Patents

Literature

36results about How to "Reduce maintenance replacement time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

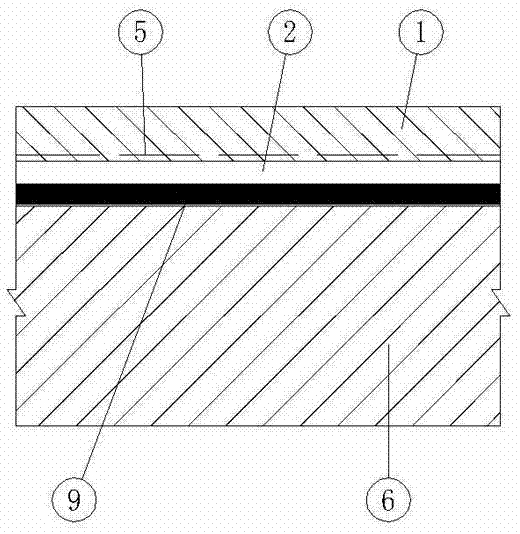

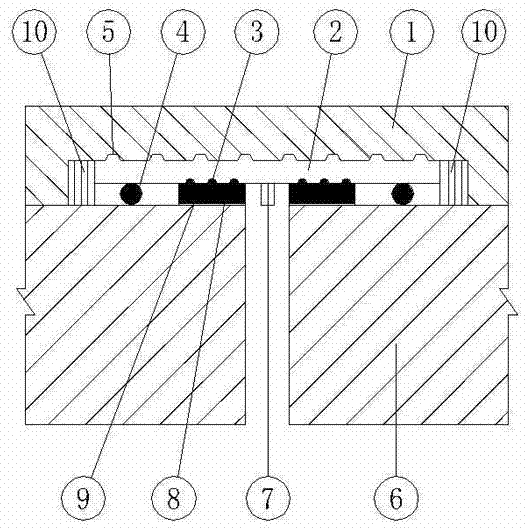

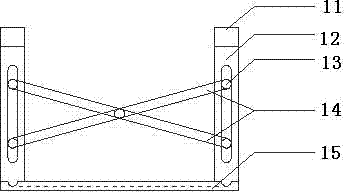

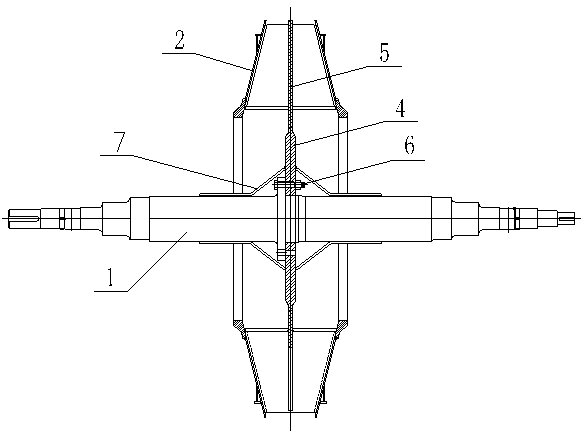

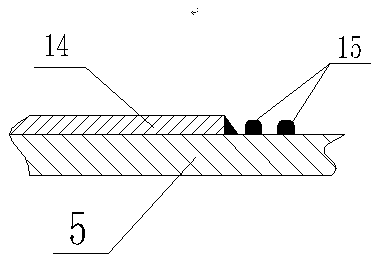

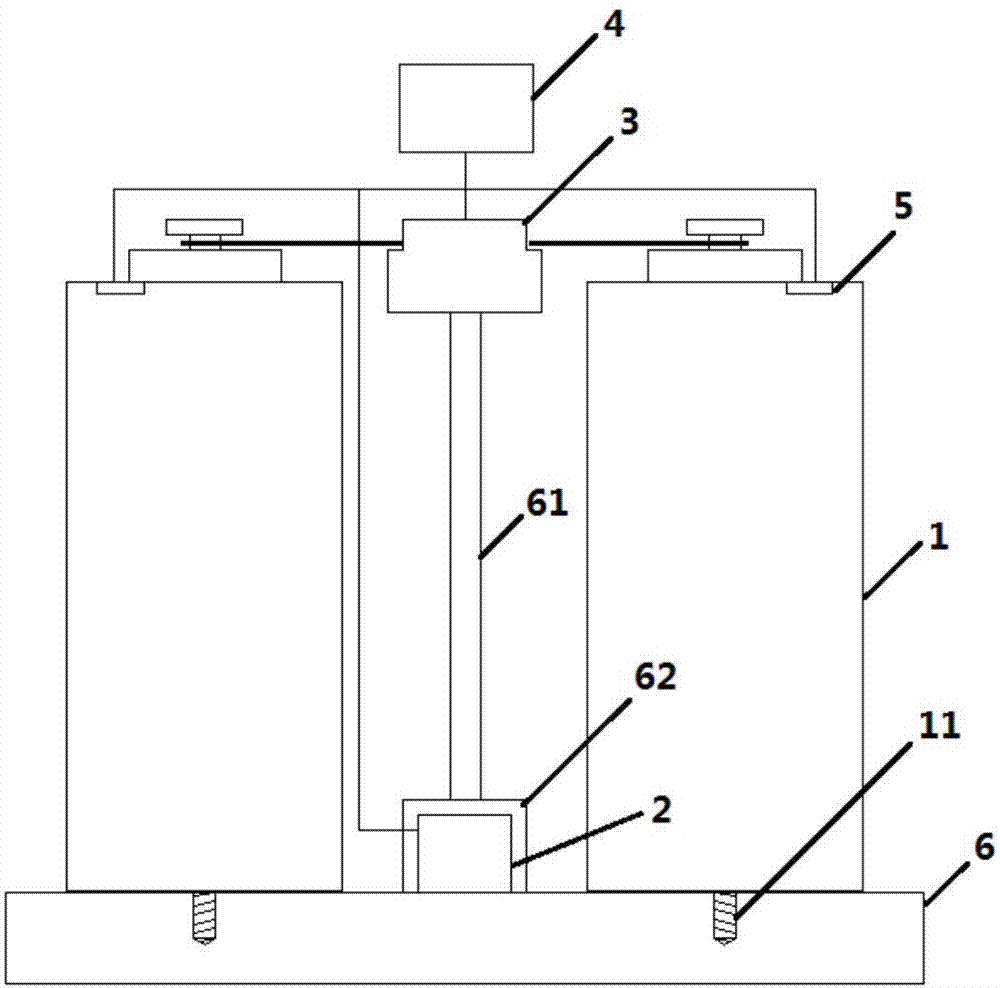

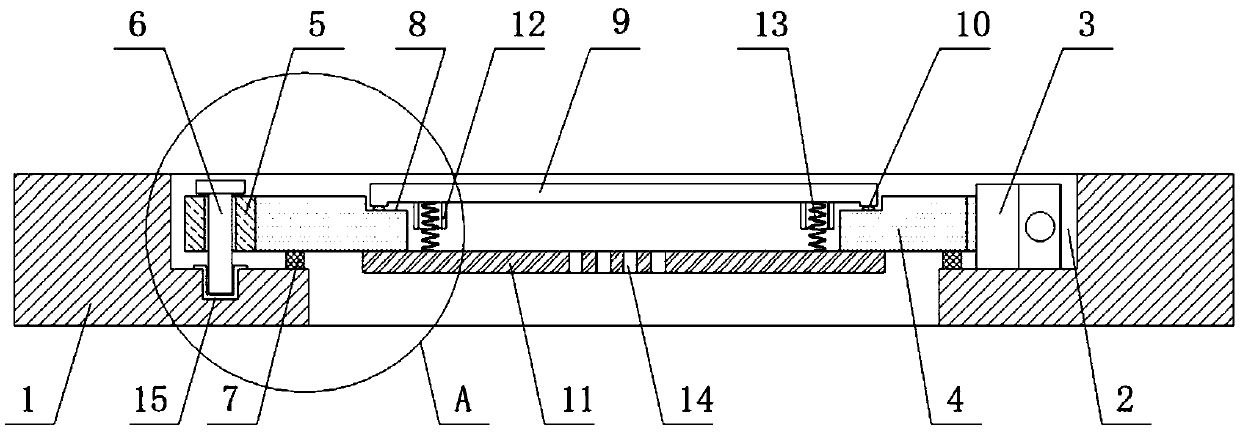

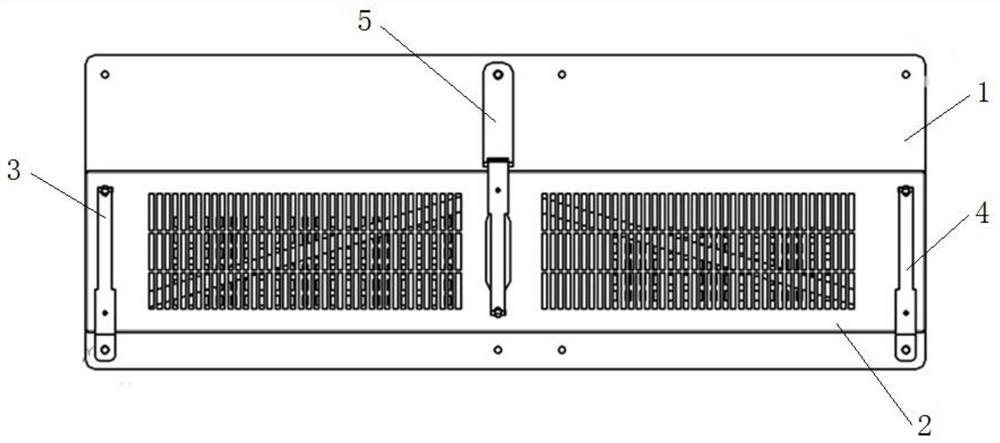

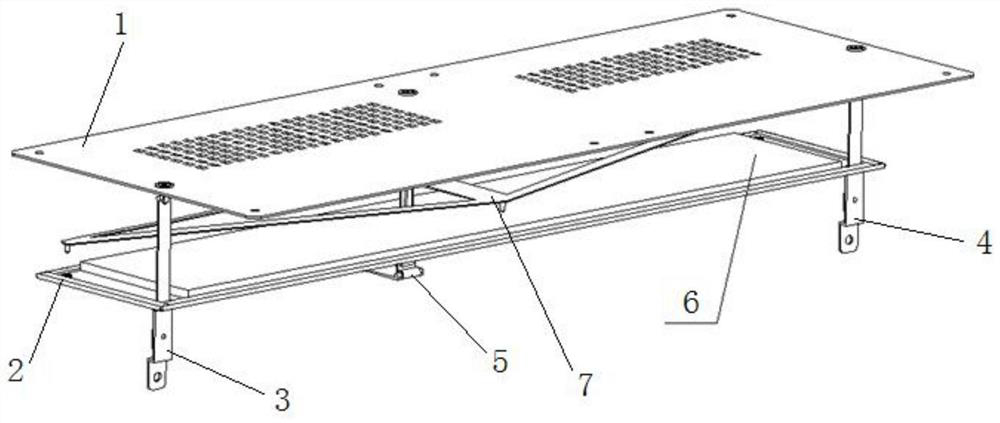

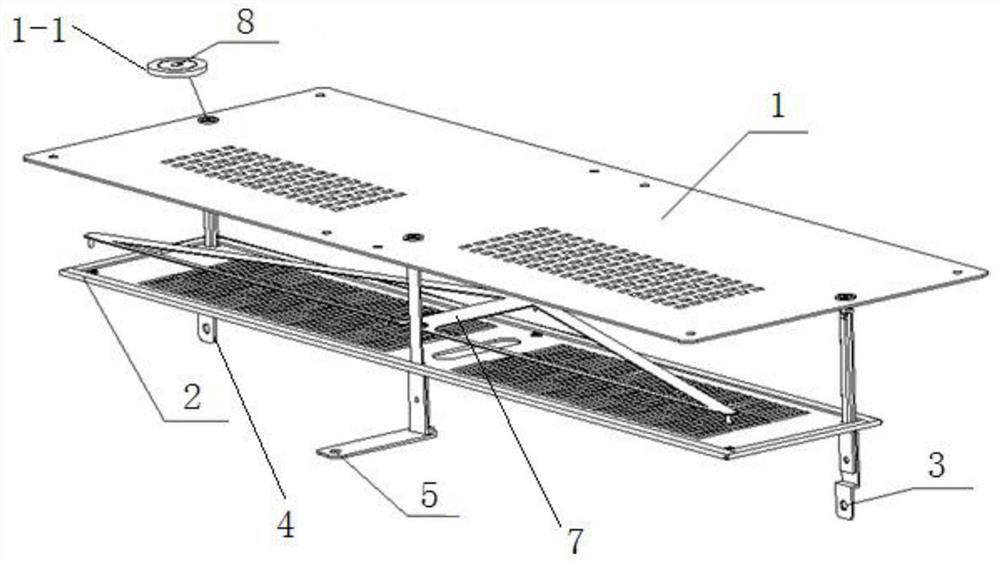

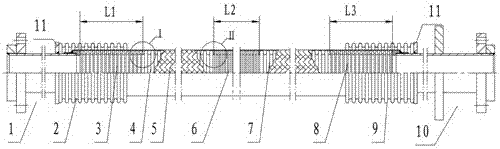

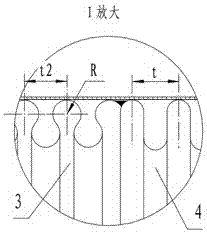

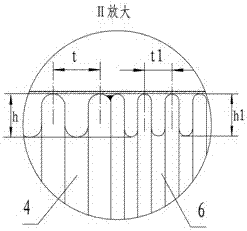

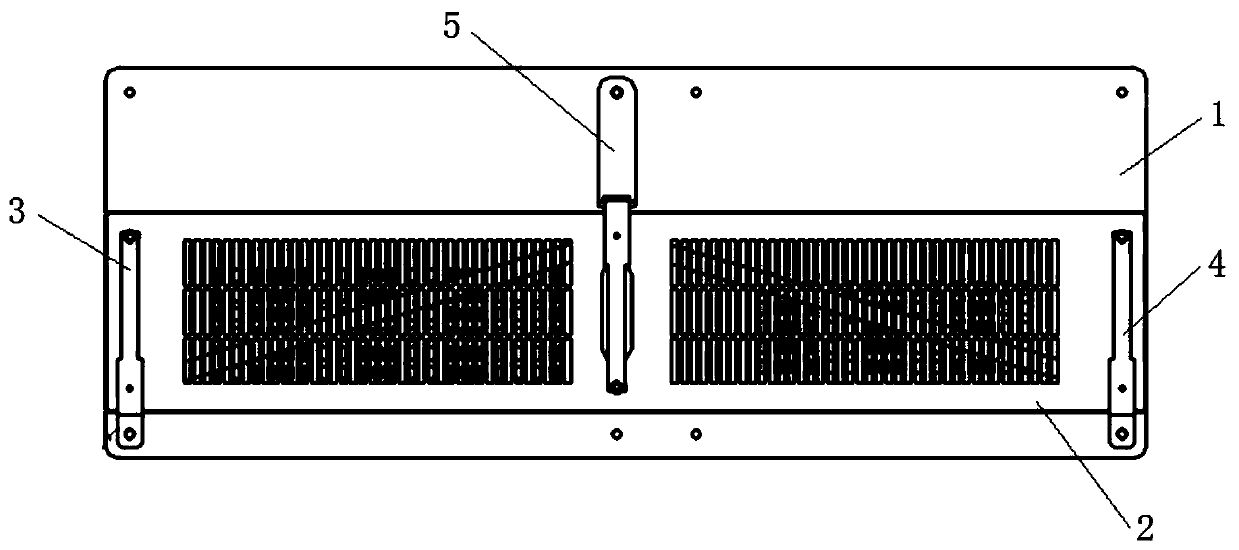

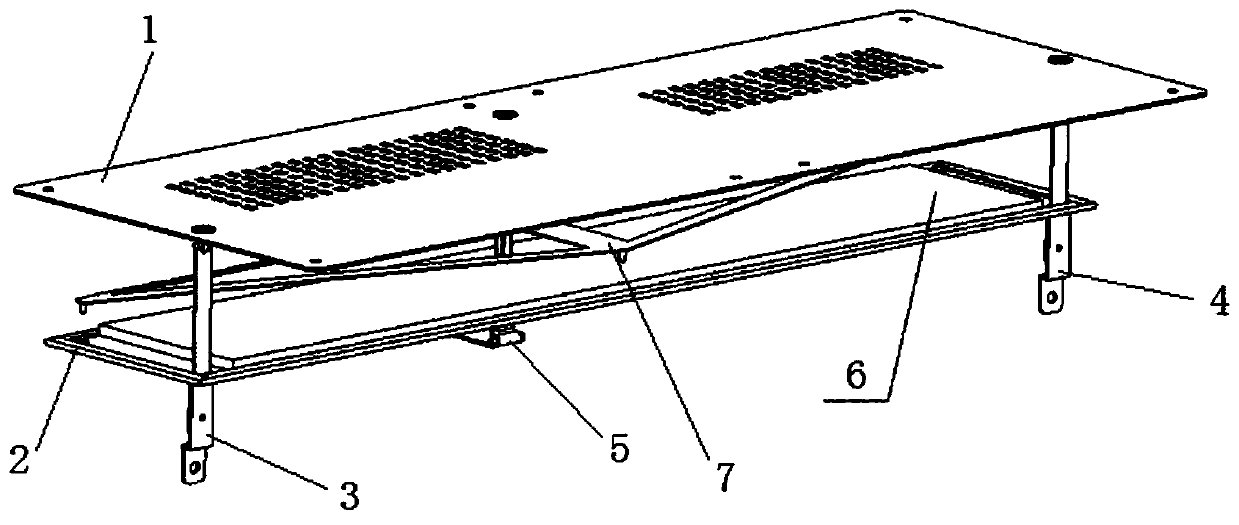

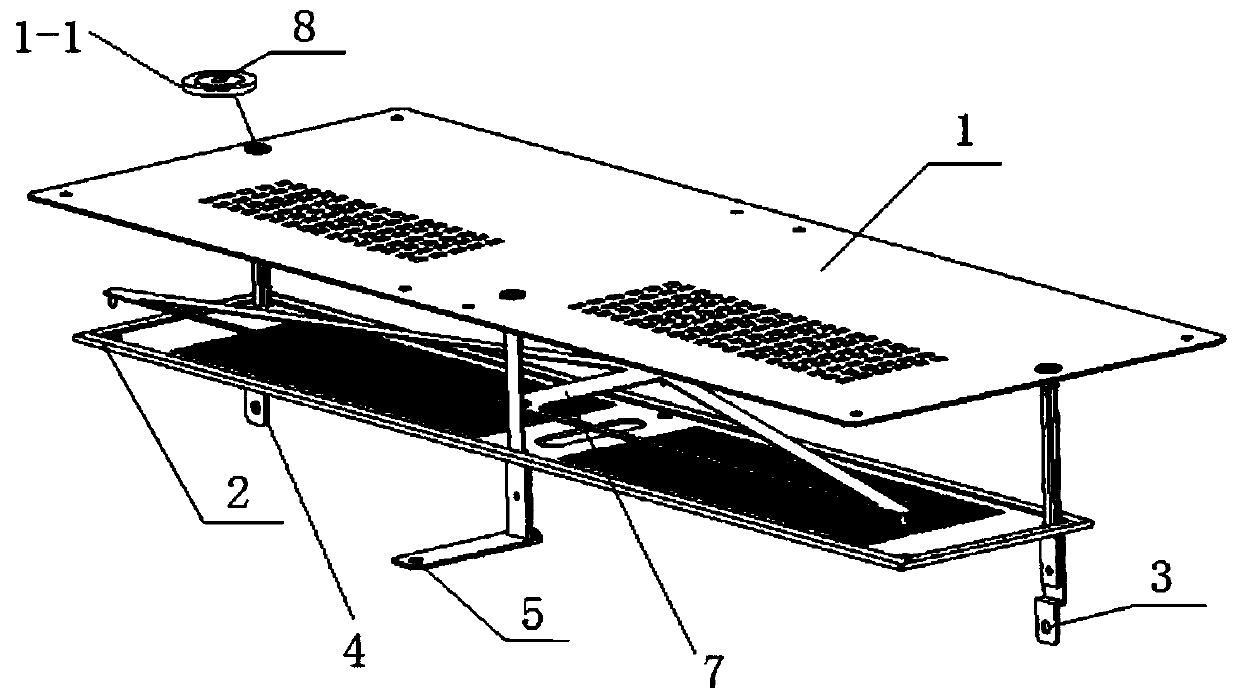

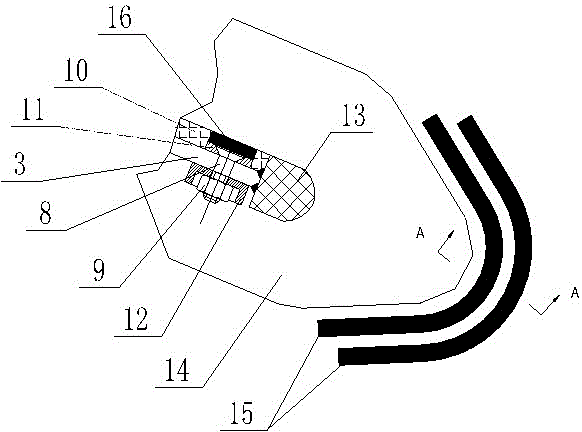

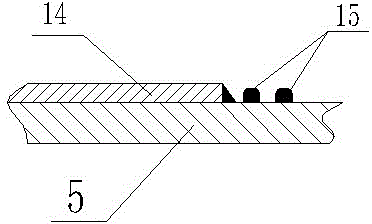

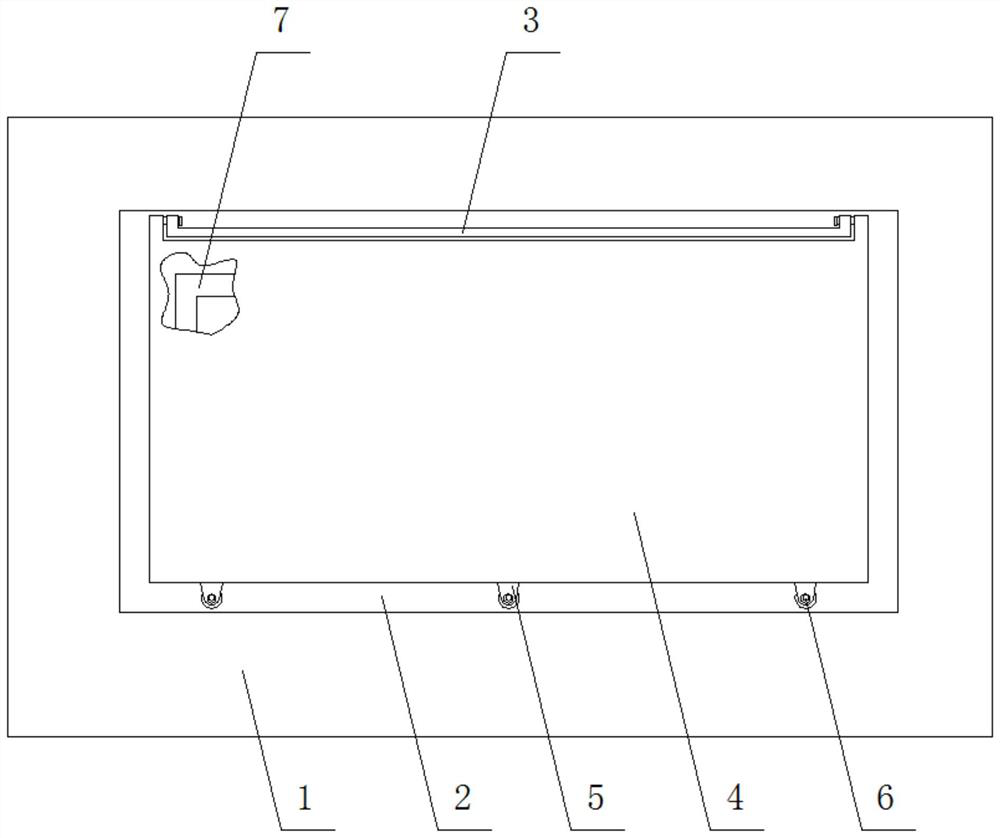

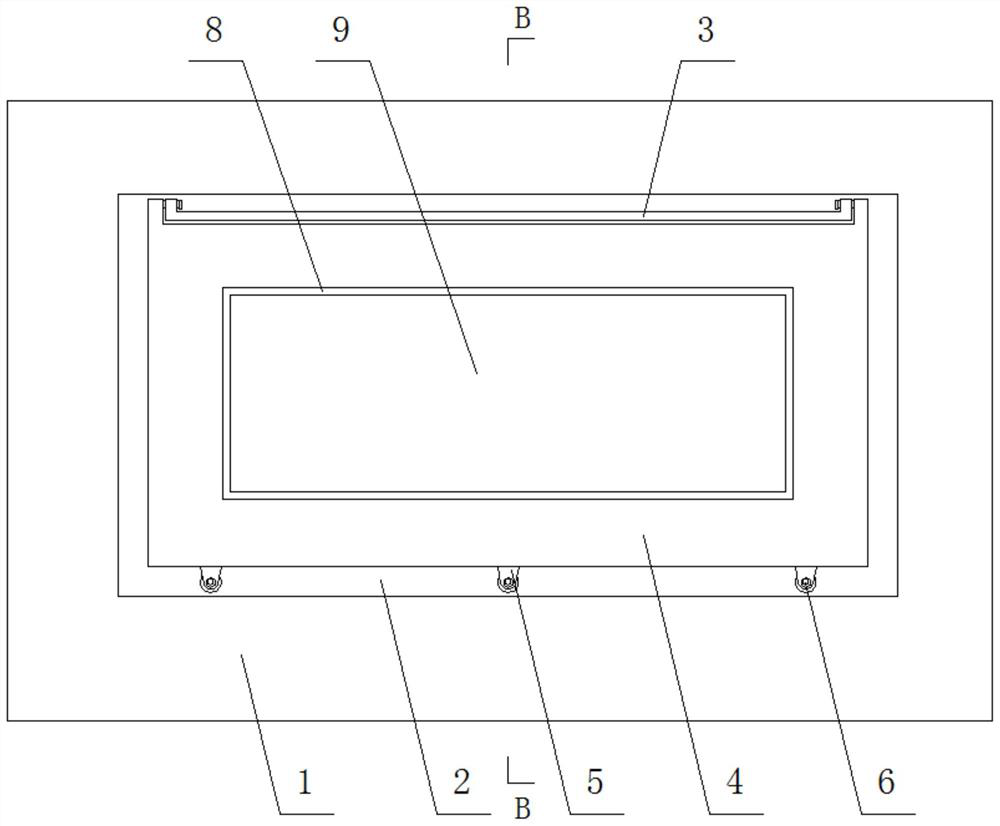

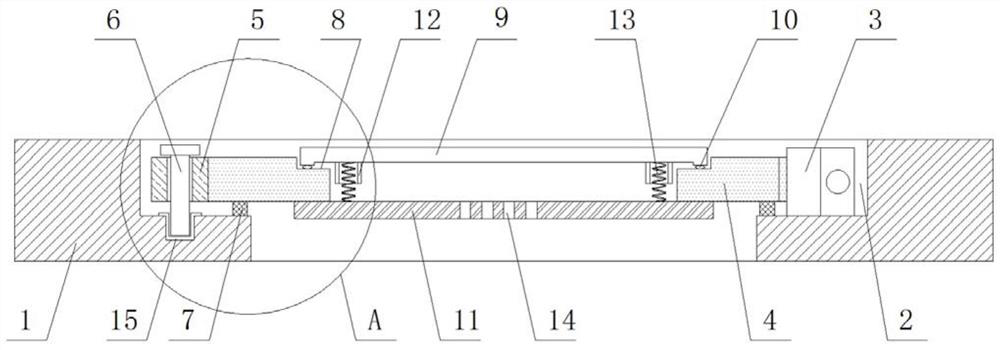

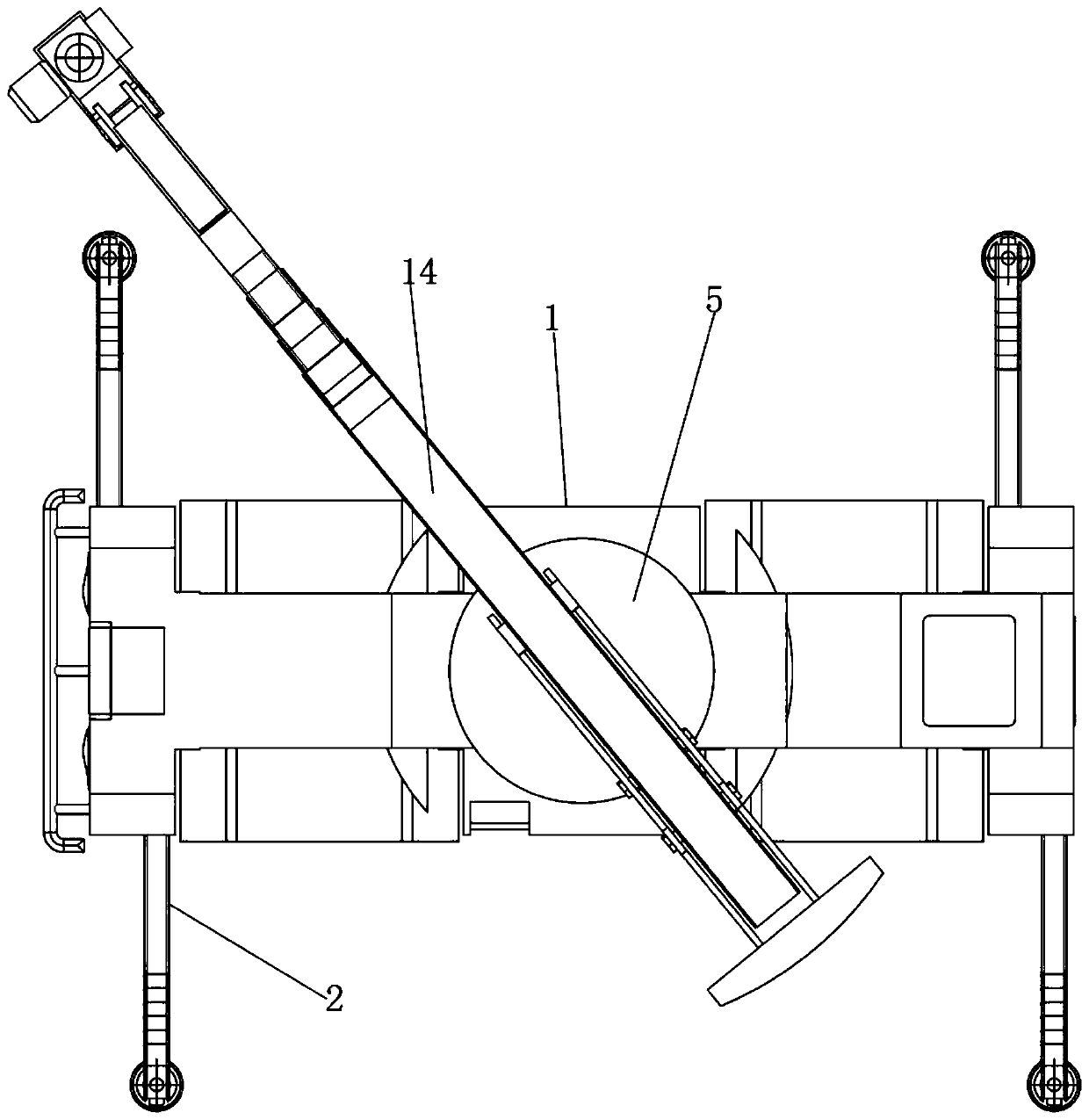

Surface seamless type bridge expansion joint

ActiveCN104762875AReduce shockReduce maintenance replacement timeBridge structural detailsBridge engineeringBridge deck

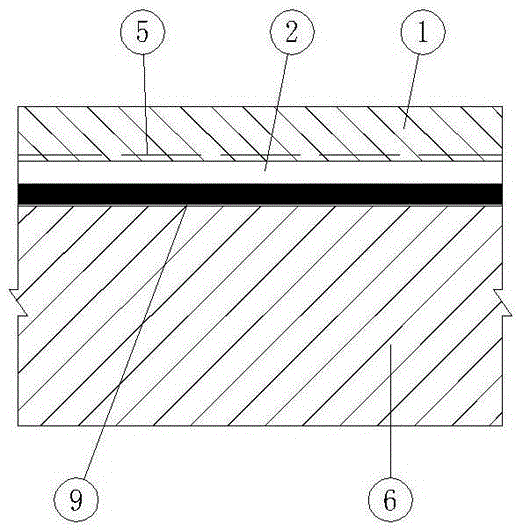

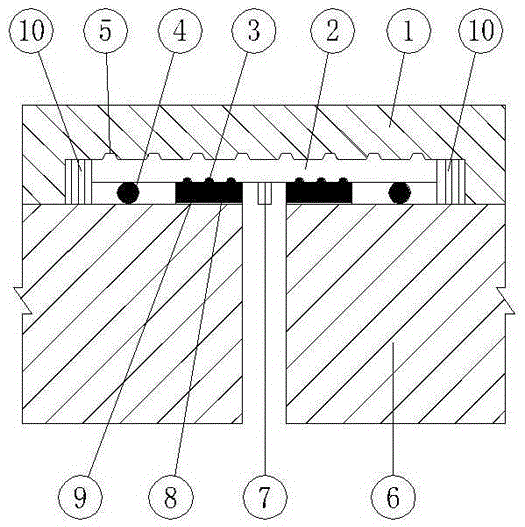

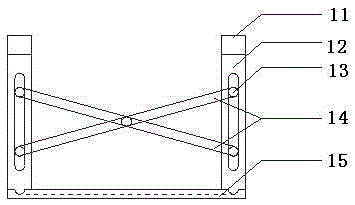

The invention belongs to the technical field of road and bridge engineering, and relates to a surface seamless type bridge expansion joint. The surface seamless type bridge expansion joint is characterized in that lower sliding plate blocks are fixed to the tops of two cement main beams through anchoring devices respectively, elastic deformation bodies are arranged at the two ends of a bearing plate, one end of each elastic deformation body is fixedly connected with the bearing plate, the other ends of the elastic deformation bodies are fixedly connected with connecting steel bars reserved on the main beams, sliding shafts are arranged between the tops of the two cement main beams and the bearing plate, lubricant grooves are formed in the contact faces of the lower sliding plate blocks and the bearing plate, antiskid grooves are formed in the contact face of the bearing plate and a bridge deck pavement layer, and a limiting check block is fixed to the middle of the lower portion of the bearing plate. The surface seamless type bridge expansion joint has the advantages that telescopic deformation of a bridge is mainly completed below the bearing plate and on the elastic deformation bodies and the bridge deck pavement layer, due to the fact that the surface of the bridge expansion joint has no seam, running comfort is improved, the impact action of running loads to the bridge is weakened, the constriction period is short, the maintenance and replacement time of the expansion joint is shortened, bridge deck maintenance and pavement layer modification are facilitated, and the service life is prolonged.

