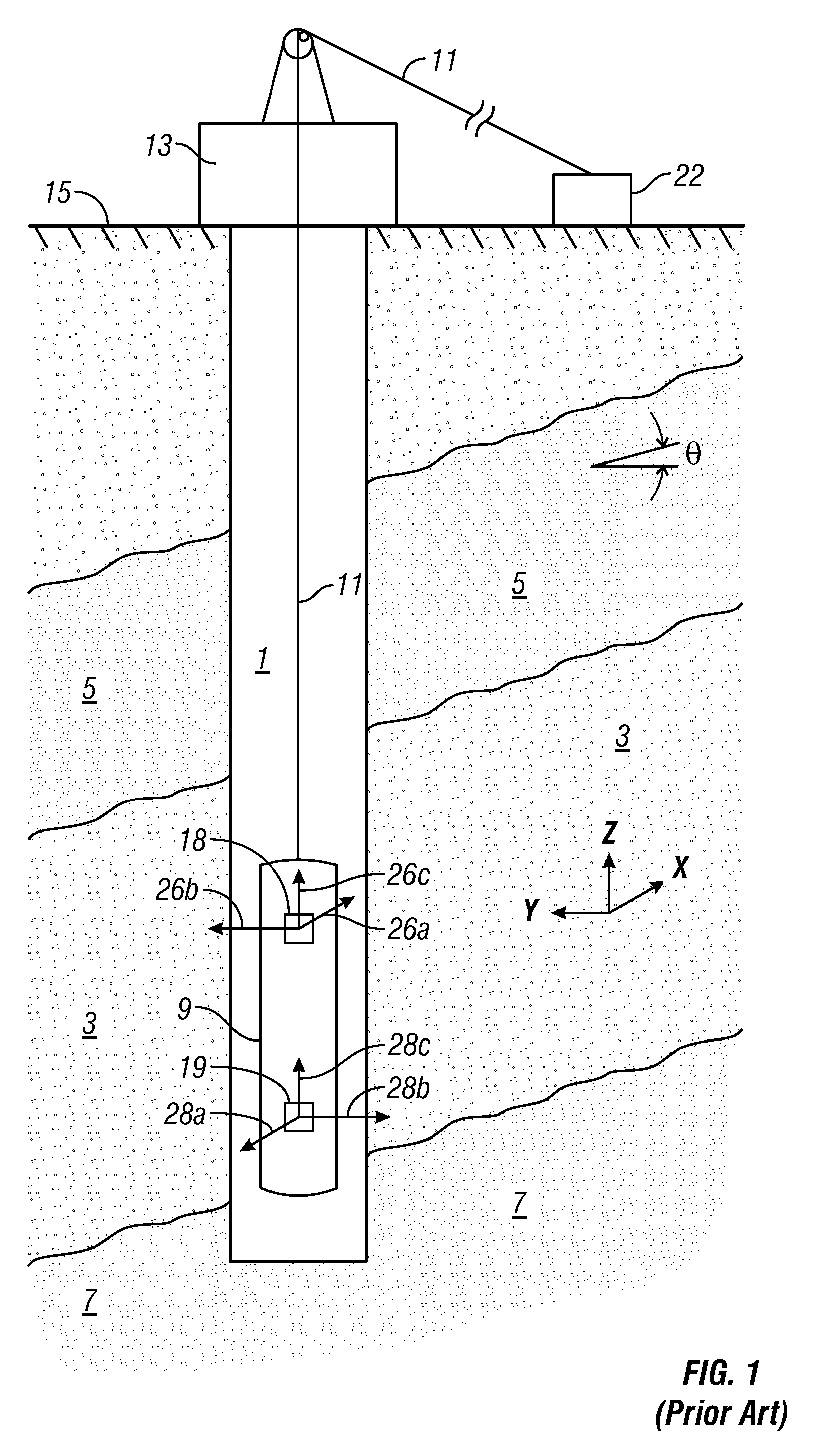

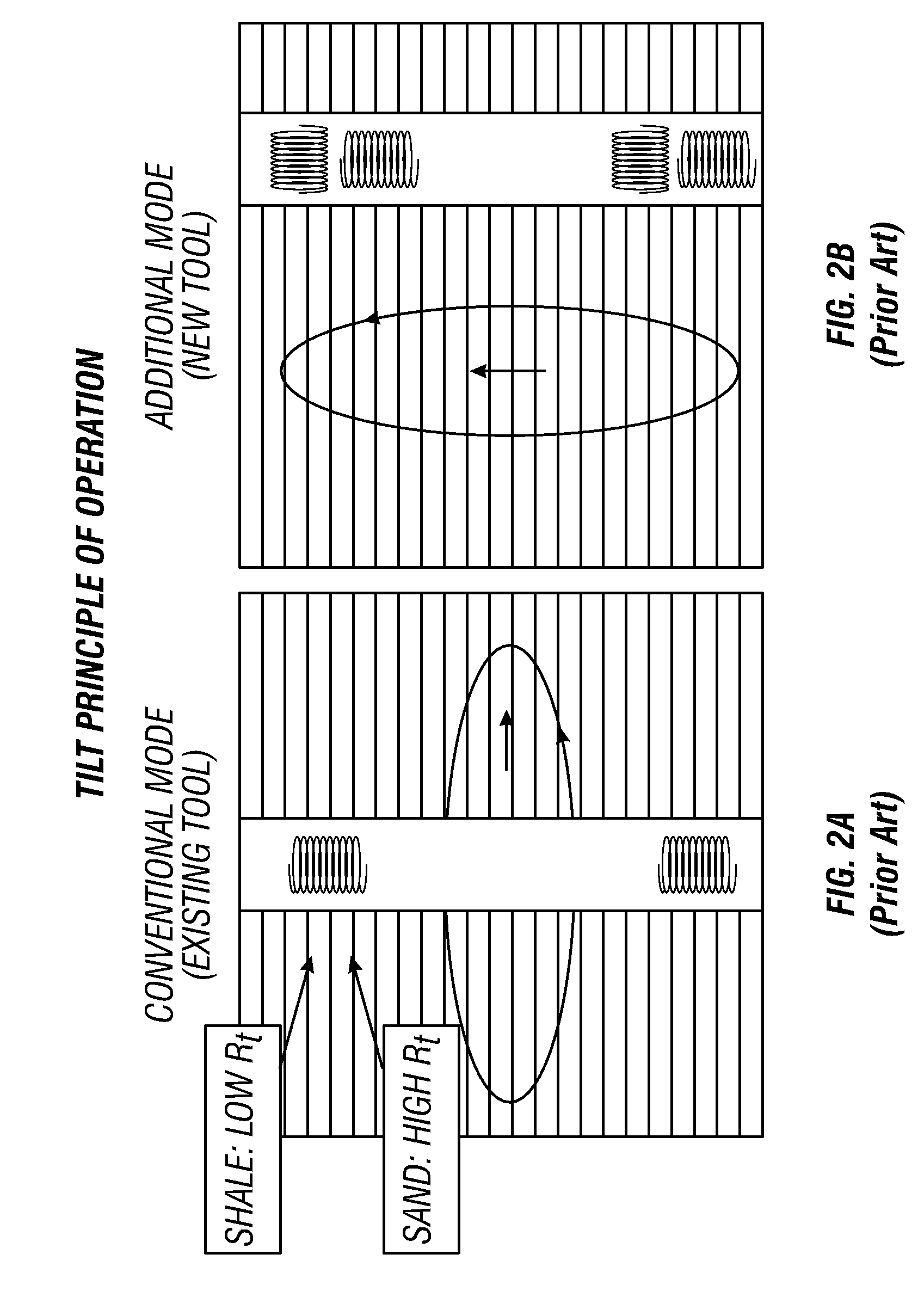

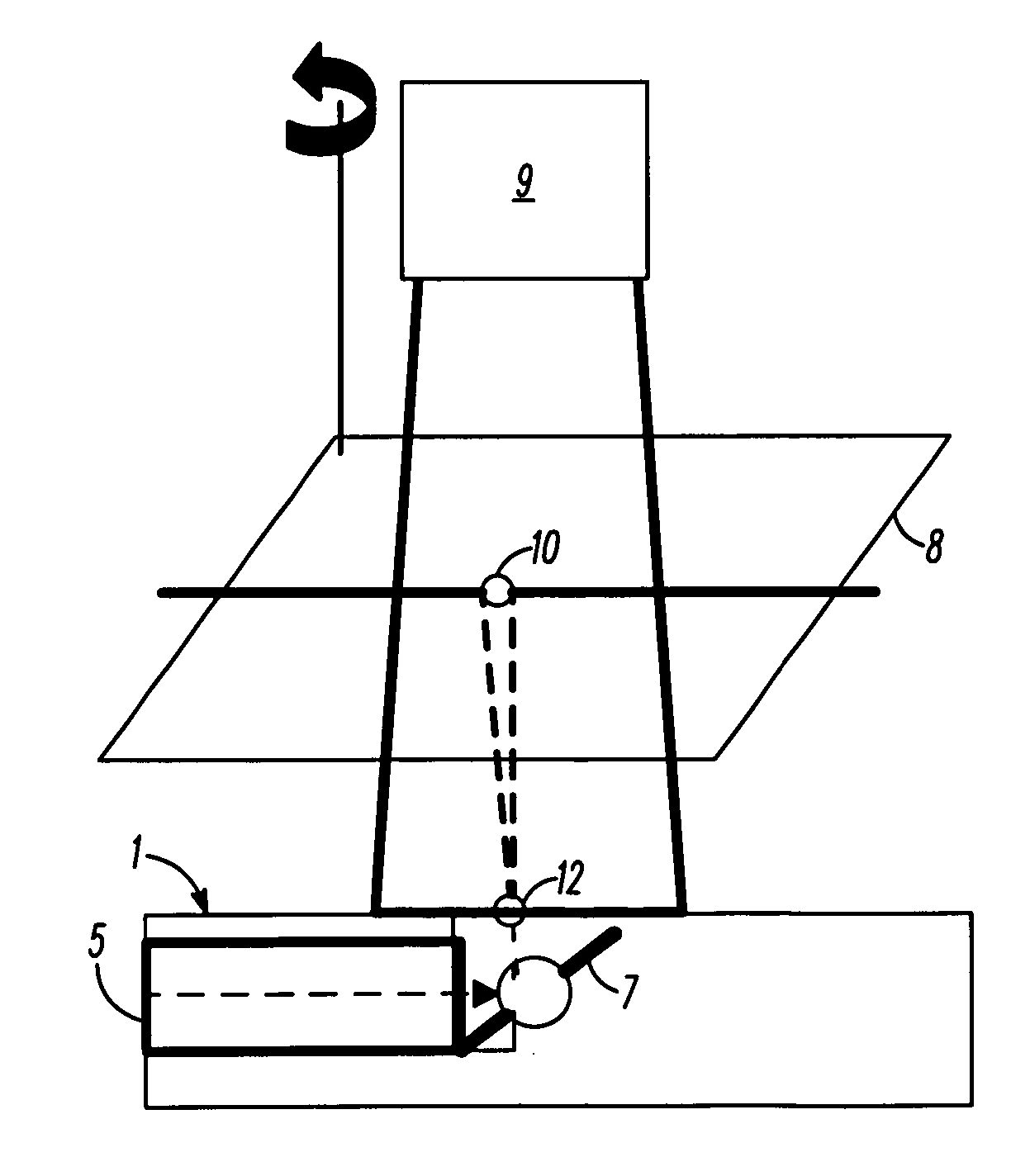

Cross-Component Alignment Measurement and Calibration

InactiveUS20070103160A1Electric/magnetic detection for well-loggingAcoustic wave reradiationComponent alignmentEngineering

A multicomponent induction logging tool is positioned within an alignment loop and the transmitter is activated at a number of rotation angles of the tool. Misalignment between the transmitter and receiver coils can be determined from the induced signals in the receiver coil.

Owner:BAKER HUGHES INC

Method for rapid positioning and mounting construction of fabricated structure concrete vertical components

InactiveCN110107094APrecise fine-tuning in placeFine-tuning in place quicklyBuilding material handlingComponent alignmentArchitectural engineering

The invention provides a method for rapid positioning and mounting construction of fabricated structure concrete vertical components, and relates to a positioning and mounting construction method. Themethod comprises the technological steps of construction preparation, site acceptance, acceptance and treatment of an original structure, surveying and setting-out, hoisting, mounting in place, grouting filling, maintenance, demolition, self-inspection and marking, and acceptance, a customized limiting formwork is utilized, steel bar precise positioning, and prefabricated wall plate and column component alignment mounting measures are adopted, an elevation, horizontal position and verticality fine-tuning correction methods are summarized, and part of measurement means in steel structure construction are introduced creatively, so that component fine-tuning in place is faster and more precise, a complete set of positioning and mounting construction technology is formed, the problem of precise positioning and mounting of the vertical components is solved, and the construction quality is ensured more easily.

