Prefabricated water treatment tank stainless steel corrugated plate module and manufacturing method thereof

A prefabricated, stainless steel technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological treatment devices, etc., can solve the problems of high dismantling cost and low recycling value, and achieve flexible molding and recycling value. High, strong corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

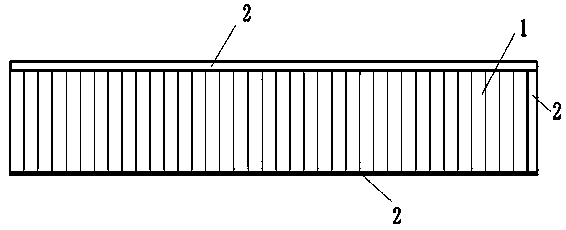

[0026] Example 1: as figure 1 , 2 As shown, a prefabricated stainless steel corrugated plate module for a water treatment tank includes a rectangular stainless steel corrugated plate 1, the cross-section at the long side of the rectangular stainless steel corrugated plate 1 is wavy, the thickness of the rectangular stainless steel corrugated plate 1 is more than 3mm, and the rectangular The wave height of the stainless steel corrugated plate 1 is 108~133mm, and the wavelength is 444.4~504.7 mm. The long sides of the rectangular stainless steel corrugated plate 1 and the short side of one side are welded with ribs 2. The ribs 2 and the rectangular stainless steel corrugated plate 1 are welded. The width of the butt surface of the butt joint is greater than the wave height; the ribs on the short side of the rectangular stainless steel corrugated plate 1 and the long side on one side are square tubes, and the ribs on the long side on the other side of the rectangular stainless s...

Embodiment 2

[0027] Embodiment 2: a kind of manufacture method of prefabricated water treatment tank stainless steel corrugated plate module, comprising the following steps:

[0028] (1) The plate is flattened, and the stainless steel plate with a thickness of more than 3mm is rolled to make the surface of the stainless steel plate flat, and then according to the required size of the non-rectangular stainless steel corrugated plate 1, a rectangular stainless steel plate is obtained by mechanical cutting and trimming;

[0029] (2) Stamping: Place the rectangular stainless steel plate on the wave-shaped mold for stamping. The wave height of the wave-shaped mold is 120~140mm, and the wavelength is 440~490. After the stamping is completed, the rectangular stainless steel corrugated plate 1 and the rectangular stainless steel corrugated plate are rebounded. The section at the long side of 1 is wave-shaped; the wave height of the rectangular stainless steel corrugated plate 1 is 90%~95% of the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com