Owner:吉林省交通规划设计院

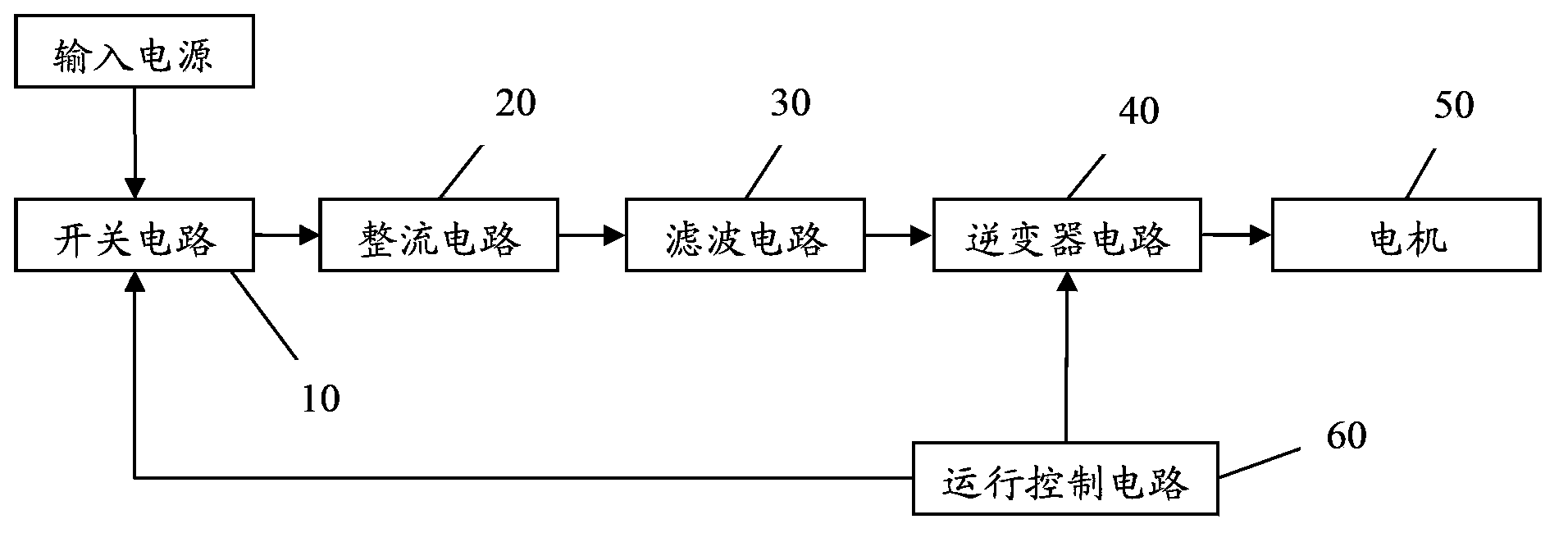

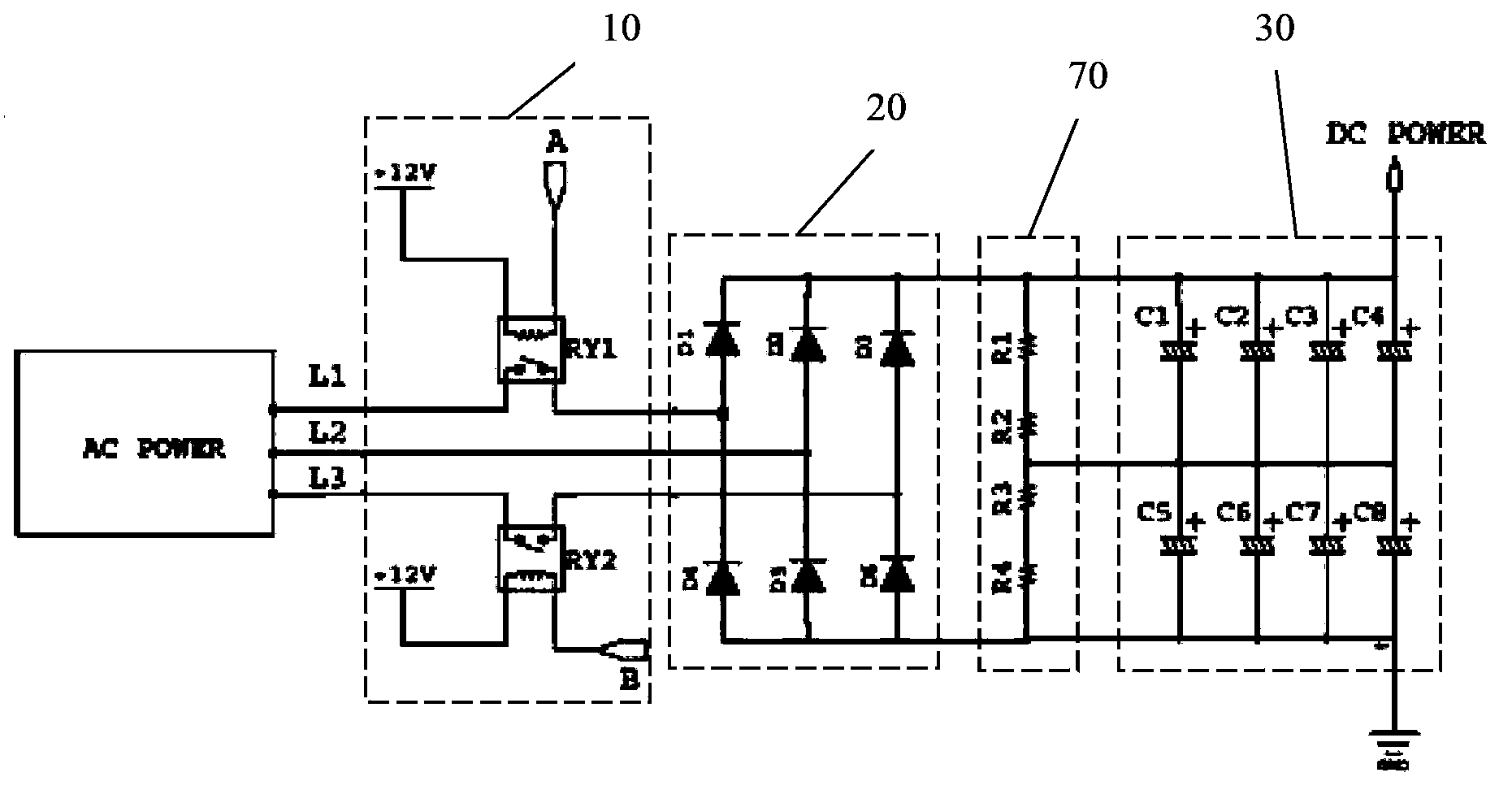

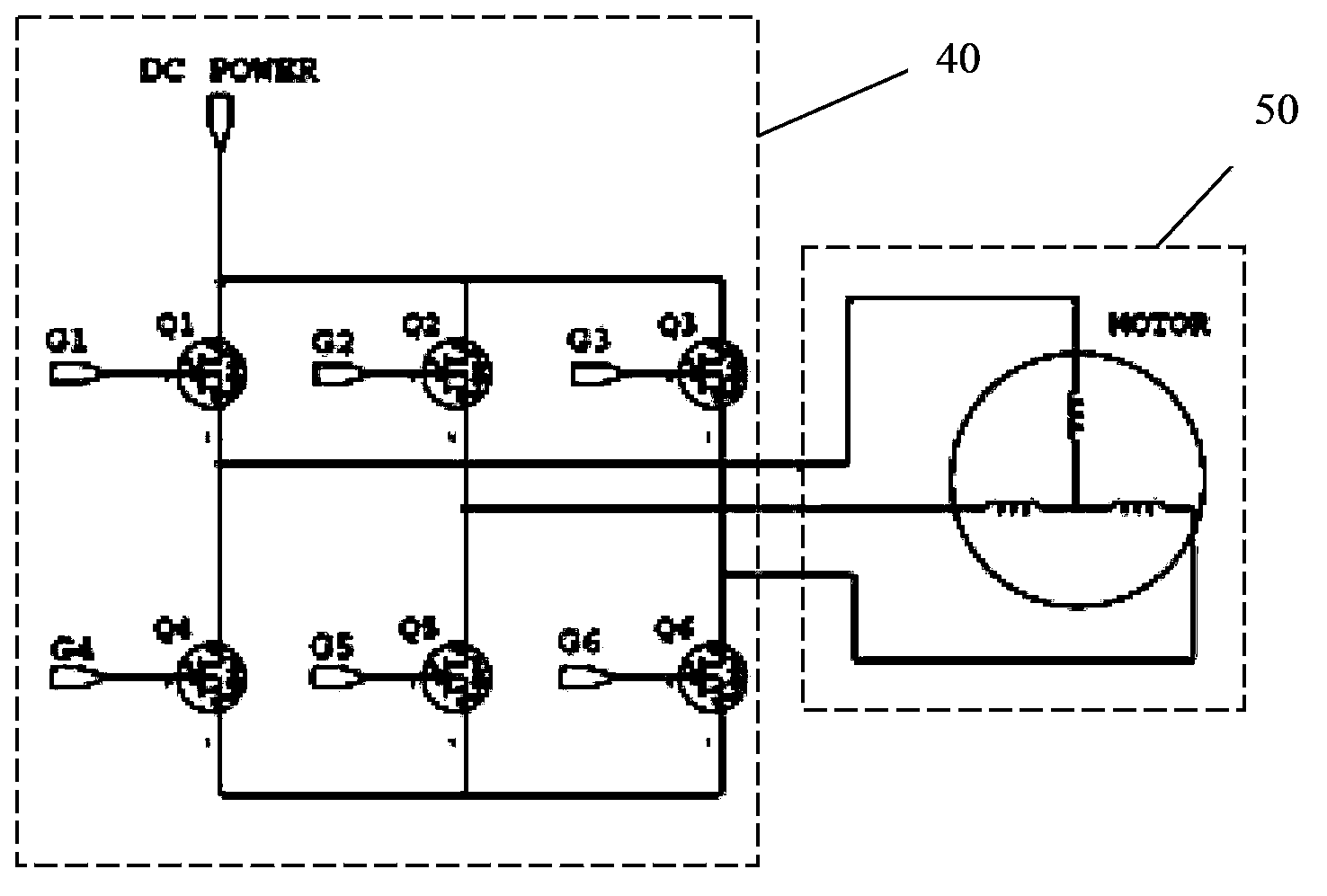

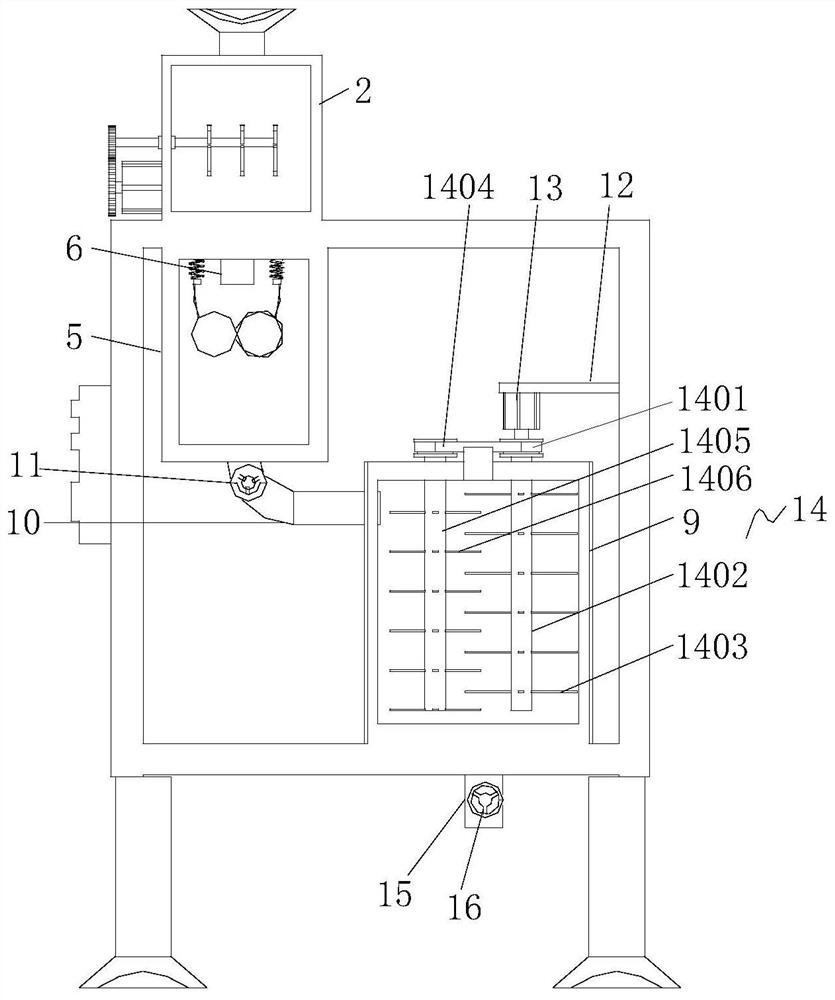

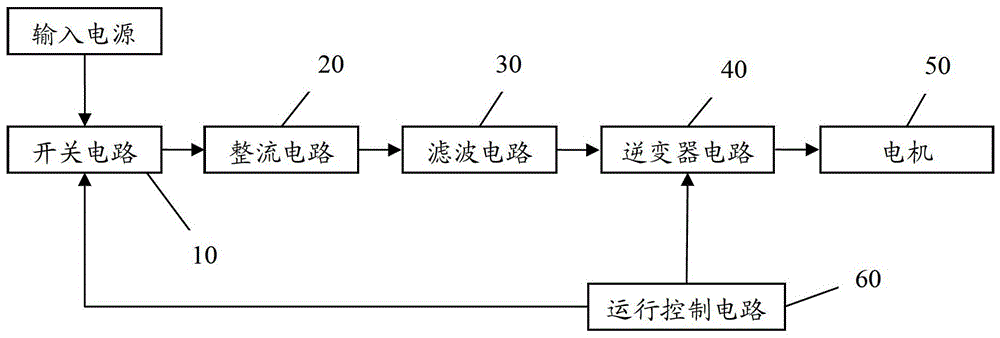

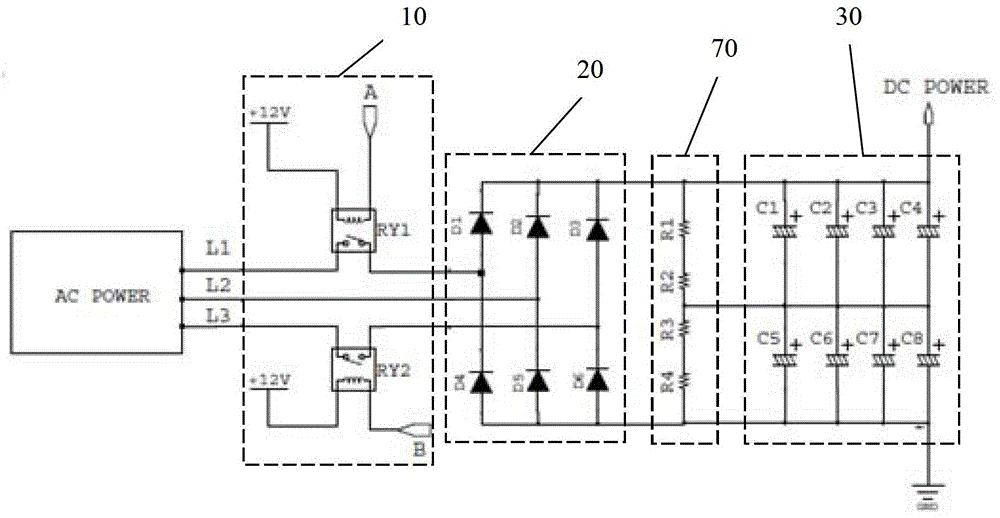

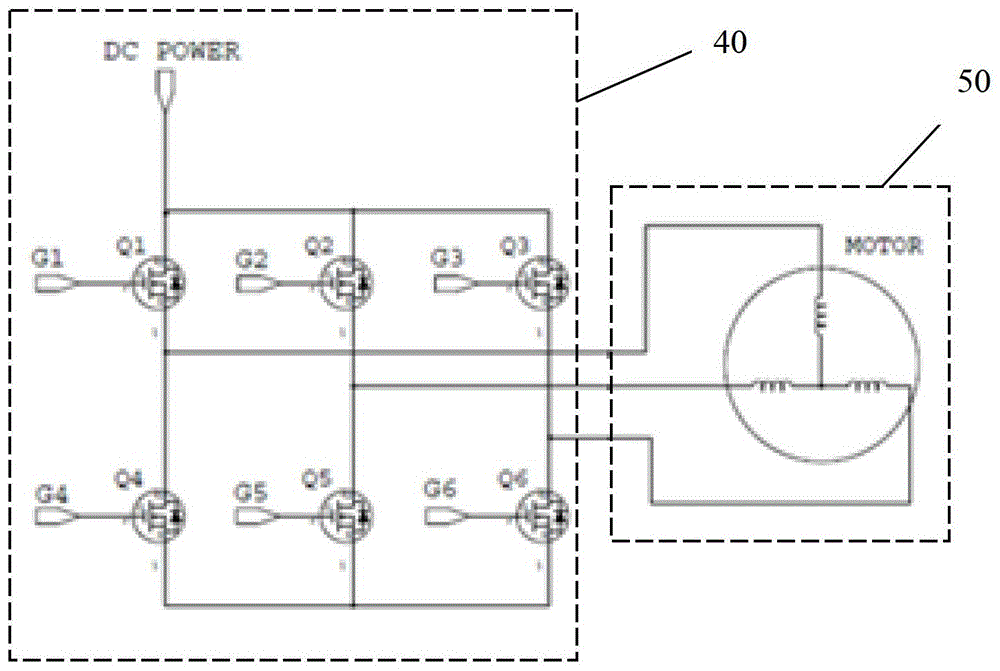

Air-conditioning capacitor discharge system

ActiveCN103545800APlay a role of security protectionEasy to operateEmergency protective arrangements for limiting excess voltage/currentPower inverterCapacitance

The invention discloses an air-conditioning capacitor discharge system which comprises a switching circuit, a rectifying circuit, a filter circuit, an inverter circuit, a motor and an operation control circuit. The switching circuit controls switching on or off of an input power supply; the rectifying circuit rectifies the input alternating current power supply; the filter circuit contains capacitance and filters the rectified power supply; the inverter circuit is driven by output of the filter circuit; the motor is driven by output of the inverter circuit; one output end of the operation control circuit is connected to the switching circuit so as to control switching on or off of the switching circuit upon the input power supply, and the other output end is connected to the inverter circuit, so that when the switching circuit is disconnected with the input power supply, the inverter circuit is controlled to output direct current to the motor. By the air-conditioning capacitor discharge system which is simple to operate and safe and reliable, electric charge stored by capacitance on the filter circuit can be rapidly released, and maintaining and replacing time is saved.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

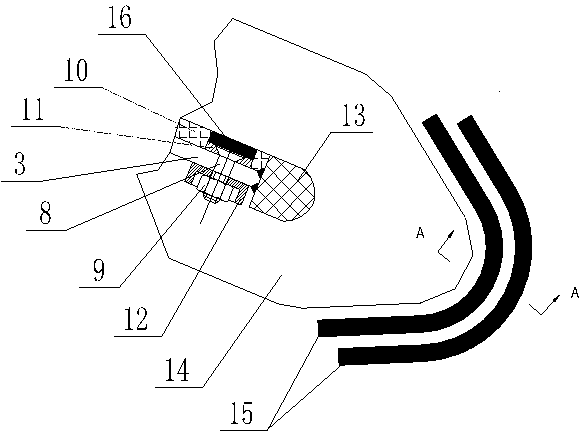

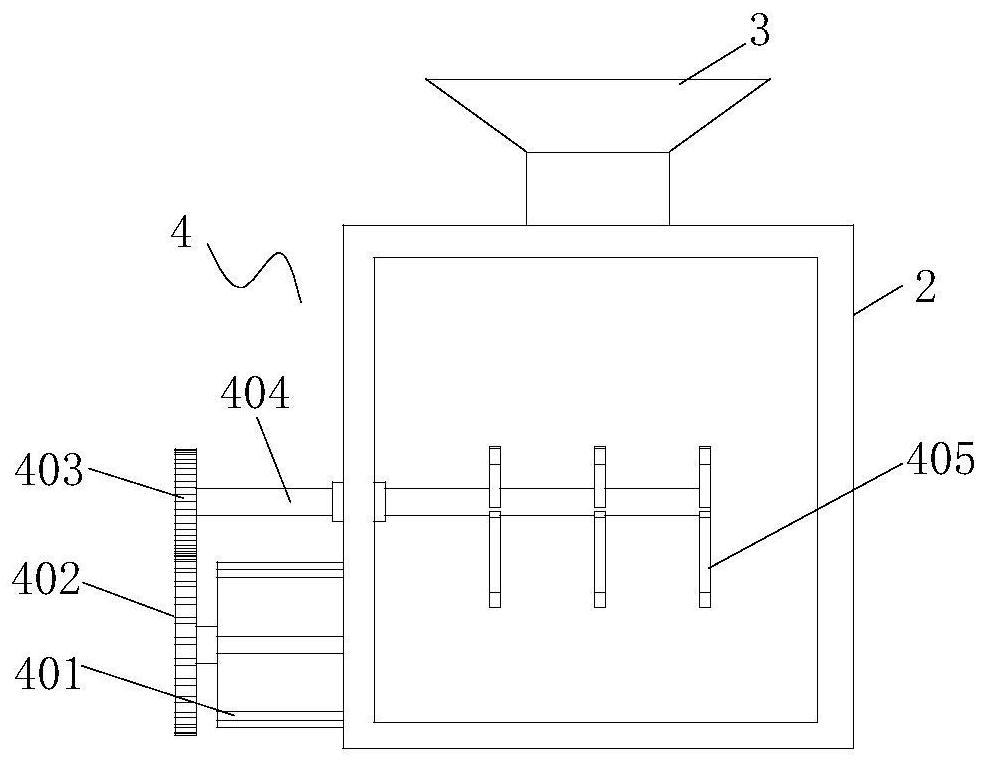

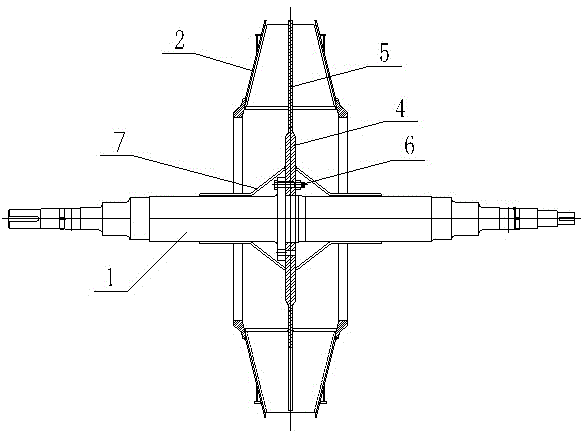

Wear-resistant fan

ActiveCN103062095AExtended service lifeReduce lossesPump componentsPumpsHigh concentrationStructural engineering

The invention aims to provide a wear-resistant fan suitable for delivering high-concentration dust. The wear-resistant fan comprises a rotor spindle, a wheel cap and a blade. The blade is formed by welding an inner central disk and an outer central disk, the rotor spindle is fixedly connected with the inner central disk through a connecting bolt, the wear-resistant fan is characterized by further comprising a protection cover, one end of the protection cover is welded with the spindle, the other end of the protection cover is welded with the inner central disk, and accordingly the connecting bolt covers an inner space enclosed by the protection cover, the spindle and the inner middle disk. An air inlet end of the blade most subjected to wear is protected by utilizing a wear-resistant nose, the blade is protected by utilizing a wear-resistant plate, and the wear-resistant nose and the wear-resistant plate can be replaced limitlessly, and accordingly service life of a rotor of the fan can be greatly prolonged; and time for maintenance and replacement is greatly shortened, loss of a user caused by halt is lowered to the minimum, and accordingly cost is saved, and productivity is increased.

Owner:ANHUI ANFENG FAN

Capacitor with standby capacitor

PendingCN107403694AShort outage timeWith explosion-proof functionMultiple fixed capacitorsThin/thick film capacitorControl engineeringControl theory

The invention discloses a capacitor with a standby capacitor. The capacitor comprises two sub-capacitors, a controller, a circuit switching device, a circuit breaker and pressure sensors. Two sub-capacitors are arranged parallelly on the same base. Two sets of terminals of the circuit switching device are connected with the terminals of the two sub-capacitors in one-to-one correspondence. After the circuit breaker is serially connected with the circuit switching device, the circuit breaker is connected with a main circuit. The controller is connected with the circuit breaker and the circuit switching device. Two pressure sensors are respectively arranged in the two sub-capacitors. The pressure sensors are connected with the controller through signal wires. The capacitor has an explosion-proof function. Furthermore when a fault of one sub-capacitor occurs, automatic power supply stoppage and switching to the other standby sub-capacitor are performed. Then automatic energization is performed. Then the faulted capacitor is manually changed for standby in the next time. The capacitor provided by the invention has advantages of saving maintenance and changing time, and ensuring normal operation of the equipment.

Owner:CHIZHOU RONGDA ELECTRIC CO LTD

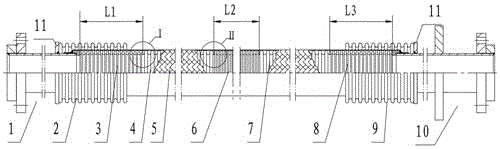

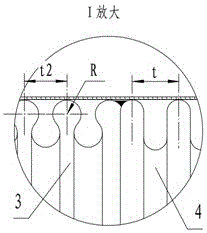

Oxygen blowing metal hose long in service life

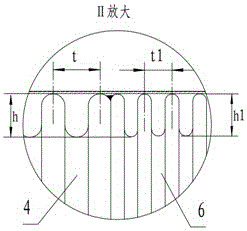

ActiveCN105673980AExtended service lifeImprove flexibilityPipeline expansion-compensationWave shapeEngineering

An oxygen blowing metal hose long in service life comprises a corrugated pipe, and a first joint and a second joint are arranged at the two ends of the corrugated pipe; the outer side of the corrugated pipe is wrapped with a metal net body, and the corrugated pipe is of a five-segment type structure formed by sequentially connecting a first pressure-resisting segment, a first transition segment, a high-flexibility segment, a second transition segment and a second pressure-resisting segment; the first pressure-resisting segment and the second pressure-resisting segment on the two sides of the corrugated pipe are in omega shapes; and the high-flexibility segment located in the middle portion of the corrugated pipe is in a deep-U-shaped wave shape, and the first transition segment and the second transition segment are in U-shaped wave shapes. According to the characteristics that the two sides of the corrugated pipe are bad in working condition and large in bearing pressure, the pressure-resisting segments in the omega shapes are arranged on the two sides of the corrugated pipe; according to the characteristic that due to insufficient flexibility, the dynamic bending portion of the middle segment of the corrugated pipe is prone to being damaged, the middle segment of the corrugated pipe is designed to be the high-flexibility segment in the deep-U-shaped wave shape; and through the improvement, the service life of the oxygen blowing metal hose is greatly prolonged, the maintenance and replacement time is greatly shortened, and improvement of steel smelting efficiency is facilitated.

Owner:石家庄巨力科技股份有限公司

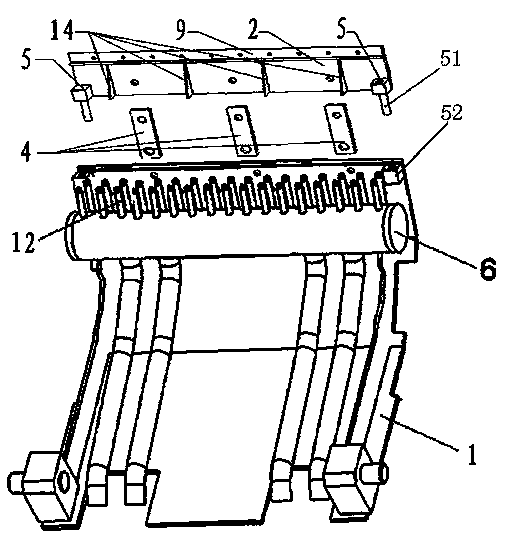

Split type hot continuous rolling cooling water retaining structure

ActiveCN103658190AEliminate local deformationEasy to replaceRollsMetal rolling arrangementsSurface coolingThermodynamics

The invention discloses a split type hot continuous rolling cooling water retaining structure which comprises a first mounting frame body, a second mounting frame body and a connecting piece. A roller cooling water collecting pipe is mounted on the concave face of the first mounting frame body, a jet nozzle is mounted opposite to the direction of a working roller in the roller cooling water collecting pipe, a lug piece is arranged on the convex face of the first mounting frame body, and the lug piece is connected with a piston rod of an air cylinder. A water cutting board is mounted at the front end of the second mounting frame body. The front end of the first mounting frame body and the rear end of the second mounting frame body are in L-shaped step face lap joint corresponding to connecting edges, and are fixed through the connecting piece to be integrally connected. According to the split type hot continuous rolling cooling water retaining structure, the front portion of a frame body of the rolling cooling water collecting pipe is designed to be of a split type structure, cooling water on the surface of a roller can be stopped from entering a rolling deformation area, the front portion which can be deformed easily can be replaced quickly and conveniently, the time for maintaining and replacing is shortened, and steel rolling operation efficiency is improved.

Owner:XINYU IRON & STEEL CO LTD

High-performance metal reflecting type heat preservation layer

InactiveCN109812646AShorten maintenance timeReduce replacement timeThermal insulationNuclear energy generationThermal insulationShock resistance

The invention discloses a high-performance metal reflecting type heat preservation layer, and belongs to high-performance heat preservation equipment. The problems that for a non-metal heat preservation material, the degradation phenomenon exists, the pit filter screen blocking risk is prone to occurring, and dust can be generated to harm health of construction personnel are solved. The high-performance metal reflecting type heat preservation layer is formed by assembling and connecting high-performance metal reflecting type heat preservation blocks, and connectors have two modes of detachableconnection and non-detachable connection and have the better high temperature resistance, corrosion resistance and thermal insulation resistance; the containment circulation pit filter screen blocking risk is effectively reduced; the nuclear power plant maintenance and replacement time is shortened; the mechanical strength is high, and the anti-seismic property and the shock resistance are good;the service life is long, and the heat preservation performance is stable in the service life; no dust is generated, no pollutant diffusion occurs, and harm of radioactive substances to operation andmaintenance personnel can be avoided or reduced; and no corrosivity is generated to the equipment or pipelines.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