Owner:NANJING NO 9 BUILDING INSTALLATION ENG

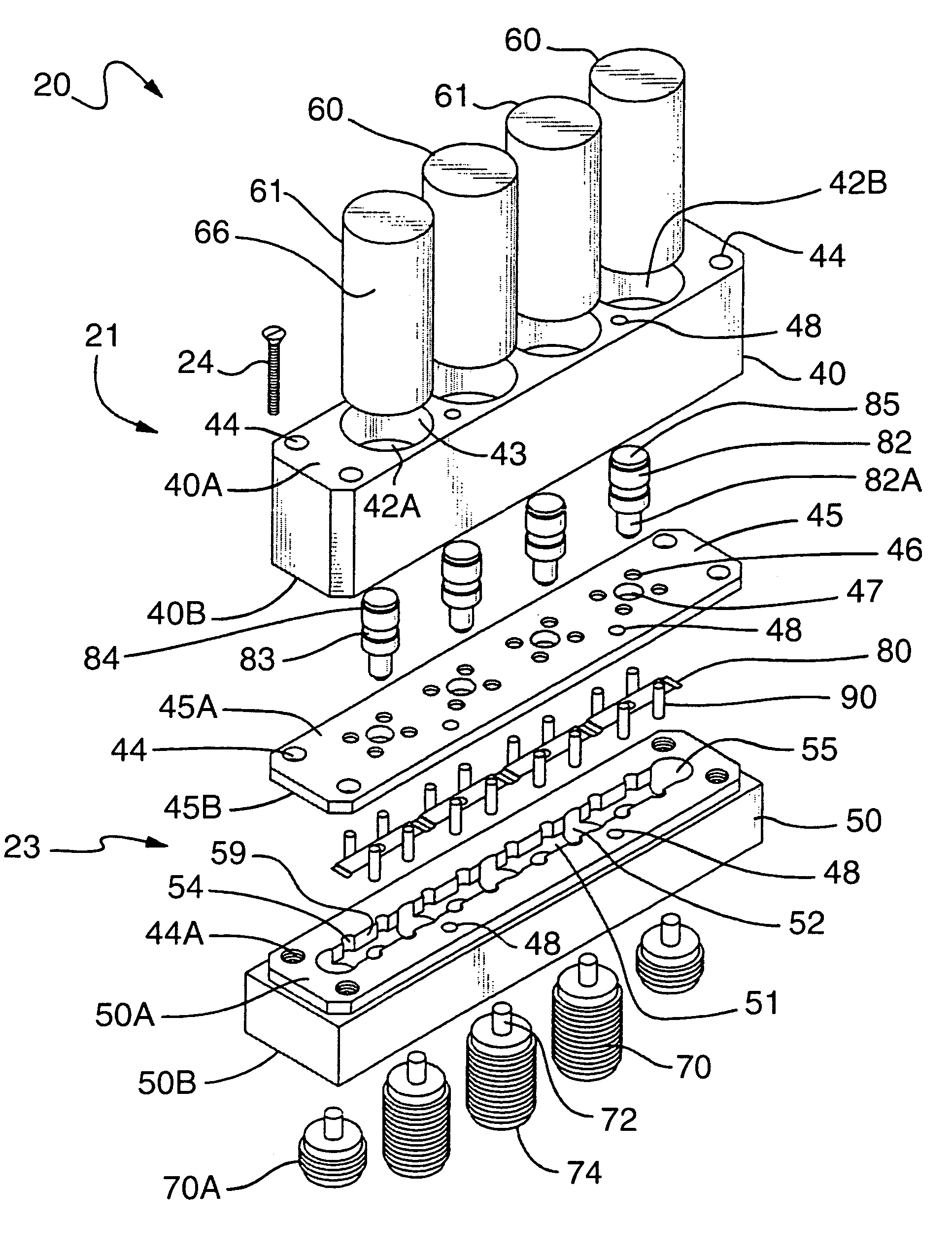

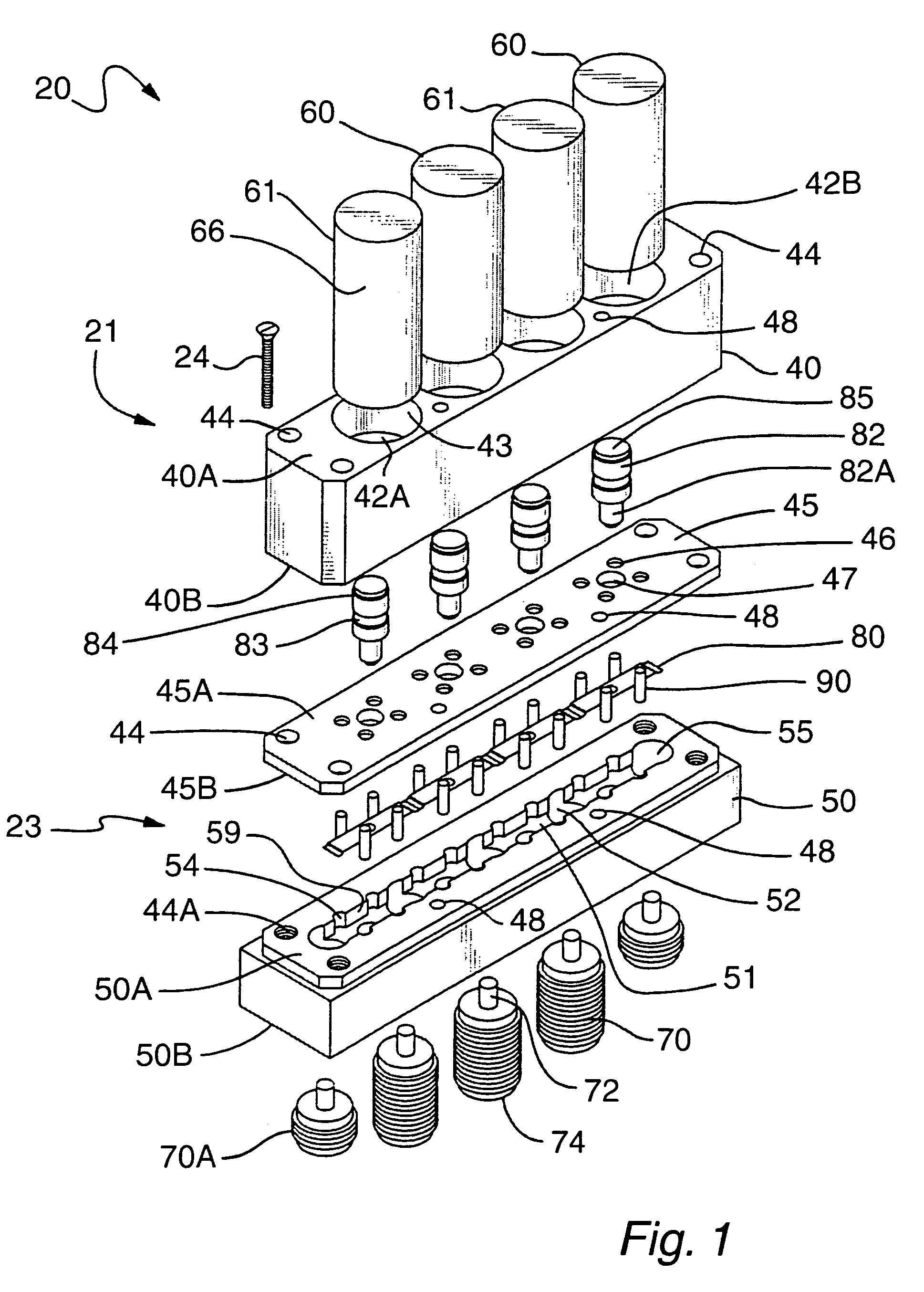

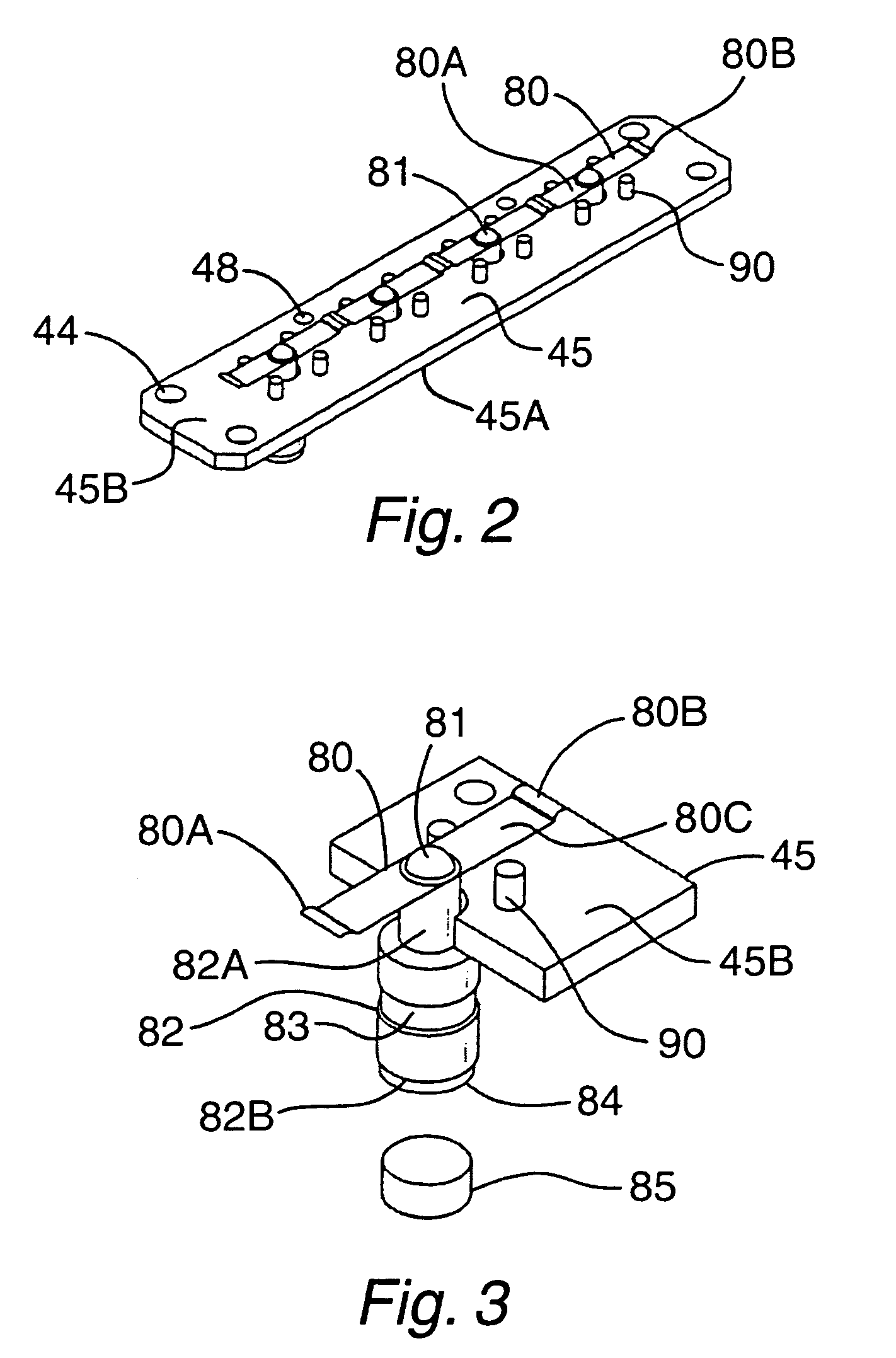

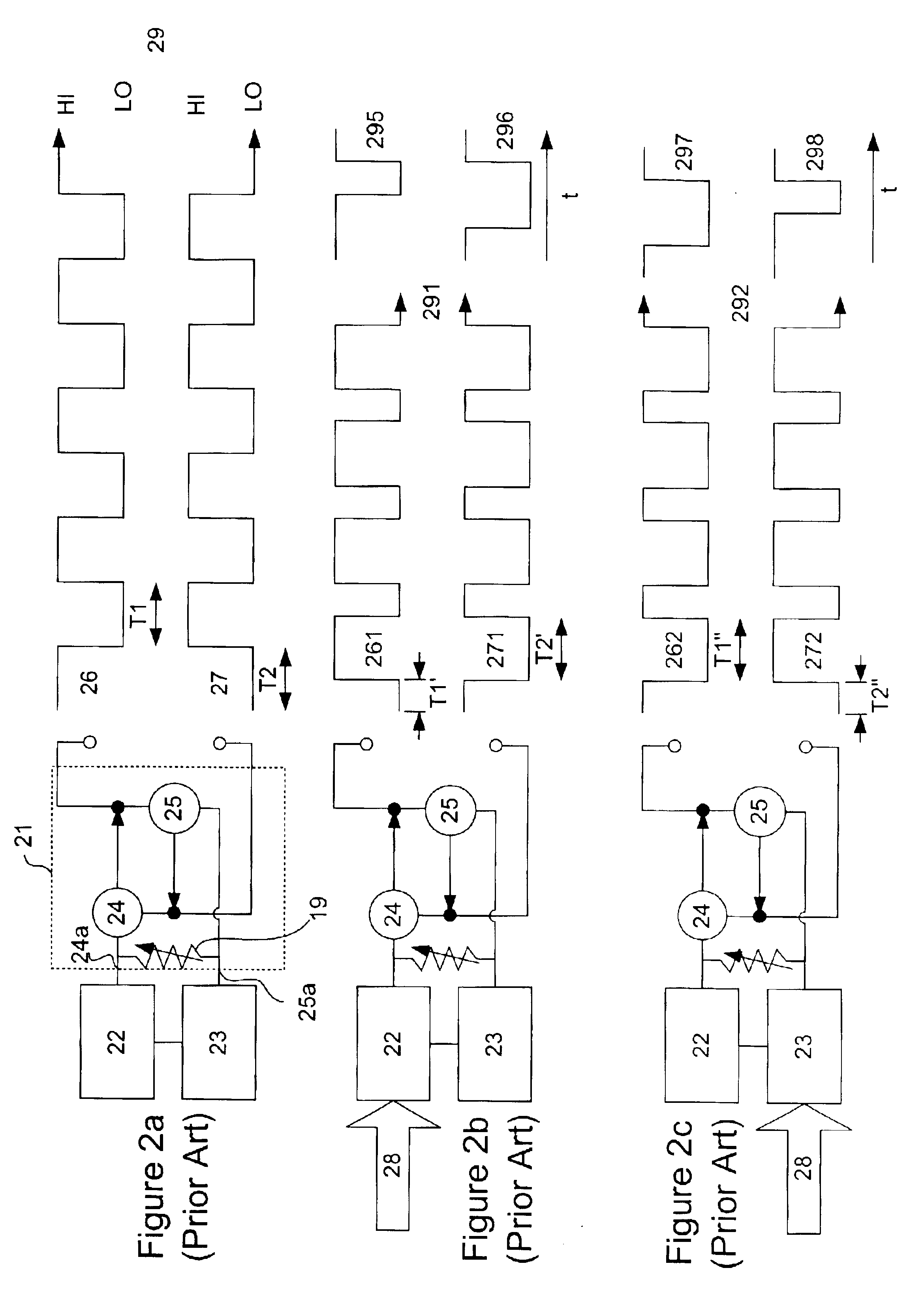

Electromechanical radio frequency switch

ActiveUS7633361B2Improve accuracyImprove operationCircuit-breaking switches for excess currentsSelector switchesWear particleComponent alignment

Owner:SCI COMPONENTS

Virtual component alignment

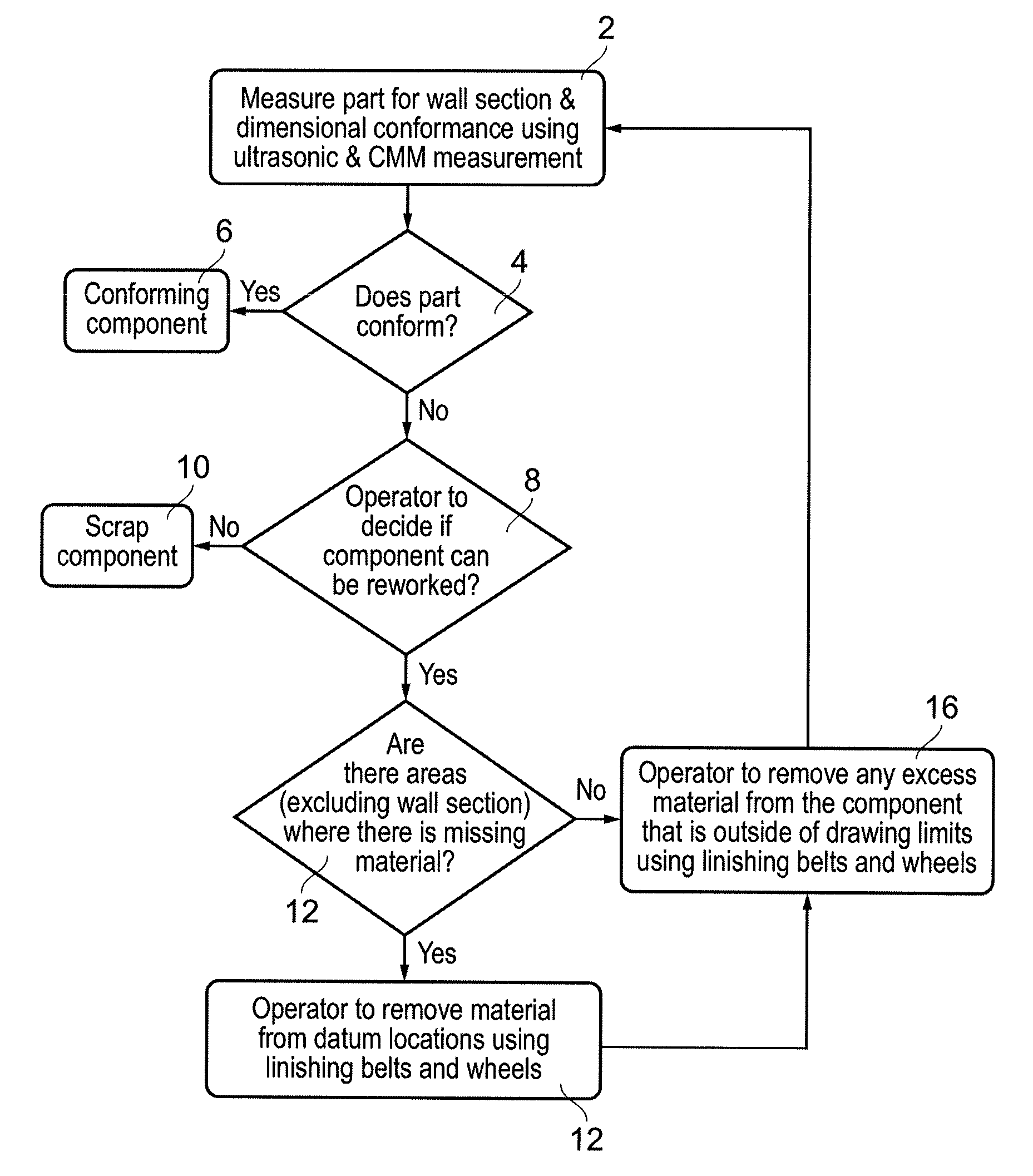

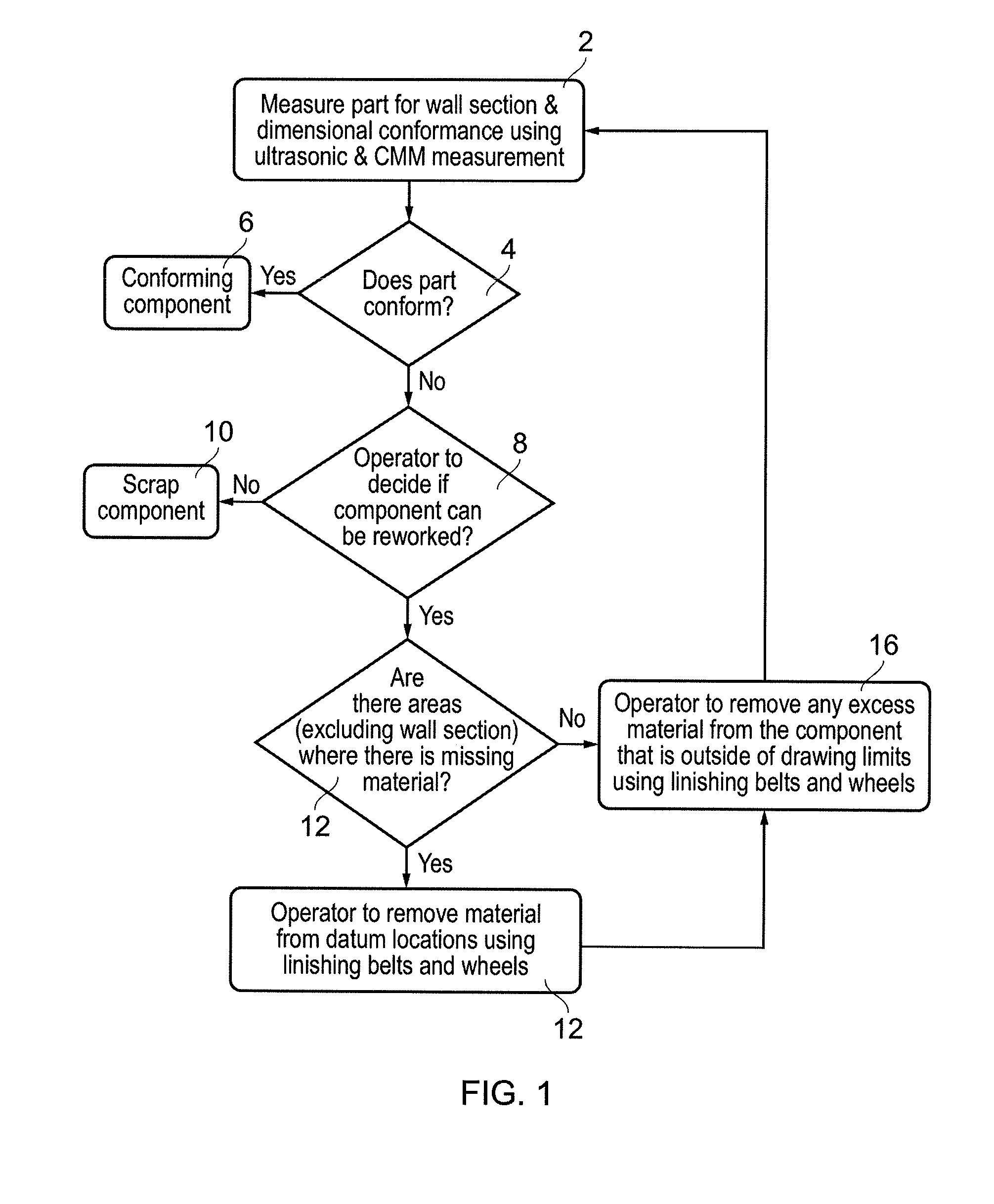

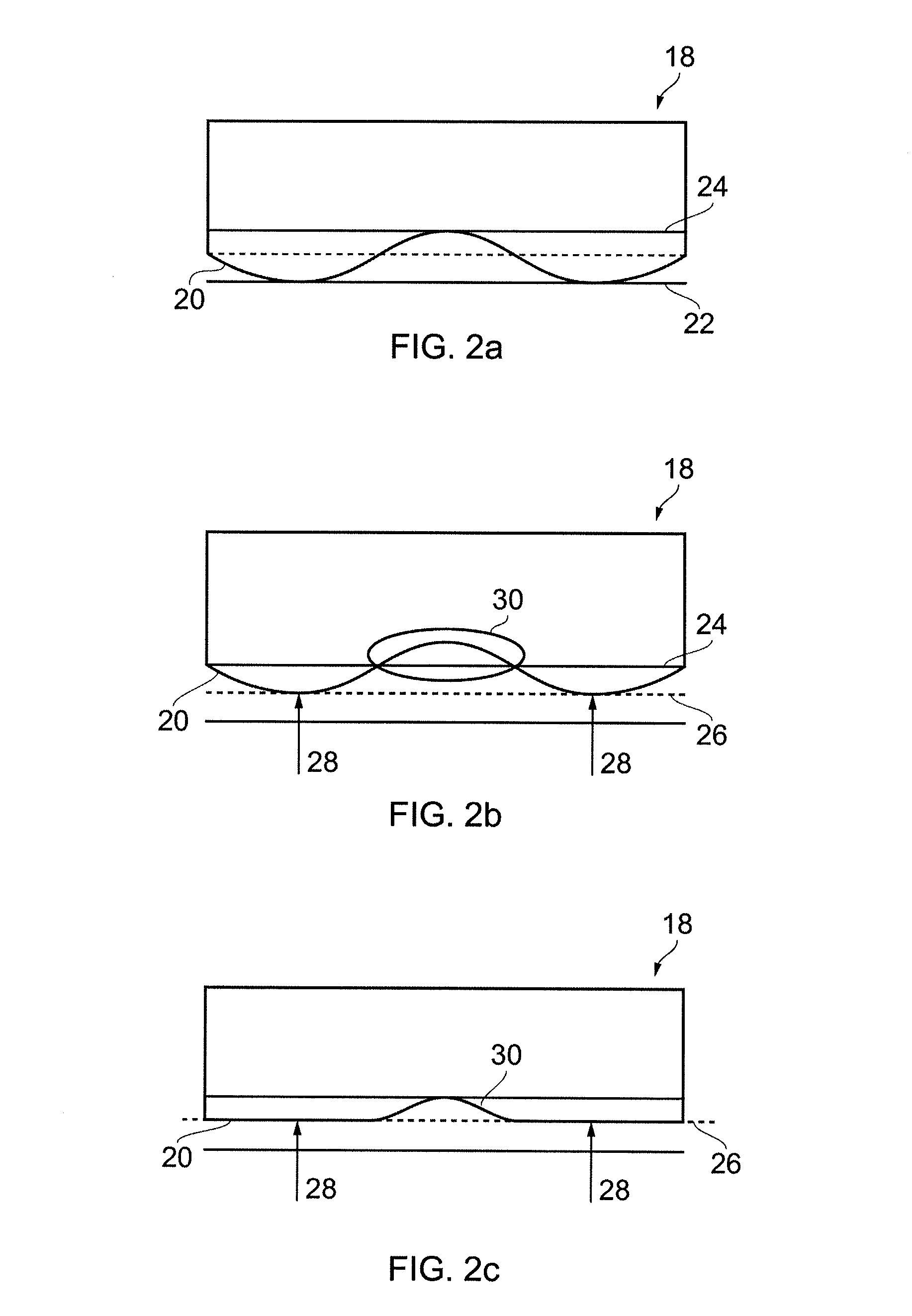

ActiveUS20160109876A1Sensitive to misalignmentReduced areaProgramme controlComputer controlComponent alignmentVirtual space

This invention concerns improvements in the inspection, assessment and re-working of manufactured components such as nozzle guide vanes (NGVs) and blades, in particular by improving the comparison of the component with nominal data. Dimensional data of a physical component is obtained and used to create a virtual digitised model of the component which is aligned with a nominal CAD model of the component in a virtual space. The correspondence is assessed and used to adjust weightings of different regions of the digitised model to improve the alignment. This process is repeated within the digital space until either conformance is reached or it is determined that this is not possible.

