Preparation method of full-body granite ceramic tile

A granite and ceramic tile technology, applied in the field of ceramic tiles, can solve the problems of long production cycle, uneven coloring of whole-body granite tiles, and high production costs, and achieve the effects of not easy to fade, reduce equipment maintenance and replacement time, and stabilize spray glaze pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

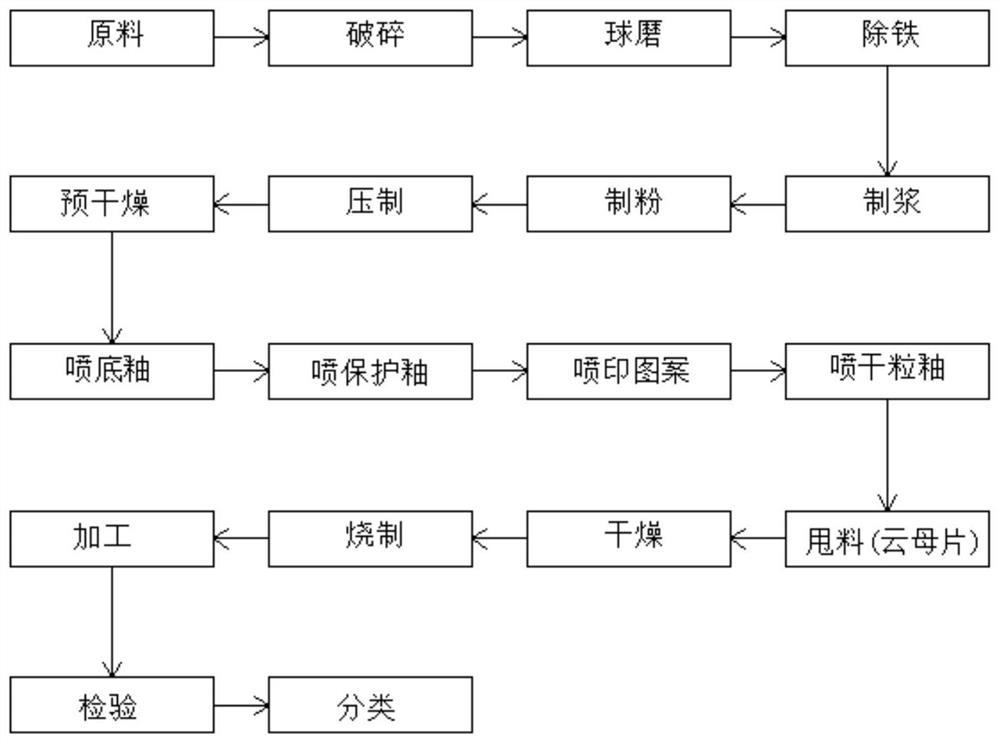

Image

Examples

specific Embodiment

[0019] A method for preparing a whole-body granite tile, comprising the following steps: S1: Crushing raw materials, ball milling, sieving and removing iron to make slurry A, the raw materials include kaolin, quartz sand, stucco, feldspar, calcite, and calcined soil , alumina, zirconium silicate, zinc oxide, burnt soil, burnt talc granite and limestone, according to the different requirements of granite types, the ratio of each raw material can be increased / decreased according to actual needs, the ball mill adopts aluminum ball stone ball mill, and the ball milling time is 10- 14 hours, the longer the ball milling time, the finer the powder formed. Iron removal is to avoid the problem that the iron element in the slurry A is oxidized and blackened by the high temperature of the kiln and causes the surface of the product to have defects; S2: the slurry A in S1 is processed Powder, pressing and pre-drying to obtain brick embryo B, slurry A reacts in the spray tower to obtain towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com