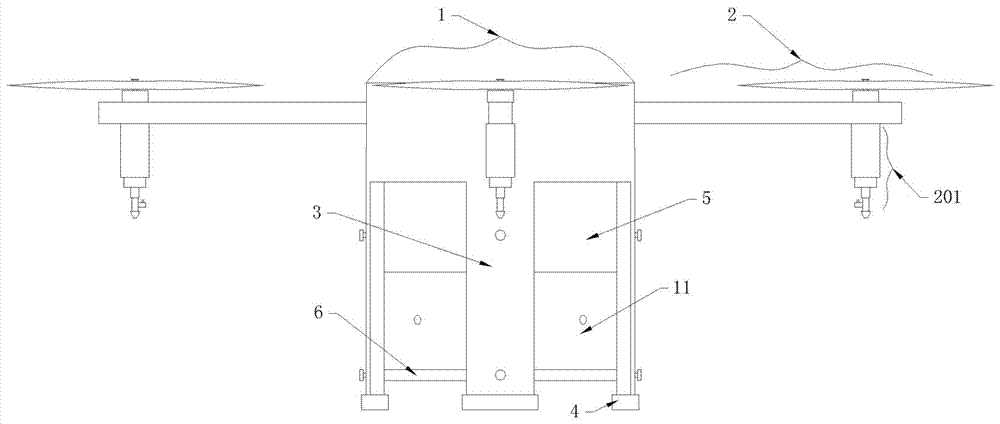

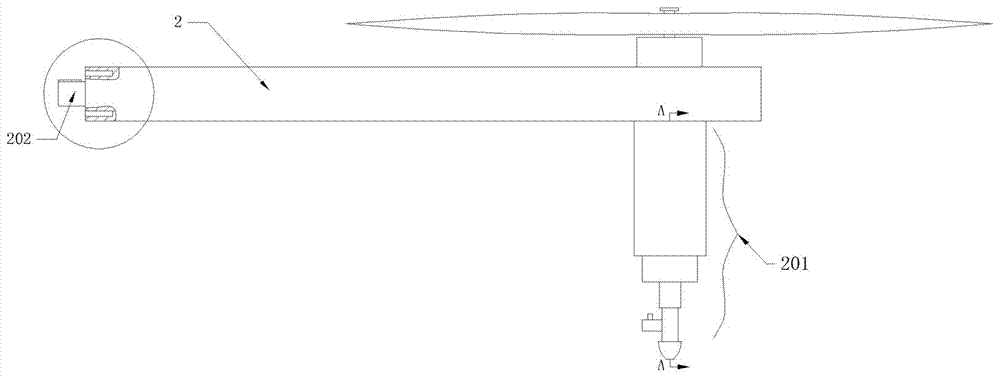

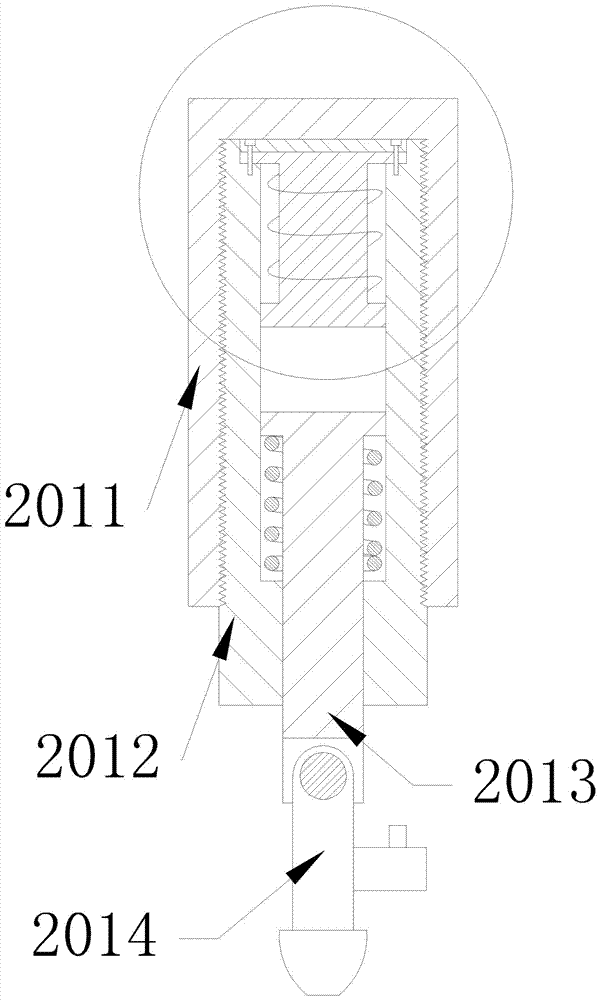

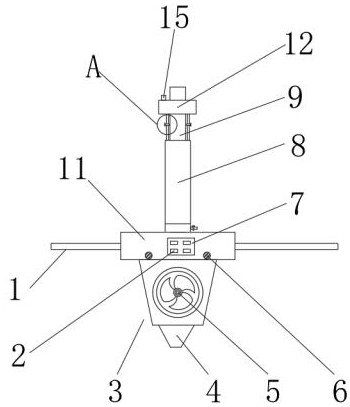

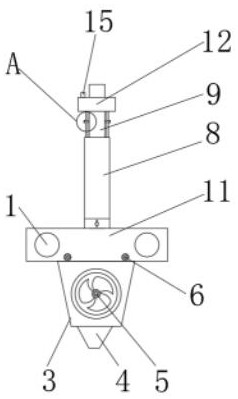

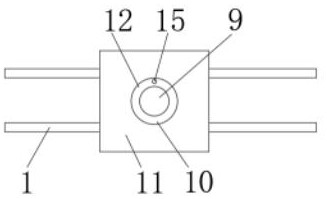

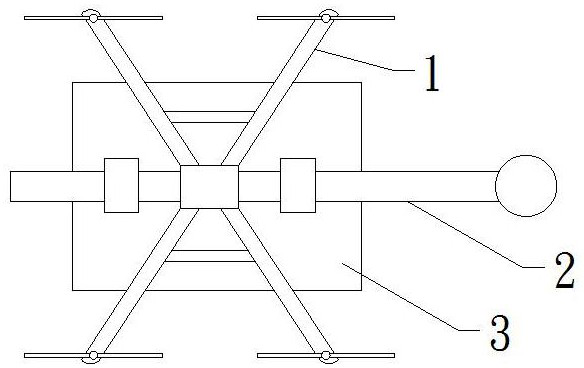

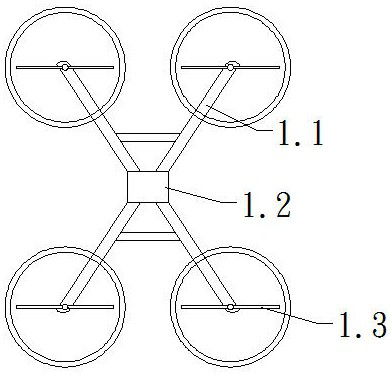

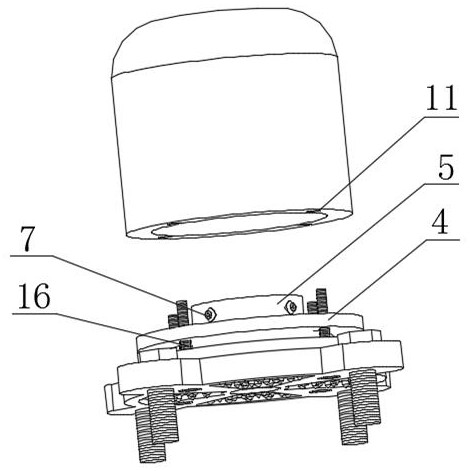

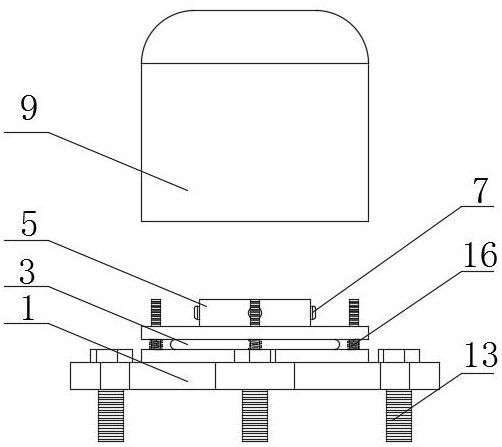

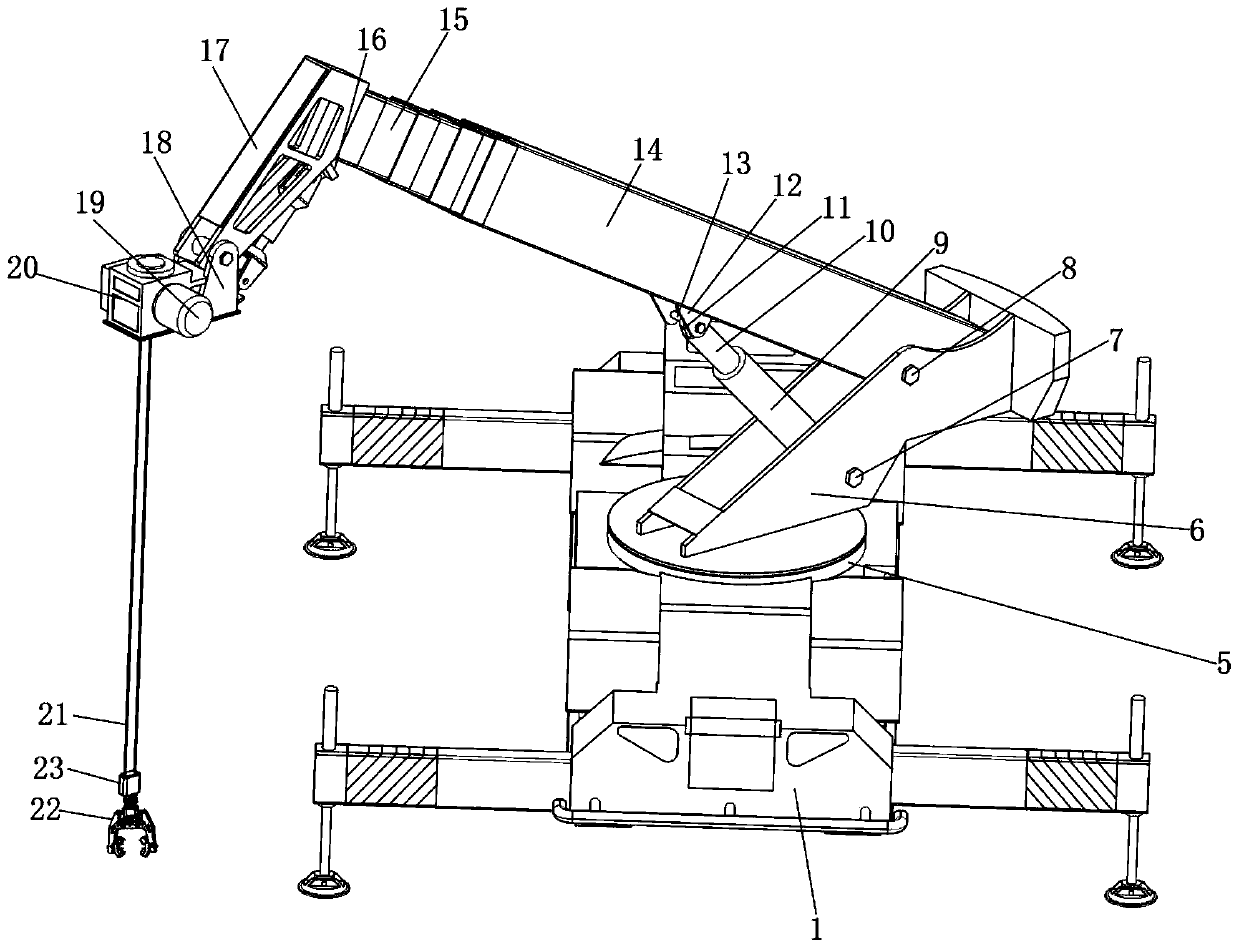

Plant protection unmanned aerial vehicle

ActiveCN107054658AQuick releaseQuick installationWeight reductionFuselagesUncrewed vehicleStructural engineering

The invention relates to a plant protection unmanned aerial vehicle. The plant protection unmanned aerial vehicle comprises a center disc, an engine arm and a medicine chest, wherein the engine arm is connected to a side face of the center disc; the medicine chest is connected to the lower part of the center disc; the center disc and the medicine chest are of cylindrical structures respectively; the side face of the center disc is cut into a plurality of rectangular planes; the left end of the engine arm is detachably connected to the positions of the rectangular planes of the center disc; and a rotor wing positioned at the upper part and a telescopic spray head positioned at the lower part are arranged at the positions, close to the right end face, of the right side of the engine arm. The plant protection unmanned aerial vehicle can be quickly dismounted and mounted, and is convenient to maintain and change, so that the maintenance and replacement time can be reduced when the plant protection unmanned aerial vehicle breaks down, and the work efficiency is improved; and through the arrangement of the telescopic spray head, the height of a nozzle can be adjusted by adjusting a telescopic cylinder to adapt to the corresponding environment.

Owner:西华县明慧农业航空服务有限公司

Power high-voltage switch cabinet graded pressure relief mechanism

ActiveCN109687310AImprove securityAvoid single-use replacementsSwitchgear arrangementsSubstation/switching arrangement casingsEngineeringMechanical engineering

The invention discloses a power high-voltage switch cabinet graded pressure relief mechanism, which comprises a cabinet top cover, a pressure relief through groove, a hinge support, a top plate, mounting buckles, a nylon bolt and a sealing ring I. The pressure relief through groove is formed in the middle of the front face of the cabinet top cover, and the hinge support is fixedly mounted at the inner bottom of one edge of the pressure relief through groove. By additionally arranging a secondary pressure relief plate on the existing top plate and mounting the secondary pressure relief plate ona pressure bearing steel plate through a pressure relief tension spring, fault gas pressures can be divided into three grades, namely the impact gas pressure which can be borne by an operator, the impact gas pressure which cannot cut off the nylon bolt, and the impact gas pressure which can cut off the nylon bolt, correspondingly, pressure relief is carried out by opening a cabinet door by the operator, pressure relief is carried out in the modes that fault gas jacks the secondary pressure relief plate and passes through a gap opening between the secondary pressure relief plate and the top plate through a vent hole, and pressure relief is carried out by shearing the nylon bolt and completely opening the top plate, so that the different fault gas pressures can be relieved in a graded modeto improve safety performance of pressure relief of the fault gas of a power distribution cabinet.

Owner:国网山东省电力公司沂源县供电公司

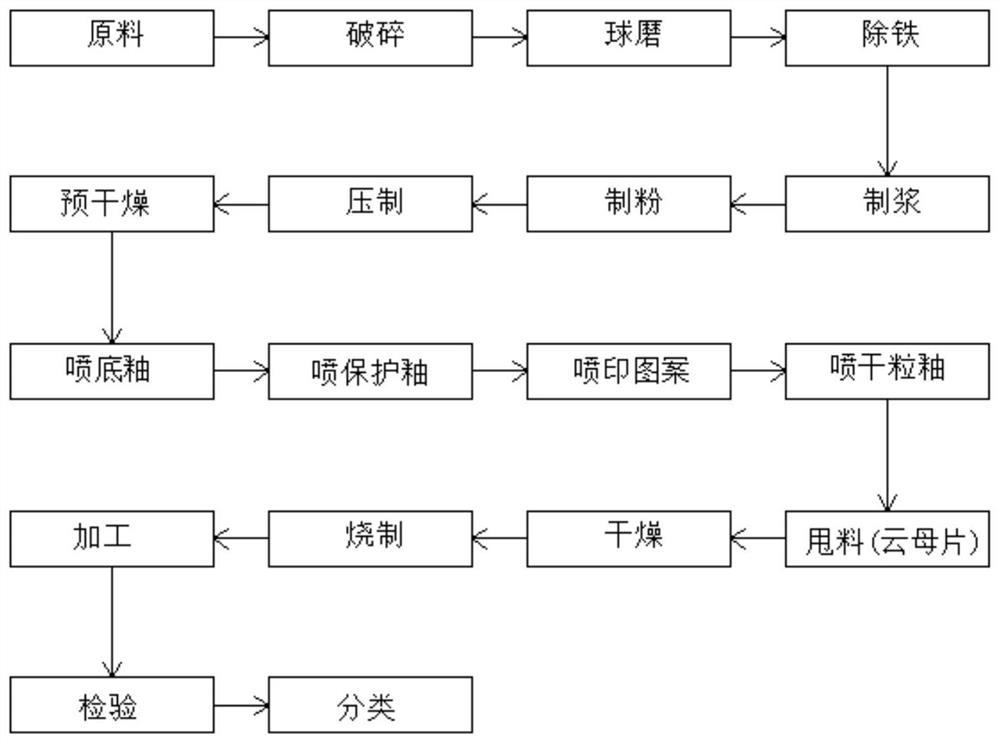

Preparation method of full-body granite ceramic tile

PendingCN112441812ASolve for uniformityResolution cycleCeramic shaping apparatusClaywaresBrickSpray nozzle

The invention belongs to the field of ceramic tiles, relates to a preparation method of a full-body granite ceramic tile and aims to solve the problems of non-uniform coloring, long production periodand high production cost of an existing full-body granite ceramic tile. The following technical schemes are adopted: the preparation method comprises the following steps that: S1, raw materials are crushed and ball-milled, the crushed and ball-milled material is sieved, and iron is removed, so that slurry A is prepared; S2, the slurry A in the S1 is subjected to powder formation, pressing and pre-drying, so that a brick blank B can be obtained; S3, the brick blank B in the S2 is sequentially subjected to ground coat spraying, protective glaze spraying, pattern spraying and dry granular glaze spraying treatment to obtain a brick blank C, the caliber of dry granular glaze spraying nozzles is 2.8-3.0 mm, each nozzle is of a spiral structure, the multiple nozzles are connected with the same glaze suction pipe, and a quarter ball valve is installed on the glaze suction pipe; and S4, the brick blank C in the S3 is subjected to material throwing and drying, the treated brick blank C is put into a firing kiln so as to be fired and molded, so that a sample D can be obtained; and S5, the sample D in the S4is processed, inspected and classified. The full-body granite ceramic tile is uniform in coloring, short in production period and low in production cost.