Owner:ROLLS ROYCE PLC

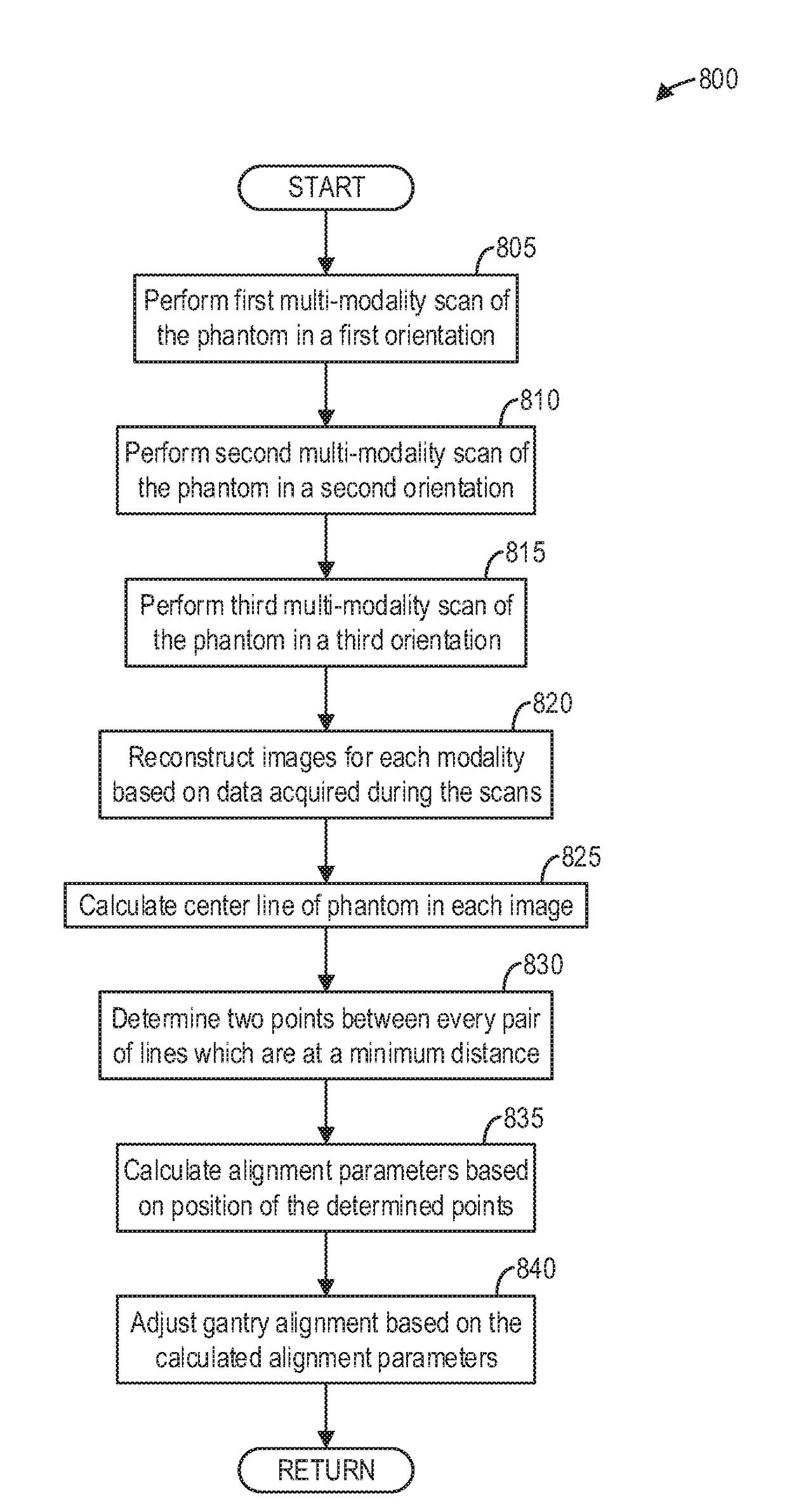

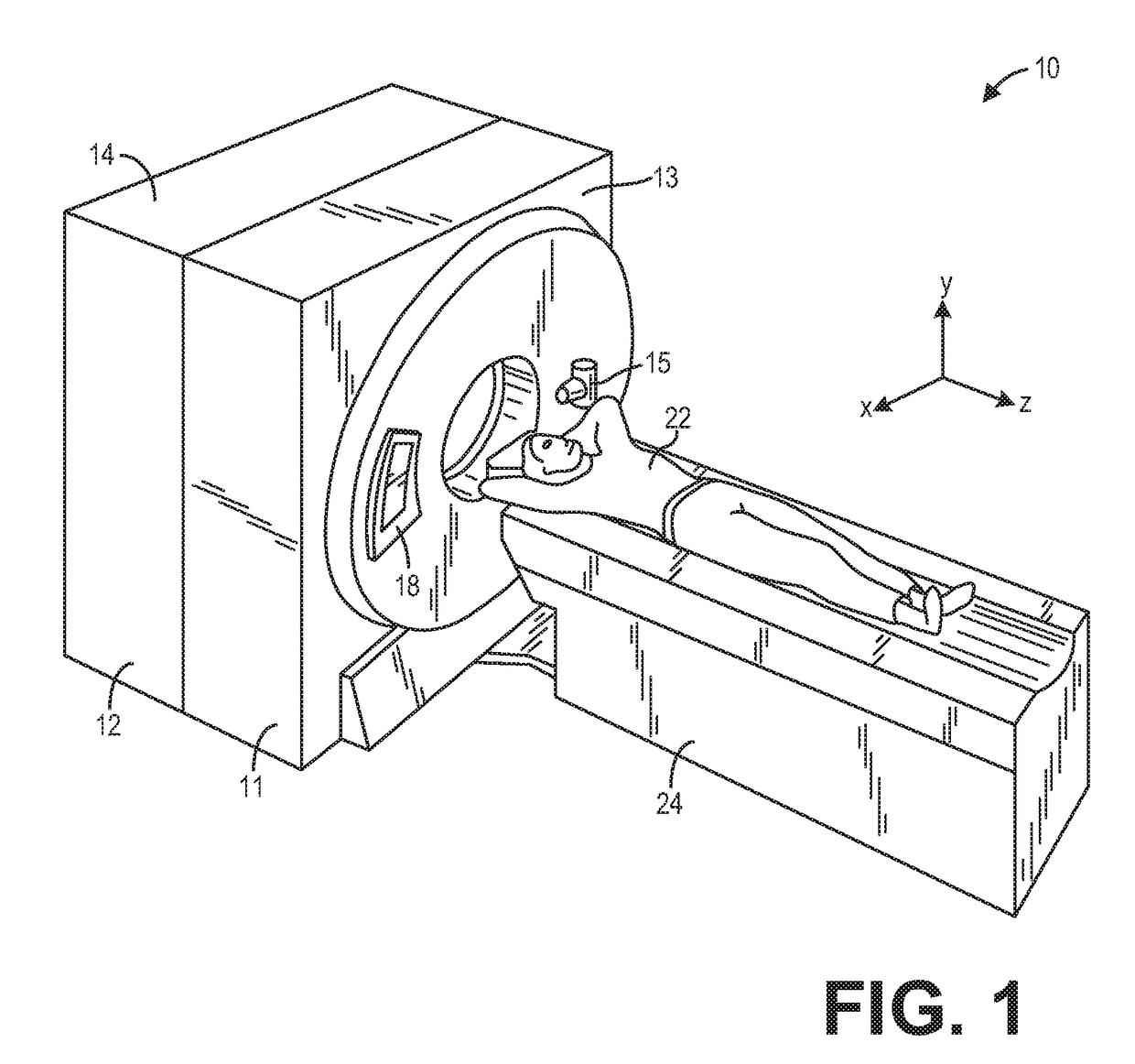

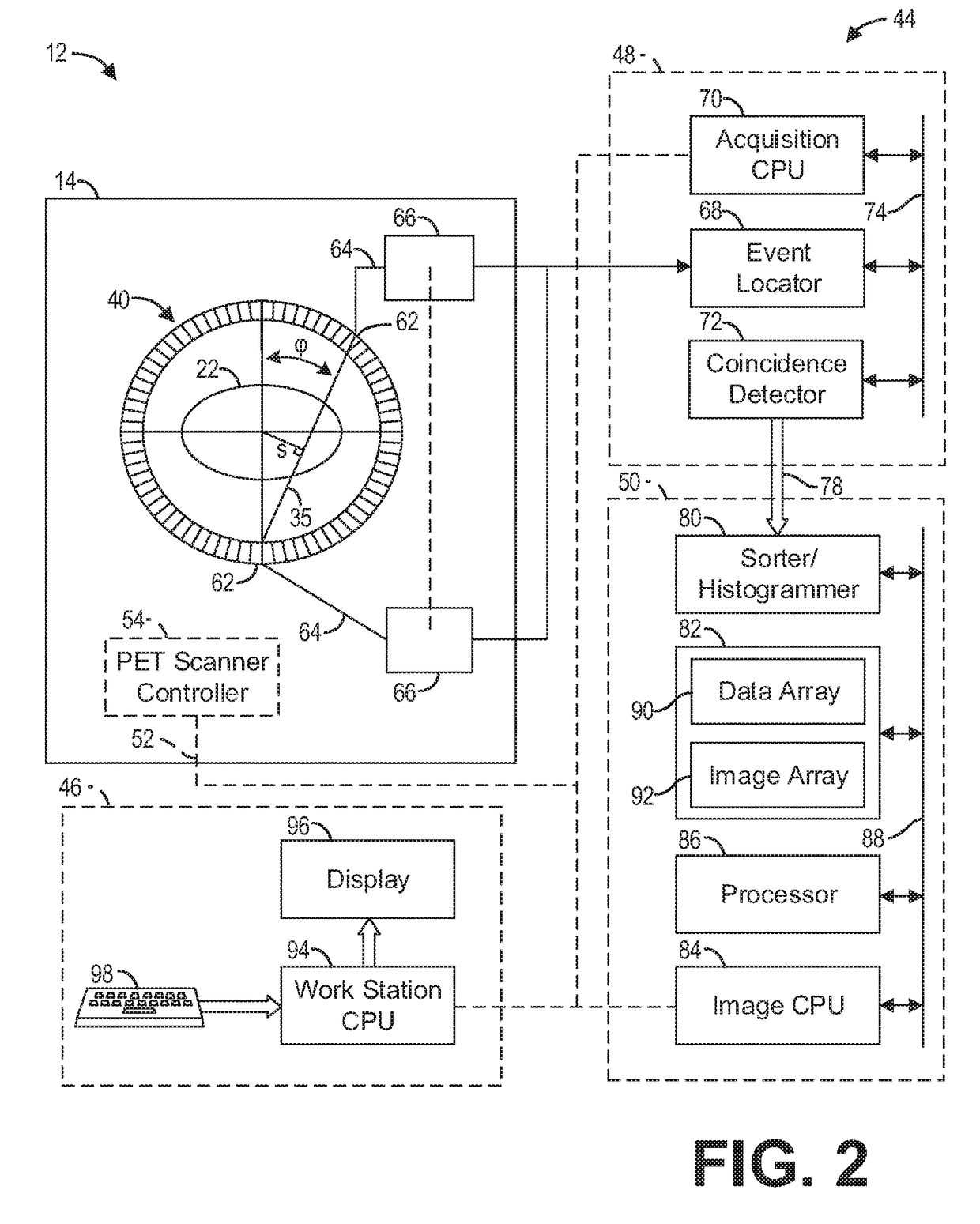

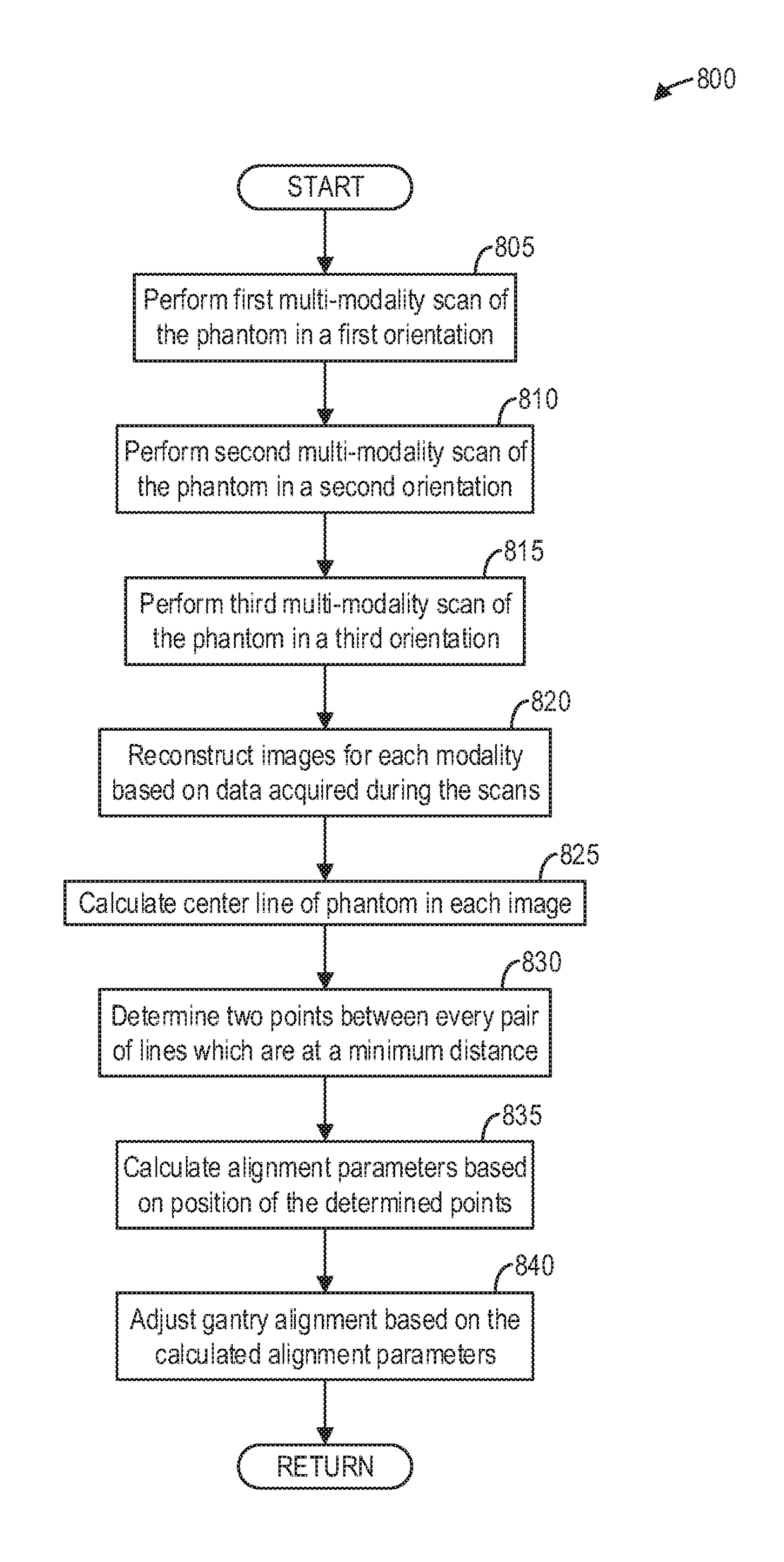

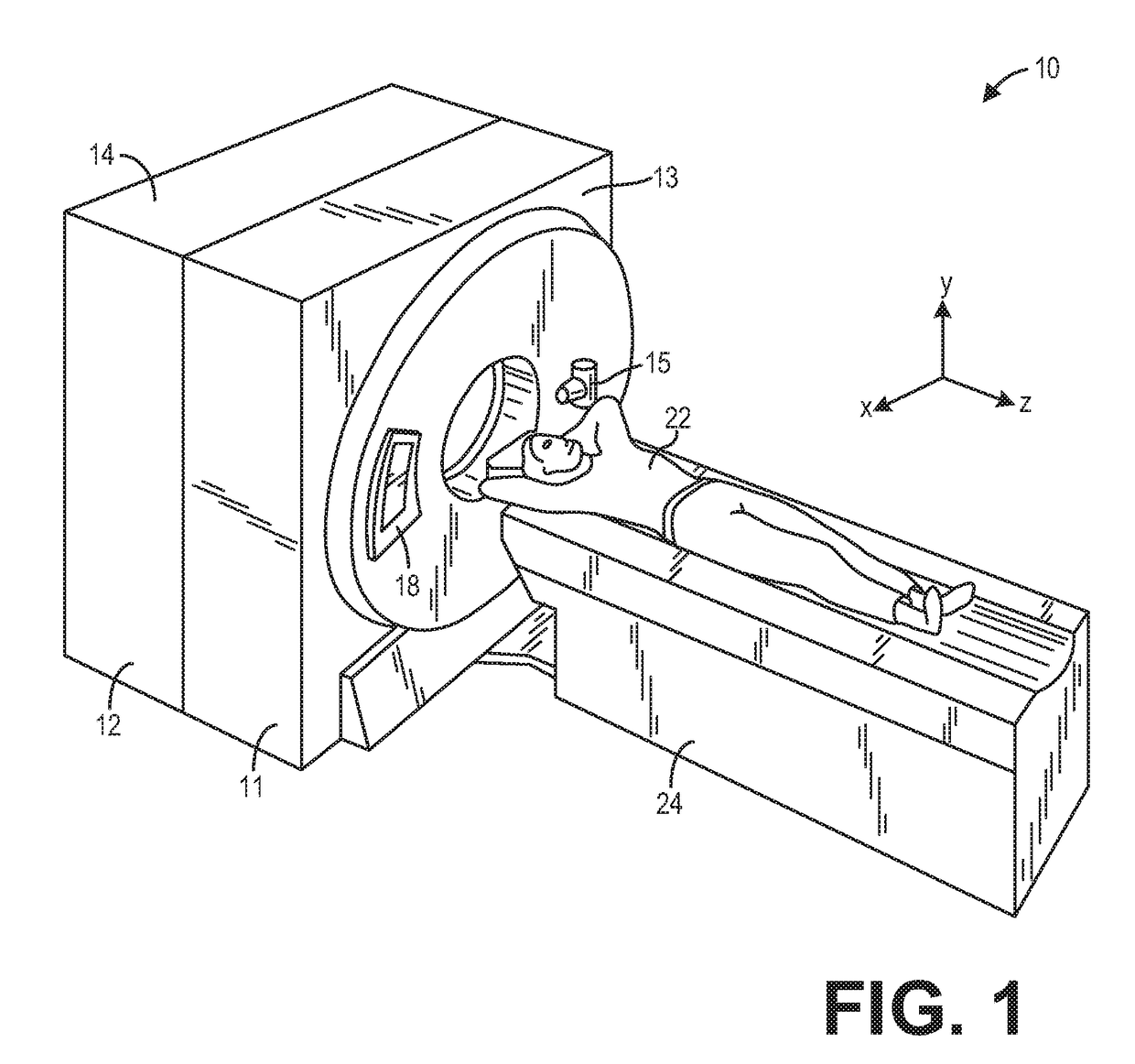

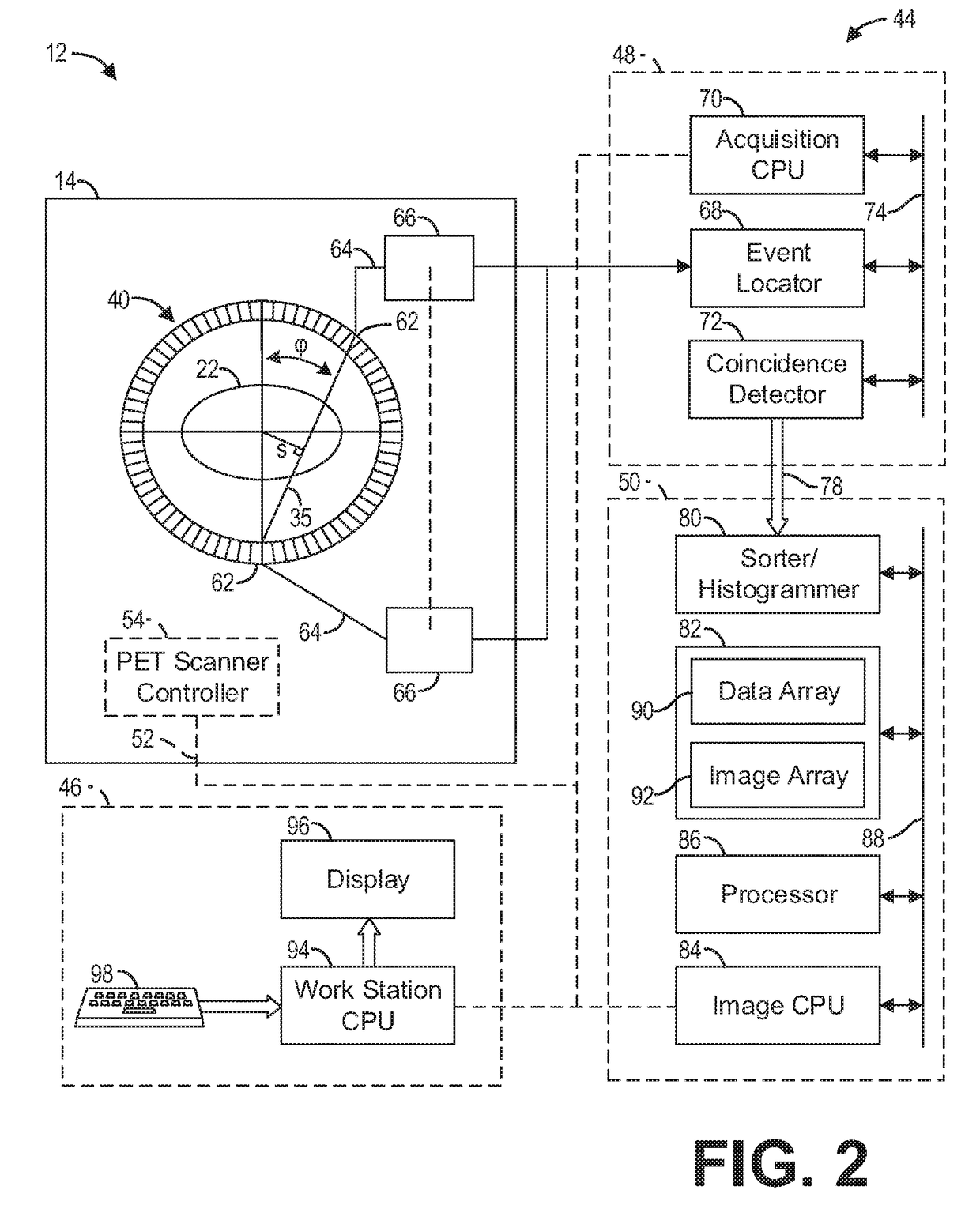

Systems and methods for multi-modality imaging component alignment

ActiveUS20180005400A1Precise alignmentImage enhancementImage analysisComponent alignmentComputer science

Methods and systems are provided for aligning components of a multi-modality imaging system. In one embodiment, a method comprises performing a plurality of scans of an object with a first modality and a second modality, wherein the object is positioned in a different orientation in each of the plurality of scans, calculating a plurality of alignment parameters of a first modality unit and a second modality unit based on the plurality of scans, and adjusting alignment of the first modality unit and the second modality unit based on the plurality of alignment parameters. In this way, components of a multi-modality imaging system may be accurately aligned using any phantom from which a unique line can be extracted in each modality scan.

