A temperature control valve spool and an automatic temperature control valve

A temperature-controlled valve, automatic technology, applied in valve details, valve devices, multi-way valves, etc., can solve the problems of easy damage to the push rod, unreproducible push rod movement, inconvenient operation, etc., to ensure flow, difficult to pressure. Disturbances of changes and sudden fluctuations, effects of design stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

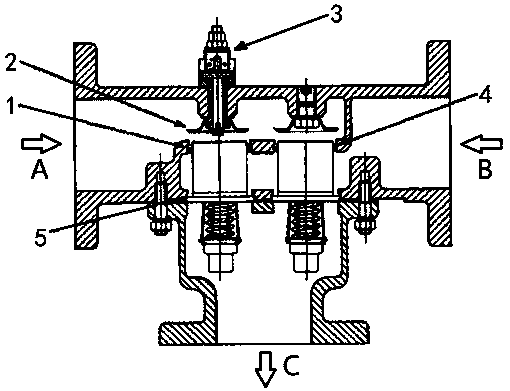

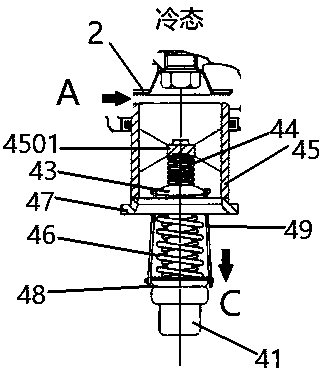

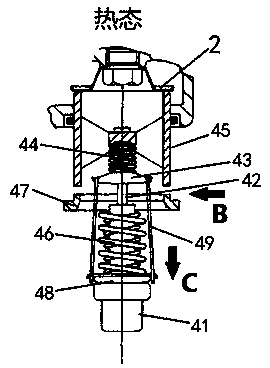

[0026] Such as figure 1 As shown, the temperature control valve automatic temperature control valve of the present invention has three ports of hot end inlet A, cold end inlet B and mixing outlet C, mainly composed of valve housing 1, valve seat 2, adjusting nut 3, valve core 4 Composed of sealing ring 5, etc., one or more identical spools 4 can be configured in parallel to meet the needs of different flow rates (parallel design of spools 4 according to the diameters of A, B, and C ports), so the present invention provides The automatic temperature control valve has wide applicability in a large flow range. In this embodiment, two spools 4 are connected in parallel as an example for structural description. Each spool 4 includes a temperature sensing package 41, a return spring 46, a spool push rod 42, a spool base 47, a spool bushing 43, an overload spring 44, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com