Electronic component supply device and its mounting method

A technology for electronic components and installation methods, applied in electrical components, electrical components, metal processing equipment, etc., can solve problems such as efficiency and long time, and achieve the effect of shortening installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following description of the present invention, the same reference numerals are used for the same parts in the drawings.

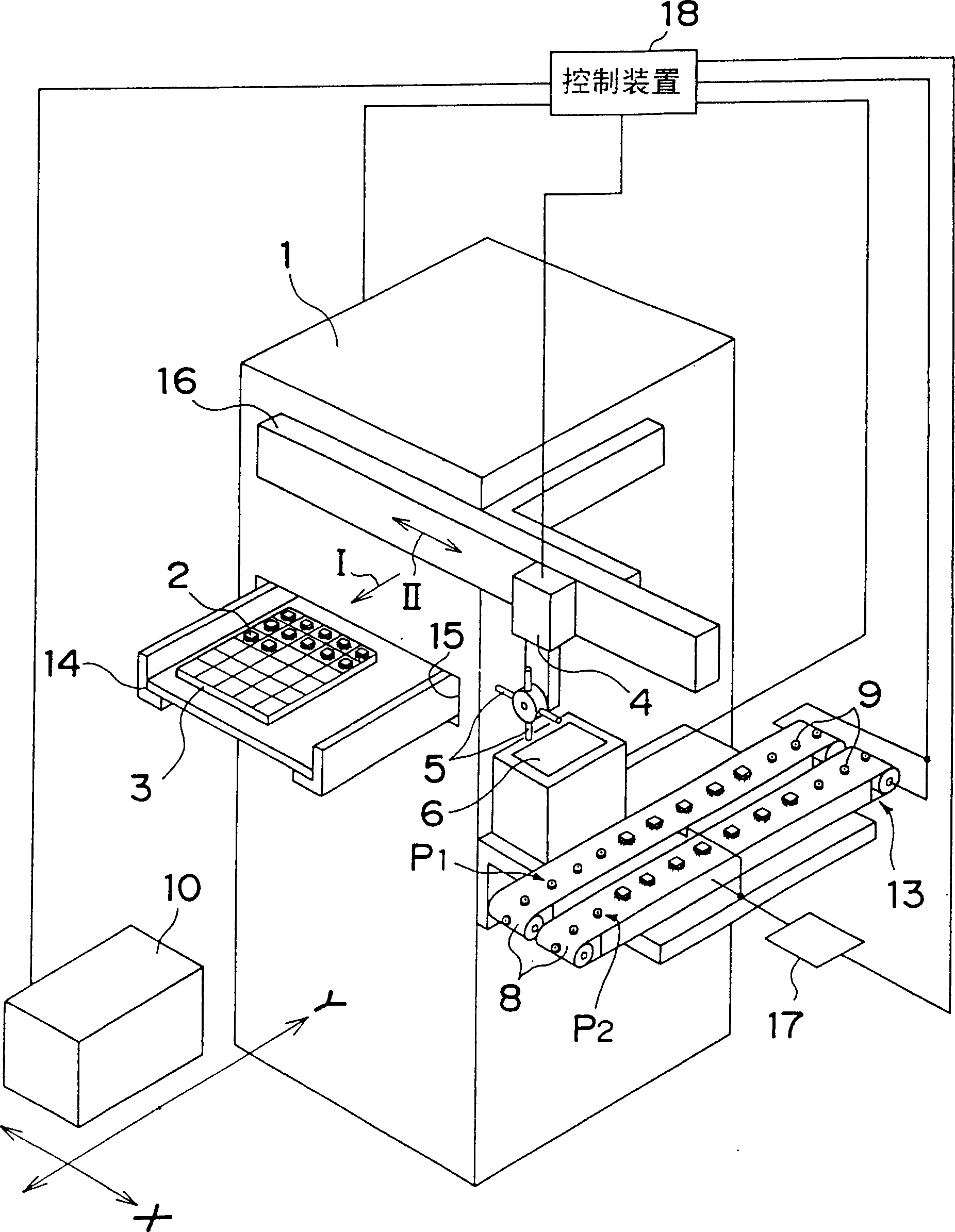

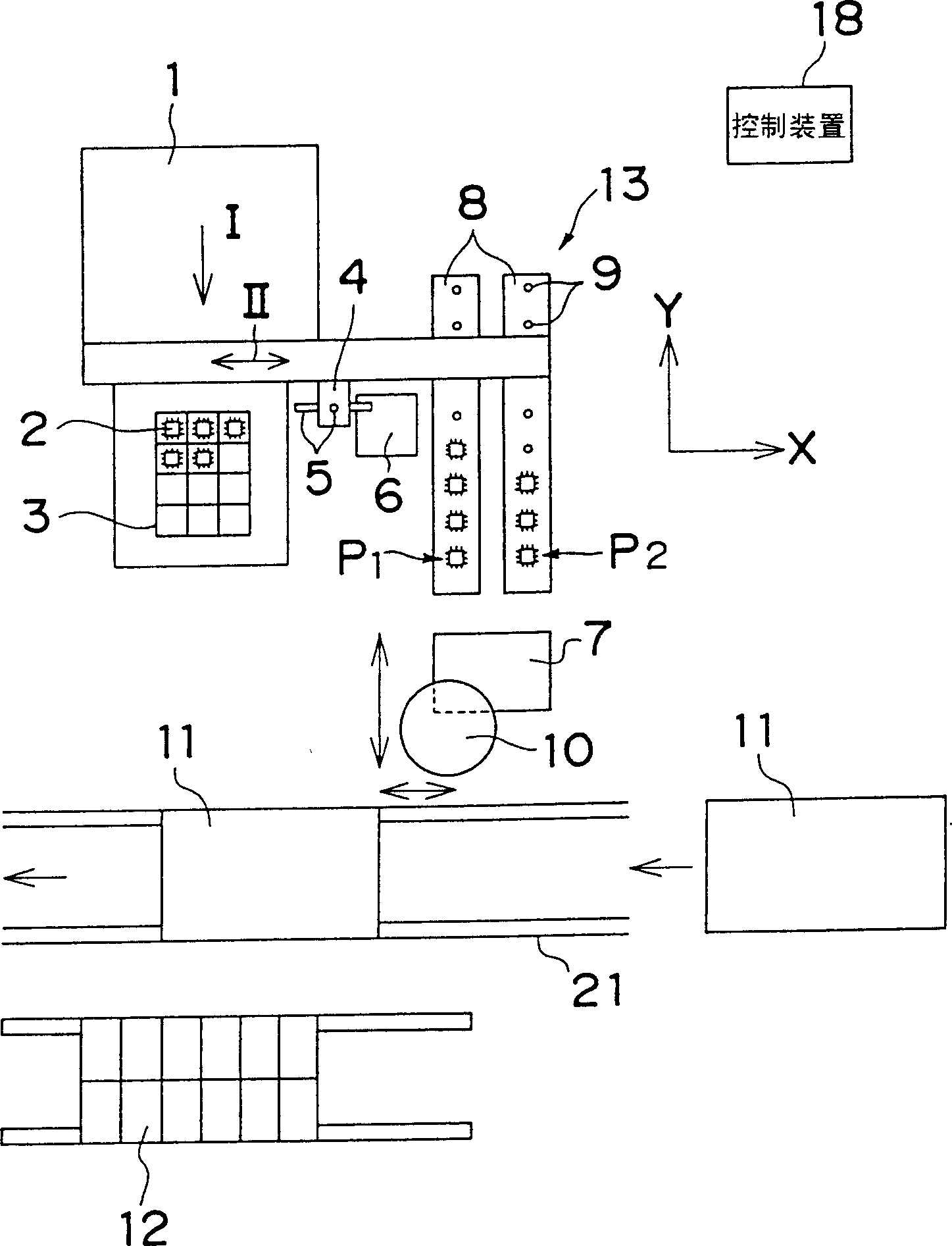

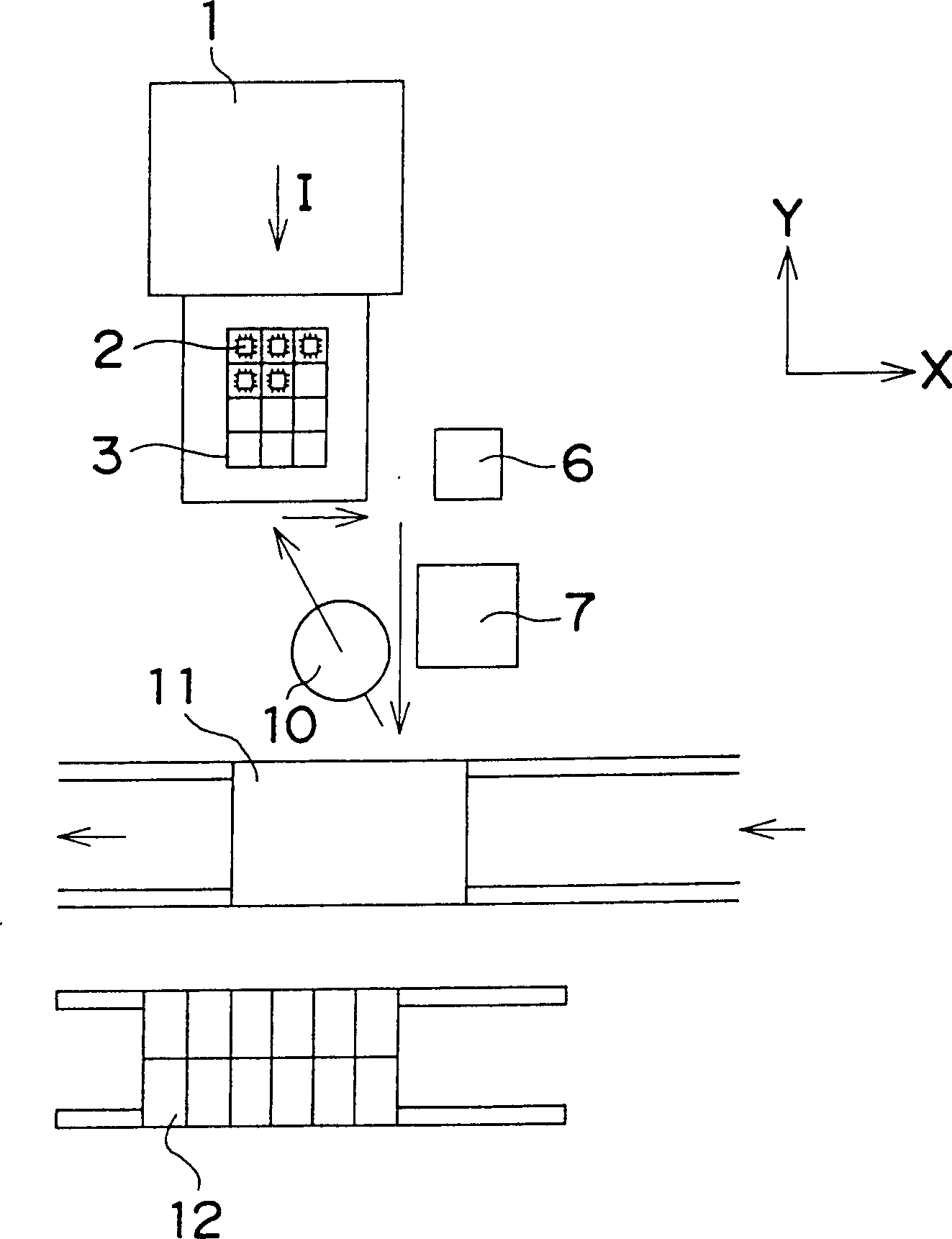

[0017] Refer to the attached figure 1 , 2 , to illustrate an embodiment of the present invention.

[0018] figure 1 Among them, the component storage device 1 stores the component storage parts 3 such as discs in which the electronic components 2 have been stored up and down in tens of stacked states, and the component storage parts 3 that have received the required electronic components are designated by the program, so that The component storage part support frame 14 of the component storage part 3 moves up and down and is transported to the take-out port 15, and is transported in the direction of the arrow I by the take-out port 15. The conveying head 4 has several kinds of conveying suction heads 5. According to the types of different electronic components 2, use the most suitable head to take out the electronic components 2 from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com