Owner:广东强辉陶瓷有限公司

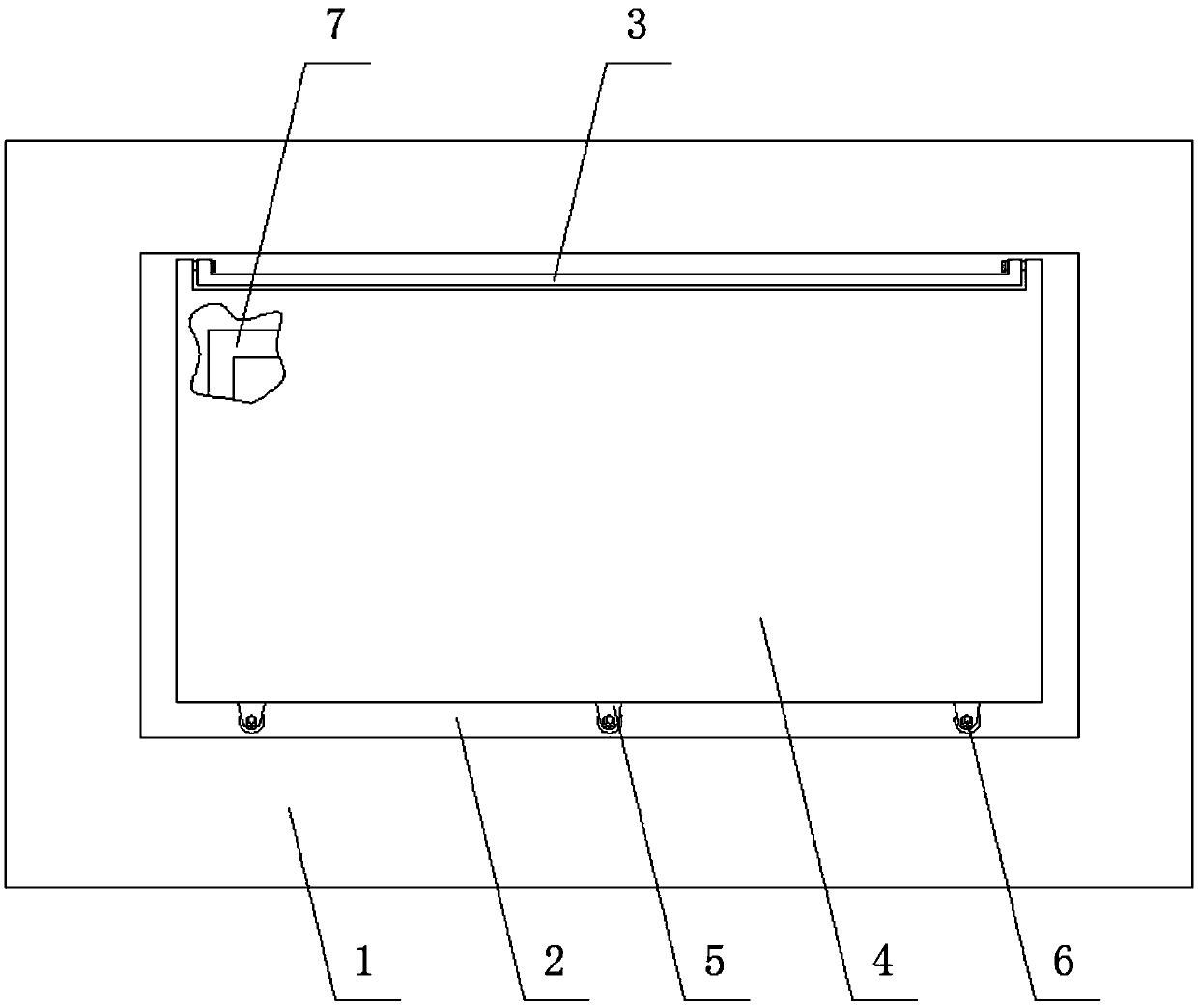

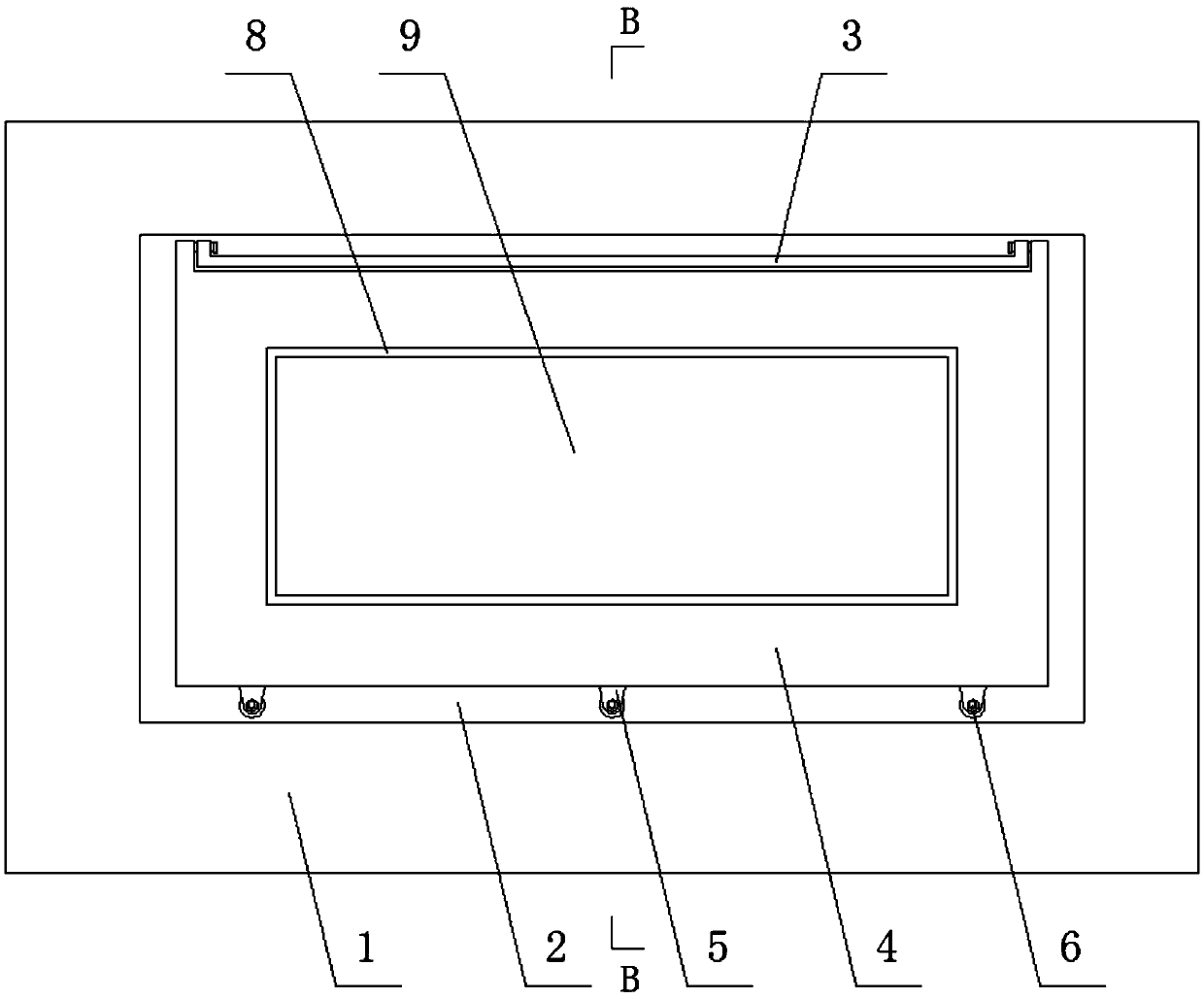

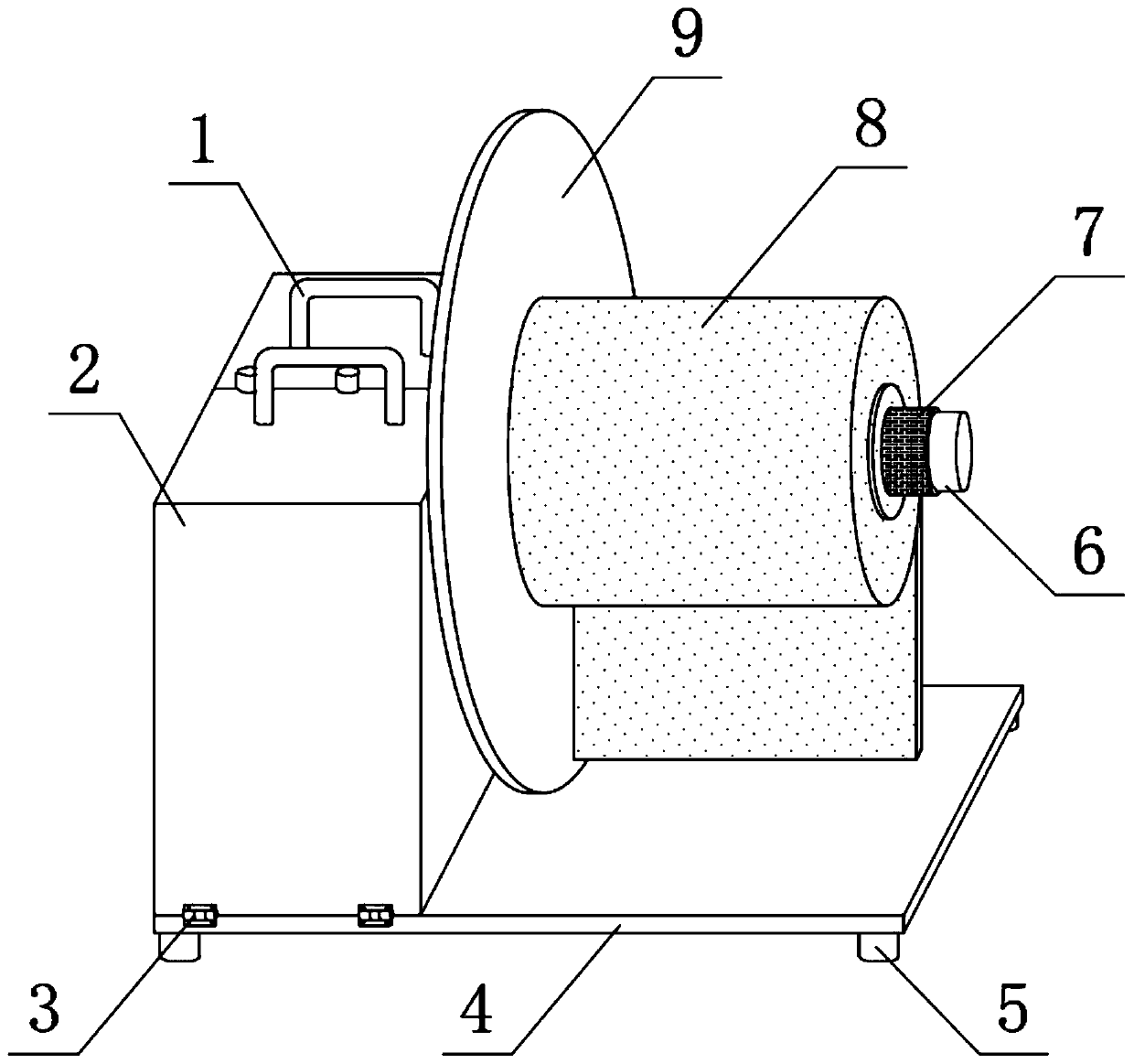

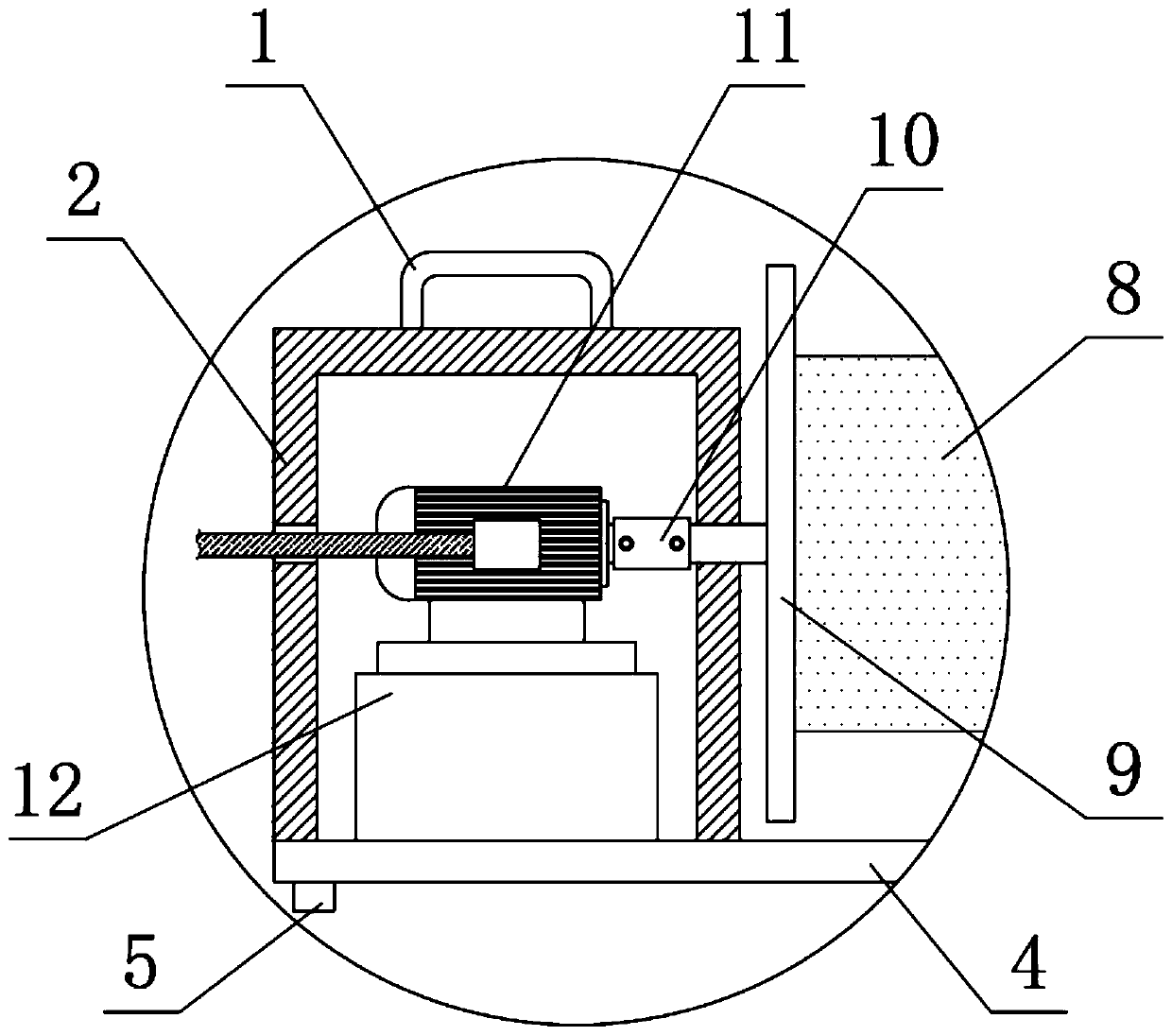

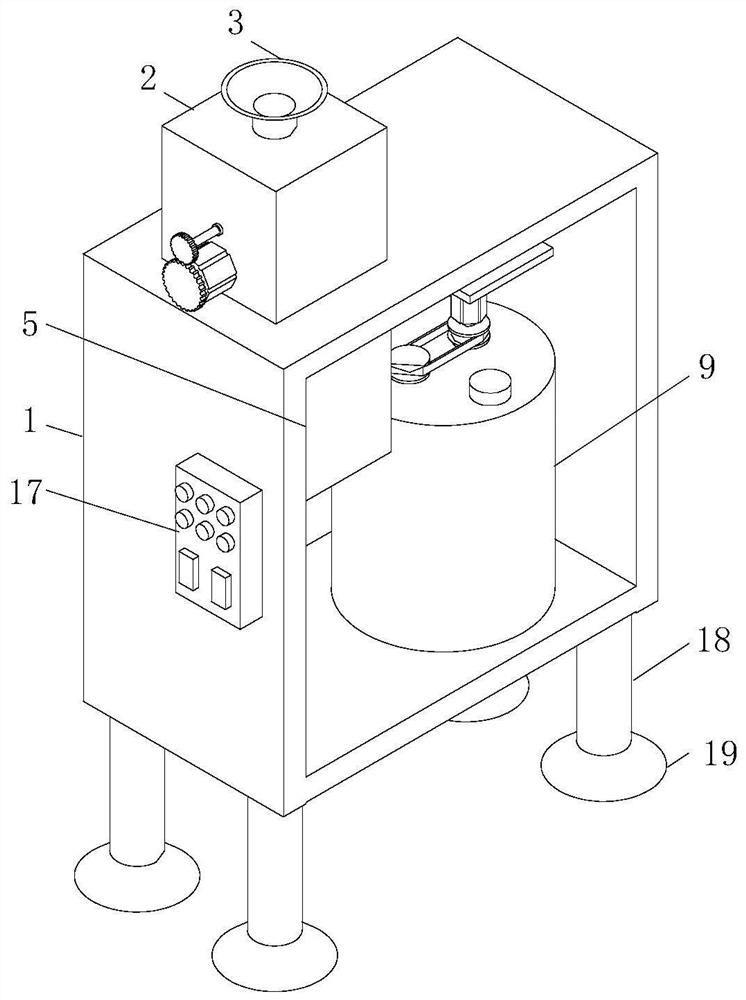

Paper winding mechanism for label digital printing machine

InactiveCN111268478AEasy to replaceImprove work efficiencyWebs handlingElectric machineryStructural engineering

The invention discloses a paper winding mechanism for a label digital printing machine. The paper winding mechanism for the label digital printing machine comprises a fixed supporting bottom plate andfixed handles. Connecting supporting bottom feet are arranged at four corners of the upper end of the fixed supporting bottom plate, and a detachable protective cover device is arranged at the upperend of the fixed supporting bottom plate. The detachable protective cover device is installed, and a front semi-circular-groove protective cover and the rear semi-circular-groove protective cover of the detachable protective cover device are fixedly connected to the fixed supporting bottom plate through rotating hinges, and meanwhile, the front semi-circular-groove protective cover and the rear semi-circular-groove protective cover of the detachable protective cover device are connected with externally threaded semi-circular connecting columns through internally threaded fixing caps, so that when a rotating motor inside the detachable protective cover device rotates, the staff disassembles the detachable protective cover device, the detachable protective cover device can be unfolded in a rotating mode, the staff can conveniently replace the damaged rotating motor, and the working efficiency is improved.

Owner:江苏欧普特条码标签有限公司

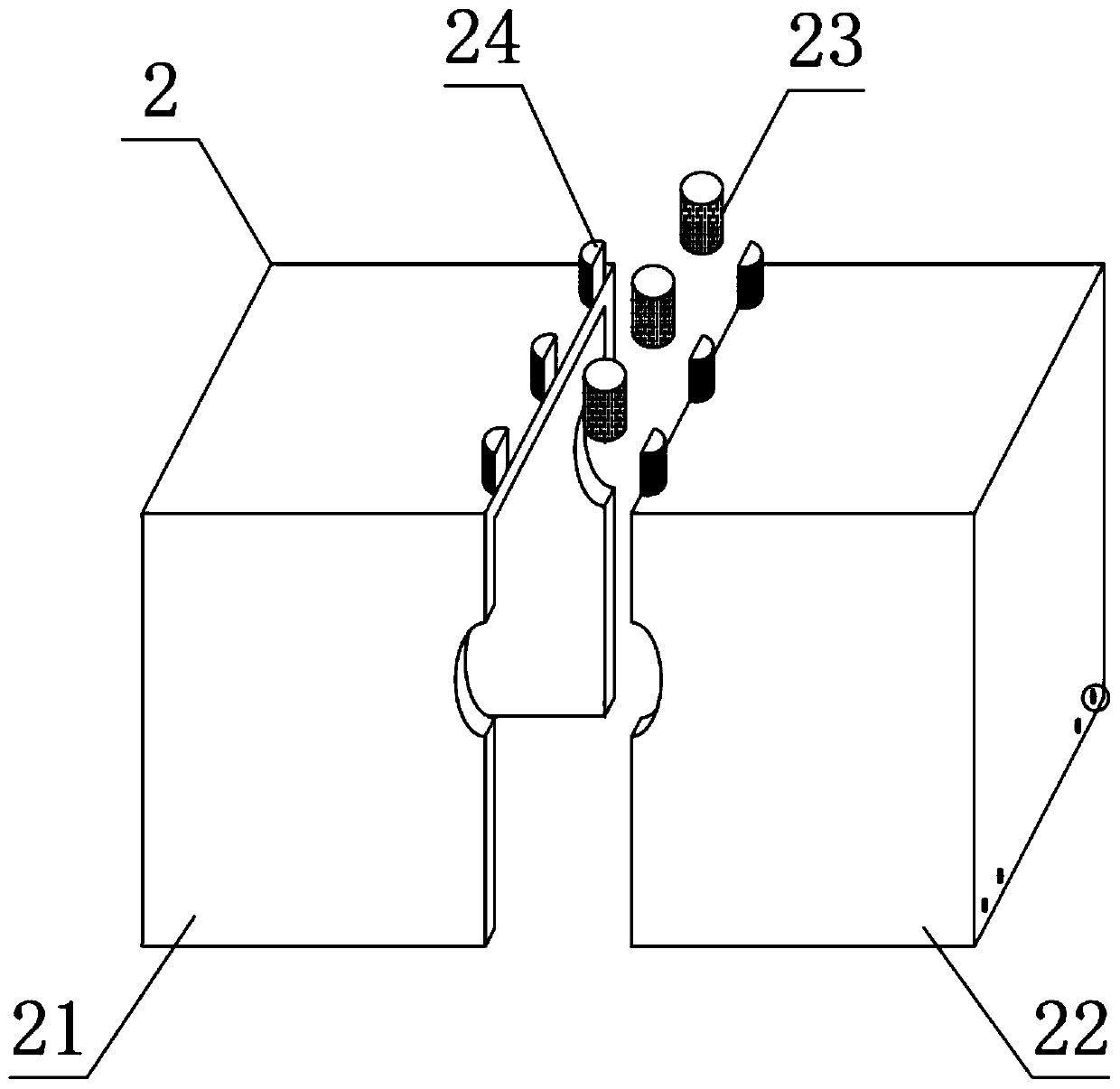

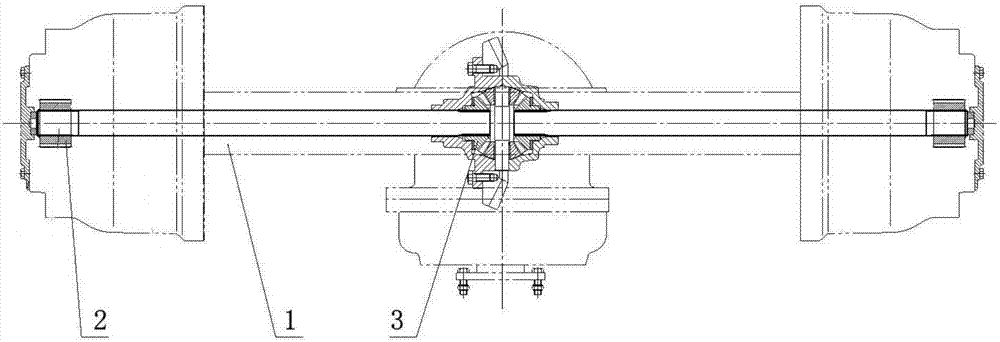

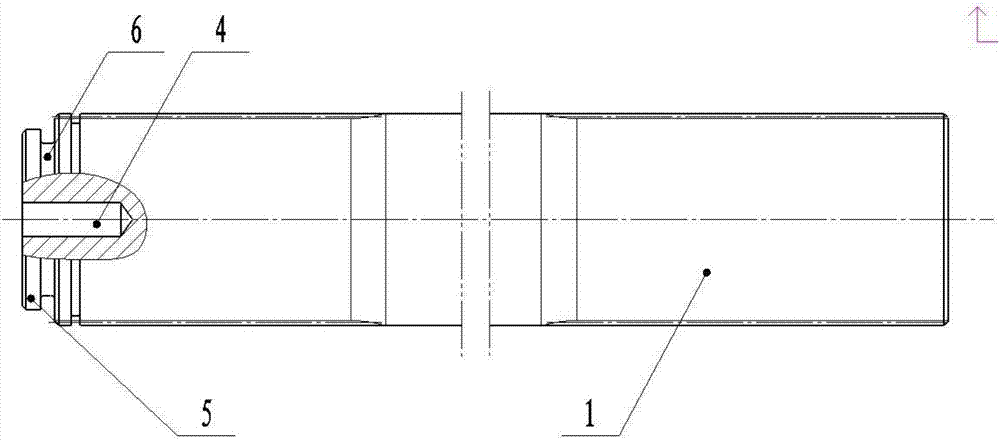

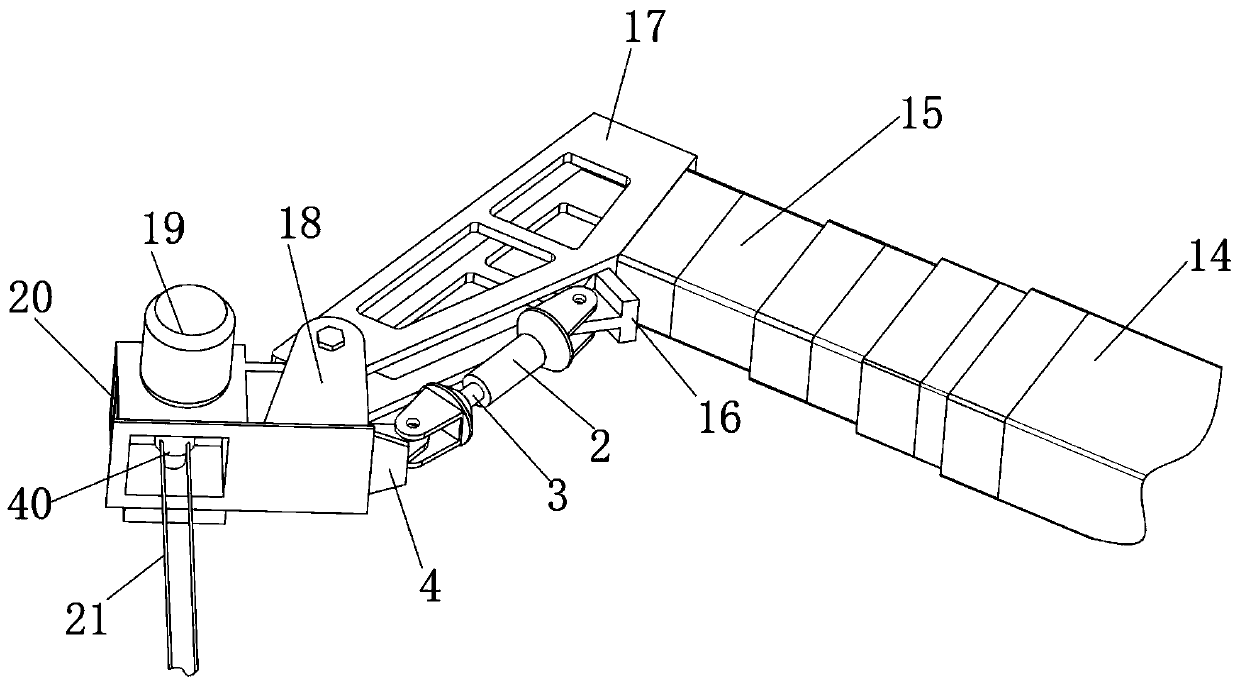

Drive half axle structure convenient to demount and demounting method thereof

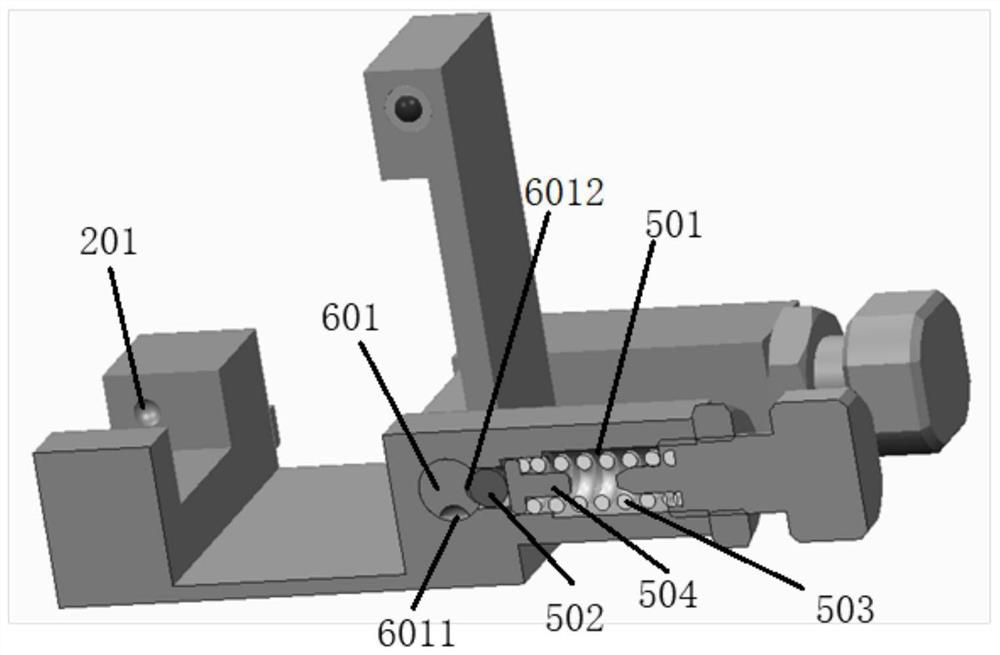

InactiveCN107202062AImprove disassembly processReduce maintenance replacement timeShaftsCouplings for rigid shaftsAutomotive engineering

The invention discloses a drive half axle structure convenient to demount and a demounting method thereof. The drive half axle structure comprises a drive half axle body. One end of the drive half axle body is connected with a hub reducer, and the other end of the drive half axle body is connected with an automobile main reducer. A boss is arranged at the end, connected with the hub reducer, of the drive half axle body and provided with an annular groove. On the basis of guaranteeing the original design mounting size of a drive half axle, an M10 threaded hole is additionally arranged in the center of the end face of the end, connected with the hub reducer, of the drive half axle; or a groove is formed in the front end of the end face. When the drive half axle is maintained or replaced, only an end cover on a hub reducer shell needs to be demounted, an M10 eyebolt is screwed to the end face of the half axle and is pulled, and the drive half axle can be pulled out easily; or, a proper steel wire which can be a rope is used for being wound in the groove, and the steel wire or rope is pulled.