Owner:GENERAL ELECTRIC CO

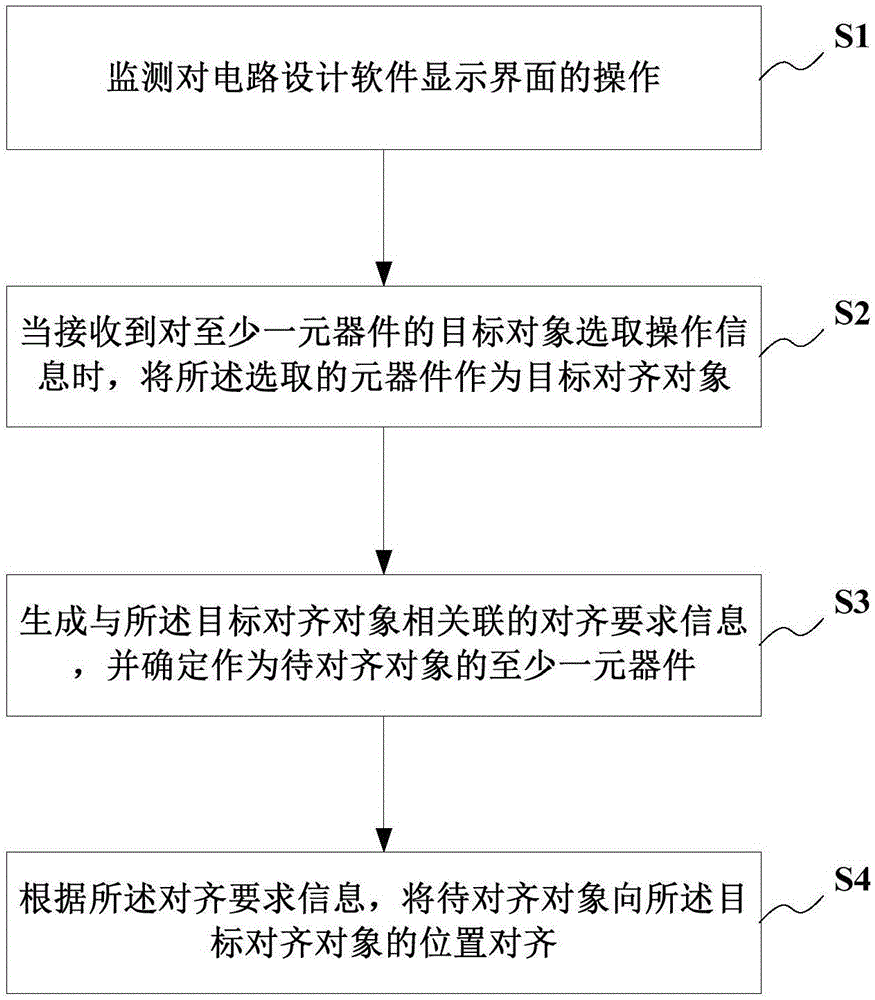

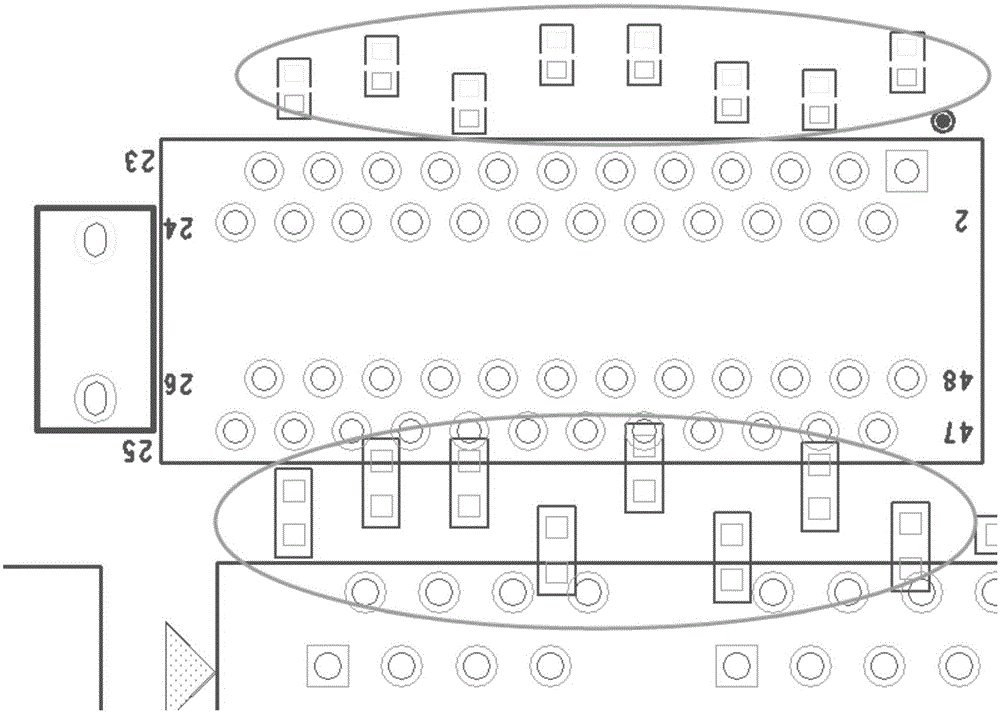

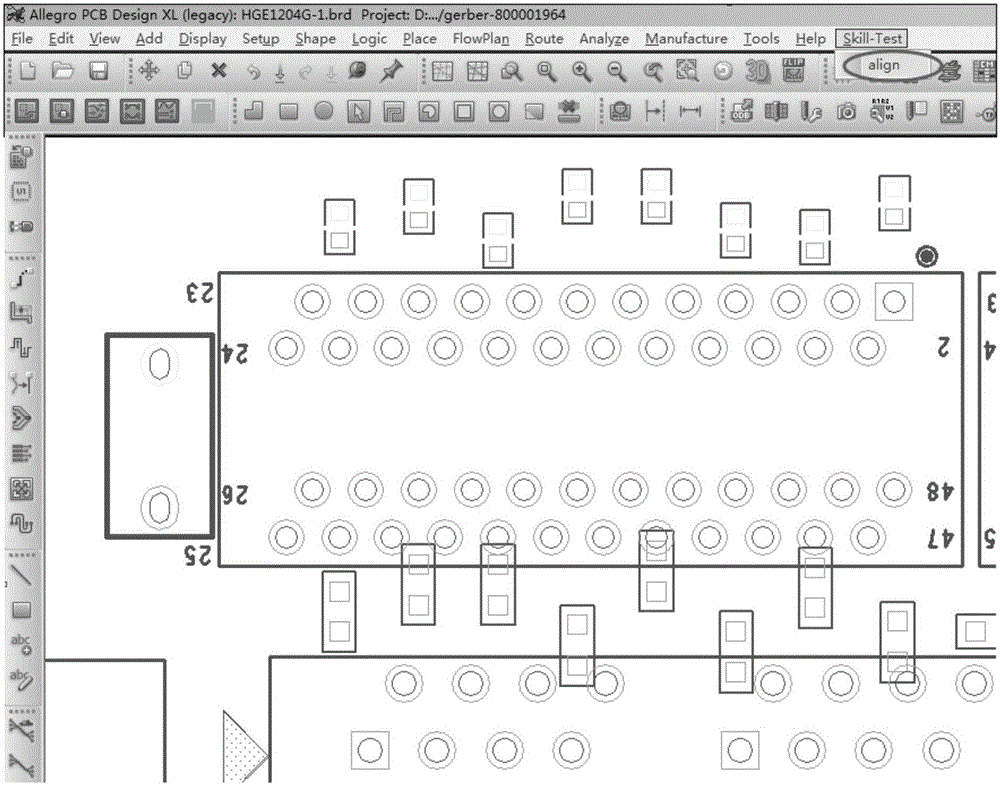

Component alignment method and system in circuit design software

InactiveCN105159560ASolve the problem of no automatic alignment functionSpecial data processing applicationsInput/output processes for data processingComponent alignmentSoftware engineering

The invention provides a component alignment method and system in circuit design software. The component alignment method comprises the following steps: monitoring an operation on a display interface of the circuit design software; when the target object selection operation information of at least one component is received, taking the selected component as a target alignment object; generating alignment requirement information associated with the target alignment object, and determining at least one component which serves as an object to be aligned; and according to the alignment requirement information, aligning the object to be aligned to a position of the target alignment object. The problem in the prior art that PCB (Printed Circuit Board) design software does not have an automatic alignment function is solved.

Owner:PHICOMM (SHANGHAI) CO LTD

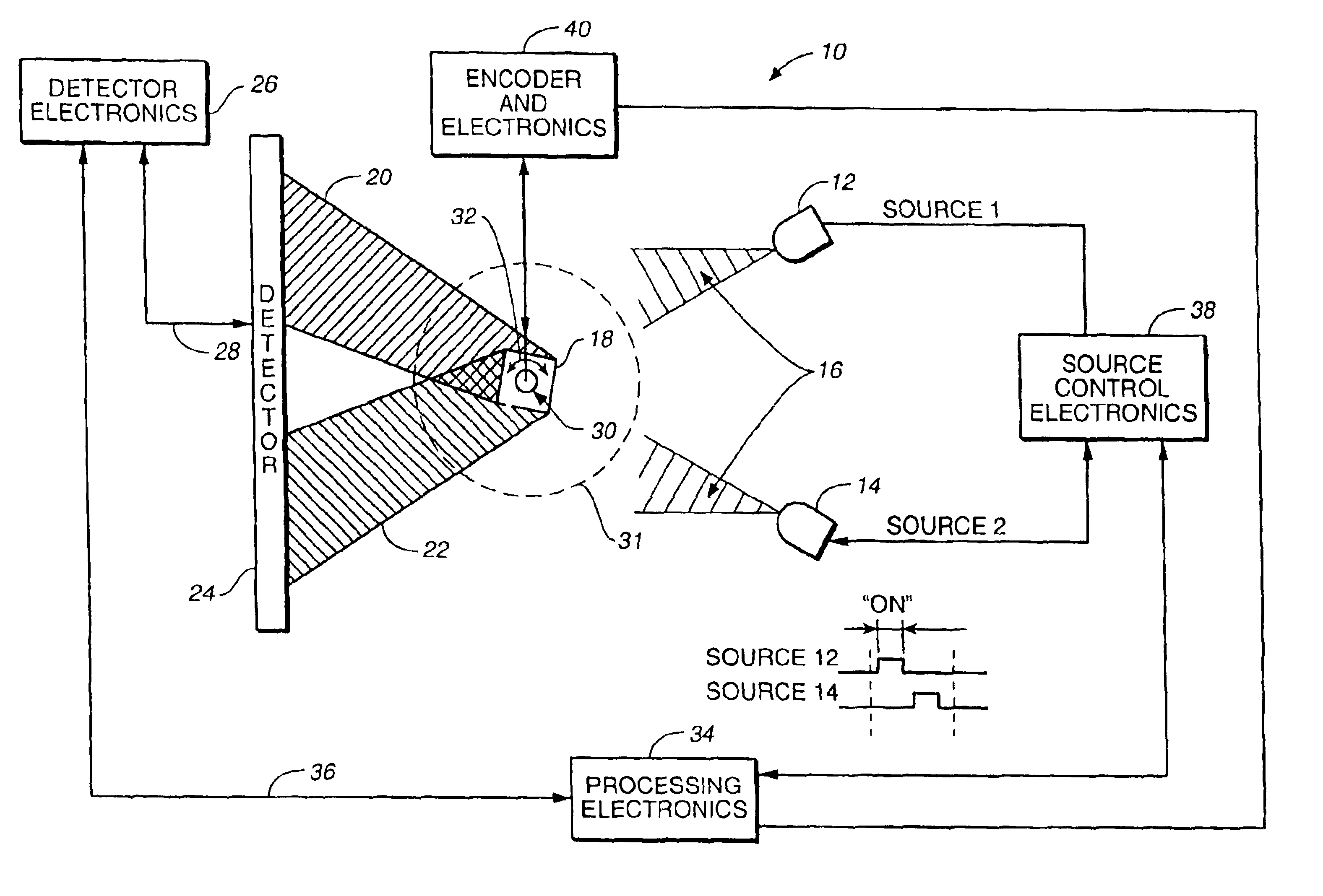

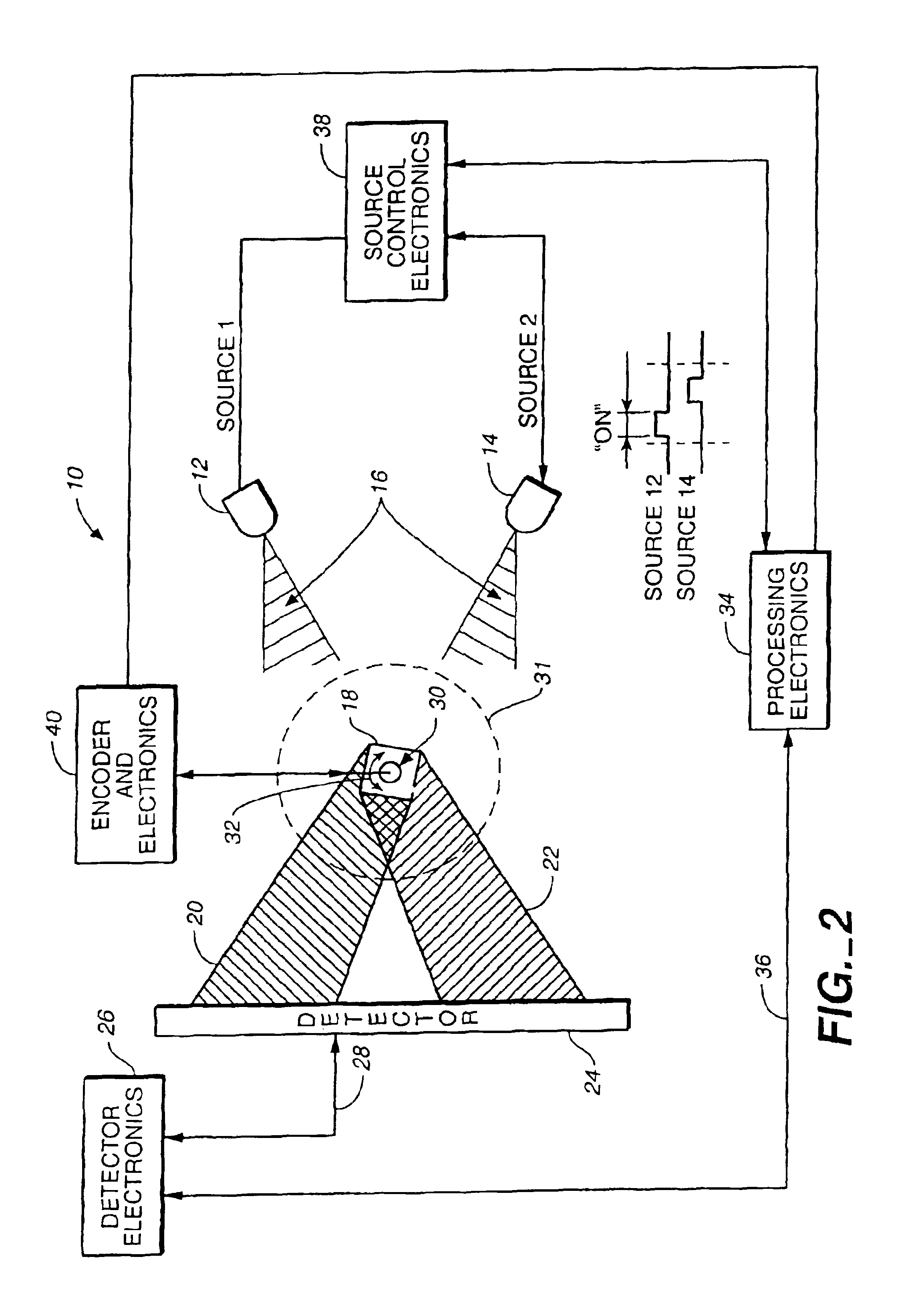

Multiple source alignment sensor with improved optics

InactiveUS6909515B2Reduces degree of divergenceShorten the counting processInvestigating moving sheetsUsing optical meansComponent alignmentEngineering

Features of the present invention provide an optical layout that can accommodate the relatively strict enclosure requirements for compact component alignment sensor. Specifically, aspects of the present invention provide a single optical component that reduces the degree of divergence, and preferably substantially collimates light from the plurality of divergent light sources prior to entering the sensing field. In this regard, part count is kept low and the physical size of the optical train itself is relatively small.

Owner:CYBEROPTICS

Cross-component alignment measurement and calibration

InactiveUS7652478B2Electric/magnetic detection for well-loggingRulers for direct readingComponent alignmentReceiver coil

A multicomponent induction logging tool is positioned within an alignment loop and the transmitter is activated at a number of rotation angles of the tool. Misalignment between the transmitter and receiver coils can be determined from the induced signals in the receiver coil.

Owner:BAKER HUGHES INC

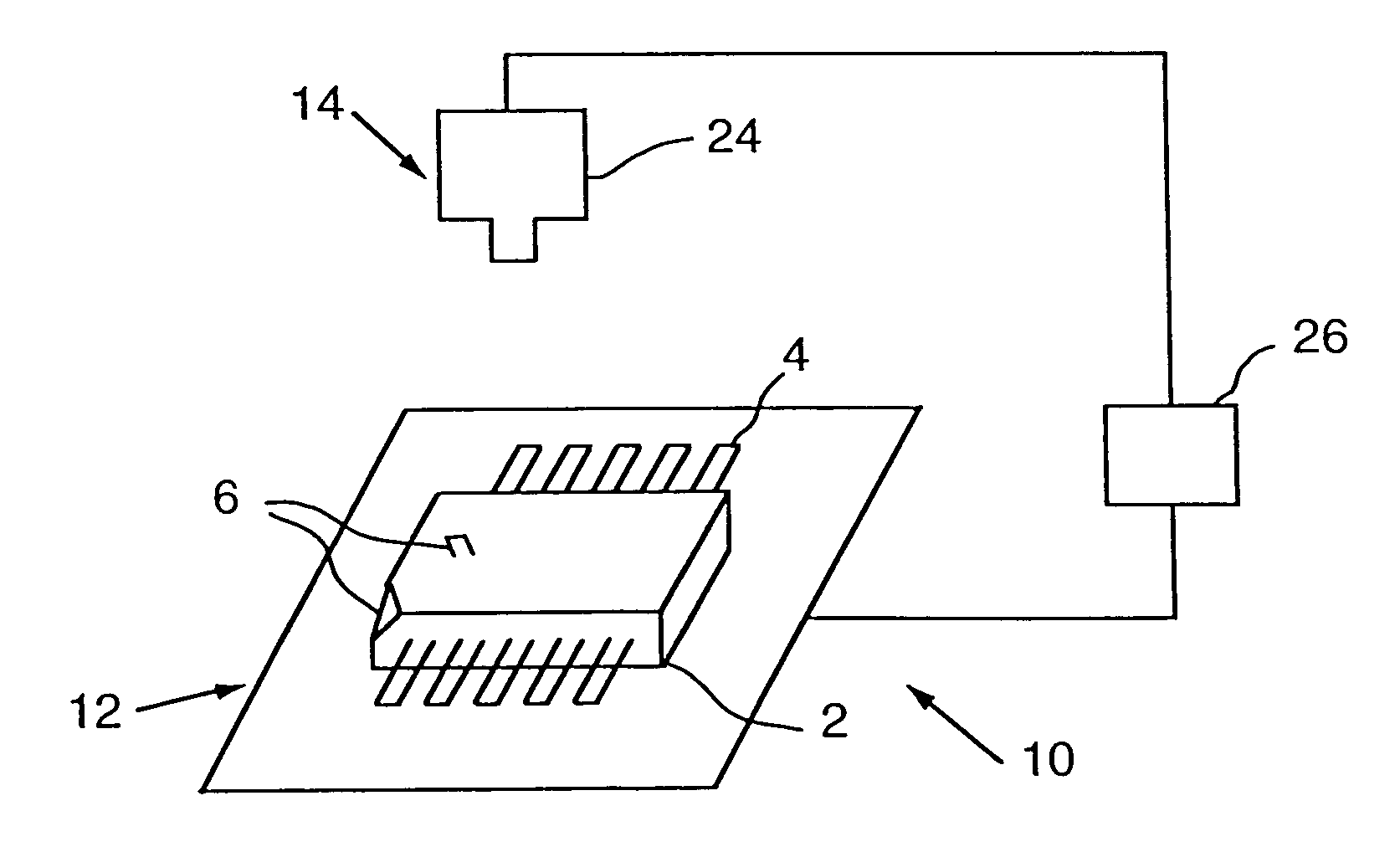

Method and arrangement for aligning an optical component on a printed wiring board

InactiveUS20040263845A1Circuit optical detailsUsing optical meansComponent alignmentMirror reflection

A method and arrangement for aligning an optical component (14) on a printed wiring board (1) by using a reflector (8) below a surface mount technology camera to determine the offset (Delta) between the printed wiring board electrical layout and the light beam in the printed wiring board optical layer. This provides the following advantages: Component alignment to optical layer and component alignment to mirror reflection in optical layer, Fast placement process for optical components, Flexible process because there is no need for component specific fixtures, and Compatible with standard SMT processes and standard SMT placement machines.

