Drive half axle structure convenient to demount and demounting method thereof

A technology of drive half shaft and body, applied in the field of drive half shaft structure and its disassembly, which can solve the problems of inconvenient disassembly and maintenance of the drive half shaft, and achieve the effects of improving disassembly processability, ensuring safety, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

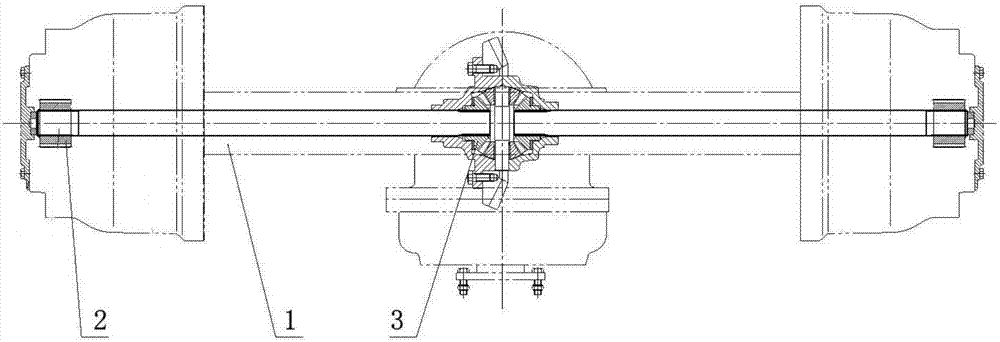

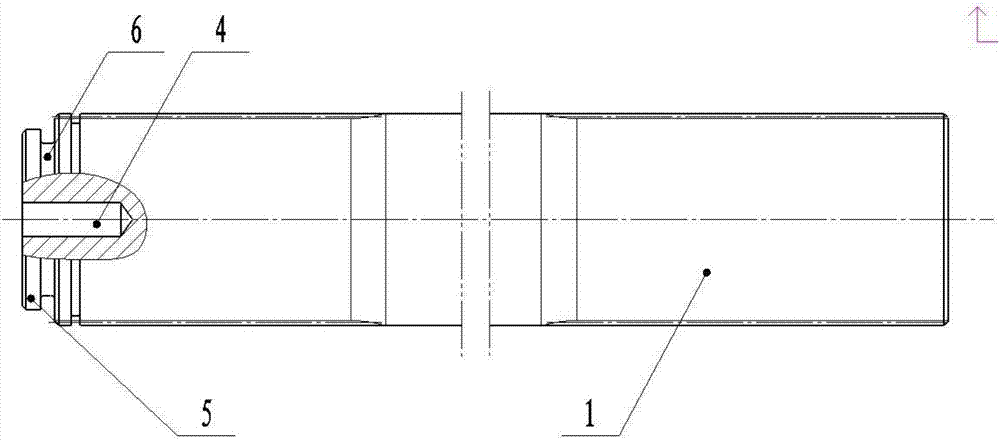

[0034] Such as image 3 As shown, the present invention is an easy-to-disassemble drive half-shaft structure, including a drive half-shaft body 1, one end of the drive half-shaft body 1 is connected to the wheel reducer 2, and the other end of the drive half-shaft body 1 is connected to the main body of the vehicle. The reducer 3 is connected, characterized in that:

[0035] A boss 5 is provided at the end of the connecting end of the driving half shaft body 1 and the wheel reducer 2 , and an annular groove 6 is arranged on the boss 5 .

[0036] The boss 6 is an annular boss.

[0037] A threaded hole 4 is added in the center of the end face of the boss 5 .

[0038] The threaded hole 4 is an M10 threaded hole.

[0039] On the basis of ensuring the original design and installation dimensions of the driving half shaft, we added an M10 threaded hole in the center of the end face of the driving half shaft connected to the wheel side reducer (such as image 3 ; Or open a groove ...

Embodiment 2

[0042] Such as image 3 As shown, the present invention is an easy-to-disassemble drive half-shaft structure disassembly method, comprising steps:

[0043] A threaded hole 4 is added in the center of the end face of the connecting end of the drive half shaft body 1 and the wheel reducer 2. When the drive half shaft body 1 needs to be disassembled, remove the end cover on the wheel reducer 2 shell and use The eyebolt is mated with the threaded hole 4, and then the half-shaft body 1 is disassembled and pulled out through the eyebolt.

[0044] It also includes the step of: setting a boss 5 at the end of the connecting end of the driving half shaft body 1 and the wheel side reducer 2, and the boss 5 is provided with an annular groove 6; when the driving half shaft body 1 needs to be disassembled , Remove the end cover on the shell of the wheel reducer 2, and use a rope to be set on the annular groove 6 to pull out the driving half shaft body 1 for disassembly.

[0045] On the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com