Owner:泸州开士乐工程技术有限责任公司

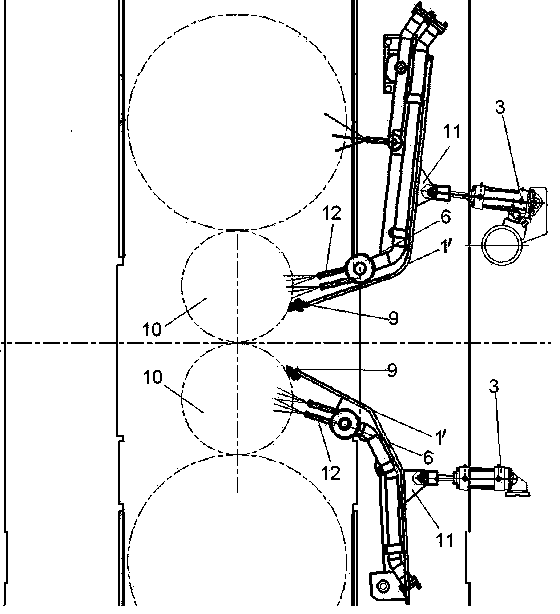

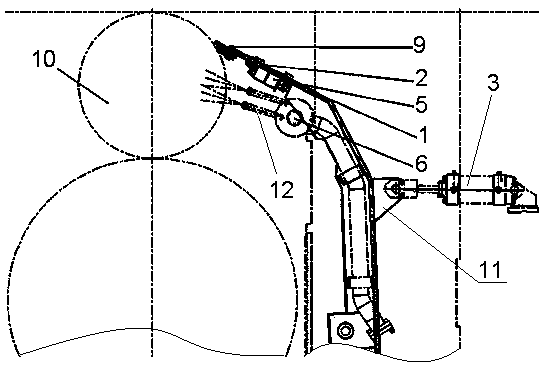

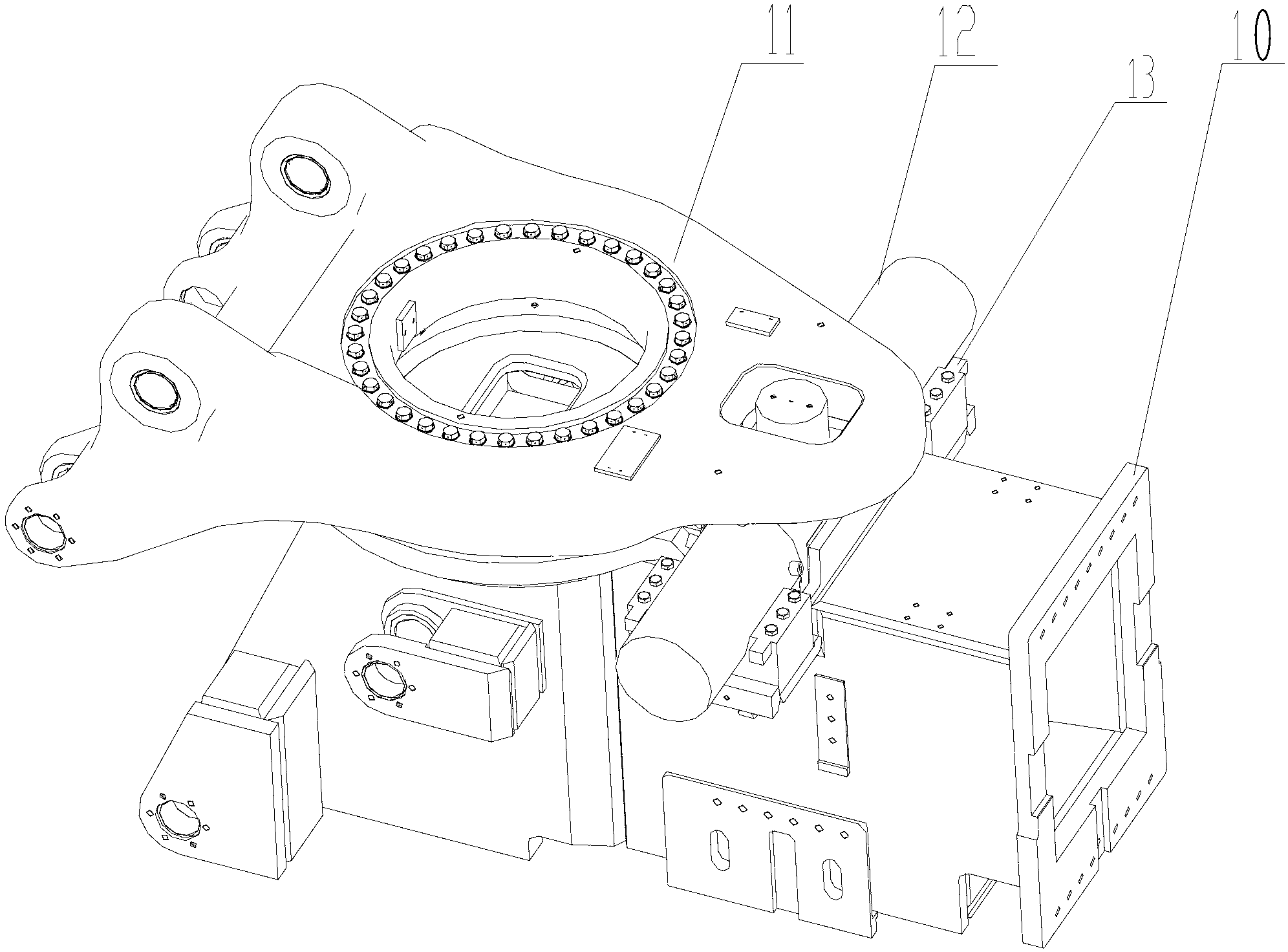

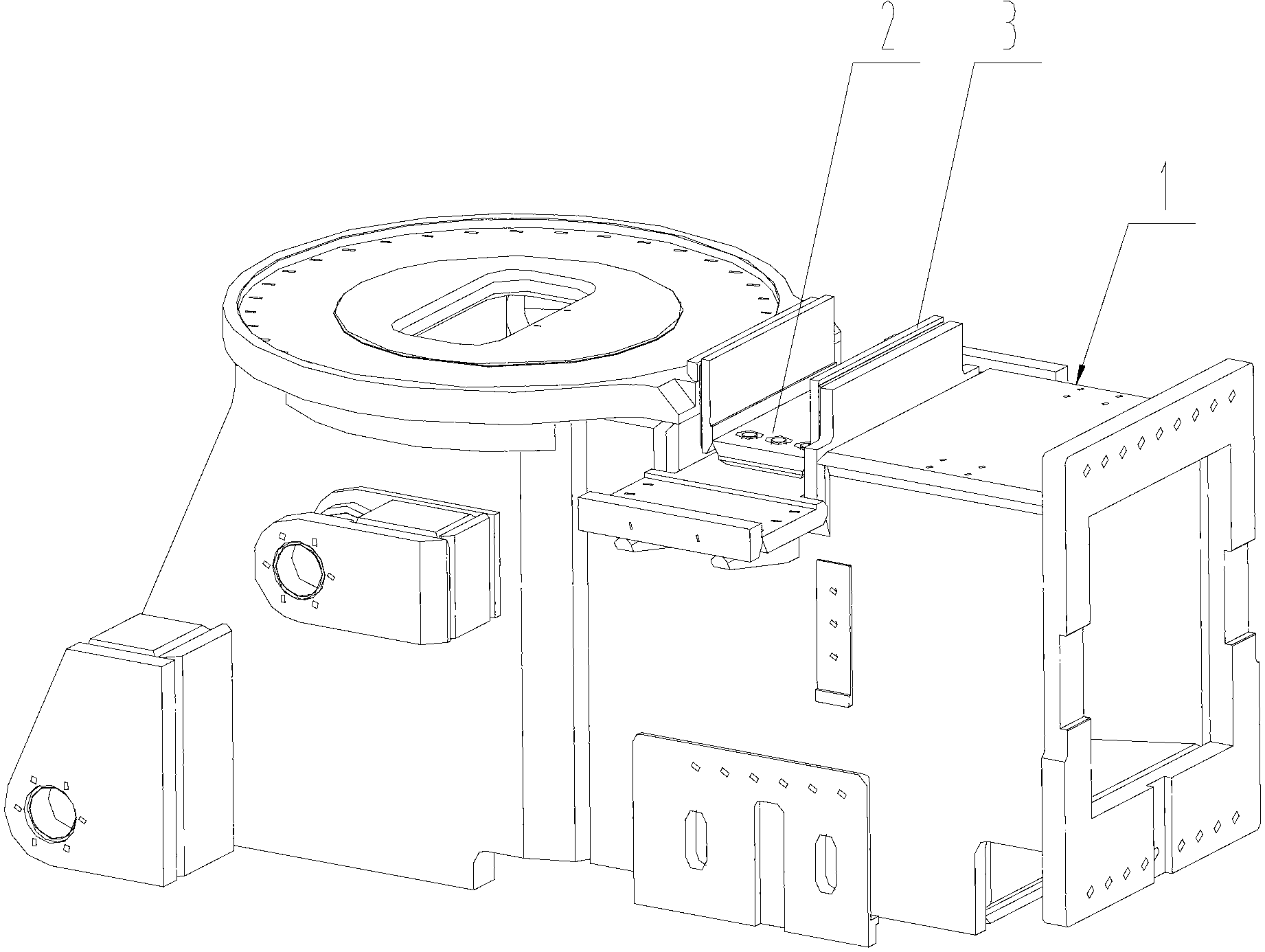

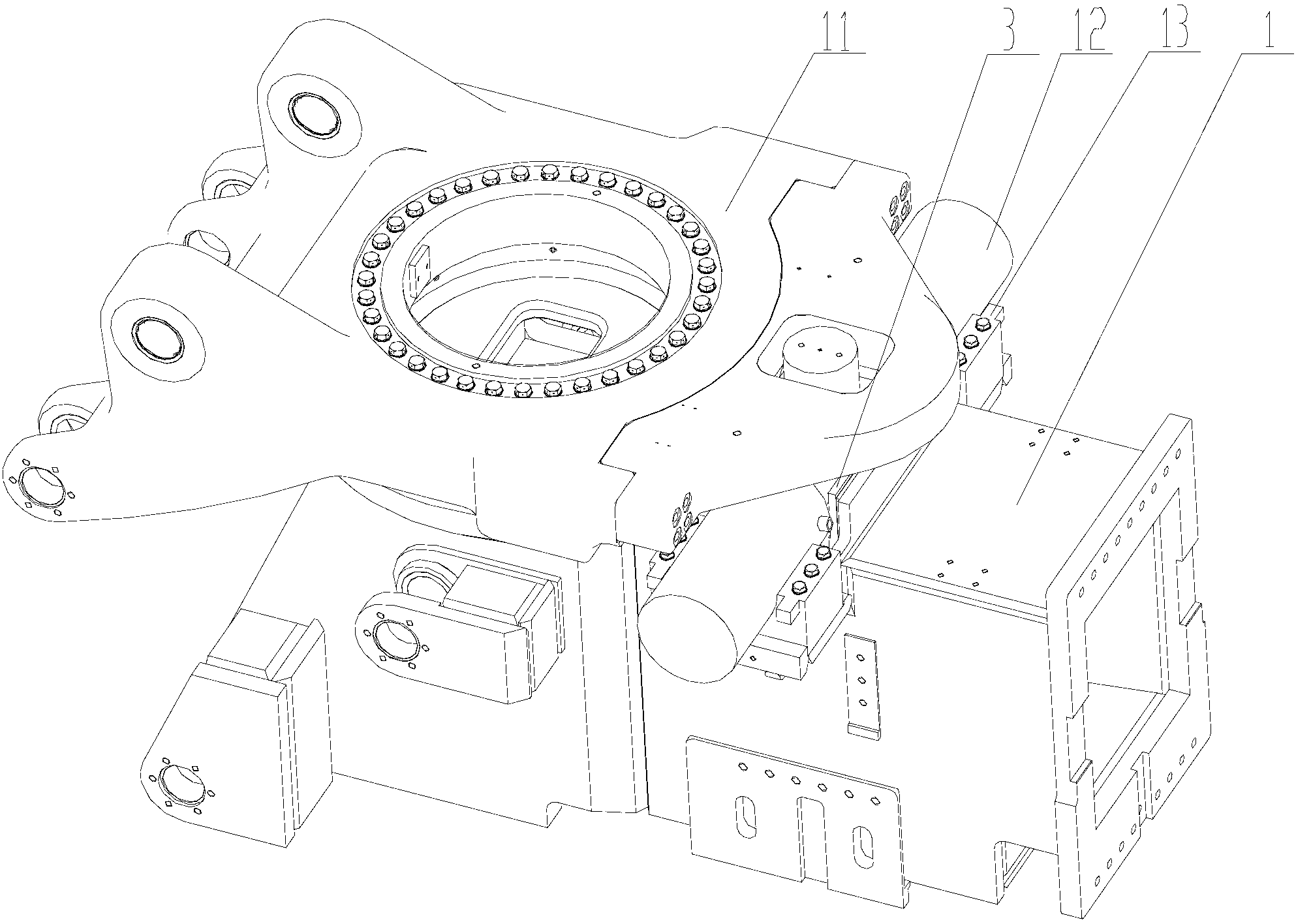

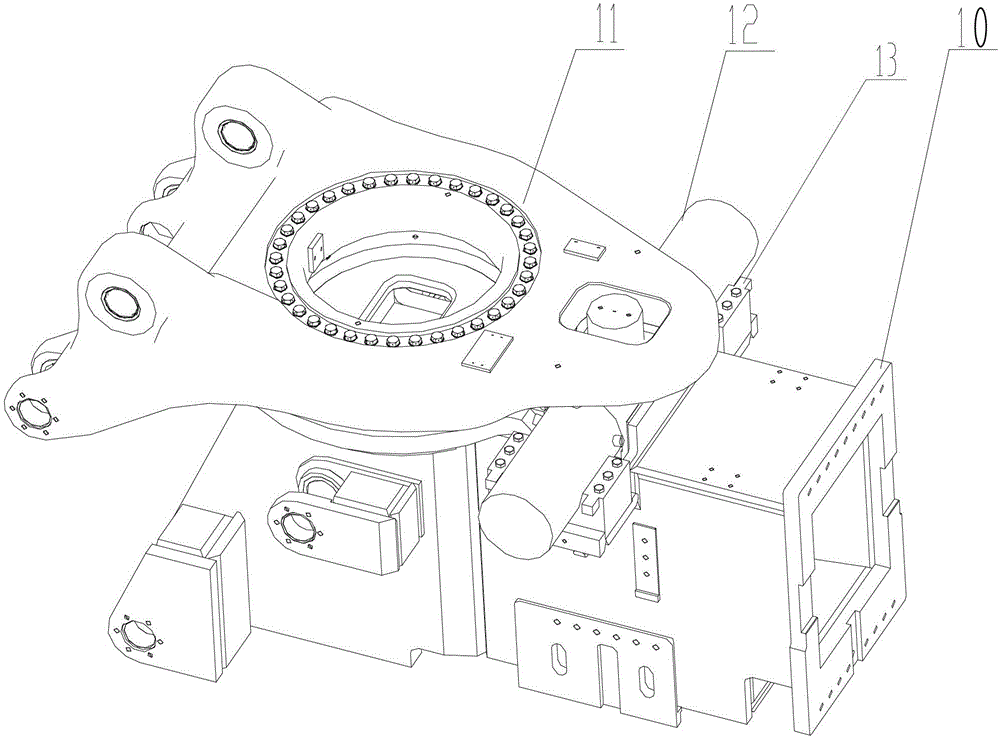

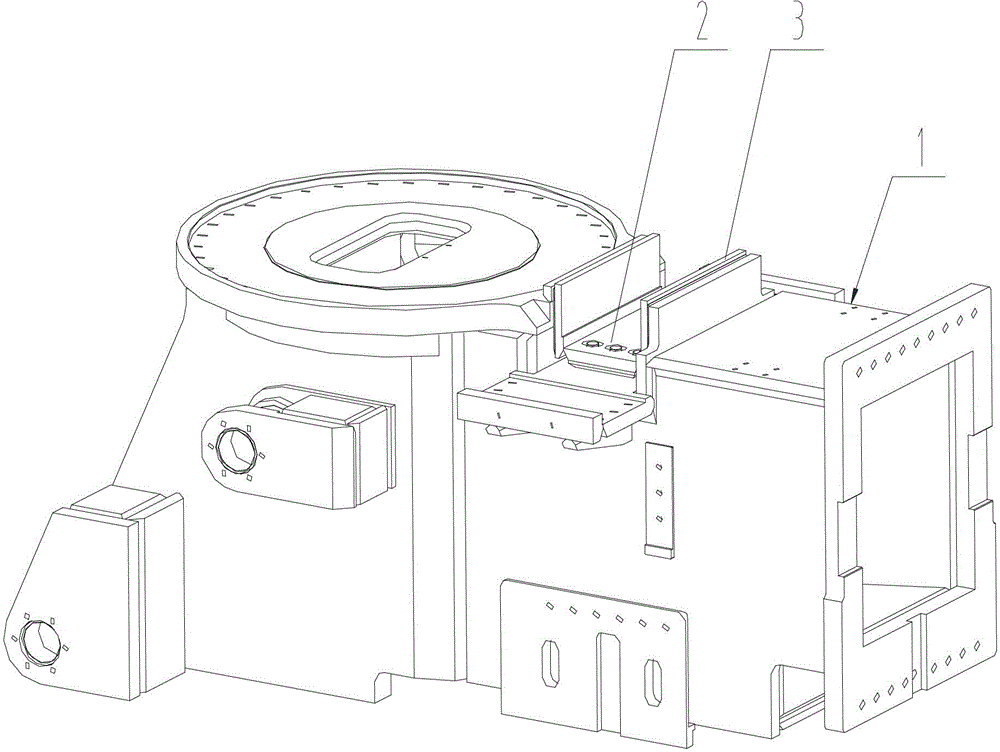

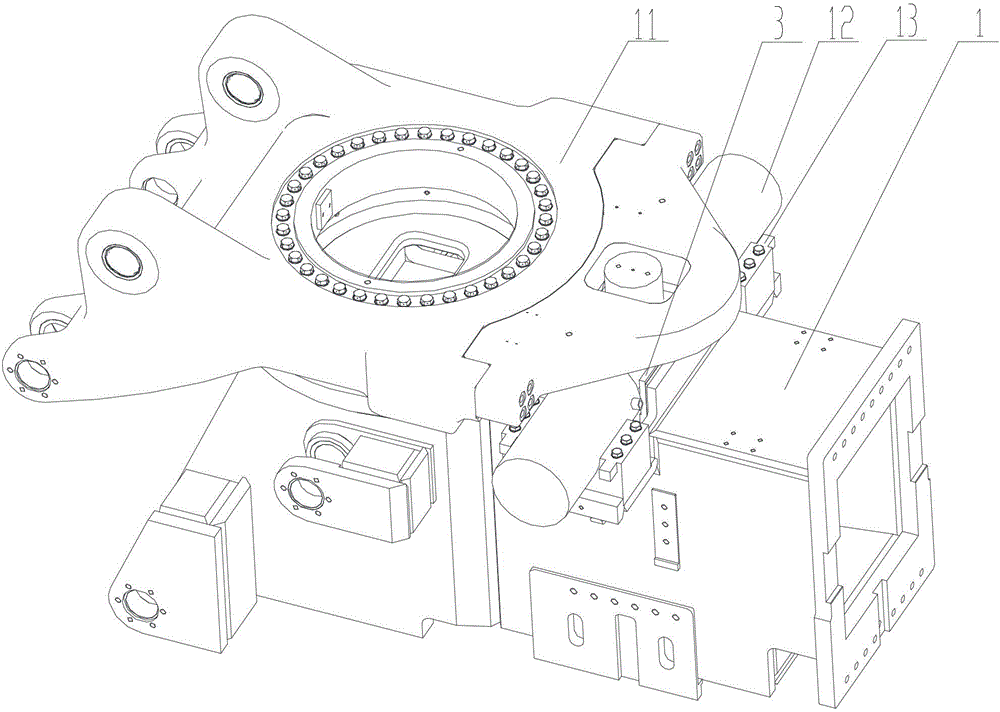

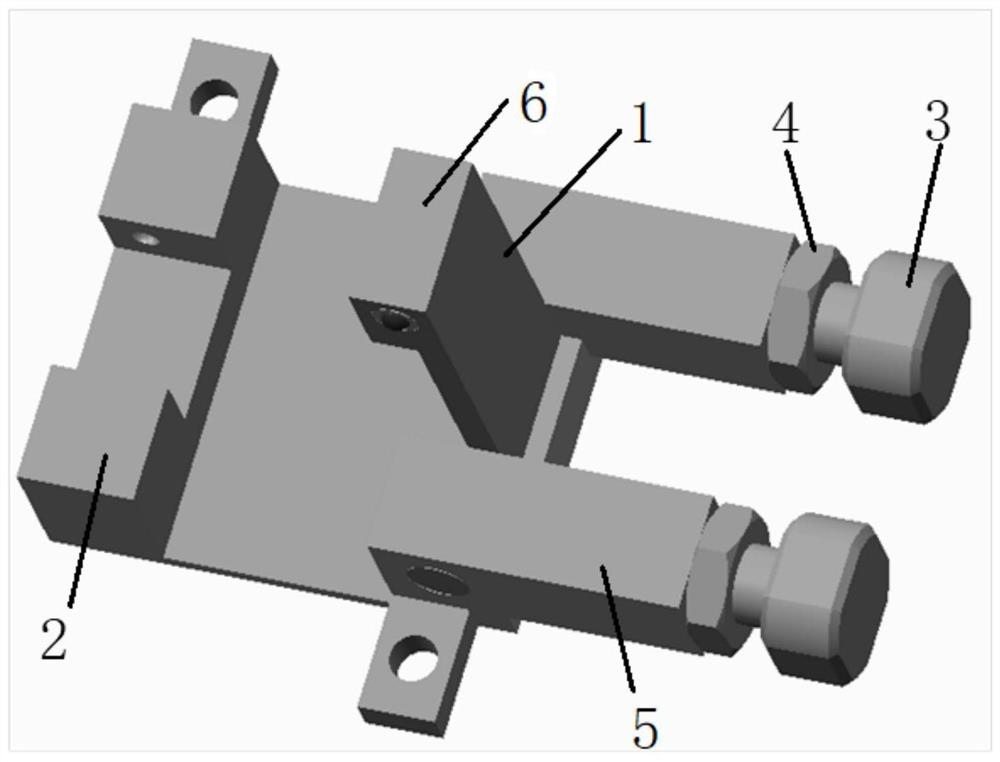

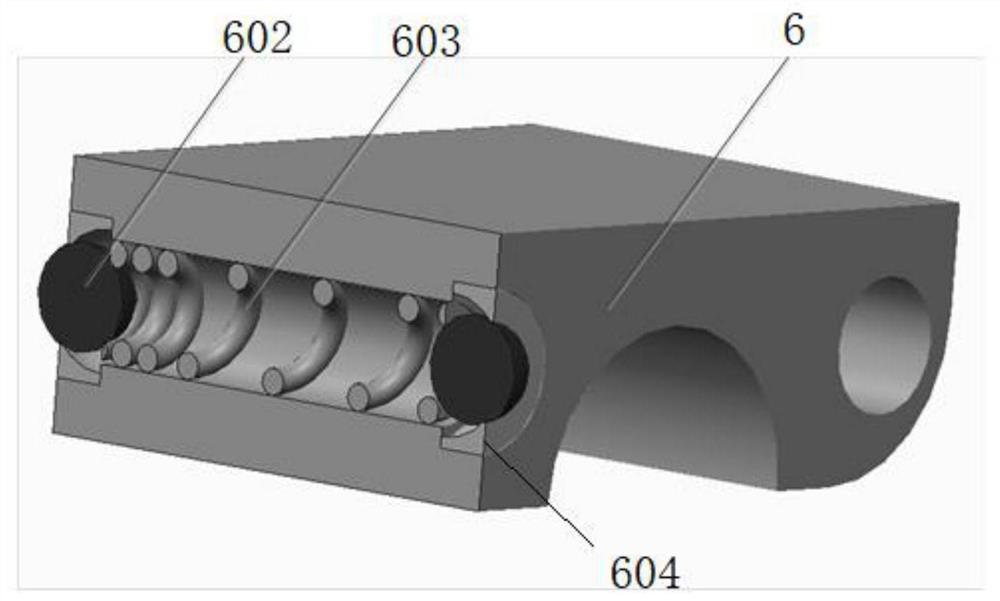

Angling cylinder mounting seat, body support and engineering machinery

ActiveCN103061758AImprove maintainabilityReduce volumeSlitting machinesRear quarterReciprocating motion

The invention discloses an angling cylinder mounting seat, a body support and engineering machinery, wherein the angling cylinder mounting seat is used for mounting an angling cylinder. The angling cylinder mounting seat comprises mounting seat side plates and a mounting seat bottom plate, wherein one of the mounting seat side plates is provided with a reciprocating motion plane contacting with the angling cylinder, the mounting seat bottom plate is connected with the mounting seat side plates and detachably connected to the body support used for mounting the angling cylinder. According to the angling cylinder mounting seat, the body support and the engineering machinery, when the reciprocating motion plane, contacting with the angling cylinder, of the angling cylinder mounting seat is abraded and loses efficacy, the angling cylinder mounting seat is detached off alone to complete repair and replacement, and thus maintainability of equipment is effectively promoted.