Owner:MOTOROLA INC

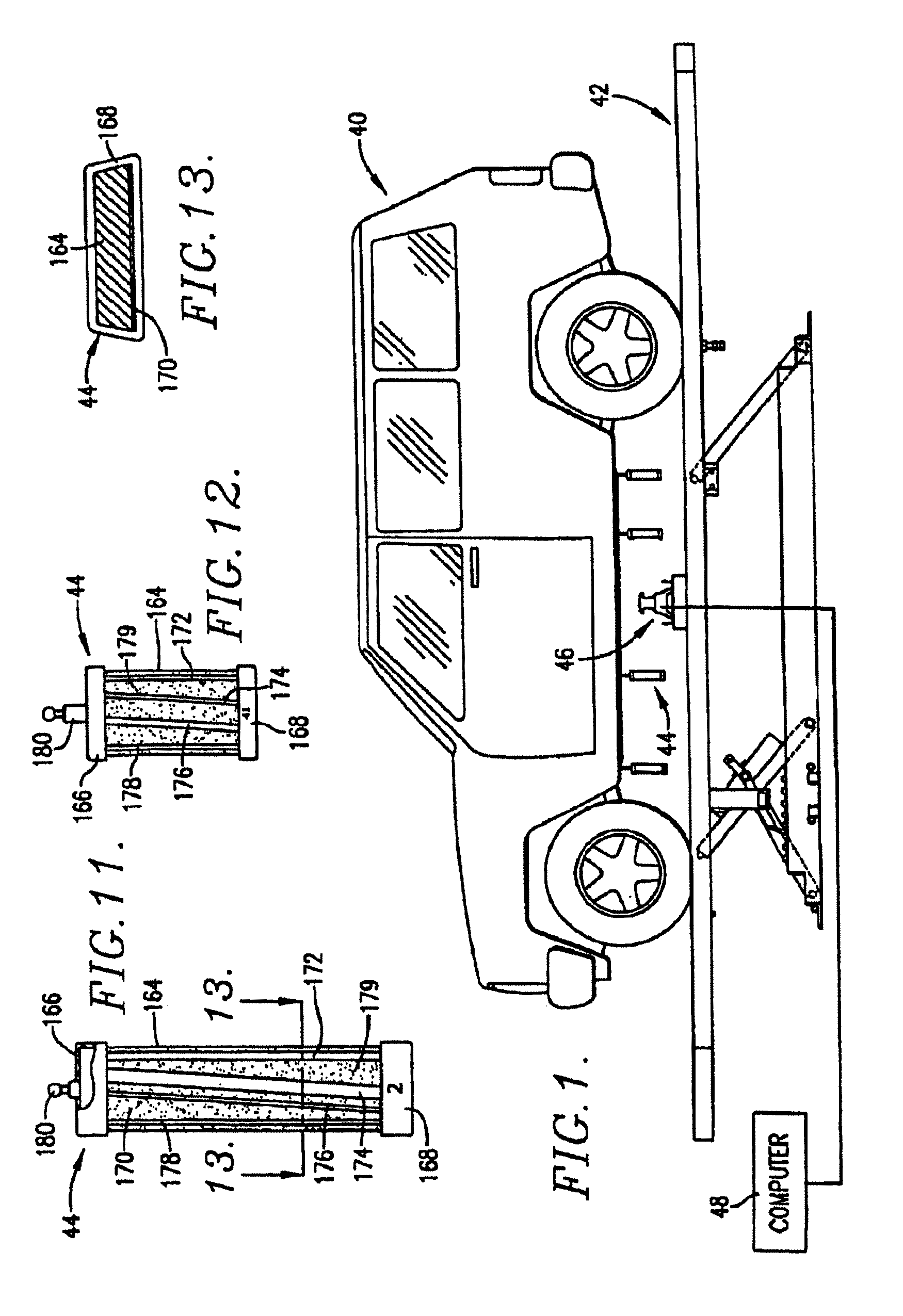

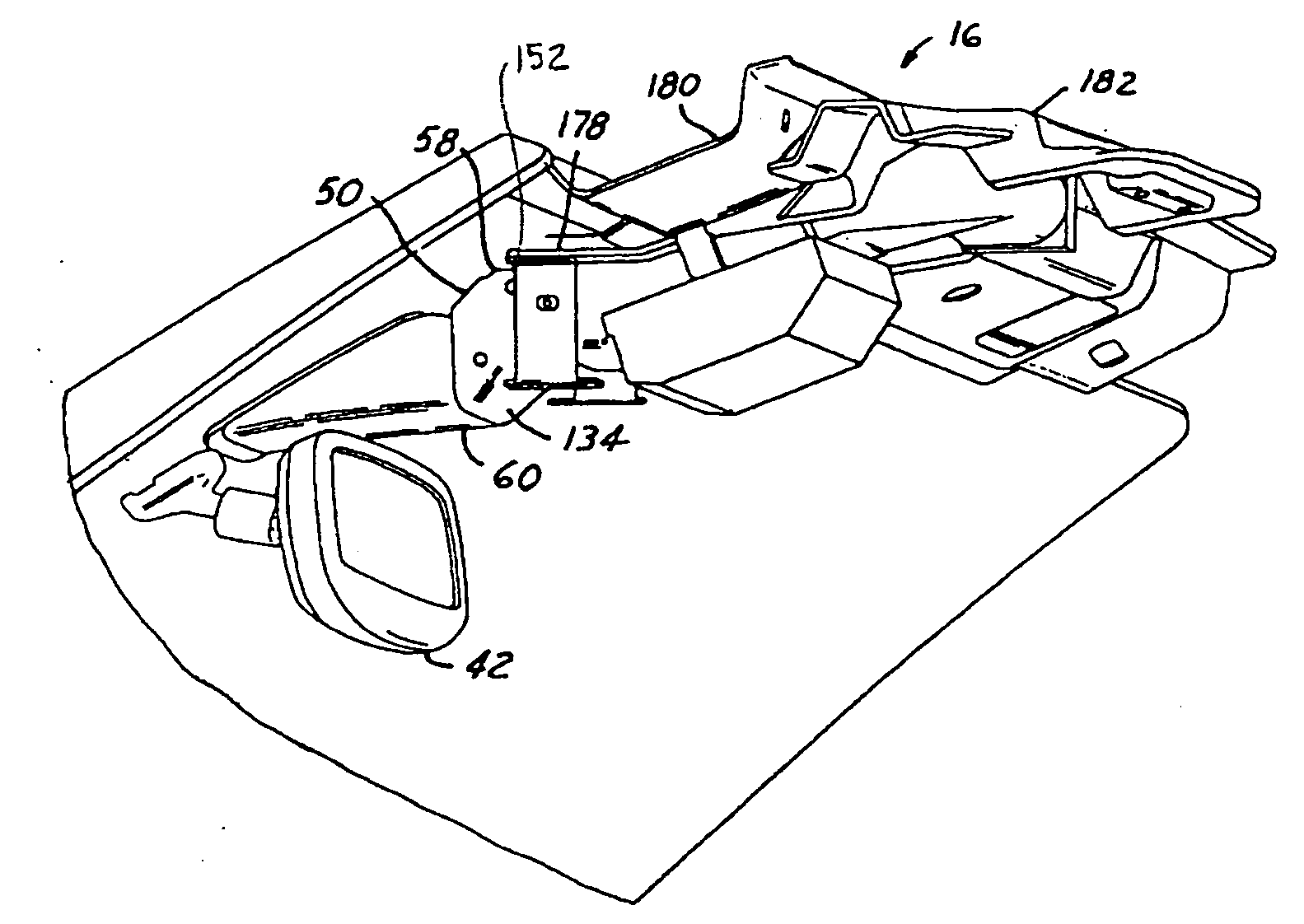

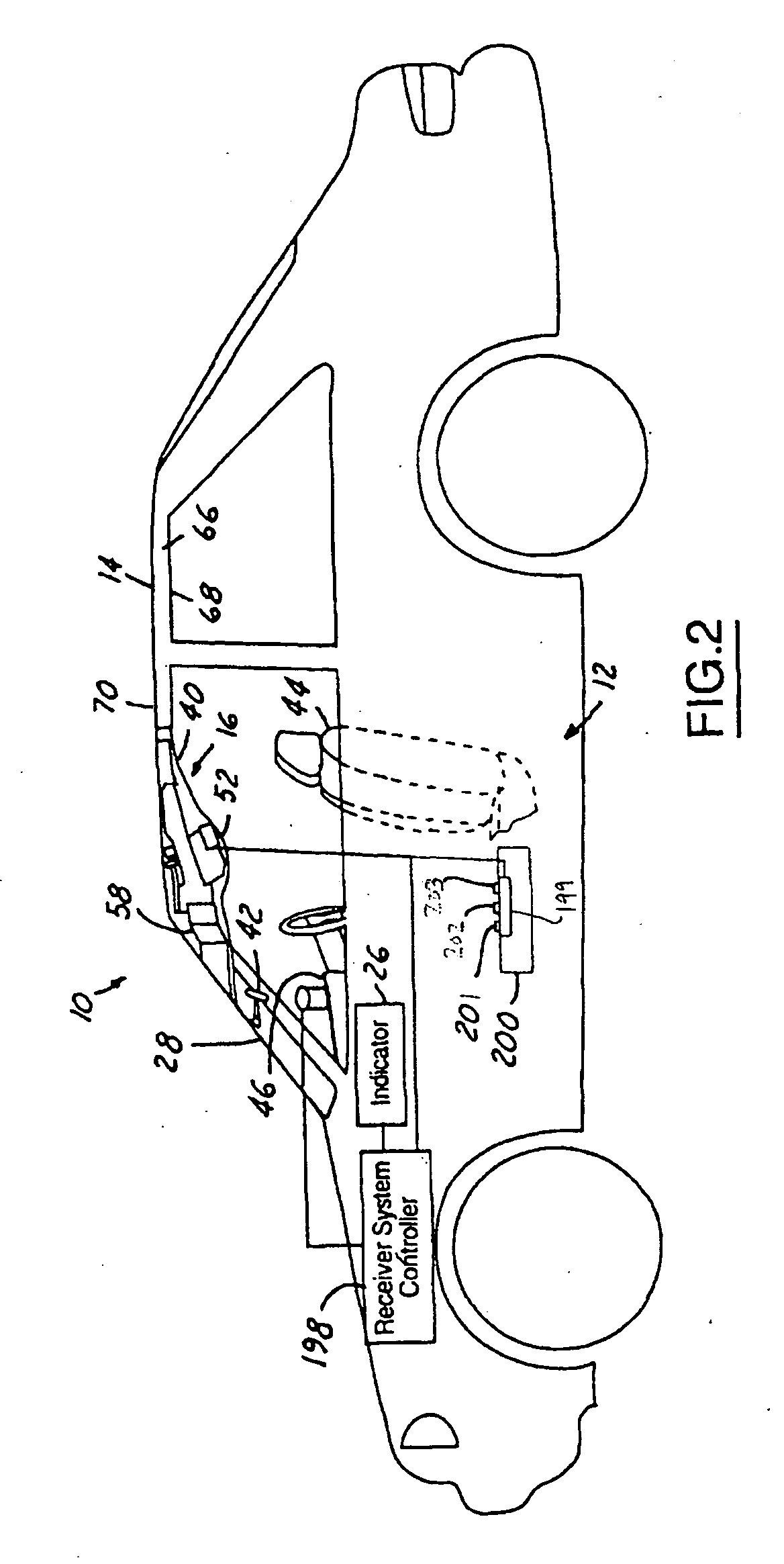

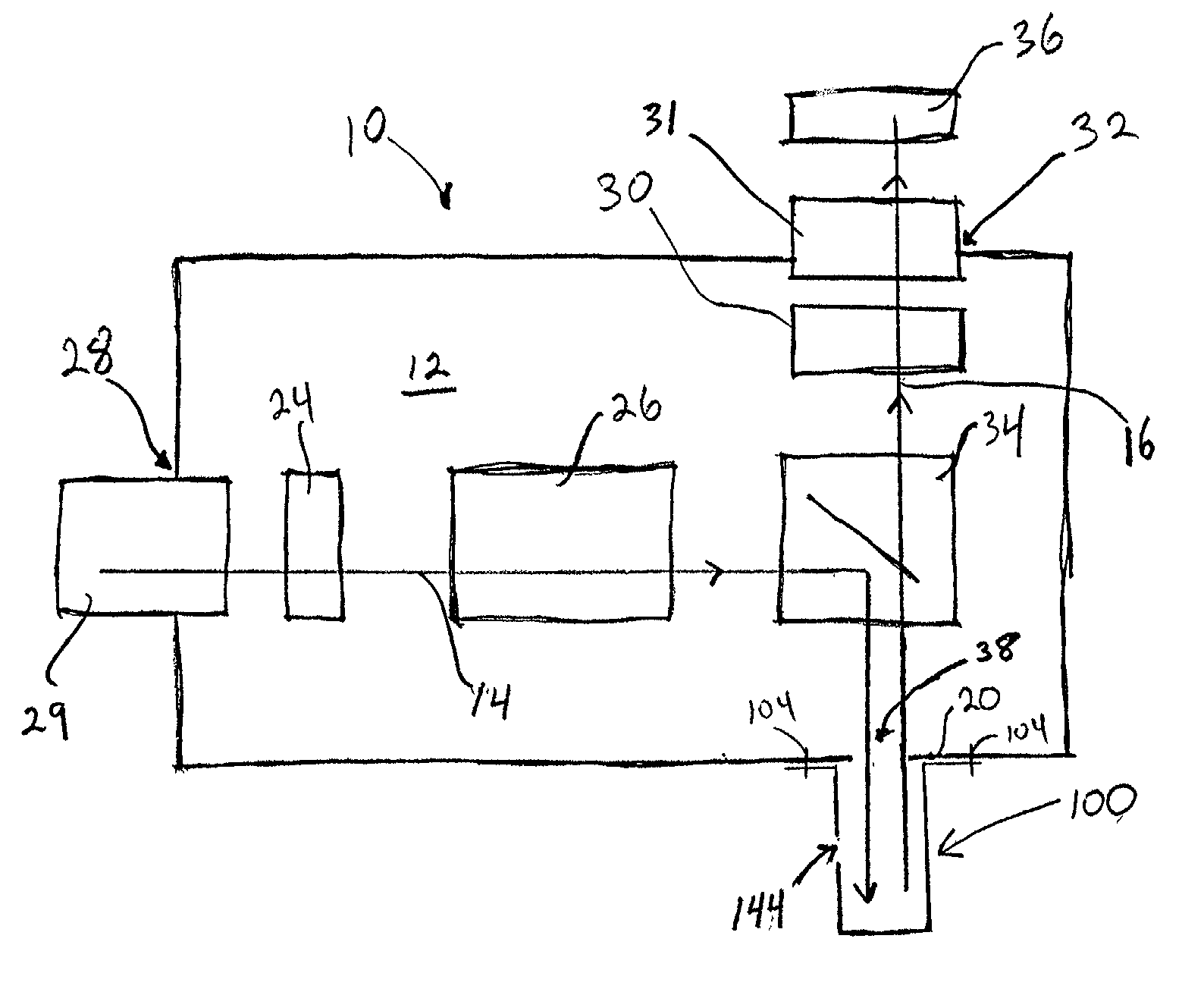

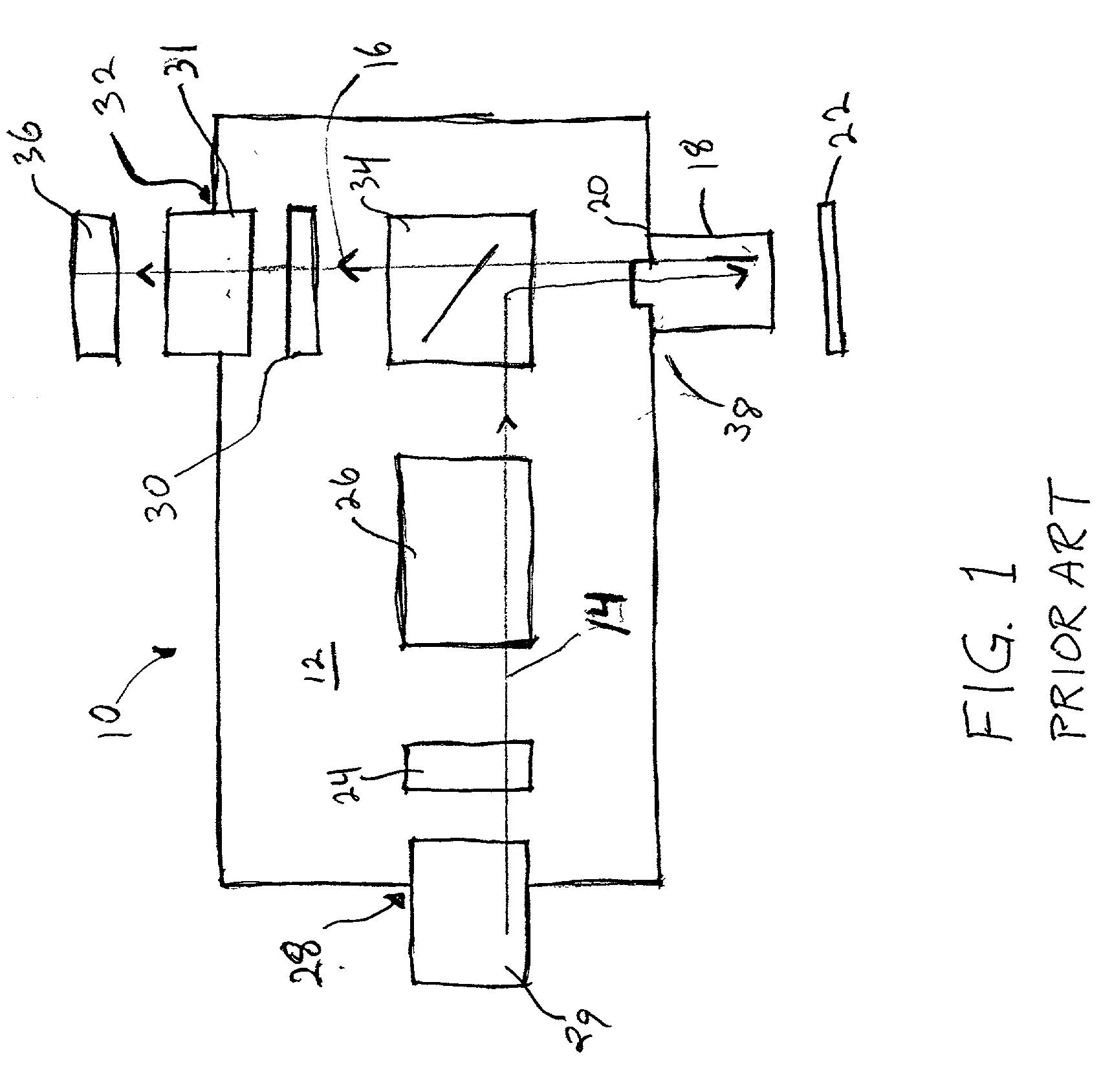

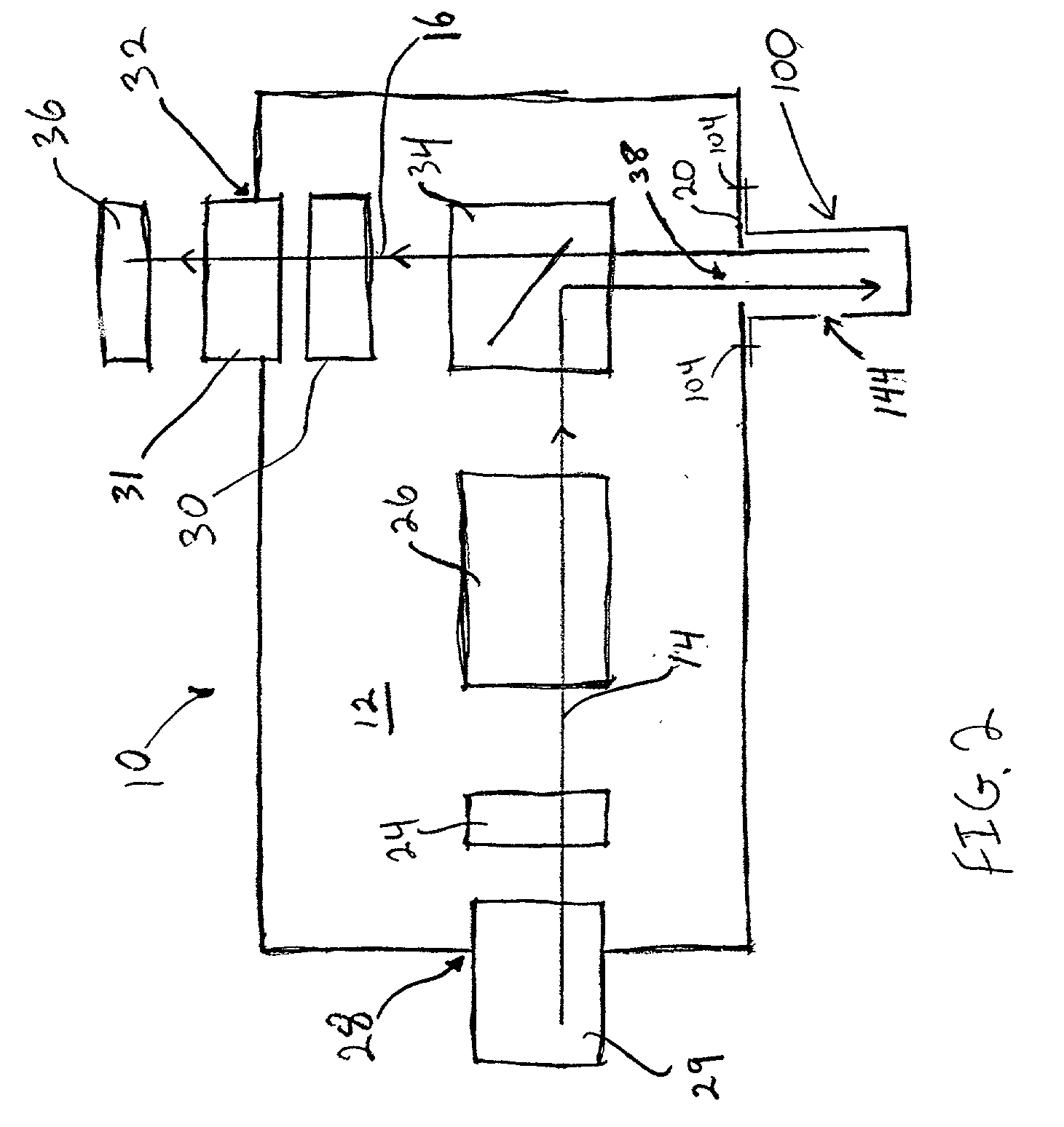

Component alignment maintaining module for an active night vision system mounted within an interior cabin of a vehicle

InactiveUS20060187667A1Maximizes optical efficiency of opticalMaximizes thermal dissipationOptical signallingTelescopesNight visionNacelle

A component alignment-maintaining module (58) for a vision system (10) that is mounted within an interior cabin (12) of a vehicle (14) includes a body (90). The body (90) includes multiple guides (91) that are fixed therein and adapted to maintain alignment of a light source (72) in relation to a beam-forming optic (100) and to direct a transmission beam (20) through a window (28) of the vehicle (14). Multiple supports (102) are configured to support the beam-forming optic (100) along a perimeter (48) of the window (28).

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Fixture for microscope component alignment

A fixture and method is provided for aligning optical elements in a microscope. The fixture attaches to an objective lens plane of the microscope and supports an alignment optical element. During optical component alignment, an alignment beam is directed along the illumination and imaging paths of the microscope through the objective lens port and into the fixture for reflection by the alignment optical element. The fixture allows an alignment optical element positioned in a single location to be used for aligning the microscope components and for adjusting the microscope objective lens.

