A tooling for laser welding of titanium semi-welded plates

A laser welding and plate technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the uneven distribution of flow resistance in the protective gas circulation area and cannot meet the needs of the laser welding environment for titanium semi-welded plates. The problem of uneven distribution of shielding gas can improve the success rate of welding, meet the requirements of inert gas protection, and improve positioning accuracy and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

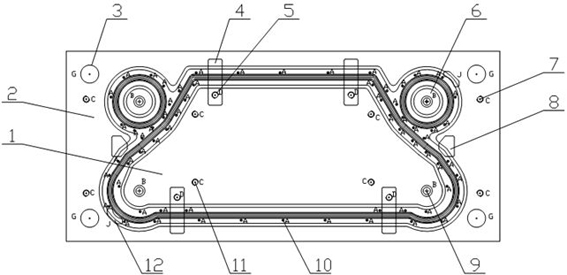

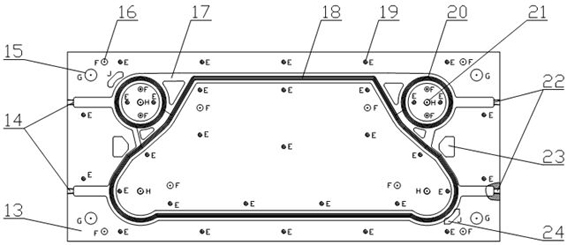

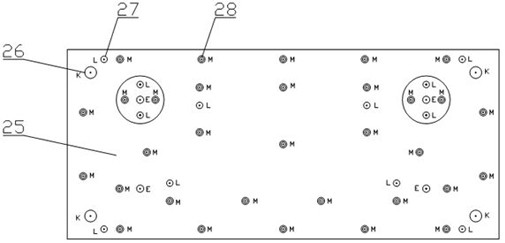

[0017] As shown in the figure, the specific implementation method is as follows:

[0018] A tooling for laser welding of titanium semi-welded plates, including an upper cover plate 1, an upper pressing plate 2, a lower positioning plate 13 and a lower fixing plate 25, the upper cover plate 1 is fixed on the upper pressing plate 2, and the lower positioning plate 13 is fixed on the lower fixing plate 25, the upper cover plate 1 and the lower positioning plate 13 cooperate to clamp the plate to be welded, and the lower positioning plate 13 is provided with a number of air guide grooves whose shape matches the welding area on the plate, The position of the air guide groove coincides with the projected position of the weld seam, and the lower positioning plate 13 located below the plate to be welded is provided with an inwardly recessed air guide area 17 for connecting the air guide grooves to each other, and the air guide area 17 covers the weld seam area , the upper end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com