Owner:SANY HEAVY EQUIP

Fluid rapid cooling thermostat for 3D printer

The invention relates to the technical field of 3D printers, and discloses a fluid rapid cooling thermostat for a 3D printer. The thermostat comprises a printer head, wherein the top of the printer head is equipped with a sliding block, a horizontal slide rail is moveably connected inside the sliding block, the outer surface of the sliding block is connected with a bolt, the outer surface of one side of the sliding block close to the top of the bolt is equipped with a controller, the top of the sliding block is equipped with a feed delivery pipe, the bottom of the feed delivery pipe runs through towards the bottom of the sliding bock and is connected with the printer head, and the outer surface of the feed delivery pipe is equipped with a water storage box. The decomposition of a calcium carbonate cooling medium in a reaction chamber inside a cooling device under high temperature makes the temperature inside the feed delivery pipe drop rapidly, and a fan is used to further radiate thehot fluid material sprayed from the printer head to make the printed fluid rapidly cooled and shaped, thereby avoiding the occurrence of collapse of print products caused by overheat of the fluid, andgreatly improving molding rate and pass rate of the product.

Owner:HUANGGANG NORMAL UNIV

Forestry reconnaissance device

PendingCN114104288AQuick installation and removalEasy to repair and replaceAircraft componentsPicture taking arrangementsEngineeringEnvironmental geology

The invention relates to a forestry reconnaissance device which comprises a rack, a reconnaissance device body and a workbin device, the rack, the reconnaissance device body and the workbin device are detachably connected, the outer wall of the reconnaissance device body is of a columnar structure, a through hole for the reconnaissance device body to penetrate through is formed in the center of the rack, and a front hanging lug is arranged at the front end of the upper surface of the workbin device; and one end of the exploration device sequentially penetrates through the front hanging lug, the through hole and the rear hanging lug to connect the rack, the exploration device and the workbin device together. Compared with the prior art, the device has the following beneficial effects that the device can be quickly disassembled and assembled and is convenient to maintain and replace, the maintenance and replacement time can be shortened when the arm of the reconnaissance unmanned aerial vehicle breaks down, and the working efficiency is improved; and the universality is high. The hollow material box device provides buoyancy for the device, and loss is reduced.

Owner:张成瑞

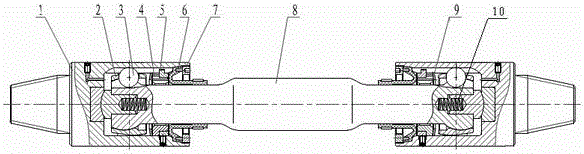

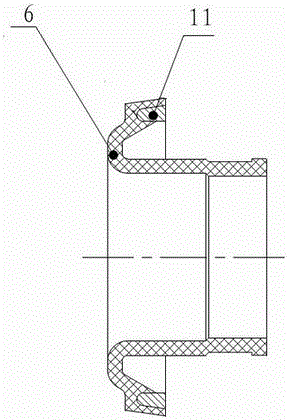

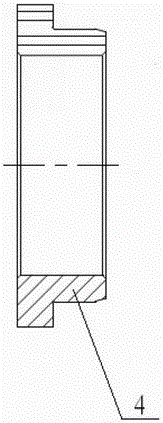

Ball cage type cardan shaft for screw drilling tool

ActiveCN103510865BImprove shock absorptionIsokineticDrilling rodsDrilling casingsDrive shaftFree state

Owner:XIANGYANG BOYA PRECISION IND EQUIP +1

A suspension type air inlet filter cotton fixing structure and fixing method

ActiveCN111420490BAchieve fixationRealize disassembly and replacementDispersed particle filtrationMembrane filtersControl engineeringStructural engineering

Owner:NANJING HUASHI ELECTRONICS SCI

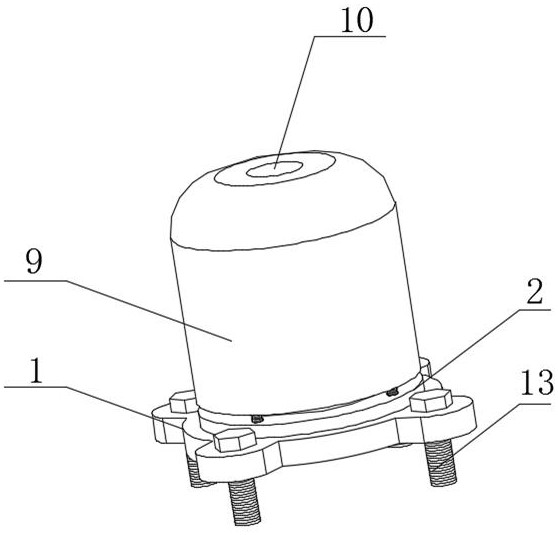

Convenient-to-disassemble-and-assemble rotor seat of refrigeration compressor

ActiveCN112696332AEasy to assemble and disassembleEasy to replacePositive displacement pump componentsPiston pumpsRefrigeration compressorMechanical engineering

The invention relates to the technical field of compressors, and discloses a convenient-to-disassemble-and-assemble rotor seat for a refrigeration compressor, which comprises a base, a fixed disc is arranged on the outer surface of the upper end of the base, a shock pad is arranged on the outer surface of the upper end of the fixed disc, and a mounting ring is arranged on the outer surface of the upper end of the shock pad; and a connecting ring is arranged on the outer surface of the upper end of the mounting ring, an inner connecting ring is arranged on the outer surface of the inner side end of the connecting ring, a limiting ring is arranged on the outer surface of the side end of the inner connecting ring, and locking pins are arranged on the outer surface of the side end of the connecting ring. The convenient-to-disassemble-and-assemble rotor seat for the refrigeration compressor is simple in structure, high in connectivity and convenient to operate, has the advantages of being convenient to assemble and disassemble, facilitating internal maintenance, enhancing connectivity, having a limiting effect on a rotating shaft, preventing internal deviation from influencing the using effect and having a damping function, therefore, the service life of a rotor is prolonged, the using stability is improved, and the use effect is improved.

Owner:江苏合球机械科技有限公司

Rotary oil cylinder mounting seat, body frame and construction machinery

ActiveCN103061758BImprove maintainabilityReduce volumeSlitting machinesReciprocating motionEngineering

The invention discloses an angling cylinder mounting seat, a body support and engineering machinery, wherein the angling cylinder mounting seat is used for mounting an angling cylinder. The angling cylinder mounting seat comprises mounting seat side plates and a mounting seat bottom plate, wherein one of the mounting seat side plates is provided with a reciprocating motion plane contacting with the angling cylinder, the mounting seat bottom plate is connected with the mounting seat side plates and detachably connected to the body support used for mounting the angling cylinder. According to the angling cylinder mounting seat, the body support and the engineering machinery, when the reciprocating motion plane, contacting with the angling cylinder, of the angling cylinder mounting seat is abraded and loses efficacy, the angling cylinder mounting seat is detached off alone to complete repair and replacement, and thus maintainability of equipment is effectively promoted.

Owner:SANY HEAVY EQUIP CO LTD

A long-life oxygen-blowing metal hose

ActiveCN105673980BExtended service lifeImprove flexibilityPipeline expansion-compensationWave shapeEngineering

An oxygen blowing metal hose long in service life comprises a corrugated pipe, and a first joint and a second joint are arranged at the two ends of the corrugated pipe; the outer side of the corrugated pipe is wrapped with a metal net body, and the corrugated pipe is of a five-segment type structure formed by sequentially connecting a first pressure-resisting segment, a first transition segment, a high-flexibility segment, a second transition segment and a second pressure-resisting segment; the first pressure-resisting segment and the second pressure-resisting segment on the two sides of the corrugated pipe are in omega shapes; and the high-flexibility segment located in the middle portion of the corrugated pipe is in a deep-U-shaped wave shape, and the first transition segment and the second transition segment are in U-shaped wave shapes. According to the characteristics that the two sides of the corrugated pipe are bad in working condition and large in bearing pressure, the pressure-resisting segments in the omega shapes are arranged on the two sides of the corrugated pipe; according to the characteristic that due to insufficient flexibility, the dynamic bending portion of the middle segment of the corrugated pipe is prone to being damaged, the middle segment of the corrugated pipe is designed to be the high-flexibility segment in the deep-U-shaped wave shape; and through the improvement, the service life of the oxygen blowing metal hose is greatly prolonged, the maintenance and replacement time is greatly shortened, and improvement of steel smelting efficiency is facilitated.

Owner:石家庄巨力科技股份有限公司

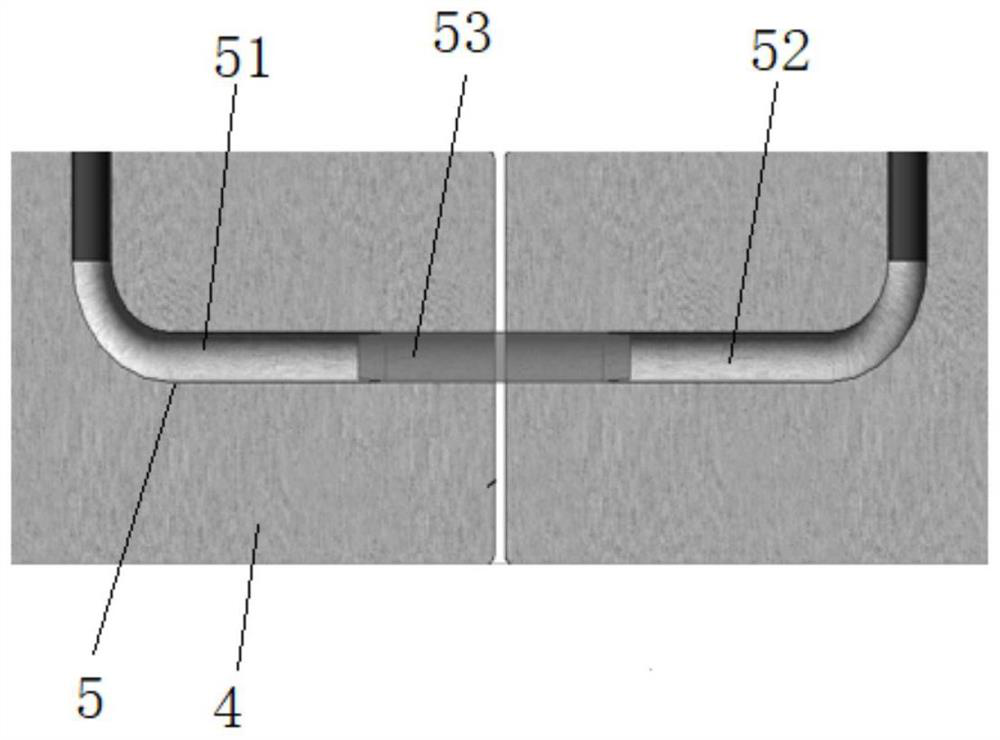

A Surface Seamless Bridge Expansion Joint

ActiveCN104762875BReduce shockReduce maintenance replacement timeBridge structural detailsExpansion joint

The invention belongs to the technical field of road and bridge engineering, and relates to a surface seamless type bridge expansion joint. The surface seamless type bridge expansion joint is characterized in that lower sliding plate blocks are fixed to the tops of two cement main beams through anchoring devices respectively, elastic deformation bodies are arranged at the two ends of a bearing plate, one end of each elastic deformation body is fixedly connected with the bearing plate, the other ends of the elastic deformation bodies are fixedly connected with connecting steel bars reserved on the main beams, sliding shafts are arranged between the tops of the two cement main beams and the bearing plate, lubricant grooves are formed in the contact faces of the lower sliding plate blocks and the bearing plate, antiskid grooves are formed in the contact face of the bearing plate and a bridge deck pavement layer, and a limiting check block is fixed to the middle of the lower portion of the bearing plate. The surface seamless type bridge expansion joint has the advantages that telescopic deformation of a bridge is mainly completed below the bearing plate and on the elastic deformation bodies and the bridge deck pavement layer, due to the fact that the surface of the bridge expansion joint has no seam, running comfort is improved, the impact action of running loads to the bridge is weakened, the constriction period is short, the maintenance and replacement time of the expansion joint is shortened, bridge deck maintenance and pavement layer modification are facilitated, and the service life is prolonged.

Owner:吉林省交通规划设计院

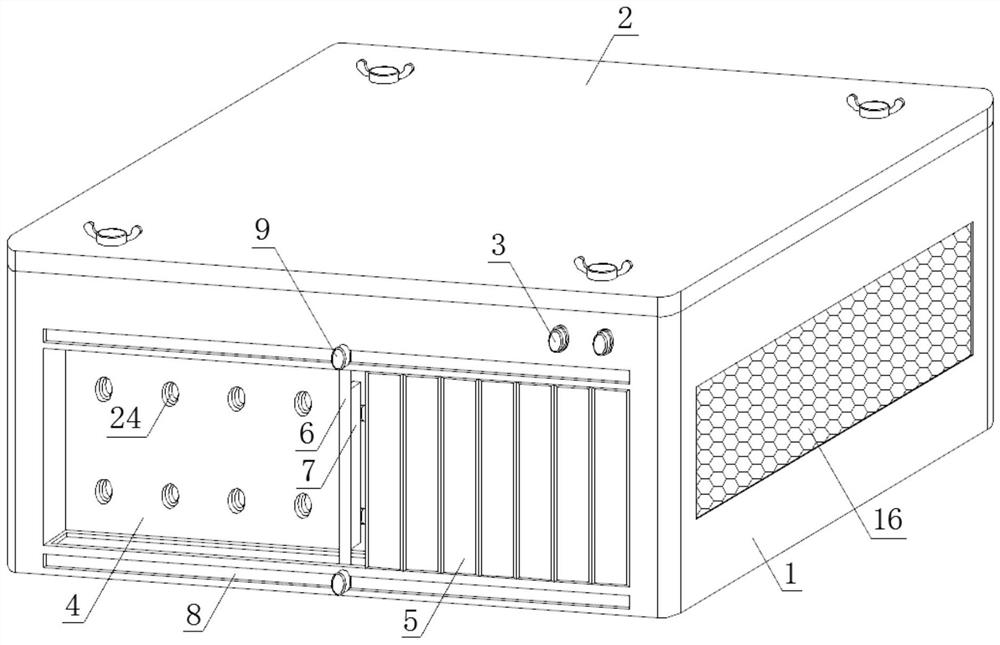

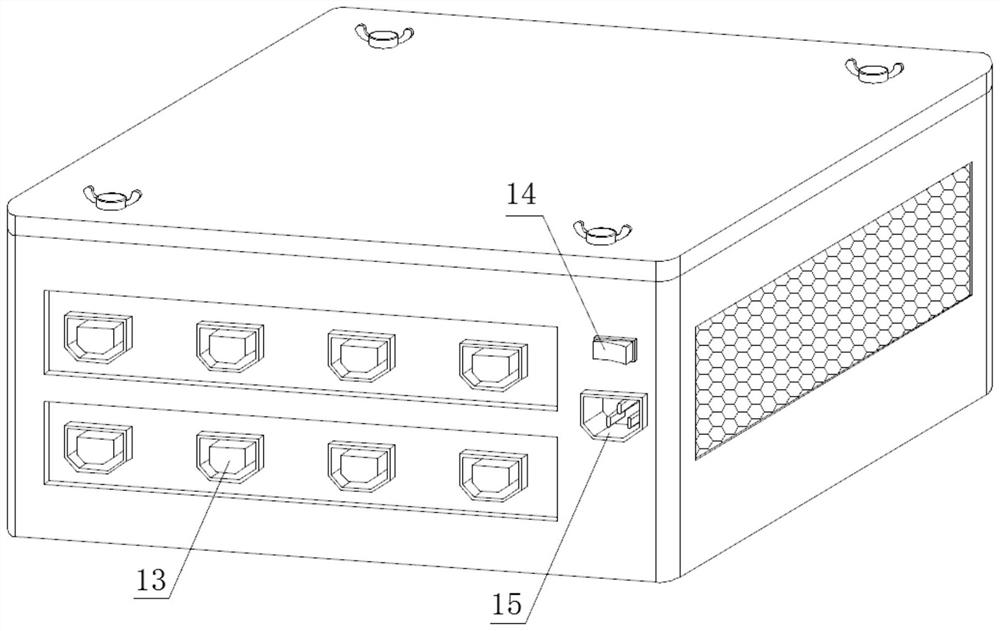

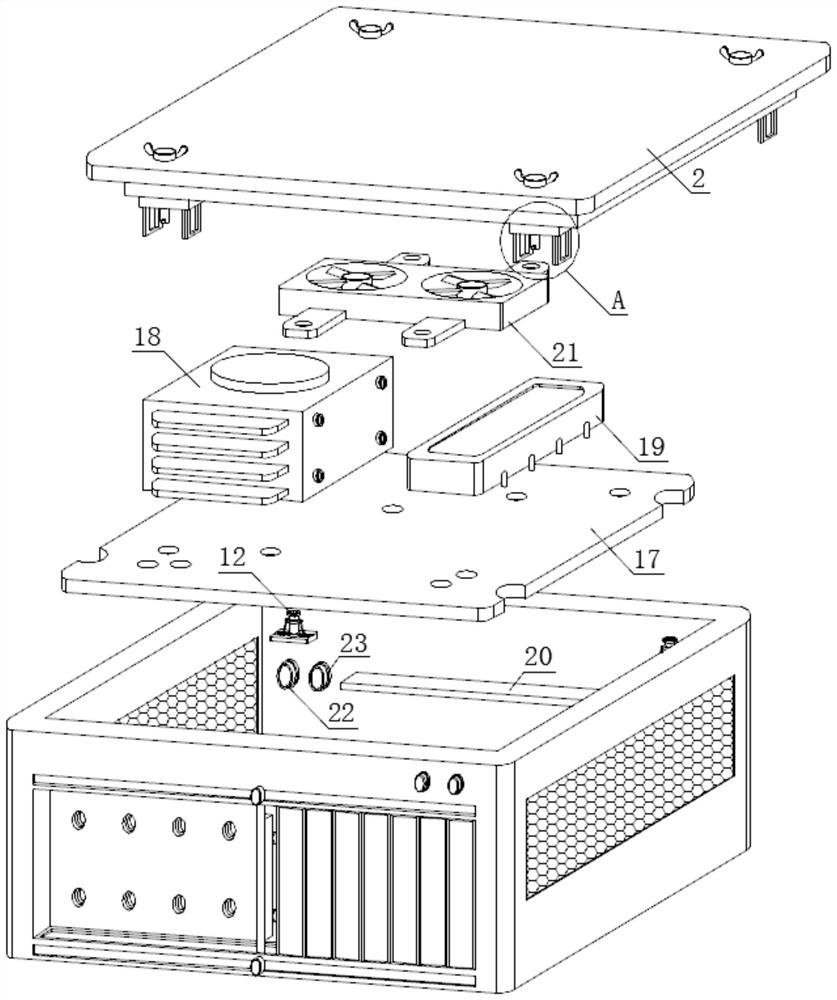

Splicing controller with 4K signal

PendingCN113645793ARealize splicing and fixingEasy to splice and installCasings/cabinets/drawers detailsEngineeringStructural engineering

The invention relates to the technical field of controllers, and discloses a splicing controller with a 4K signal. The splicing controller comprises a machine box and a top cover, display screen bodies of LED touch display screens are clamped in inner cavities of mounting clamping grooves through mounting clamping seats, and the adjacent display screen bodies are connected through limiting columns and limiting holes on the side walls of the mounting clamping seats. A movable rod with a limiting abutting plate is movably clamped in an mounting clamping groove in one side of the machine box, the limiting abutting plate is buckled with a limiting clamping opening in the tail end of the limiting column adjacent to the limiting abutting plate, a limiting groove is formed in the outer wall of the front end plate of the machine box at the end of the movable rod and provided with an elastic bolt, and the tail end of the elastic bolt is connected with the end of the movable rod. The movable rod moves to drive the limiting abutting plate to be buckled with the limiting column to lock the display screen body, splicing and fixing of the LED touch display screen are achieved, a display control panel can be conveniently additionally installed in the later period, meanwhile, splicing and installing of the LED touch display screen are achieved, only the LED touch display screen needs to be replaced when a part of the display screen is damaged, and the maintenance and replacement time is shortened.

Owner:深圳市东闽炬创电子有限公司

Pipeline fixing device and pipeline fixing method for space station

ActiveCN110686127BQuick releaseEasy to fixPipe supportsSnap-action fastenersEngineeringStructural engineering

The invention relates to a pipeline fixing device and a pipeline fixing method for a space station, belonging to the field of aerospace technology, and solves the problems in the prior art that the pipelines of various systems in the space station are fixed or loosened with low efficiency and the fixing method is easy to fail. The pipeline fixing device of the present invention includes a pipeline fixing frame and a compression device; the compression device includes a compression device body and a locking structure, and the locking structure is used to adjust the locking force received by the compression device body; the compression device body The first end is hinged to the first end of the pipeline fixing frame. The invention is used for fixing pipelines used in space stations.