Owner:SOLURIS +1

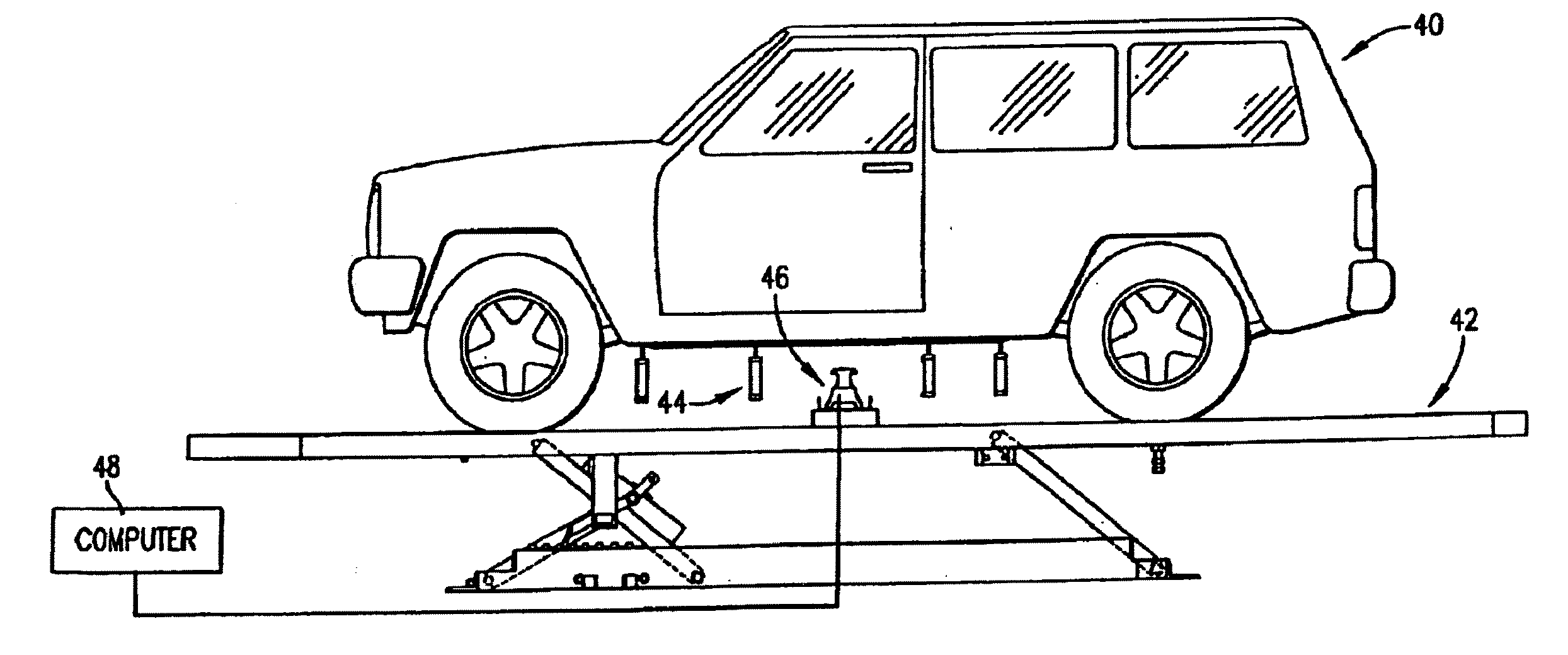

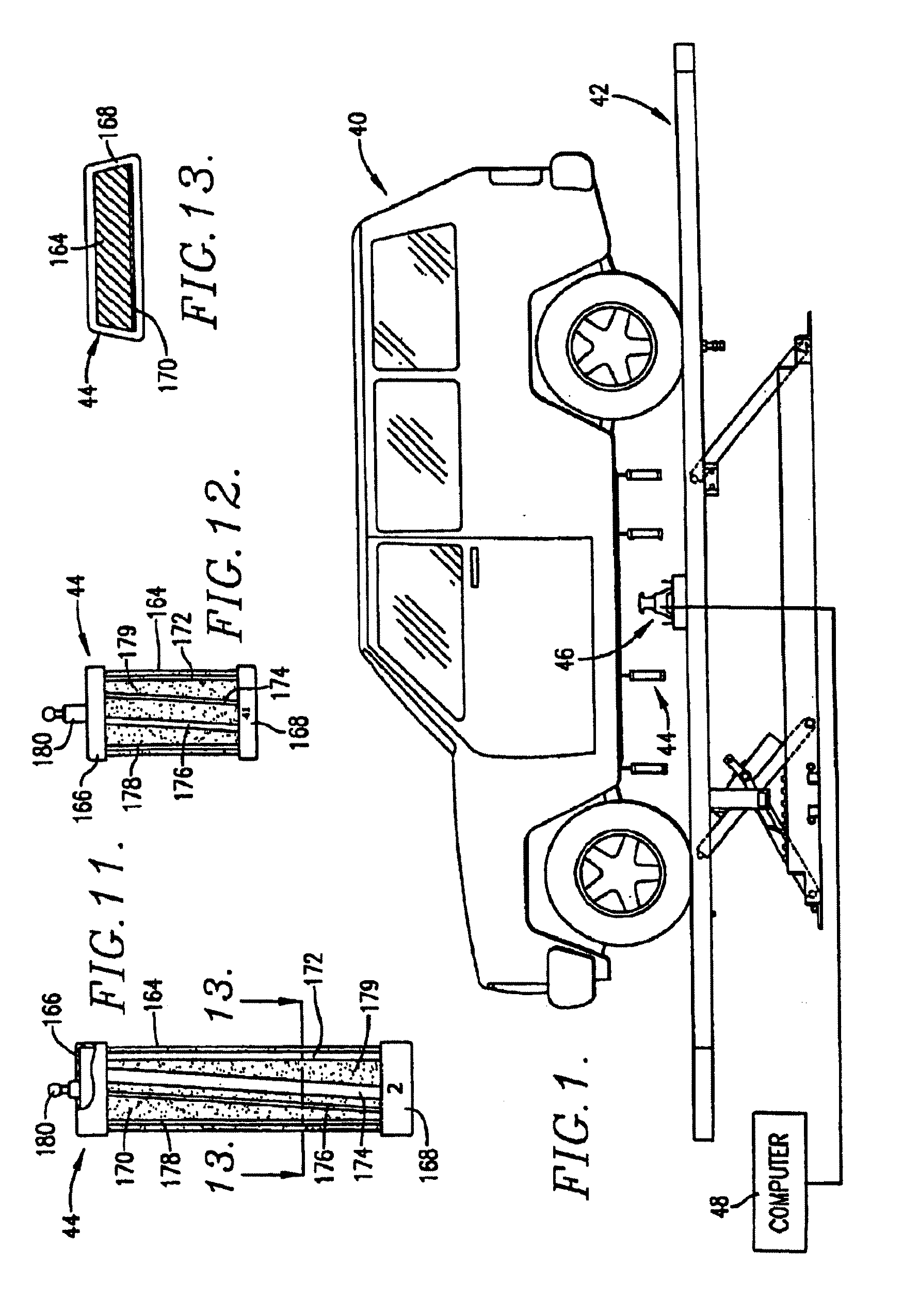

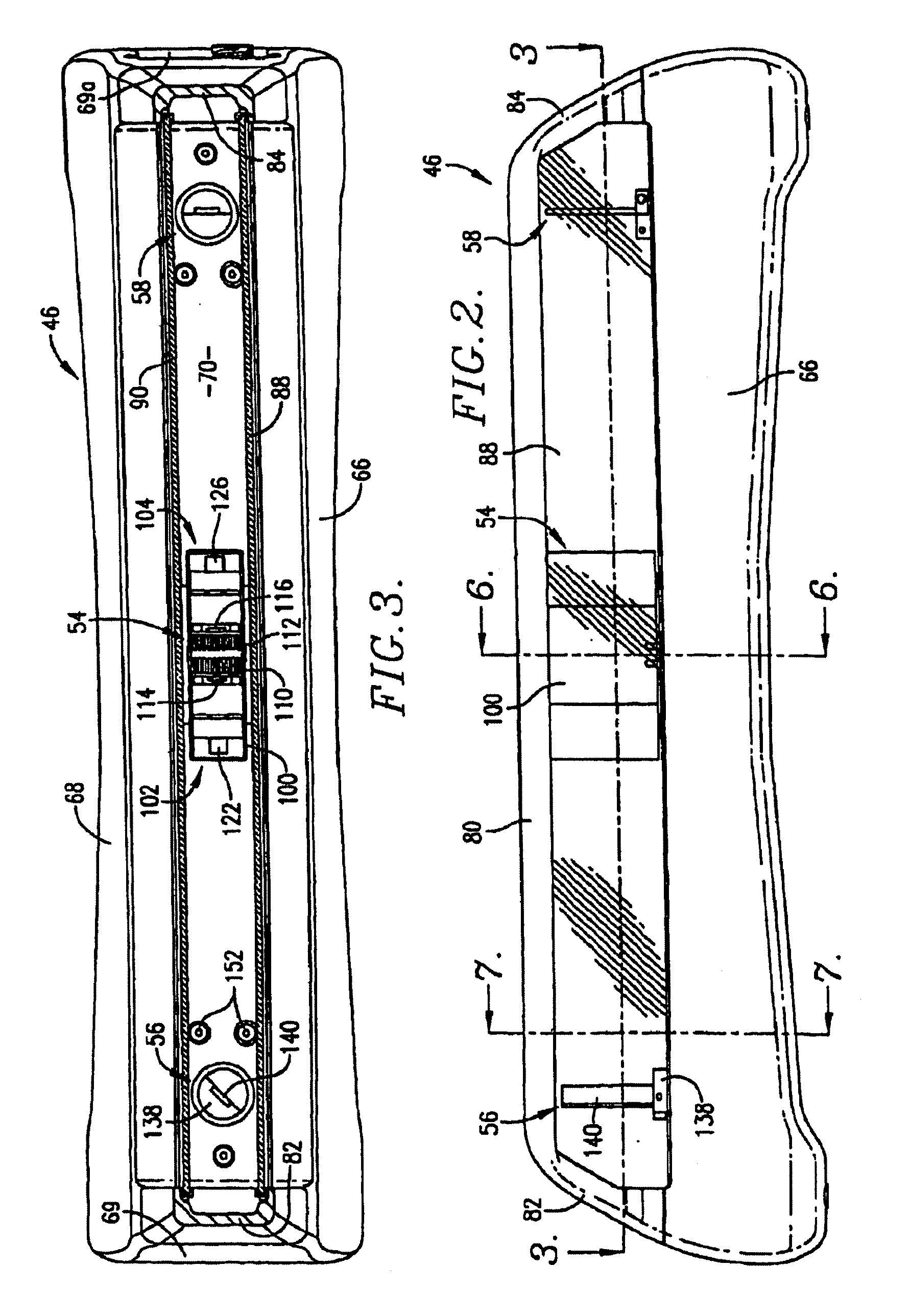

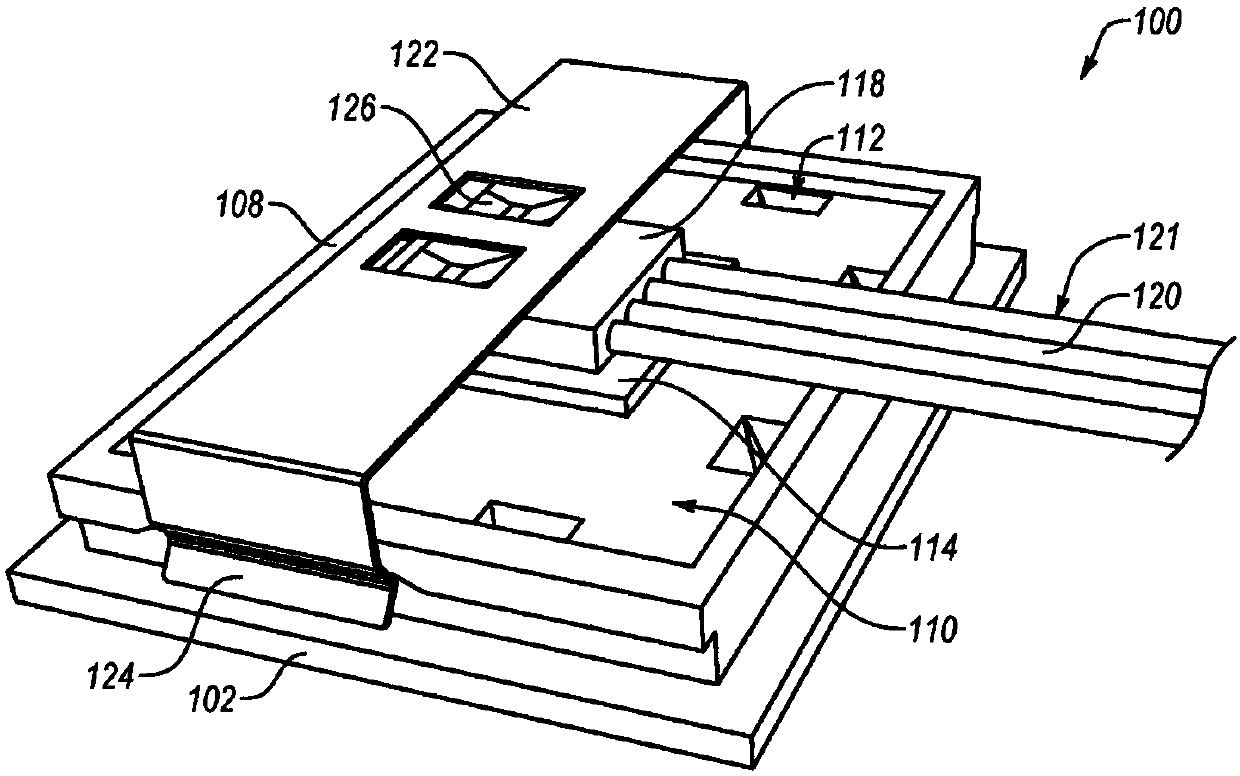

Laser scanning apparatus with improved optical features

InactiveUS20070076193A1Easy and reliable alignment mechanismAvoid problemsUsing optical meansMechanical measuring arrangementsData averagingFiber

Laser scanners are used for determining deformation in vehicle bodies and the like, using a laser scanning apparatus in conjunction with a plurality of coded targets suspended from (or in known relationship to) known reference points on the vehicle to calculate three dimensional spatial coordinates defining the actual positions of the targets, and to compare such calculated positions with manufacturer-provided specification values. The present invention provides improved signal collection through the use of an independent synchronization circuit that uses a fiber optic cable for signal collection; improved component isolation through the use of a mounting plate and isolation mounts; improved component alignment through the use of easier and more reliable alignment mechanisms; and improved data collection and processing through the use of onboard data averaging and filtering.

Owner:VEHICLE SERVICE GROUP LLC

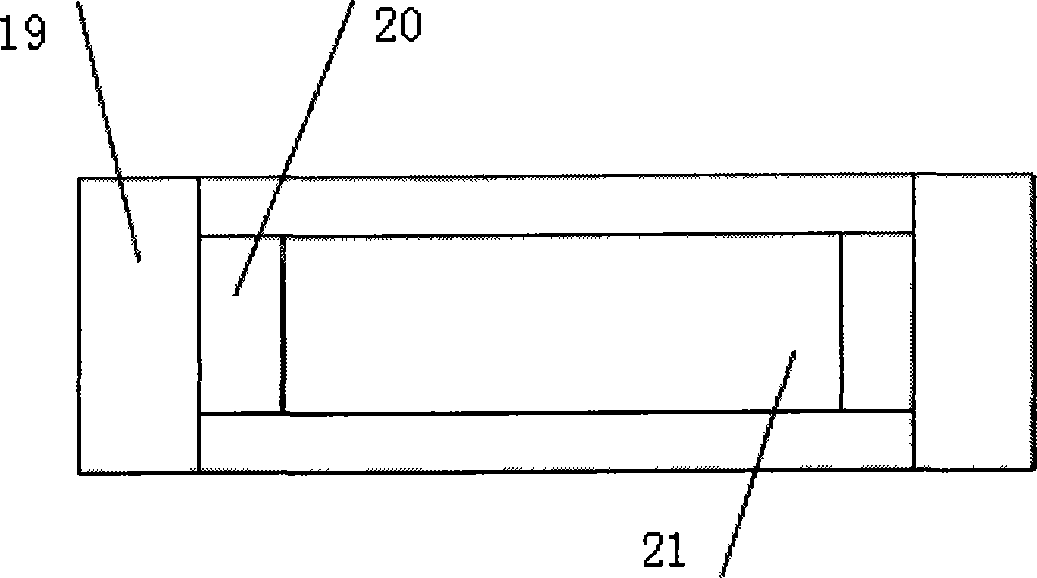

Component alignment

A system may include a substrate and a lens component. The substrate may include pads and solder protuberances. Each solder protuberance may be located on a pad. The lens component may define groovessized to receive at least a portion of the solder protuberances. The lens component may be positioned relative to the substrate such that at least a portion of each solder protuberance is positioned within the grooves. An optoelectronic transceiver comprises the system and a fiber optic cable including a cable lens component, a plurality of optical fibers at least partially positioned in the cablelens component, and a lens clip configured to be removably located on the transceiver lens component.

Owner:FINISAR

Fixture for microscope component alignment

A fixture and method is provided for aligning optical elements in a microscope. The fixture attaches to an objective lens plane of the microscope and supports an alignment optical element. During optical component alignment, an alignment beam is directed along the illumination and imaging paths of the microscope through the objective lens port and into the fixture for reflection by the alignment optical element. The fixture allows an alignment optical element positioned in a single location to be used for aligning the microscope components and for adjusting the microscope objective lens.

Owner:SOLURIS +1

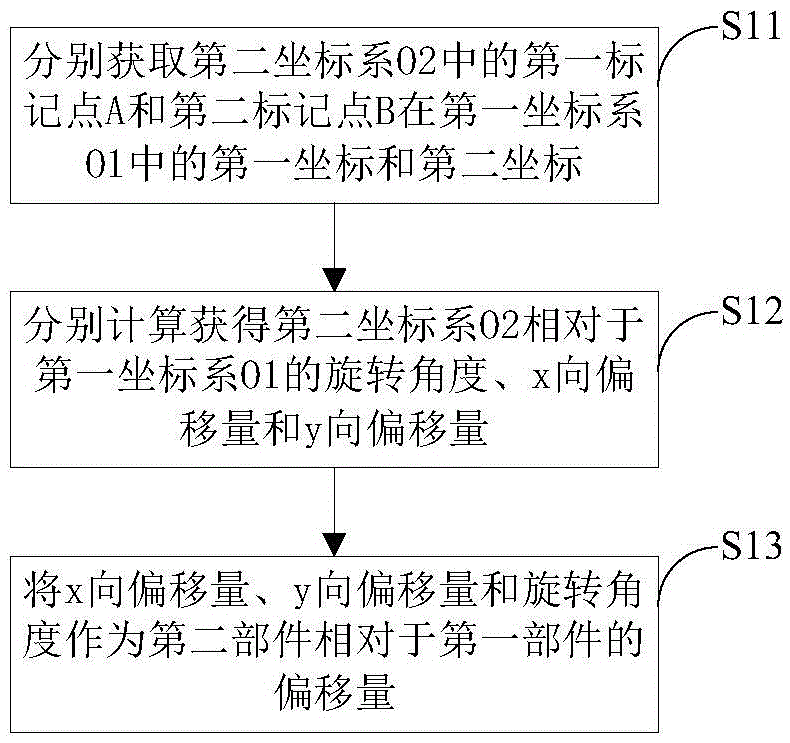

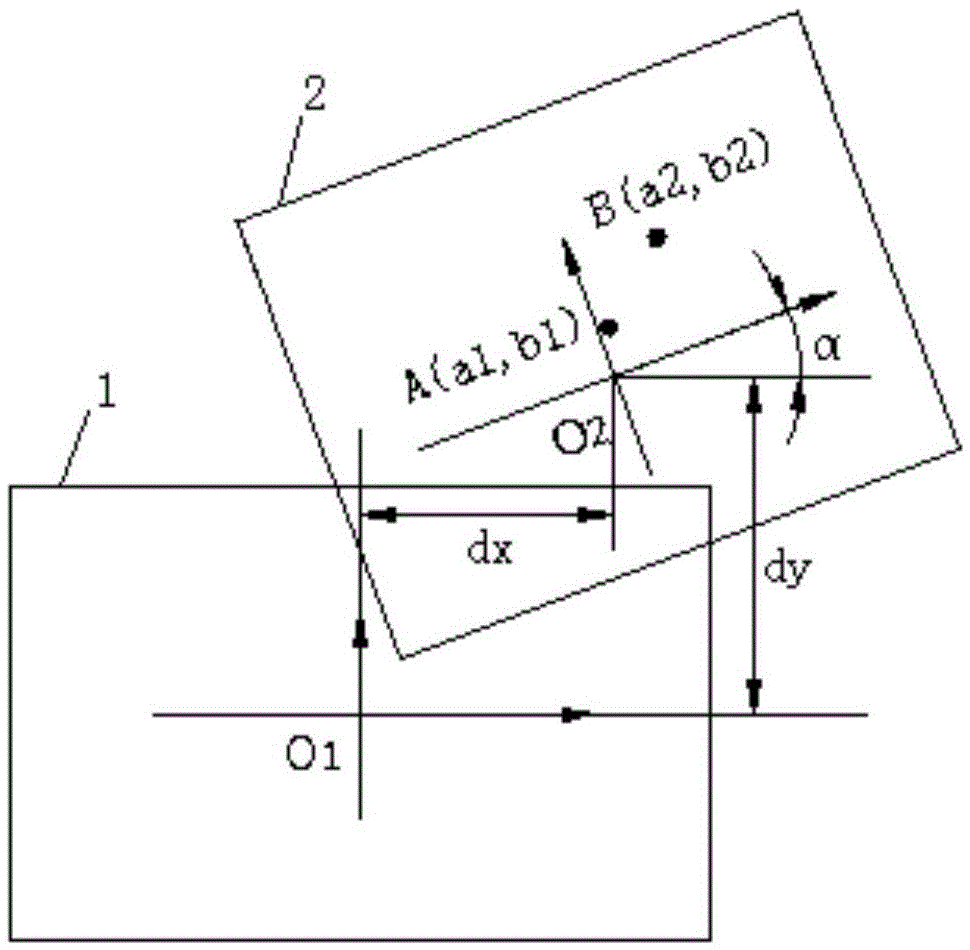

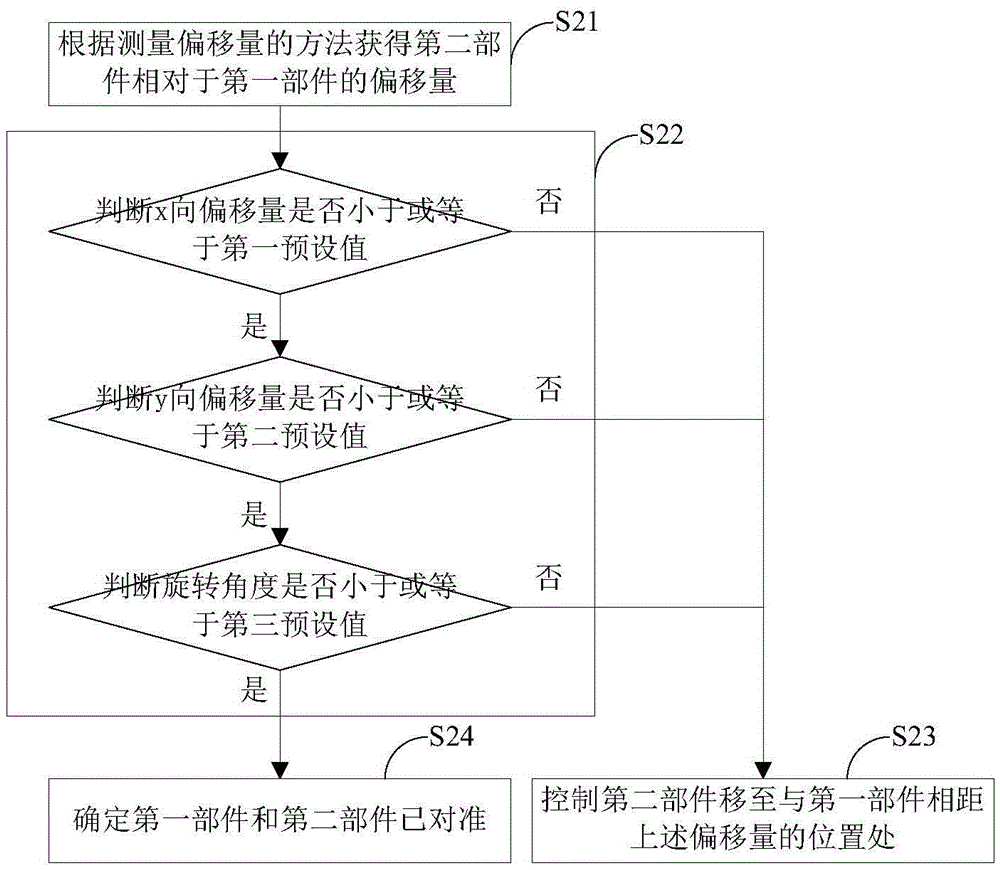

Offset measurement method and device and component alignment method and device

InactiveCN105627922AHigh measurement accuracyAccurate calculationUsing optical meansComponent alignmentComputer science

The invention discloses an offset measurement method and device and a component alignment method and device. The offset measurement method comprises the steps that first coordinates and second coordinates in a first coordinate system O1 of a first mark point A and a second mark point B in a second coordinate system O2 are respectively acquired; the rotation angle alpha, x-direction offset dx and y-direction offset dy of the second coordinate system O2 relative to the first coordinate system O1 are respectively acquired through calculation; and the x-direction offset dx, the y-direction offset dy and the rotation angle alpha act as offset of a second component relative to a first component. The offset measurement method and device have the advantages of high measurement precision, and alignment of the first component and the second component is realized by using the offset measurement method so that alignment precision can be enhanced.

