Component alignment

One component, one part technology, applied in the field of component alignment, can solve problems such as high alignment cost and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

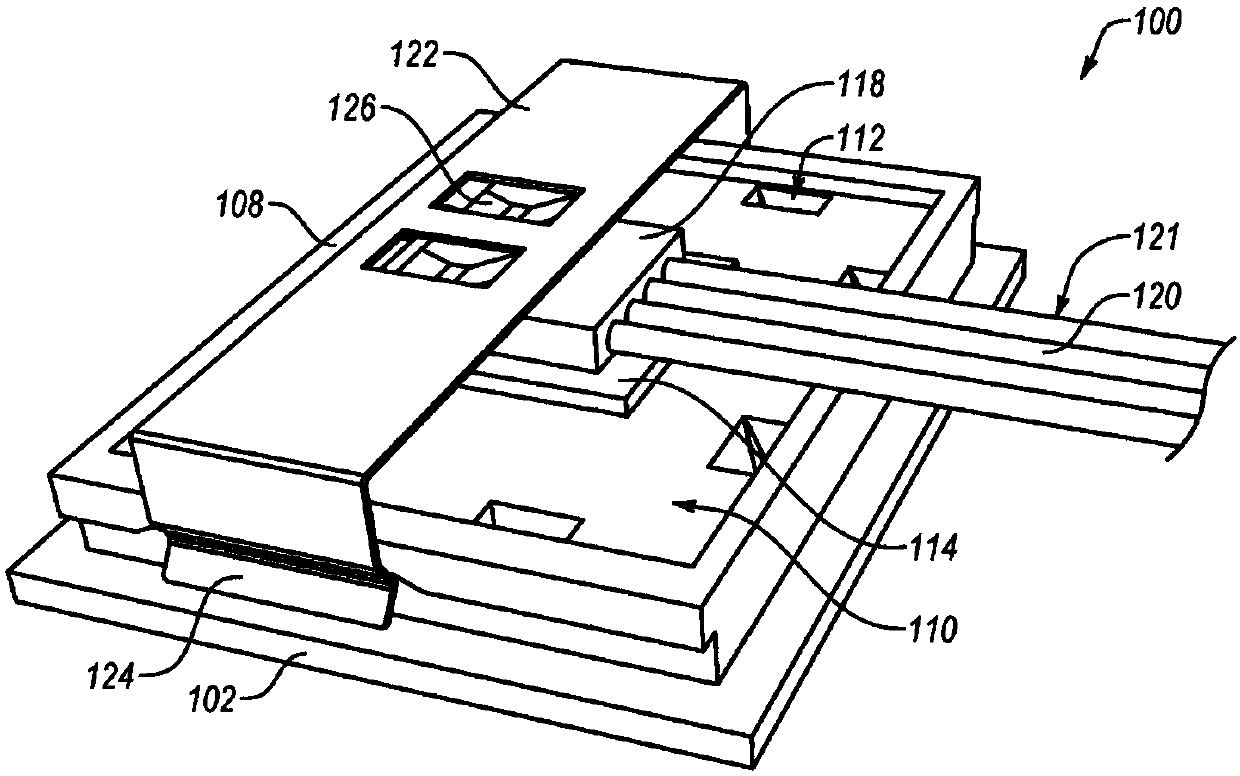

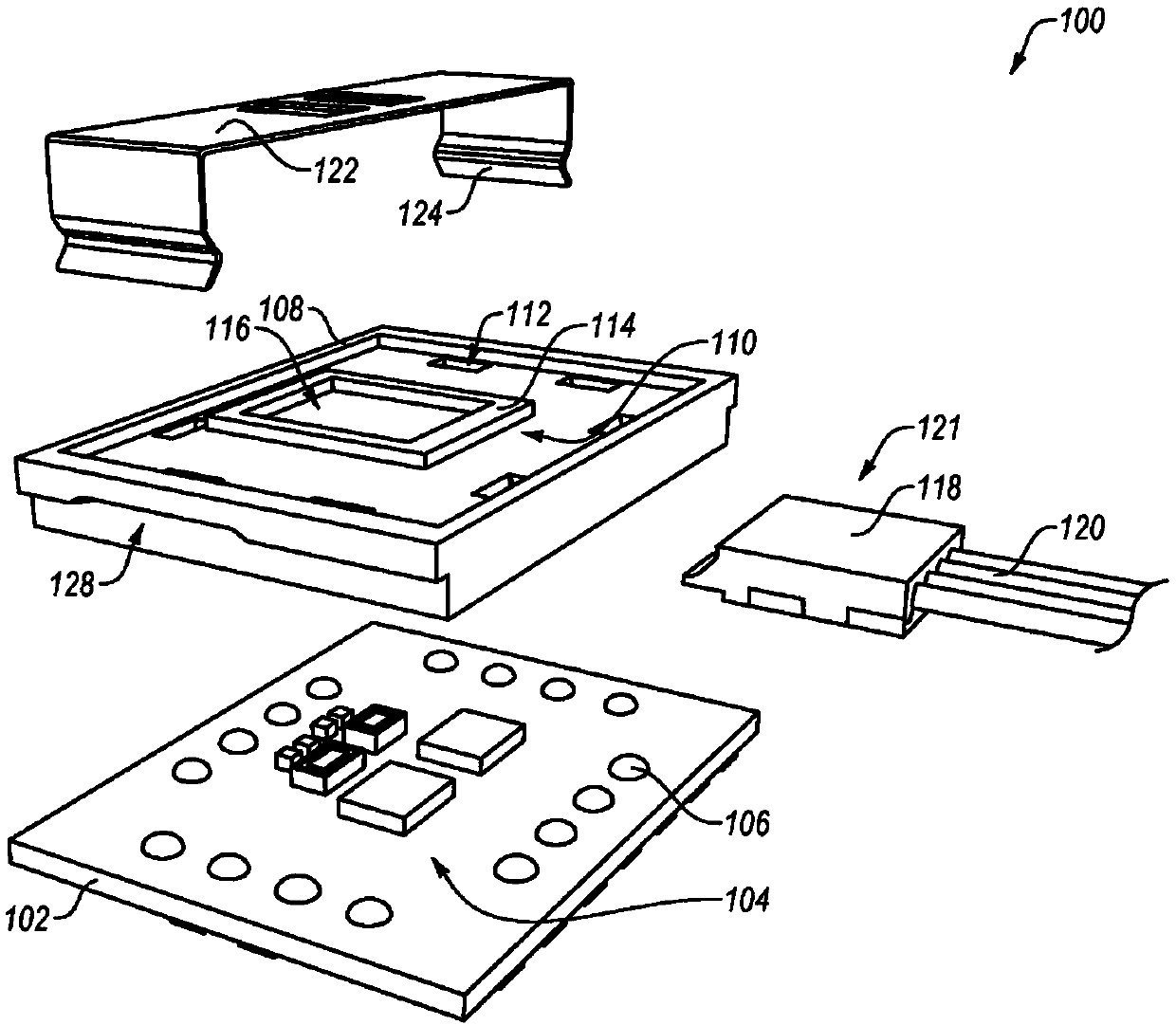

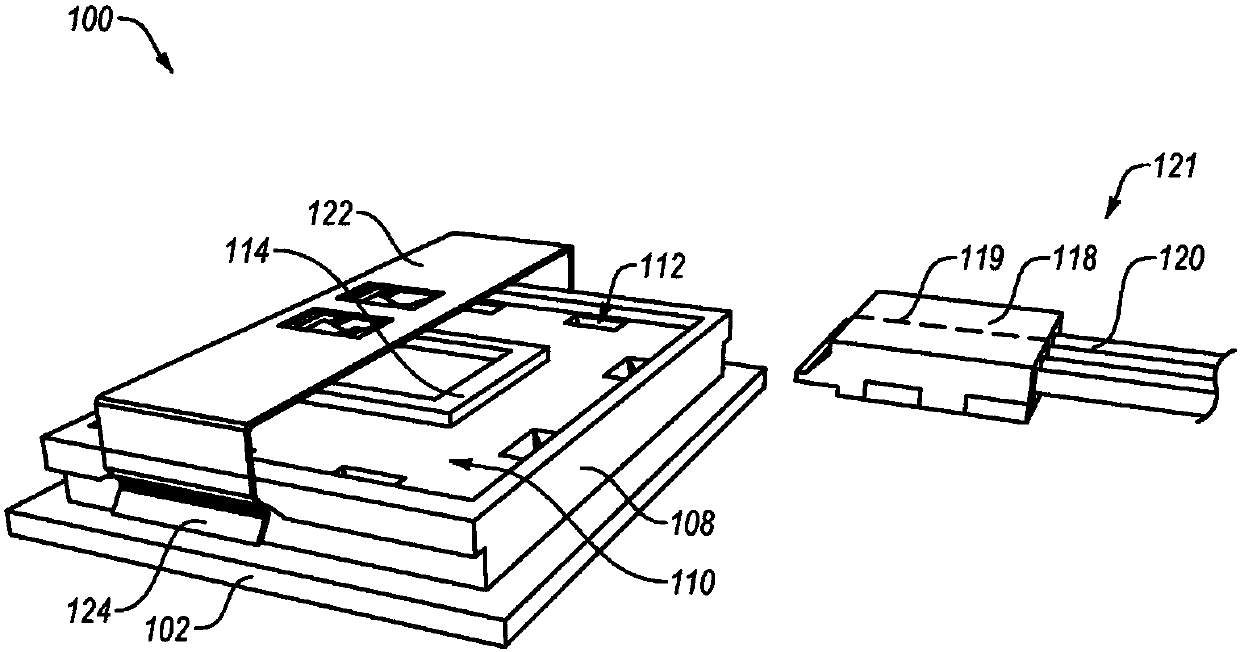

[0015] The expectation is that the passive alignment of optoelectronic components could be conceptually similar to fitting components together like a very precise jigsaw puzzle. Passive alignment can be relatively inexpensive, especially compared to active alignment. However, limitations in the physical accuracy of low-cost materials such as plastics and glass have hindered the fabrication of lenses, circuit boards, and low-cost mechanical components with the inherent accuracy sought for high-speed optoelectronic devices.

[0016] Embodiments described herein can facilitate high-precision alignment of optoelectronic and optical components without the need for robotic positioning systems or closed-loop feedback. Advantageously, embodiments can facilitate relatively accurate low-cost processes such as photolithographic metal patterning, plastic molding, etc. use together. Thus, for example, the final position of the part may be determined by the inherent accuracy of the most a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com