A Classified Pressure Relief Mechanism for Electric High Voltage Switchgear

A high-voltage switchgear and pressure relief technology, which is applied in the direction of switchgear, switchgear settings, electrical components, etc., can solve the problems that faulty gas cannot be eliminated in time, safety performance cannot be fully reflected, and the pressure of faulty gas is backlogged, etc., so as to save maintenance Replacement time, avoid one-time use replacement, and improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

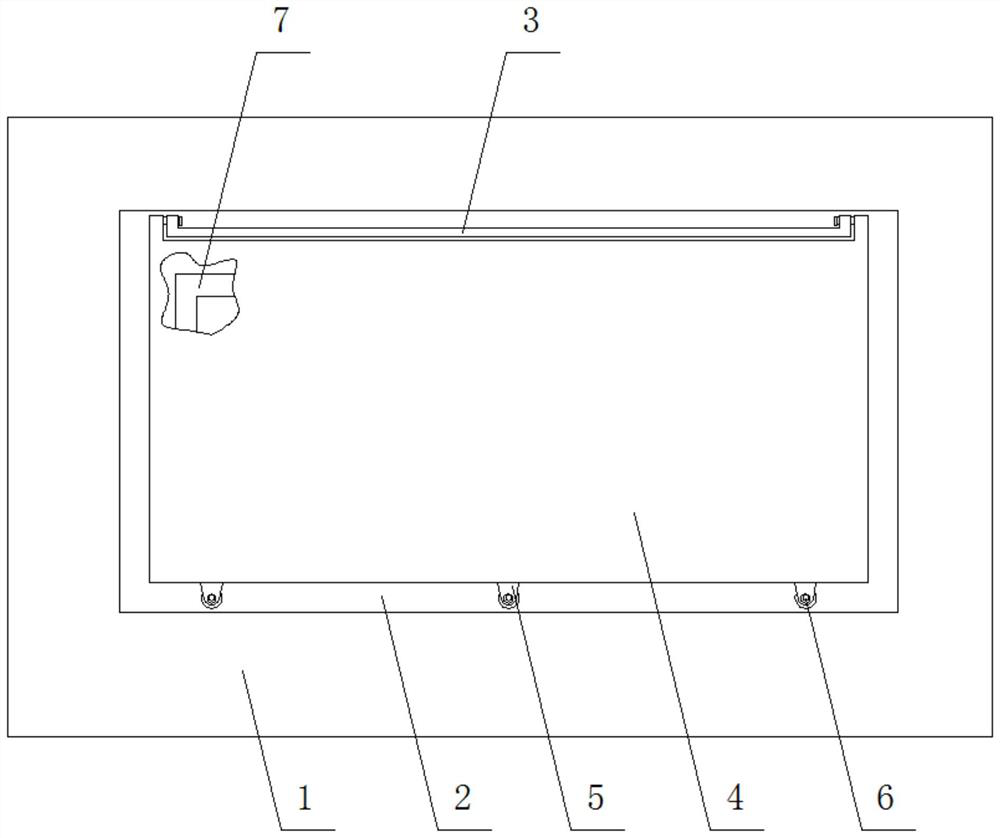

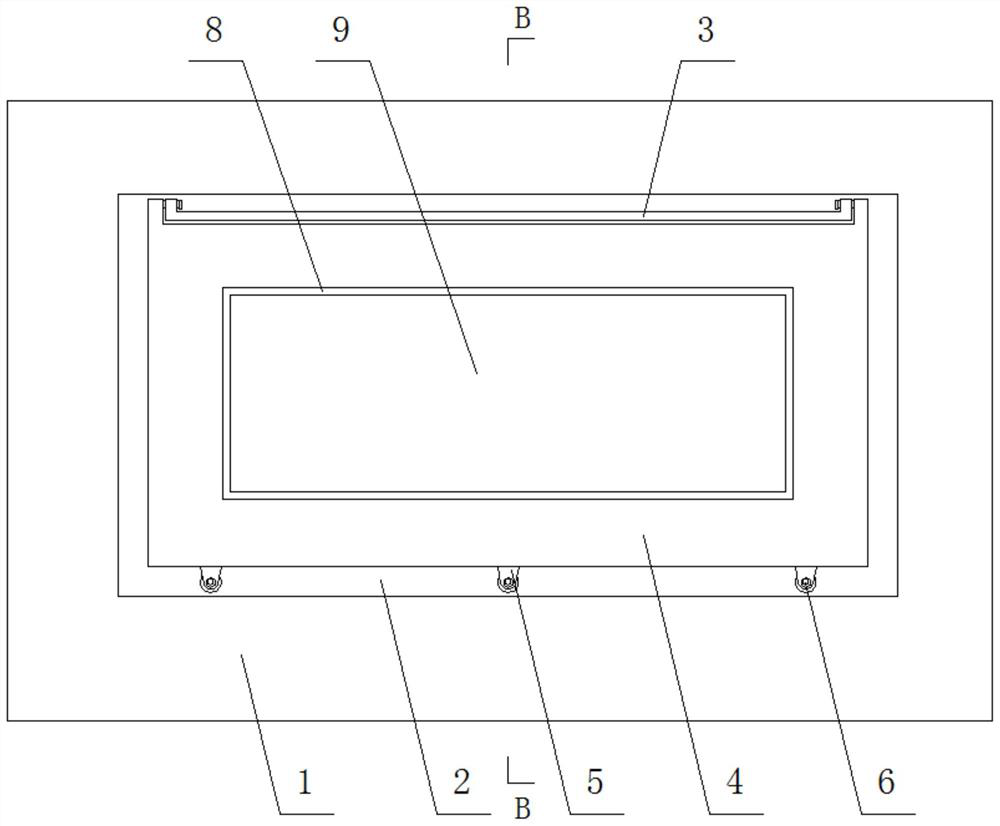

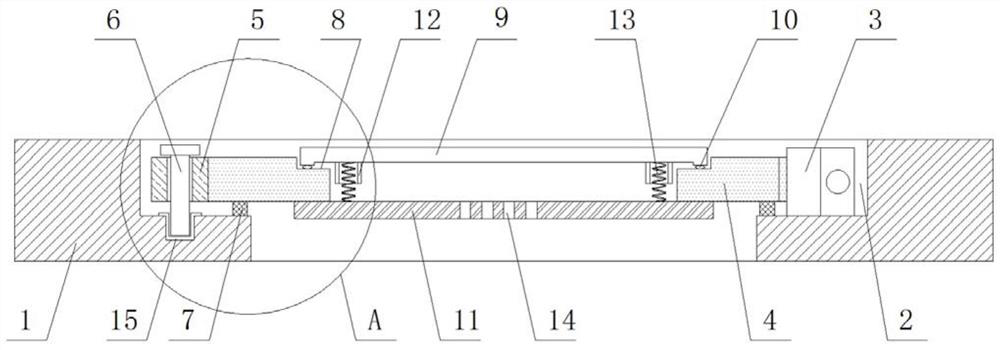

[0024] see Figure 2-4 , a graded pressure relief mechanism for electric high-voltage switchgear, including a cabinet top cover 1, a pressure relief channel 2, a hinge support 3, a top plate 4, a mounting buckle 5, nylon bolts 6 and a sealing ring I7, and the front of the cabinet top cover 1 There is a pressure relief channel 2 in the middle, and a hinge support 3 is fixedly installed on the inner bottom of one side of the pressure relief channel 2. The side of the cabinet is fixedly connected with the installation buckle 5, the installation buckle 5 is fixedly connected with the cabinet top cover 1 through the nylon bolt 6, the nylon bolt 6 is threaded with the cabinet top cover 1, the edge of the bottom of the top plate 4 is fixedly installed with a sealing ring Ⅰ7, and the top plate 4 passes through The sealing ring I7 seals the pressure relief channel 2 opened on the top of the top cover 1 of the cabinet, and the front of the top plate 4 is provided with a secondary pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com