Owner:POLAR LIGHT TECH CO LTD

Systems and methods for multi-modality imaging component alignment

ActiveUS10049465B2Precise alignmentImage enhancementImage analysisDiagnostic Radiology ModalityComponent alignment

Methods and systems are provided for aligning components of a multi-modality imaging system. In one embodiment, a method comprises performing a plurality of scans of an object with a first modality and a second modality, wherein the object is positioned in a different orientation in each of the plurality of scans, calculating a plurality of alignment parameters of a first modality unit and a second modality unit based on the plurality of scans, and adjusting alignment of the first modality unit and the second modality unit based on the plurality of alignment parameters. In this way, components of a multi-modality imaging system may be accurately aligned using any phantom from which a unique line can be extracted in each modality scan.

Owner:GENERAL ELECTRIC CO

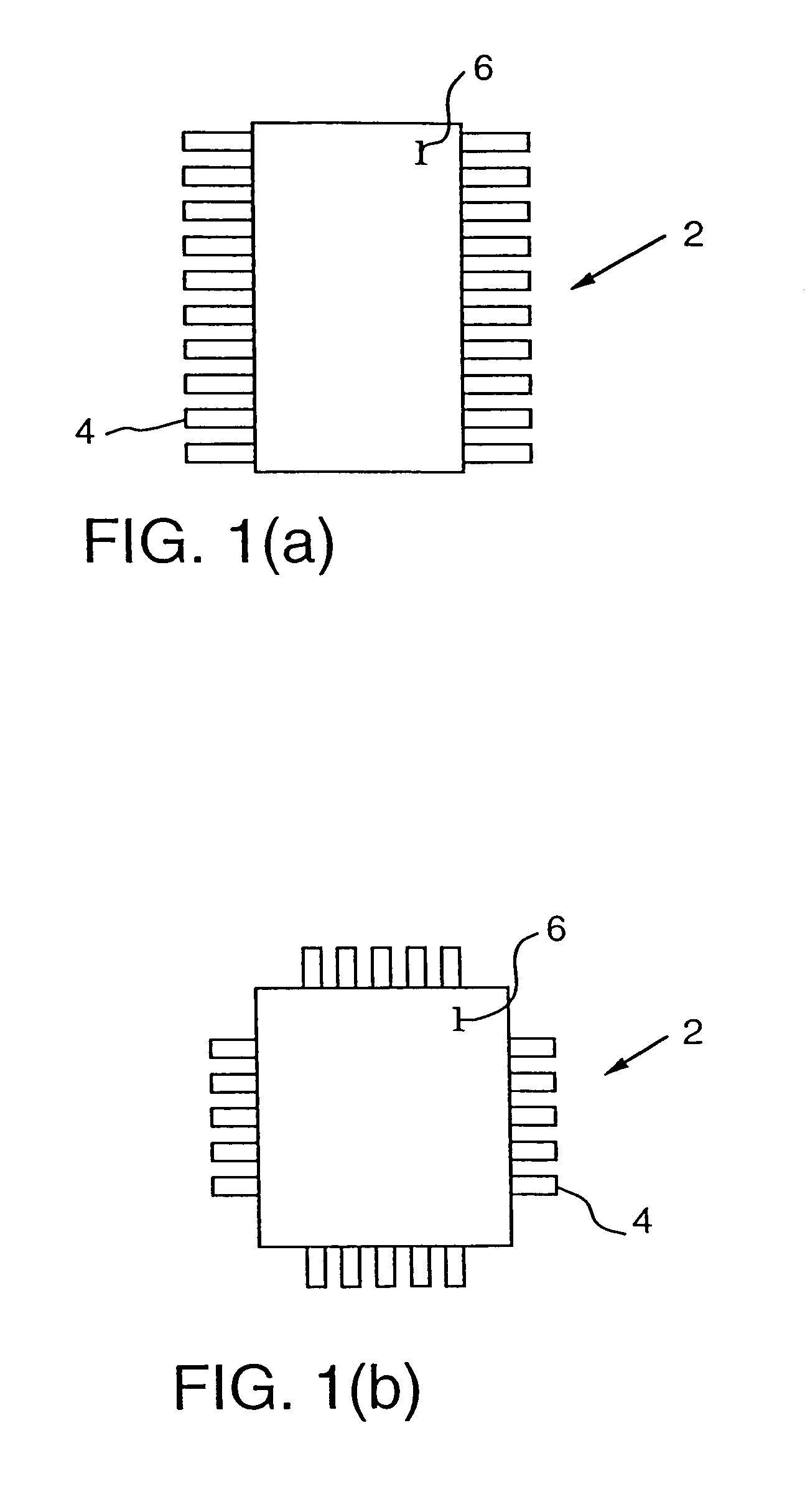

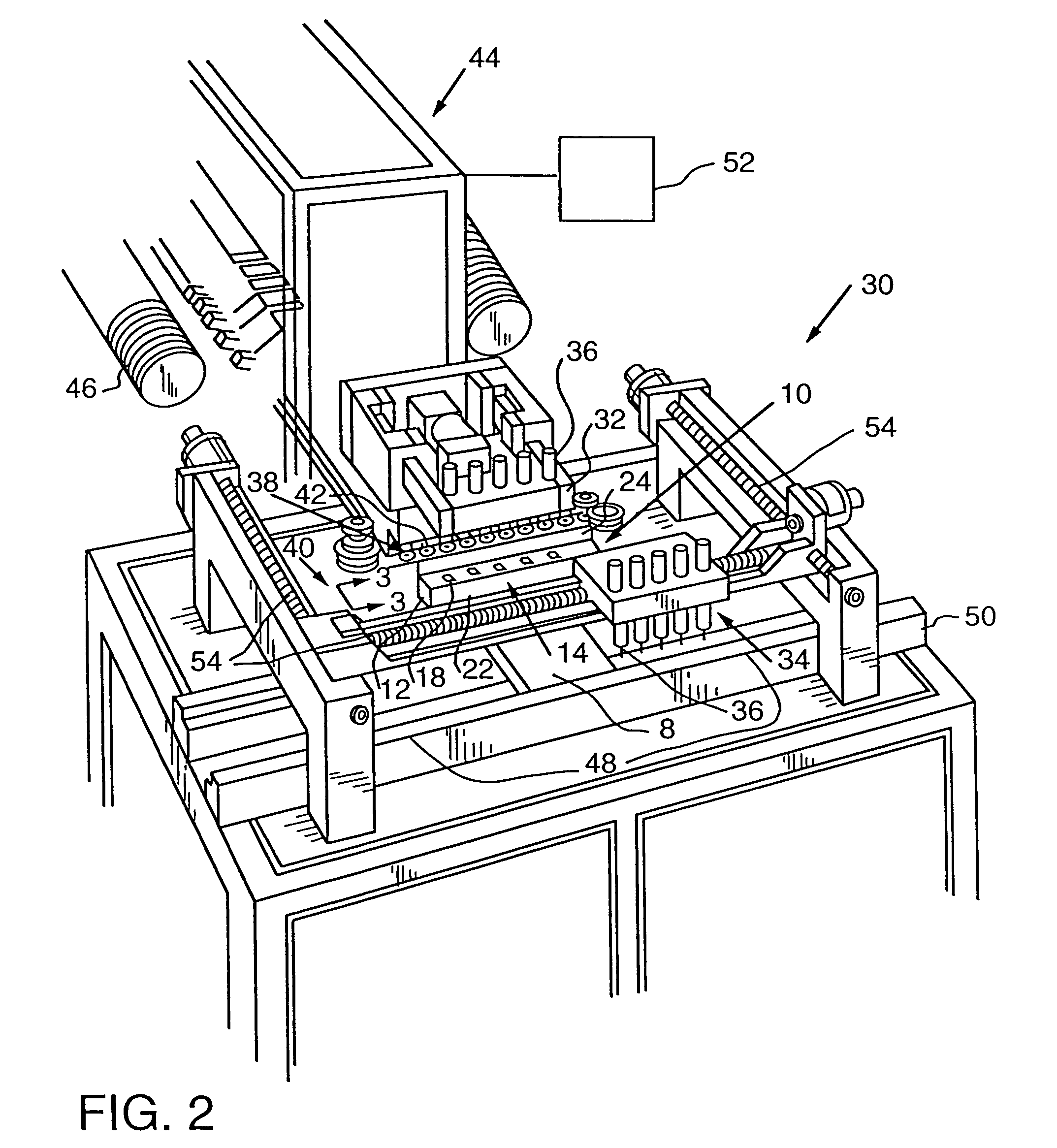

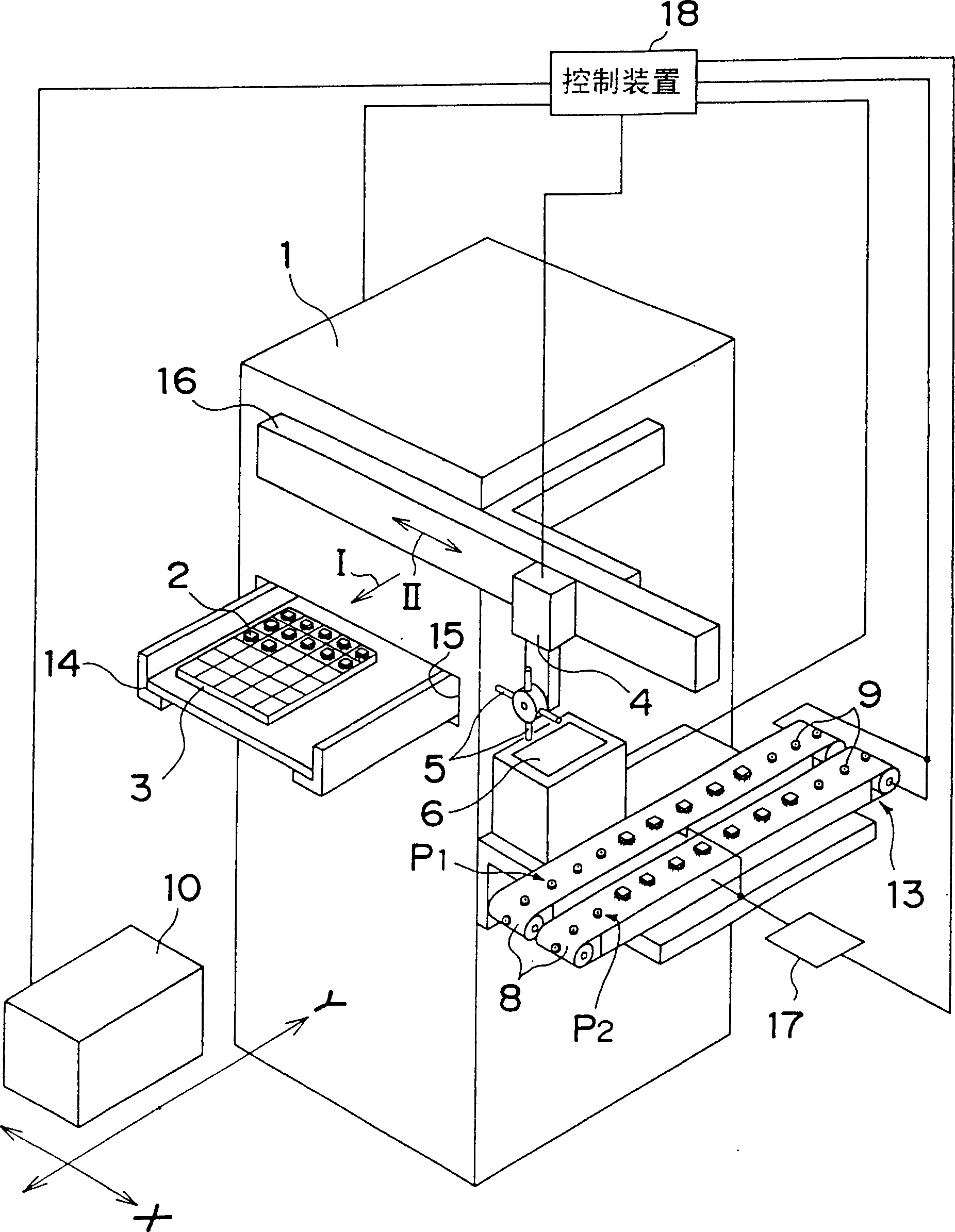

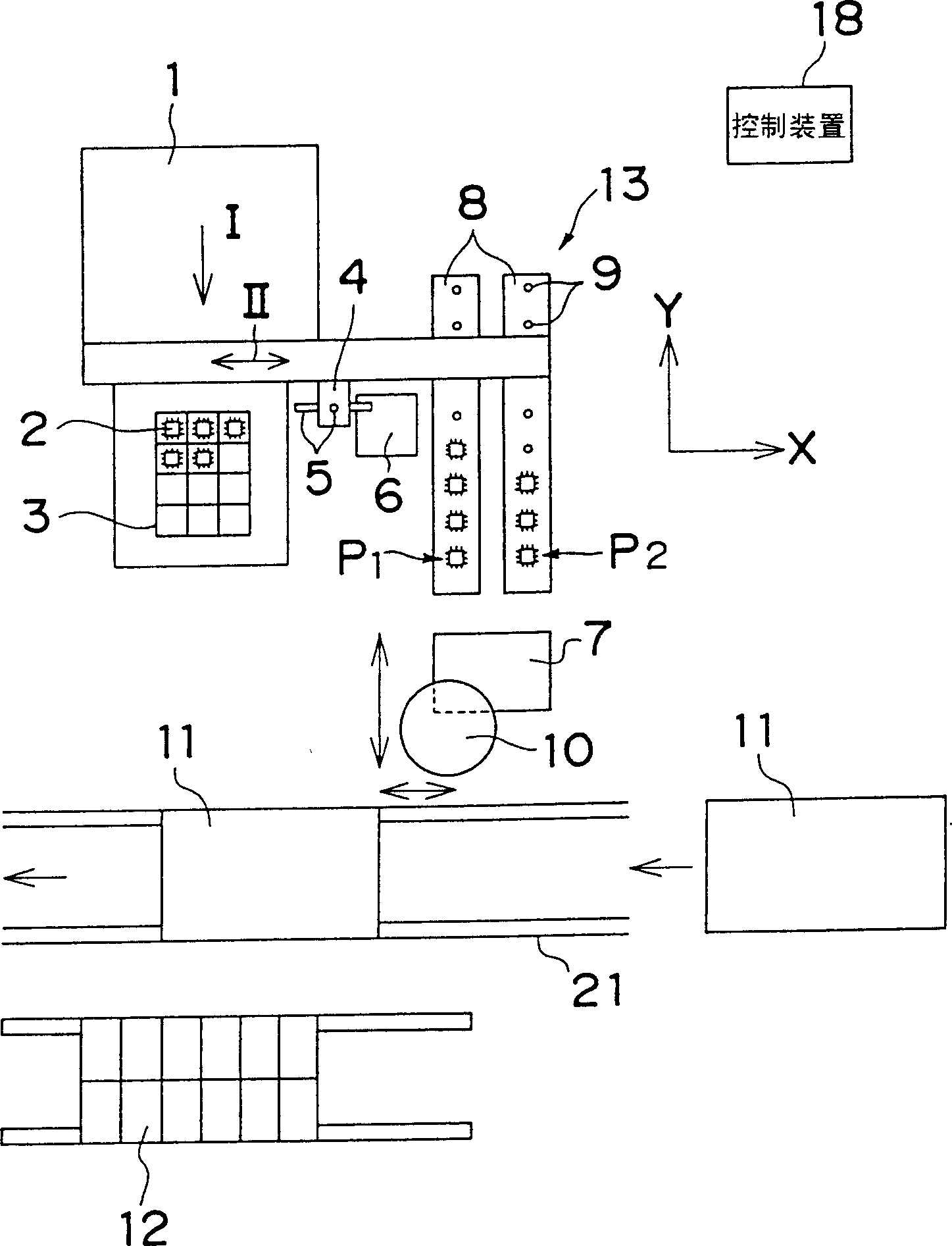

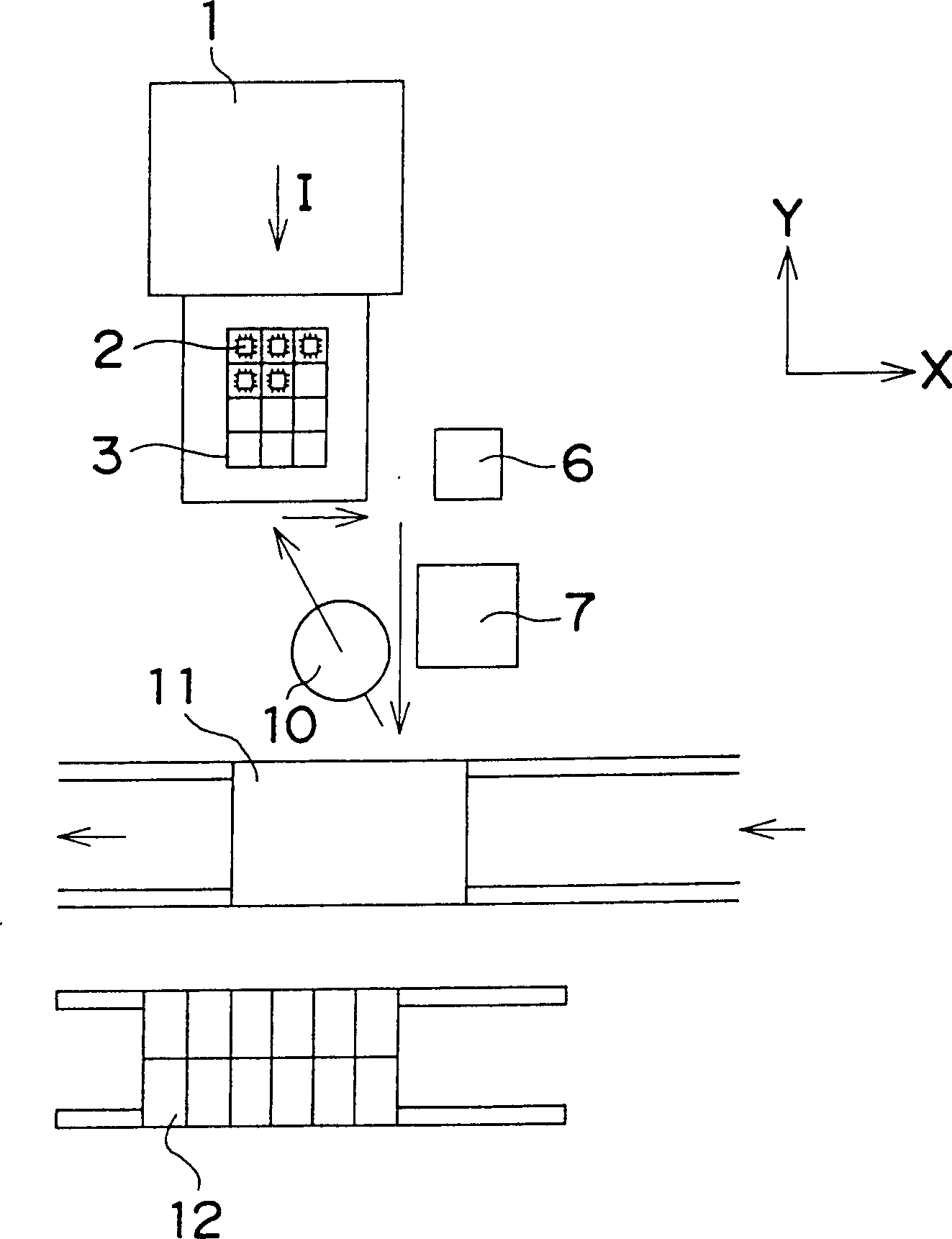

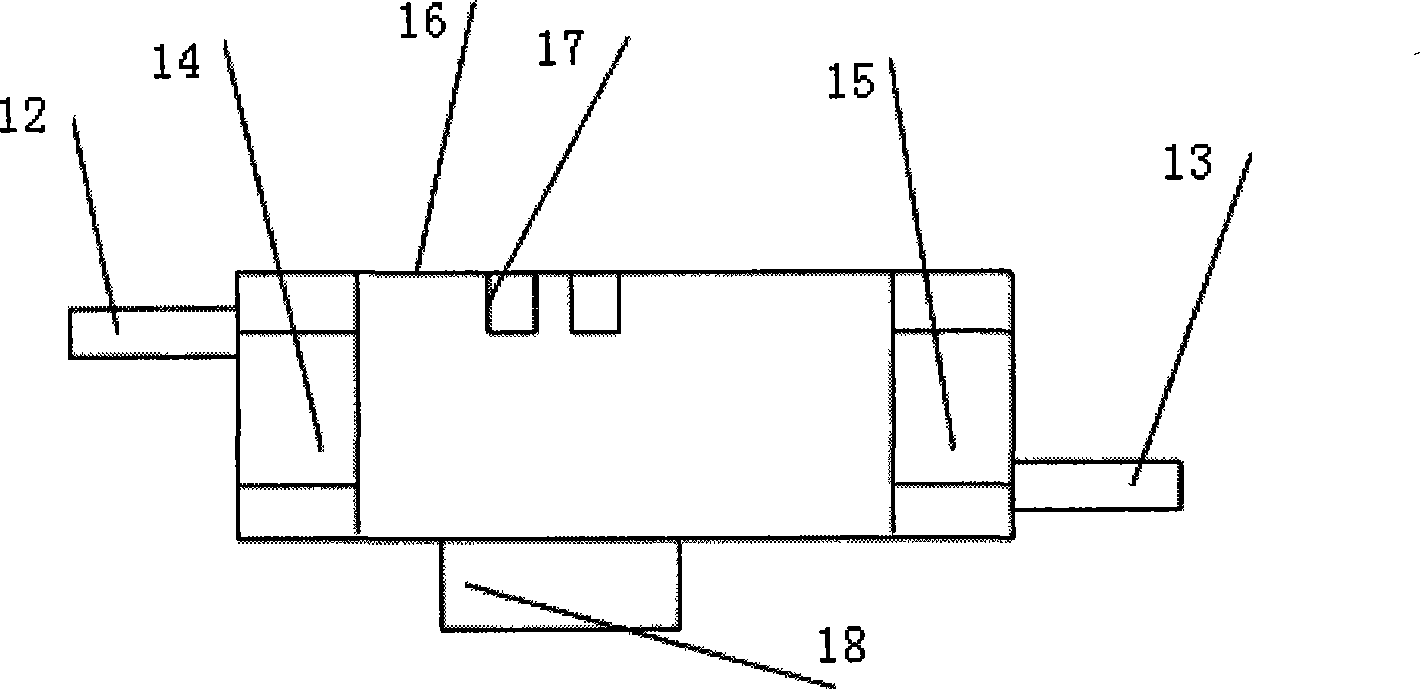

Electronic component supply device and its mounting method

InactiveCN1516548AShorten delivery timeImprove productivityMetal working apparatusElectrical componentsProduction rateComponent alignment

The present invention has for its object to provide an apparatus and a method for feeding electronic components to a mounting head with high productivity. In order to accomplish the object of the present invention, an electronic component (2) taken out from a component storage section (3) by a transfer head (4) is held by means of a suction operation and transferred and inspected as to whether it is good or defective by a good / defective component inspecting device (6). Thereafter the electronic component is delivered to an alignment suction nozzle (9) on a component alignment section (13) The sequence of the above-operations is repeated, whereby the electronic components (2) inspected and then aligned in the order of mounting can be supplied to a mounting head (10). According to the present invention, a mount time for the electronic components in a mount process is greatly shortened, so that productivity is expected to be improved. The electronic components can be inspected before aligned in the order of mounting, which further enhances mount efficiency.

