Split type hot continuous rolling cooling water retaining structure

A water-retaining structure and cooling water technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of deformation of the cooling water header frame body of the roll, unable to recover quickly, etc., to improve the rolling operation rate and simple structure. , to eliminate the effect of local deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

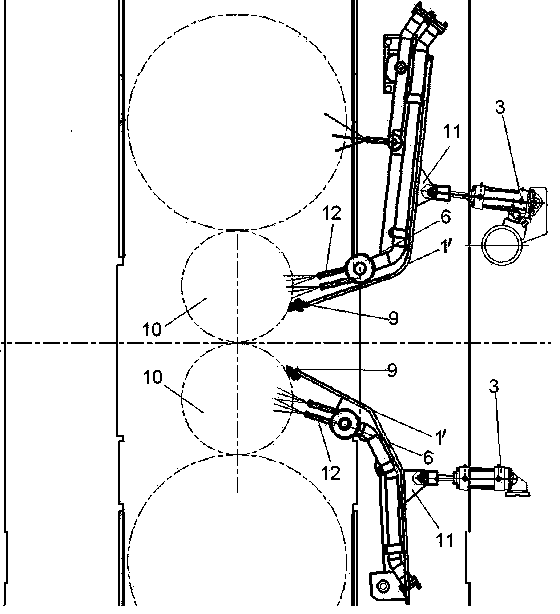

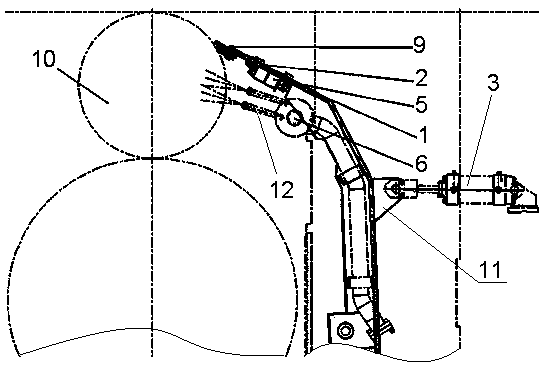

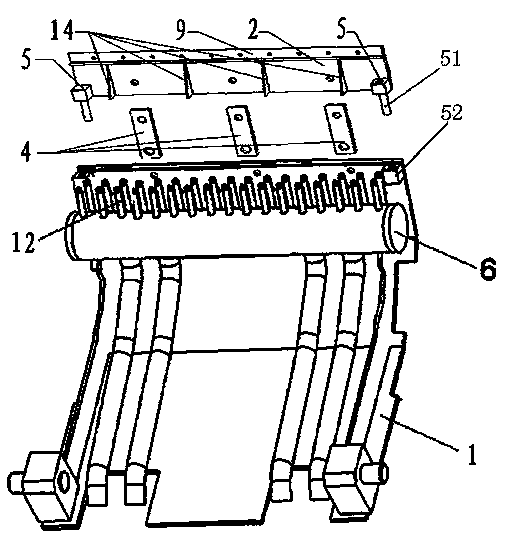

[0021] Example 1: The present invention is a split cooling water retaining structure for hot continuous rolling, which is used in pairs and installed directly opposite to the rolling mill to cool the upper and lower work rolls 10 . figure 2 Shown is a schematic view of the present invention installed on the lower work roll 10 in use, combined with image 3 , including: the first mounting frame body 1 and the second mounting frame body 2 are both made of 20mm-25mm steel plates, the first mounting frame body 1 is a curved arc panel, and the concave surface is equipped with a roll cooling water header 6, and the convex surface is set There are lugs 11, and the lugs 11 are connected with the cylinder piston rod 3; the second installation frame body 2 is a flat plate, and its front end is equipped with a water cutting plate 9, which is fixed with bolts, and the water cutting plate 9 is closely attached to the working surface by the pressure of the cylinder. On the surface of the...

Embodiment 2

[0022] Example 2: Such as Figure 4~7 As shown, in order to facilitate disassembly and assembly, the present invention provides a schematic front view of another fixing method.

[0023] Such as Figure 7 As shown, one end of the connector 4 is provided with an opening slot 41 and both sides are provided with grooves 43, and the middle of the other end is provided with a "one"-shaped groove 42, which is convenient to install according to the first installation frame body 1 and the second installation frame body 2. Adjust the fixed position of the bolt 8 through the mounting holes provided on both sides of the corresponding connection side. Such as Figure 4~6 As shown, the two ends of the locking plate 7 are bent in a “П” shape, and the center is provided with a bolt 8 connecting hole, and the curved end of the locking plate 7 is stuck in the groove 41 of the connecting piece 4, and then the locking plate 7 is locked by the bolt 8. Connect with the second mounting frame bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com