Owner:BEIJING MECHANICAL EQUIP INST

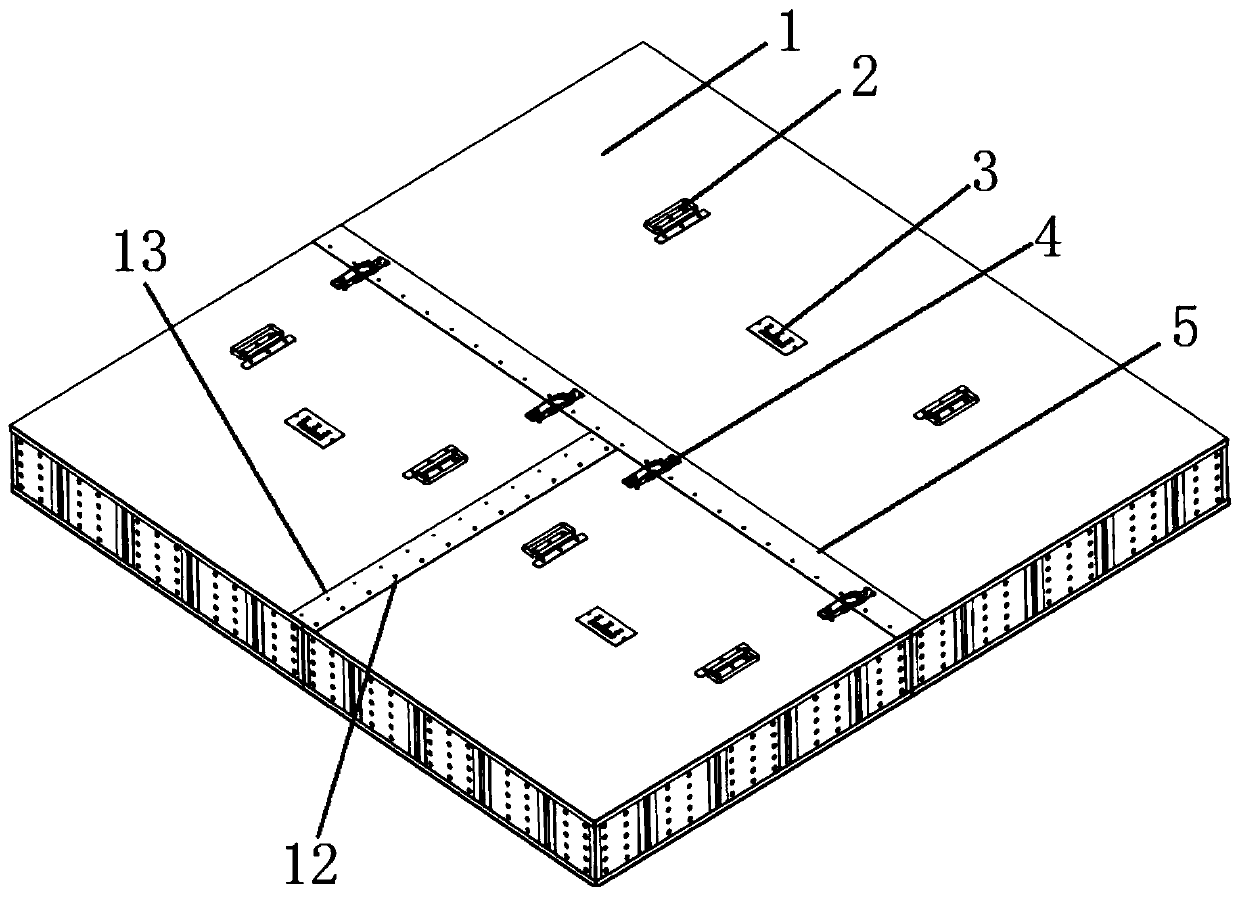

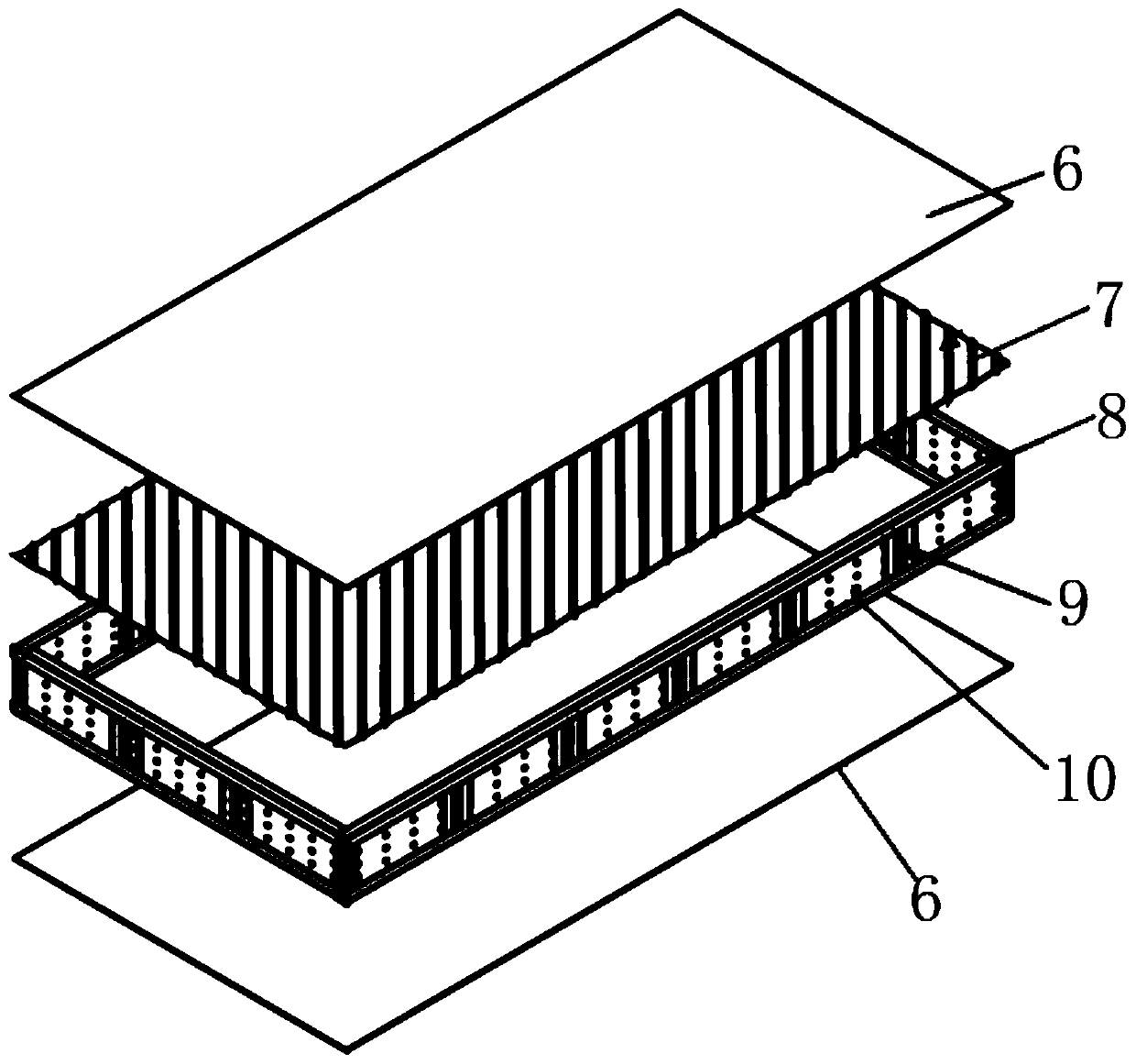

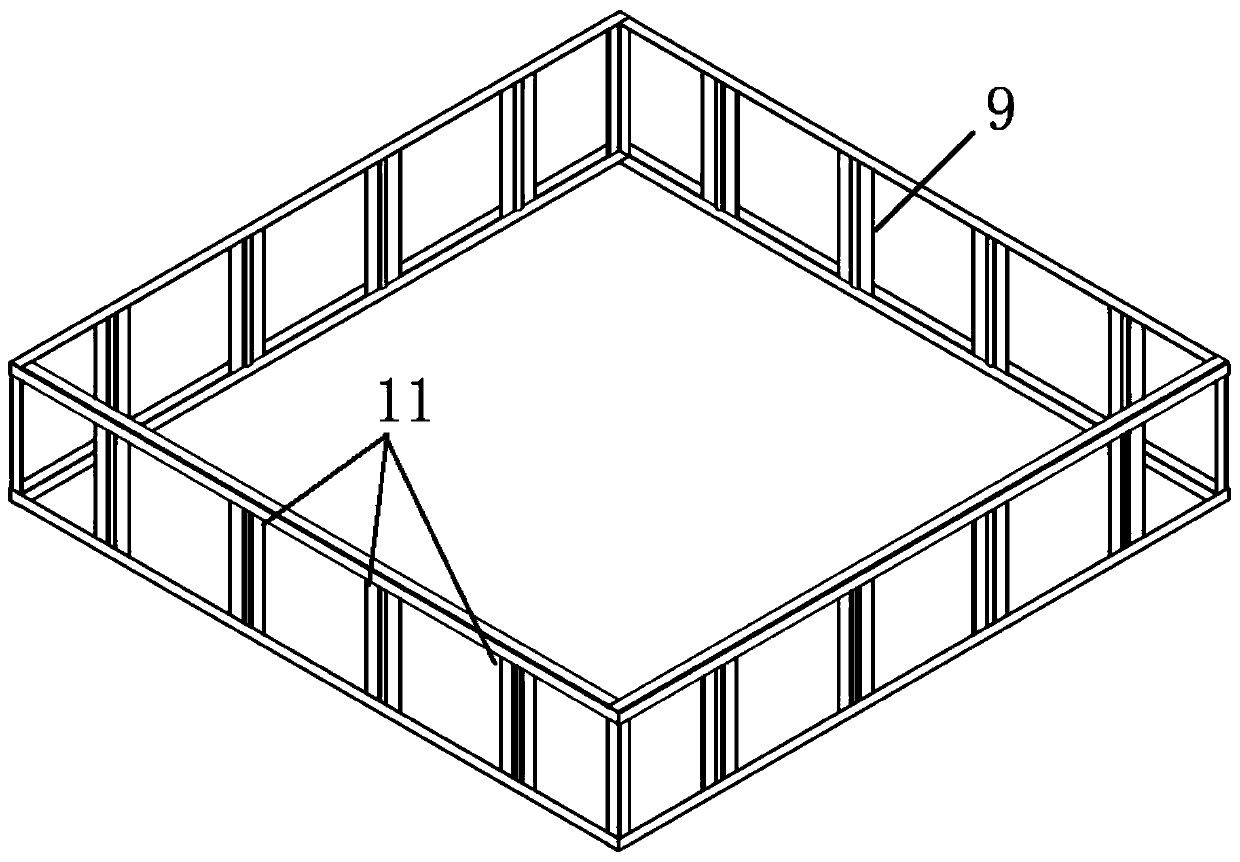

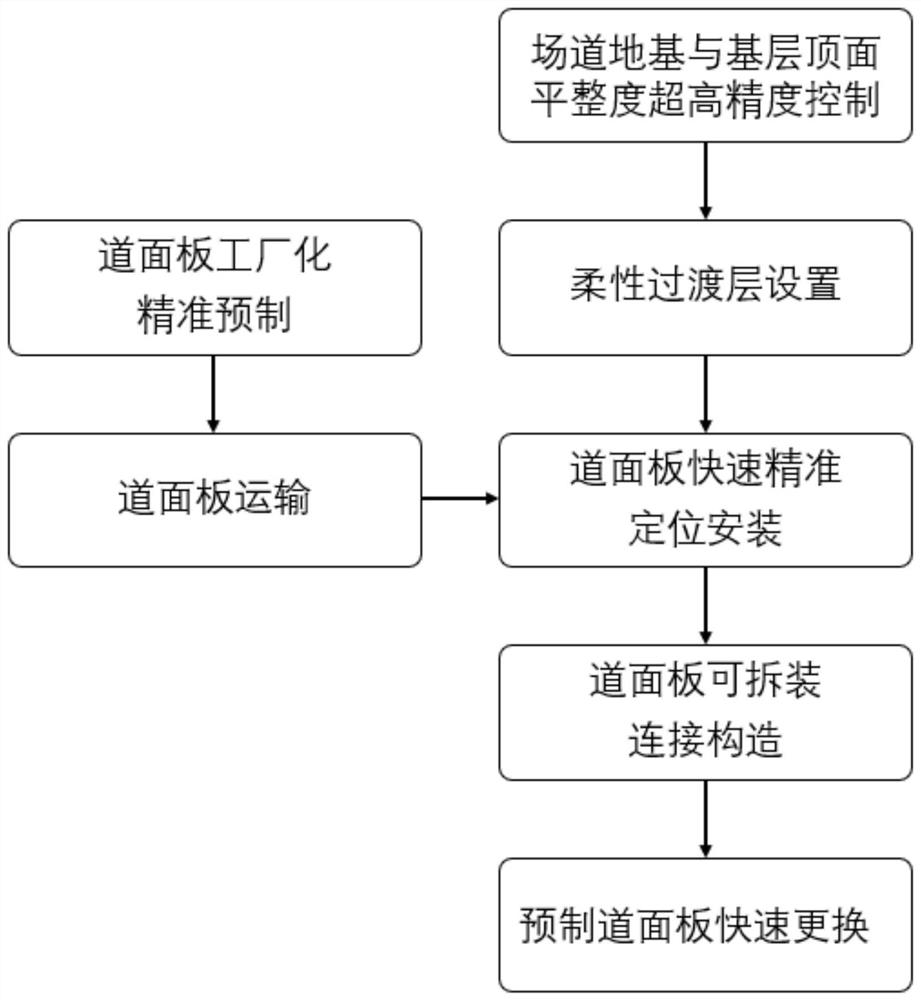

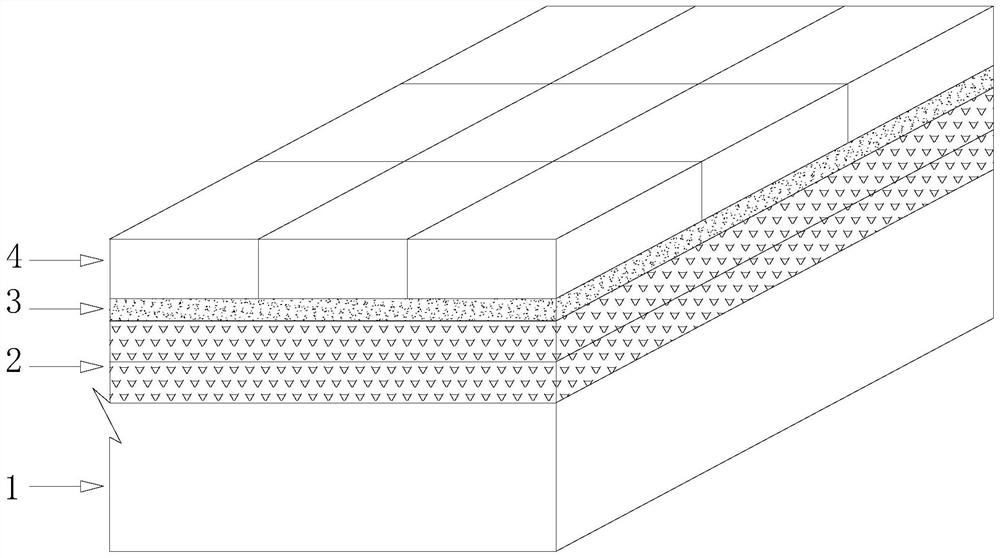

A new type of airport prefabricated pavement system

ActiveCN112746543BQuality improvementIncreased durabilityTemporary pavingsRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a novel airport assembly pavement system, which includes a field foundation, a base layer arranged on the foundation, a flexible transition layer, and a prefabricated road panel; a method for controlling the flatness precision of the field foundation and the top surface of the base layer, and a flexible transition layer The construction control method, the precise positioning and installation method of the prefabricated pavement, the detachable connection structure of the pavement and the rapid replacement method of the prefabricated pavement realize the accurate and rapid installation, replacement and maintenance of the airport pavement. This system and method improves the quality and durability of the airport pavement, avoids the wet operation of concrete in the construction of the airport pavement, greatly improves the mechanization and intelligence level of construction, effectively reduces the amount of labor, and significantly shortens the on-site pavement construction period. In order to greatly improve the efficiency and convenience of airport track construction, operation and maintenance in areas with poor weather conditions, short construction period and resource scarcity. At the same time, the time required for maintenance and replacement of road panels is greatly reduced, which better meets the needs of high-efficiency operation of busy transport airports.

Owner:NO 4 ENG COMPANY LTD OF CCCC FIRST HARBOR ENG COMPANY +1

Suspension type air inlet filter cotton fixing structure and fixing method

ActiveCN111420490AFast fixationQuickly realize disassembly and replacementDispersed particle filtrationMembrane filtersStructural engineeringMechanical engineering

The invention discloses a suspension type air inlet filter cotton fixing structure and a fixing method. The fixing structure comprises an air inlet plate, a grating plate, a first overturning pressingplate assembly, a second overturning pressing plate assembly, filter cotton and two limiting pieces. The grating plate is positioned at the lower part of the air inlet plate; the filter cotton is positioned between the grating plate and the air inlet plate; the upper end of each limiting piece is fixedly connected to the air inlet plate, the lower end of each limiting piece penetrates out of thegrating plate, one end of the first overturning pressing plate assembly and one end of the second overturning pressing plate assembly are rotationally connected with the lower ends of the corresponding limiting pieces, and the other end of the first overturning pressing plate assembly and the other end of the second overturning pressing plate assembly are detachably connected to the lower surfaceof the air inlet plate. The overturning pressing plate assembly which is specially designed is adopted to be matched with the air inlet plate and the grating plate, so the filter cotton can be rapidlyfixed, disassembled, assembled and replaced by rotating the overturning pressing plate assembly, structural parts do not need to be integrally disassembled, and the maintenance and replacement time can be effectively shortened.

Owner:NANJING HUASHI ELECTRONICS SCI

Double copper paper producing and processing device and operation method thereof

PendingCN113559762AImprove finenessConvenient crushing and rolling operationRotary stirring mixersMixing materials pretreatmentProcess engineeringIndustrial engineering

The invention belongs to the technical field of coated paper, and particularly relates to a double copper paper producing and processing device. The device comprises a supporting frame, wherein a cutting box is fixed to the top of the supporting frame, a feeding opening is formed in the top of the cutting box, a cutting device is arranged on the surface of the cutting box, a processing box is fixed to the inner wall of the top of the supporting frame, a rolling device is installed on the surface of one side of the treatment box, a cleaning mechanism is arranged in the treatment box, and a stirring barrel is installed on the inner wall of the bottom of the supporting frame. According to the invention, wood pulp is preliminarily cut and smashed through the cutting device at the cutting box, so a foundation is laid for later smashing work, pulping time is shortened, and production efficiency is improved; the smashed pulp is conveniently smashed and ground through the arrangement of the rolling device; and large particles in the pulp are smashed through cooperation of a groove and a protruding part, so the fineness of the pulp is improved, and the quality of a pulp product is guaranteed.

Owner:镇江欣茂纸品贸易有限公司

Air conditioner capacitor discharge system

ActiveCN103545800BPlay a role of security protectionEasy to operateEmergency protective arrangements for limiting excess voltage/currentCapacitancePower inverter

The invention discloses an air-conditioning capacitor discharge system which comprises a switching circuit, a rectifying circuit, a filter circuit, an inverter circuit, a motor and an operation control circuit. The switching circuit controls switching on or off of an input power supply; the rectifying circuit rectifies the input alternating current power supply; the filter circuit contains capacitance and filters the rectified power supply; the inverter circuit is driven by output of the filter circuit; the motor is driven by output of the inverter circuit; one output end of the operation control circuit is connected to the switching circuit so as to control switching on or off of the switching circuit upon the input power supply, and the other output end is connected to the inverter circuit, so that when the switching circuit is disconnected with the input power supply, the inverter circuit is controlled to output direct current to the motor. By the air-conditioning capacitor discharge system which is simple to operate and safe and reliable, electric charge stored by capacitance on the filter circuit can be rapidly released, and maintaining and replacing time is saved.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

A wear-resistant fan

ActiveCN103062095BExtended service lifeReduce lossesPump componentsPumpsHigh concentrationProduction rate

The invention aims to provide a wear-resistant fan suitable for delivering high-concentration dust. The wear-resistant fan comprises a rotor spindle, a wheel cap and a blade. The blade is formed by welding an inner central disk and an outer central disk, the rotor spindle is fixedly connected with the inner central disk through a connecting bolt, the wear-resistant fan is characterized by further comprising a protection cover, one end of the protection cover is welded with the spindle, the other end of the protection cover is welded with the inner central disk, and accordingly the connecting bolt covers an inner space enclosed by the protection cover, the spindle and the inner middle disk. An air inlet end of the blade most subjected to wear is protected by utilizing a wear-resistant nose, the blade is protected by utilizing a wear-resistant plate, and the wear-resistant nose and the wear-resistant plate can be replaced limitlessly, and accordingly service life of a rotor of the fan can be greatly prolonged; and time for maintenance and replacement is greatly shortened, loss of a user caused by halt is lowered to the minimum, and accordingly cost is saved, and productivity is increased.

Owner:ANHUI ANFENG FAN

A Classified Pressure Relief Mechanism for Electric High Voltage Switchgear

ActiveCN109687310BImprove securityAvoid single-use replacementsSwitchgear arrangementsSubstation/switching arrangement casingsStructural engineeringMechanical engineering

Owner:国网山东省电力公司沂源县供电公司

Multifunctional lifting device for unmanned crane

InactiveCN111232828AImprove stabilityEasy to liftLoad-engaging elementsCranesHydraulic cylinderClassical mechanics

The invention discloses a multifunctional lifting device for an unmanned crane. The multifunctional lifting device comprises a base and a rotary disc; the position, close to the center position, of the top surface of the base is provided with the rotary disc, and the top of the rotary disc is fixedly provided with a supporting frame; the top of the supporting frame is provided with a supporting arm; when the height of an object does not reach the moving condition, a second hydraulic rod in a second hydraulic cylinder is controlled to move towards the outer side, thus, the clamping height of the object is further increased, the object moving height is reached, the object is avoided making contact with an object on the ground, and movable transferring work of the object in different directions is facilitated; the top of an installation seat is provided with a clamping plate, the clamping plate is provided with a through hole, and an insert rod penetrates through the interior of the through hole; the appearance outline of the clamping plate and the interior outline of a clamping groove are the same, so that when the clamping plate at the top of the installation seat is inserted into the clamping groove, the insert rod is inserted into the through hole formed in the clamping plate conveniently, installing work of the installation seat is facilitated, and a special gripper is convenient to replace; and the working efficiency is improved, and the time for maintaining and replacing a traditional gripper is greatly shortened.

Owner:合肥市春华起重机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com