Owner:PANASONIC CORP

Active optical component alignment system and method

InactiveUS6897464B2Beam/ray focussing/reflecting arrangementsInvestigating moving sheetsNeuro controllerComponent alignment

An alignment system and method is disclosed, the alignment system and method provide for alignment of at least one component to an optical signal using a neural controller circuit. The neural controller circuit facilitates parallel and sequential alignment of a plurality of components to the optical signal.

Owner:TRZECIESKI MIKE A

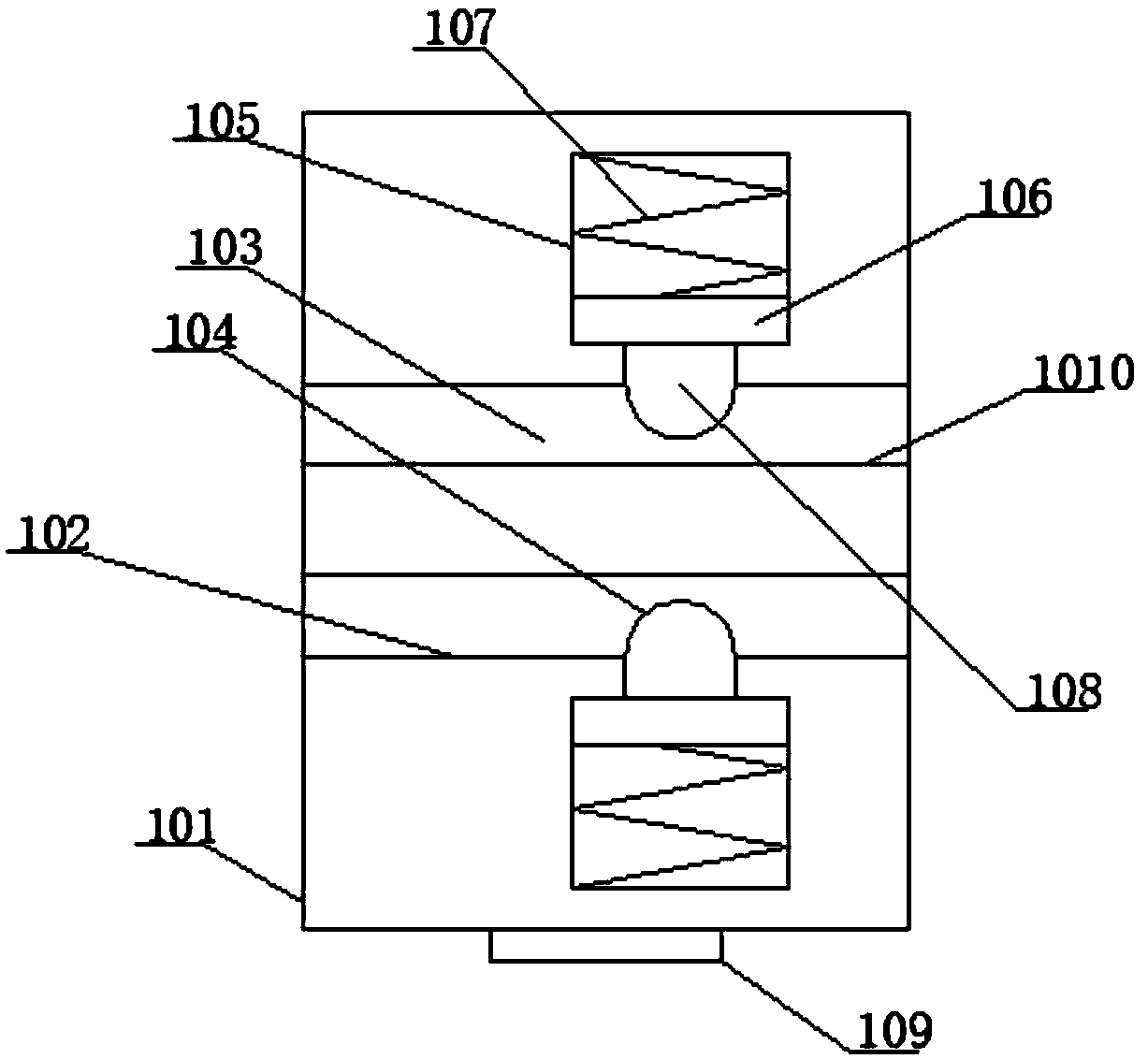

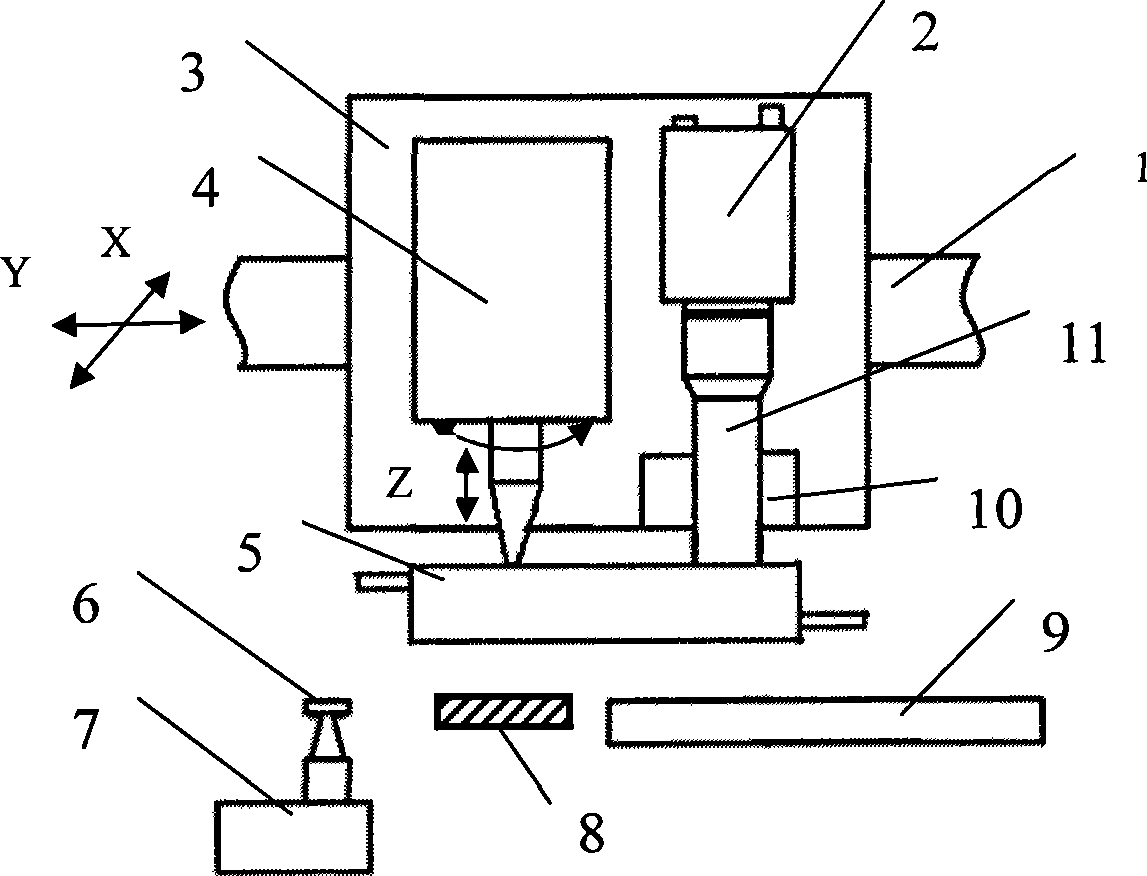

Vision component alignment apparatus

InactiveCN101487693AAchieve stable imagingSave time at workUsing optical meansCamera lensComponent alignment

An aligning device of visual components belongs to a device for measuring space position of objects and locating the objects, which solves the disadvantages that the existing device just has unidirectional identification or serial locating so as to realize bidirectional identification of components and mounting positions thereof as well as follow-up parallel locating. The aligning device comprises a movement mechanism, an operating mechanism, an electronic camera, a mechanism for fixedly adjusting lens and an optical path system. The movement mechanism can move along X-Y direction; the operating mechanism is installed on a support plate fixed with a bracket of the movement mechanism; an executive component of the operating mechanism moves up and down along Z direction and can conduct rotary movement along Z direction; the electronic camera is jointed together with the lens via a port by means of rotating, and is fixed on the support plate by a fixed adjusting mechanism; the optical path system is composed of two parts of an inclined reflector array and a horizontal reflector array, and the inclined reflector array is fixedly installed on the support plate and comprises two mutually parallel inclined reflectors having an angle of 45 degrees with a horizontal surface; a horizontal reflector platform is parallel to the horizontal surface and is installed between a component supply mechanism and a component mounting workbench. The visual aligning detection of components in installation can be simultaneously carried out in assembly process, thereby improving the accuracy and efficiency of installation operation.

Owner:HUAZHONG UNIV OF SCI & TECH

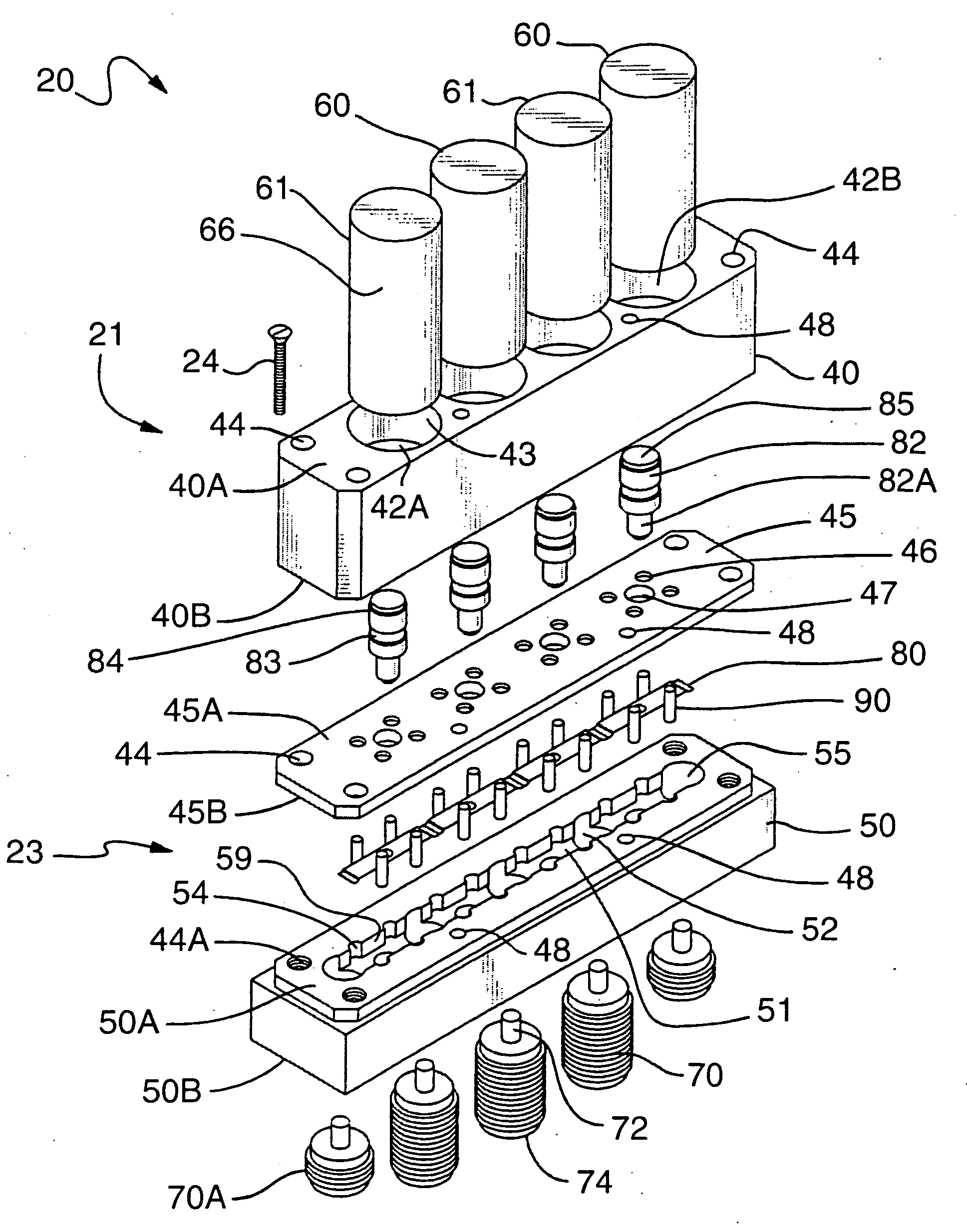

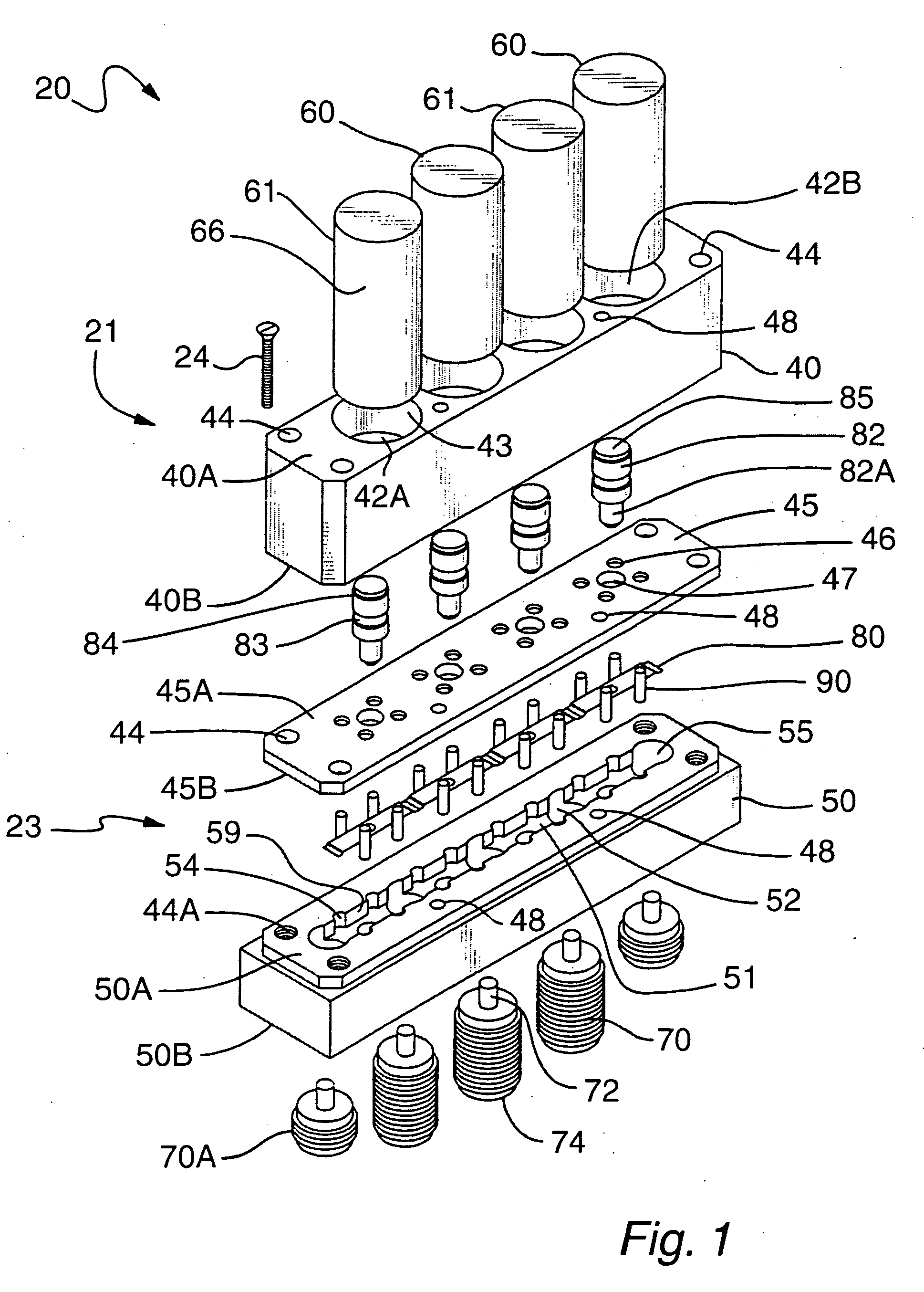

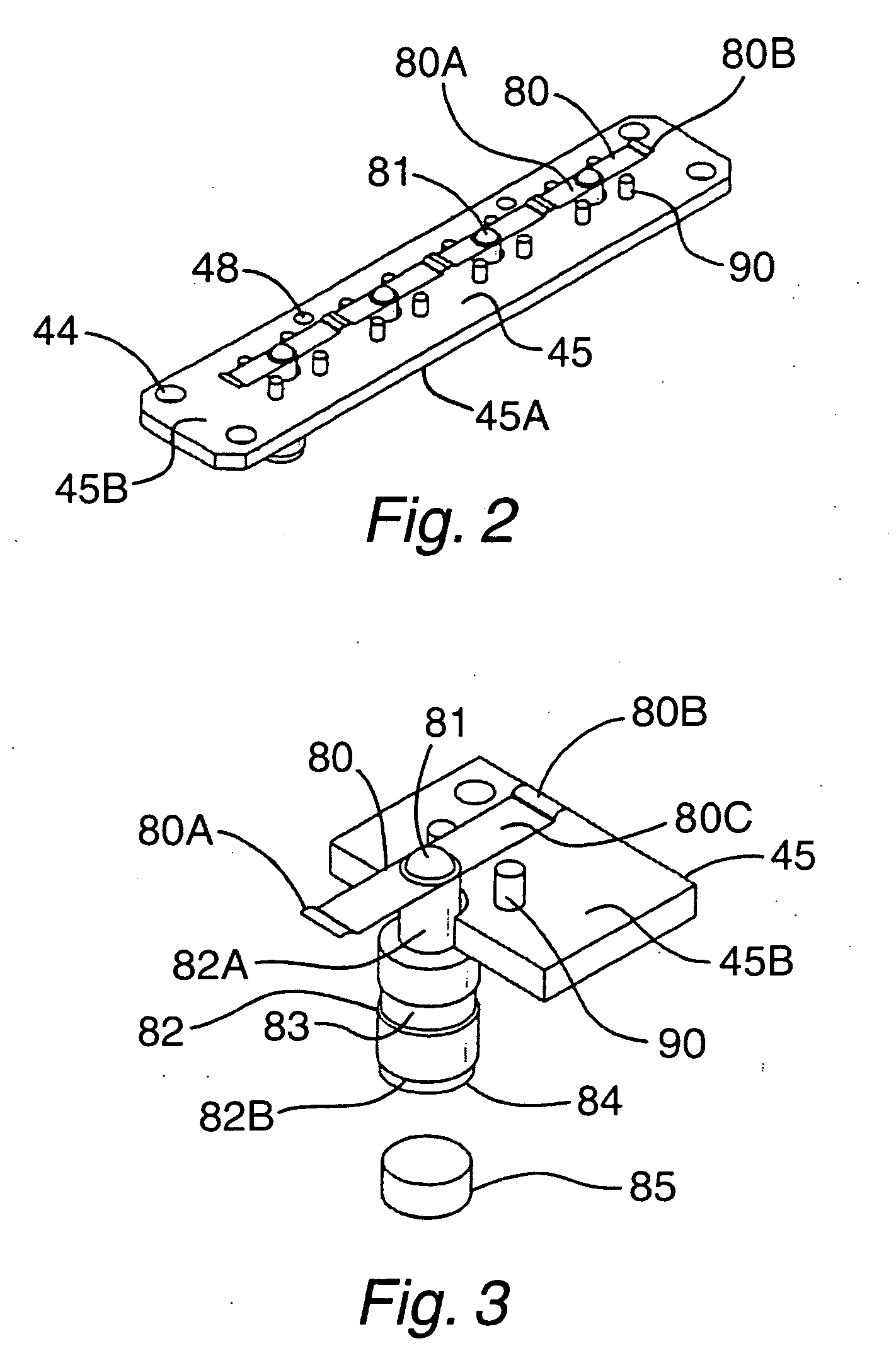

Electromechanical radio frequency switch

ActiveUS20090160585A1Friction travelExtended service lifeCircuit-breaking switches for excess currentsSelector switchesWear particleComponent alignment

An improved electromechanical RF switch provides enhanced reliability and lifespan by incorporating a middle plate between the case and base elements for locating the guide pins, reed holders and reeds to increase accuracy in critical component alignment. The middle plate reduces required precision during assembly of the switch, thus increasing assembly accuracy while reducing labor cost. The guide pins are made of a hard insulator such as glass to generate less wear particles, and the reed holder has a groove filled with lubricant to trap any wear particles that result from sliding friction during switch operation. Optionally, a low-friction bushing is used within the case bore to further reduce sliding friction during reed holder travel. The reeds are made of thin, flexible metal and have ends shaped so that when the ends contact switching terminals, a wiping action removes any surface contamination from both the reed ends and the terminals.

Owner:SCI COMPONENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com