Vision component alignment apparatus

A technology for alignment devices and components, applied in measuring devices, optical devices, instruments, etc., can solve problems such as work efficiency limitations, and achieve the effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

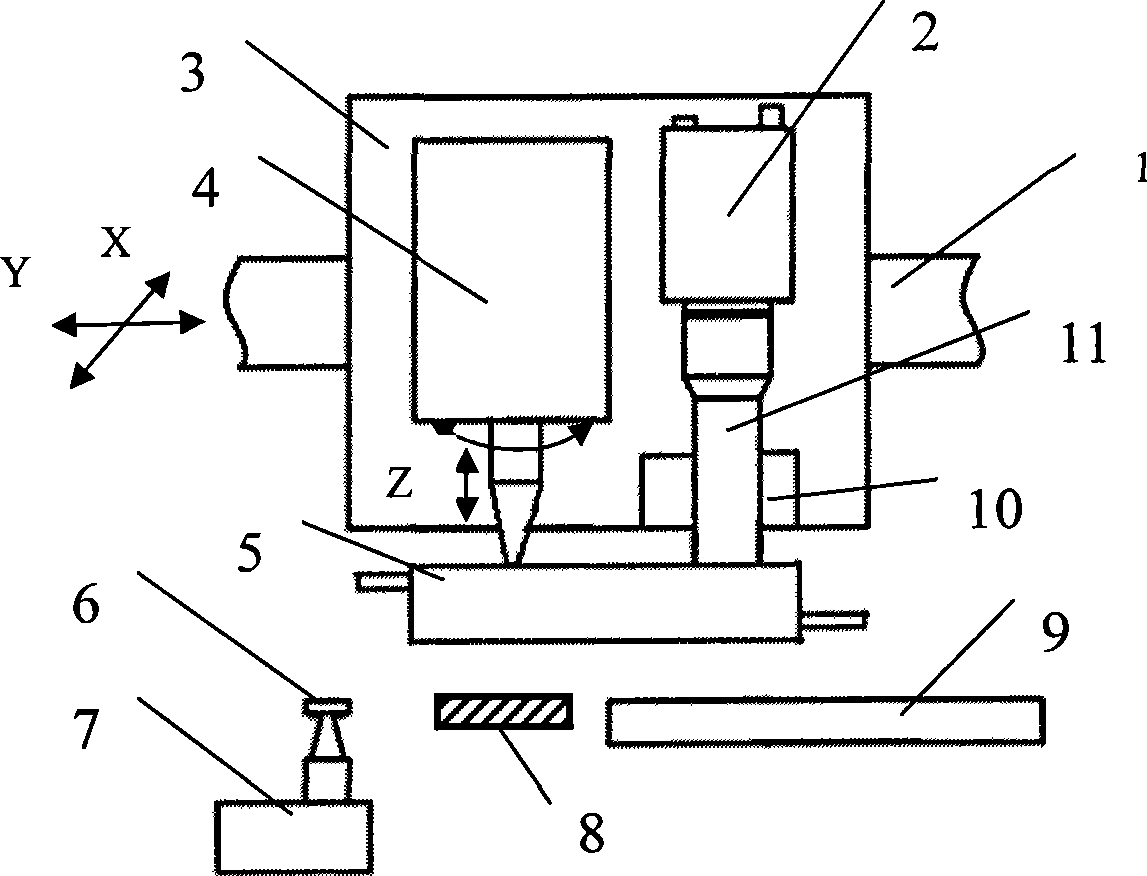

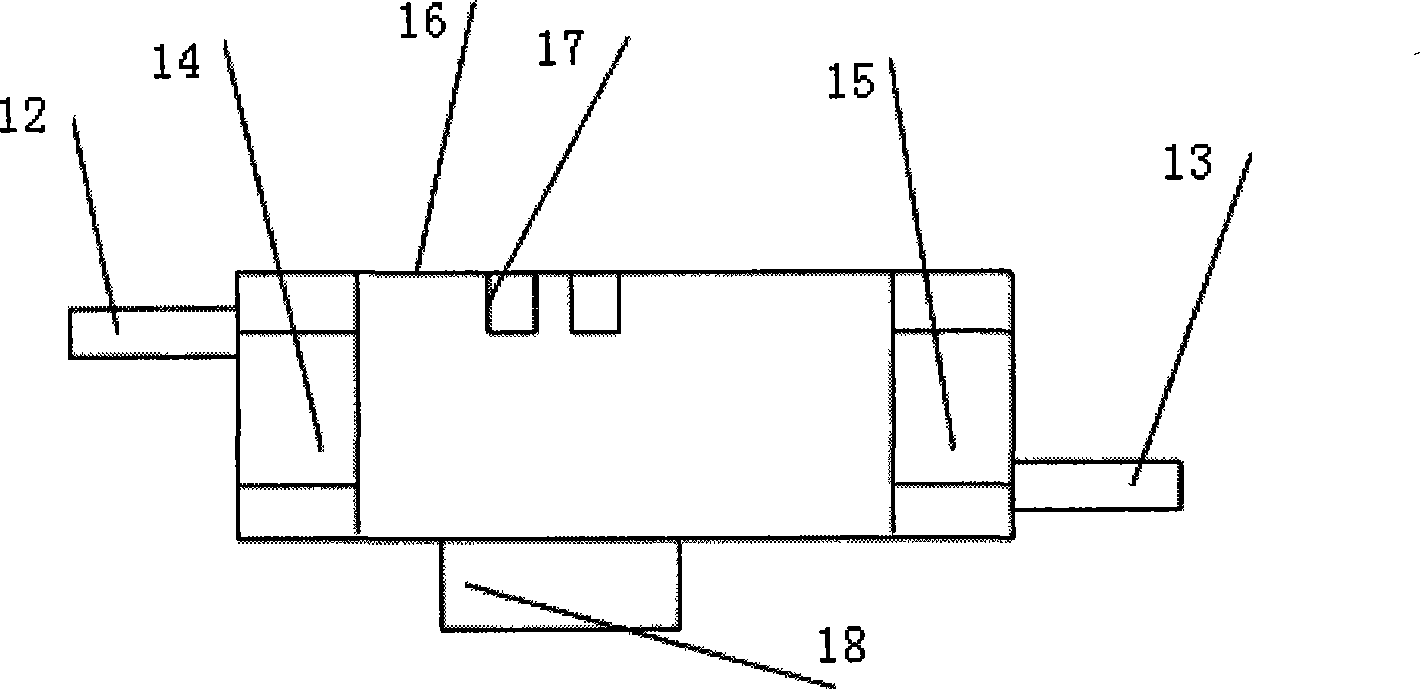

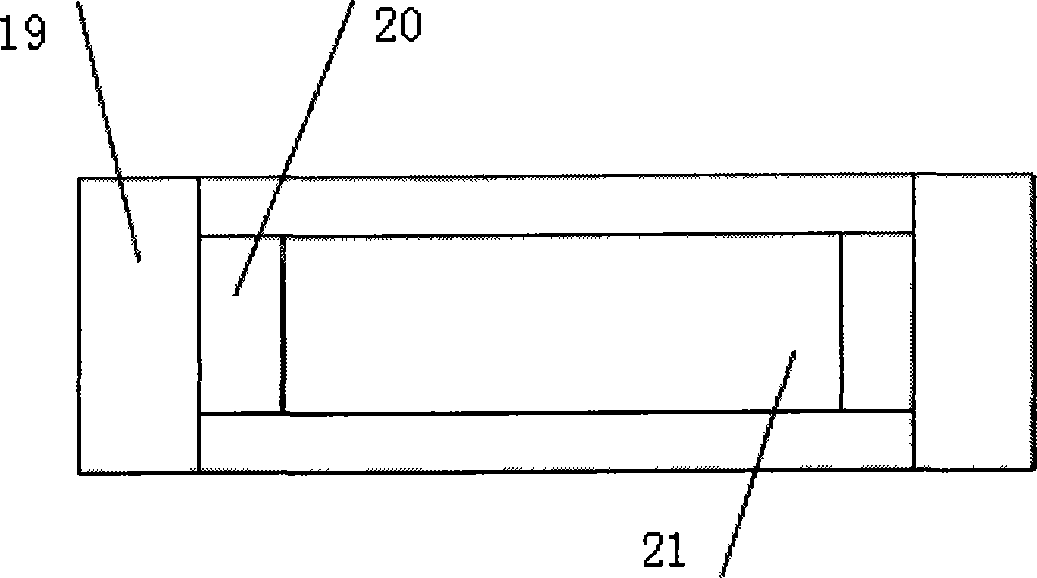

[0025] like figure 1As shown, the present invention consists of an X-Y motion mechanism, a component pick-and-place operating mechanism, a CCD electronic camera, a lens and its fixed adjustment mechanism, and a group of optical paths composed of oblique reflector groups and straight reflectors. Among them, the operating mechanism 4 that can vacuum absorb or adhere parts is installed on the support plate 3 fixed with the movement mechanism bracket 1, the movement mechanism can move along the X-Y direction, and the support plate 3 follows it; the execution part of the operation mechanism 4 can be Move up and down along the Z direction, and can rotate along the Z direction. The CCD electronic camera 2 and the optical lens 11 are screwed together through the interface, and the lens 11 and the electronic camera 2 are fixed on the support plate 3 by the lens fixing adjustment mechanism 10, which can follow the support plate 3; Adjust the distance from the lens 11 to the actual imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com